INSTRUCTION MANUAL

Amplifier-separated Type

Inductive Proximity Sensor

GA-311

Amplifier GH-غSE

Sensor head

Thank you very much for using SUNX products. Please read this

Instruction Manual carefully and thoroughly for the correct and optimum

use of this product. Kindly keep this manual in a convenient place for quick

reference.

٨

٨

Never use this product as a sensing device for

personnel protection.

In case of using sensing devices for personnel

protection, use products which meet standards, such

as OSHA, ANSI or IEC etc., for personnel protection

applicable in each region or country.

WARNING

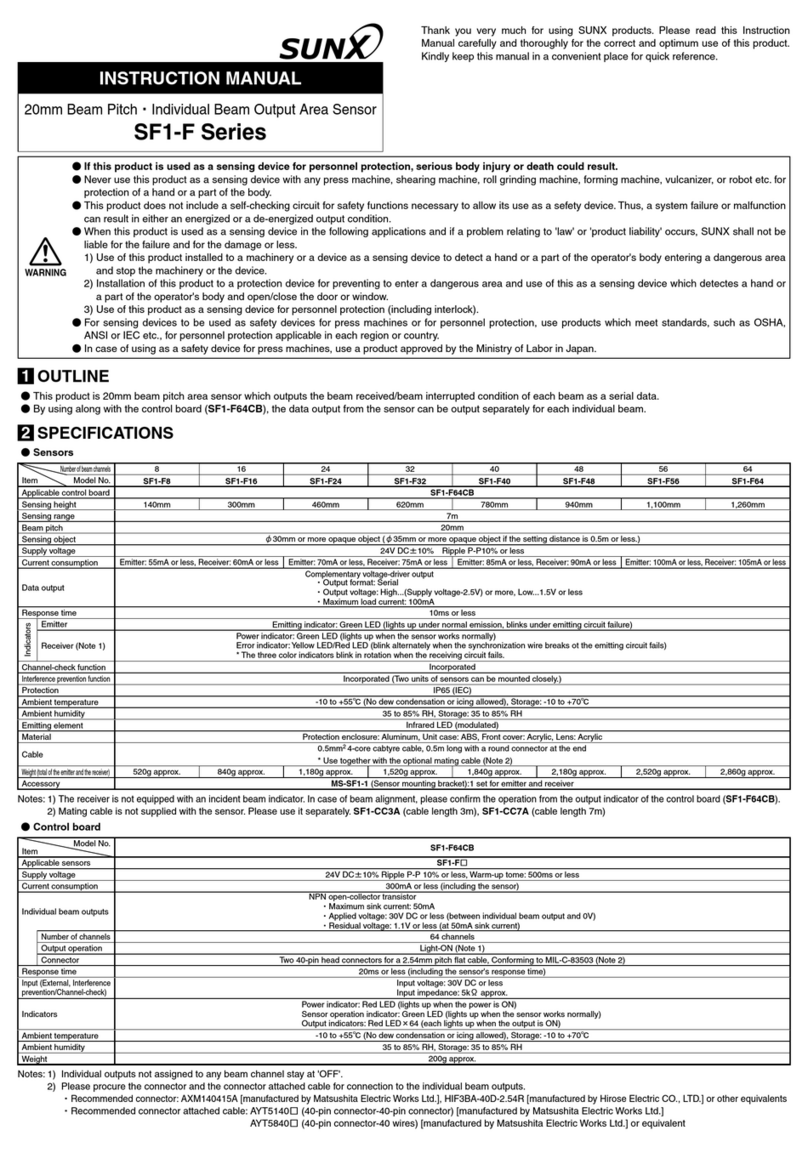

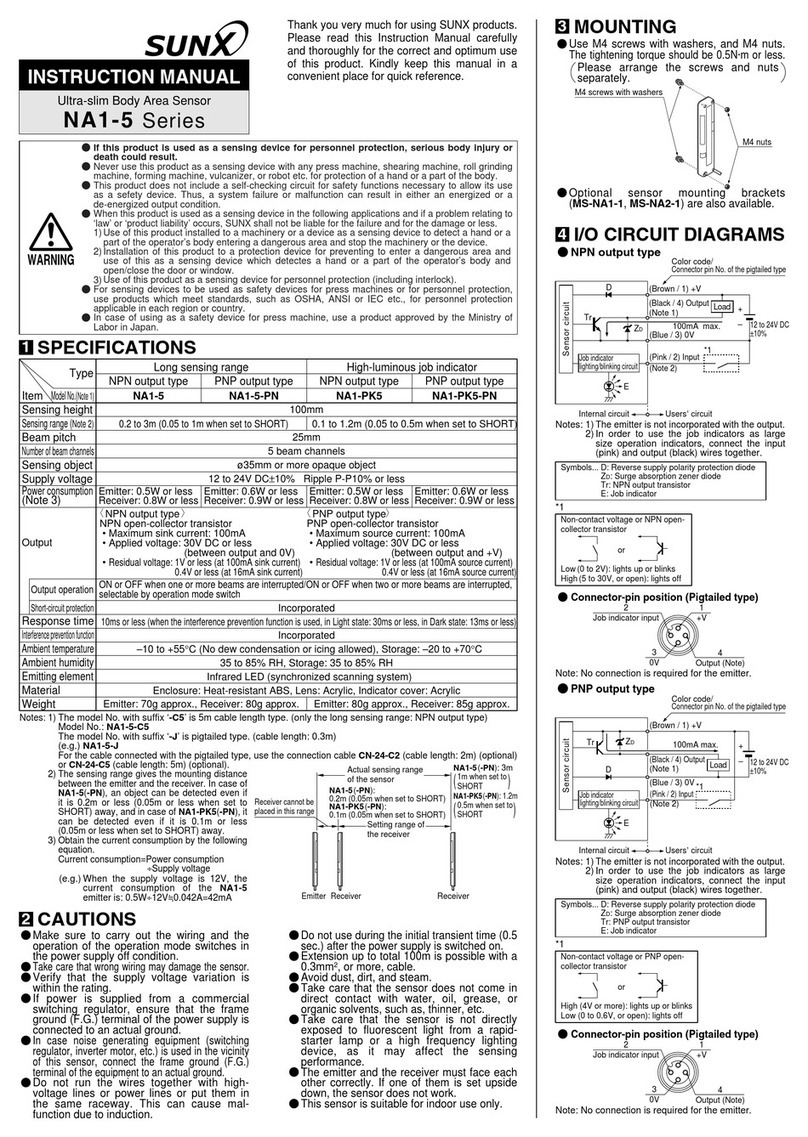

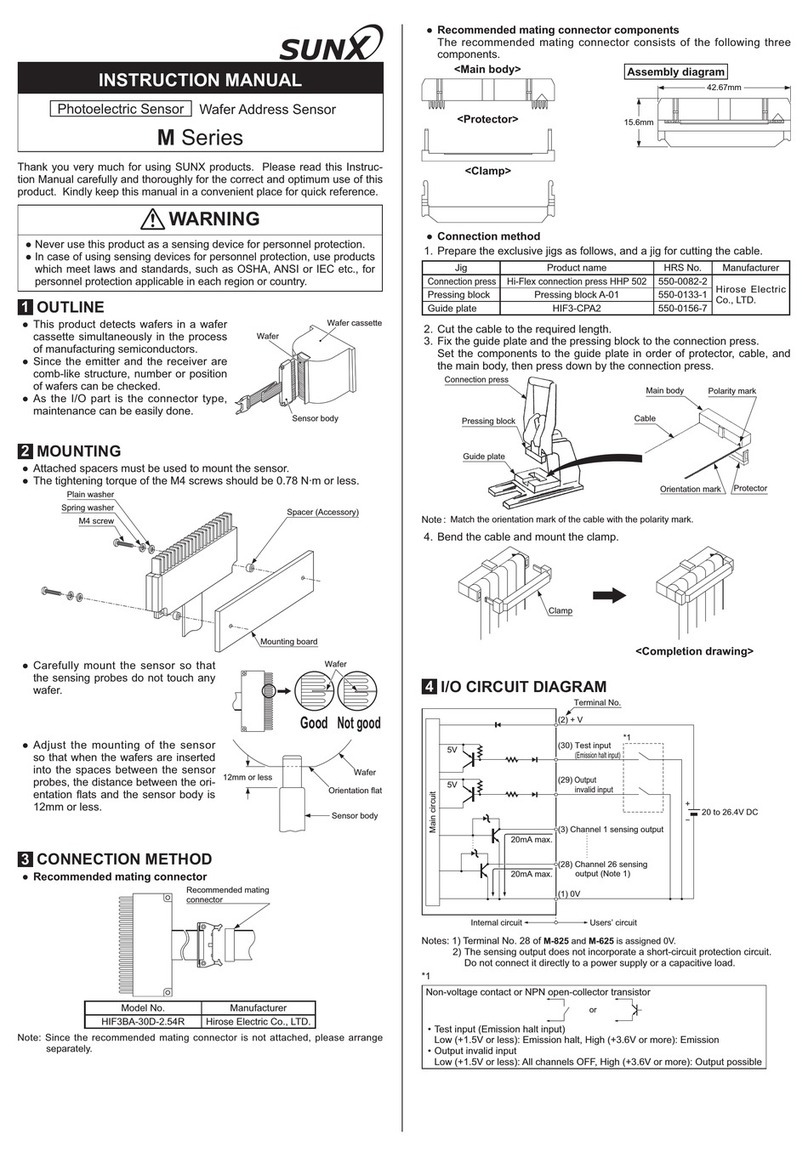

SPECIFICATIONS

1

Cable (Note 4)

Connector attached oil resistant high frequency coaxial cable, 3m long

[Spatter resistant cable for GH-F8SE (Outer shield: Fluorine resin)]

Enclosure:

SUS303

Sensing part:

PVC

Enclosure:

SUS303

Sensing part:

ABS

Enclosure:

SUS303

Sensing part:

PAR

Enclosure:

SUS303

Sensing part:

ABS

Enclosure:

SUS303

Sensing part:

Fluorine resin

Material

Temp. characteristic

(Note 3)

Within r5%Within r7% Within r4%

-10 to +60, Storage: -20 to +70Ambient temperature

IP50 (IEC)

IP67 (IEC), IP67g (JEM)Protection 0.04mm or less

0.07mm or less

0.05mm or lessHysteresis (Note 2) Iron 1010t1mm

Stable sensing range

(Note 1)

0 to 0.8mm0 to 0.6mm 0 to 2.0mm0 to 1.0mm

Max. operation distance

(Note 1)

1.8mm1.2mm 4.0mm2.4mm

GH-3SE GH-F8SEGH-2SE GH-8SEGH-5SE

Spatter-resistant type

Cylindrical type

GA-311Applicable amplifier

Model No.

Item

Type

Iron 55t1mm

Standard sensing object

35 to 85% RH, Storage: 35 to 85% RH

Ambient humidity

15g approx.

35g

approx.

40g

approx.

55g

approx.

Weight

٨Sensor head

Notes: 1)

2)

3)

4)

The stable sensing range represents the sensing range for which the sensor

can satisfy all the given specifications with the standard sensing object.

The maximum operation distance represents the maximum distance for

which the sensor can detect at +20constant ambient temperature.

Usage within the stable sensing range is recommended for accurate

sensing applications.

Value is given for the stable sensing range.

The value represents the variation in the operation distance, that has been

set within the stable sensing range at +20, for an ambient temperature

drift from 0 to +55. (The value is for sensor head on its own.)

The length of the sensor head cable cannot be changed.

Notes: 1)

2)

3)

50mA, if five, or more, amplifiers are connected in cascade.

The value represents the variation in the operation distance, that has been

set within the stable sensing range at +20, for an ambient temperature

drift from 0 to +55. (The value is for amplifier on its own.)

The cable for amplifier connection is not supplied as an accessory. Make

sure to use the optional quick-connection cable given below.

Main cable (3-core):CN-73-C1 (cable length 1m), CN-73-C2 (cable length 2m)

CN-73-C5 (cable length 5m)

Sub-cable (1-core) :CN-71-C1 (cable length 1m), CN-71-C2 (cable length 2m)

CN-71-C5 (cable length 5m)

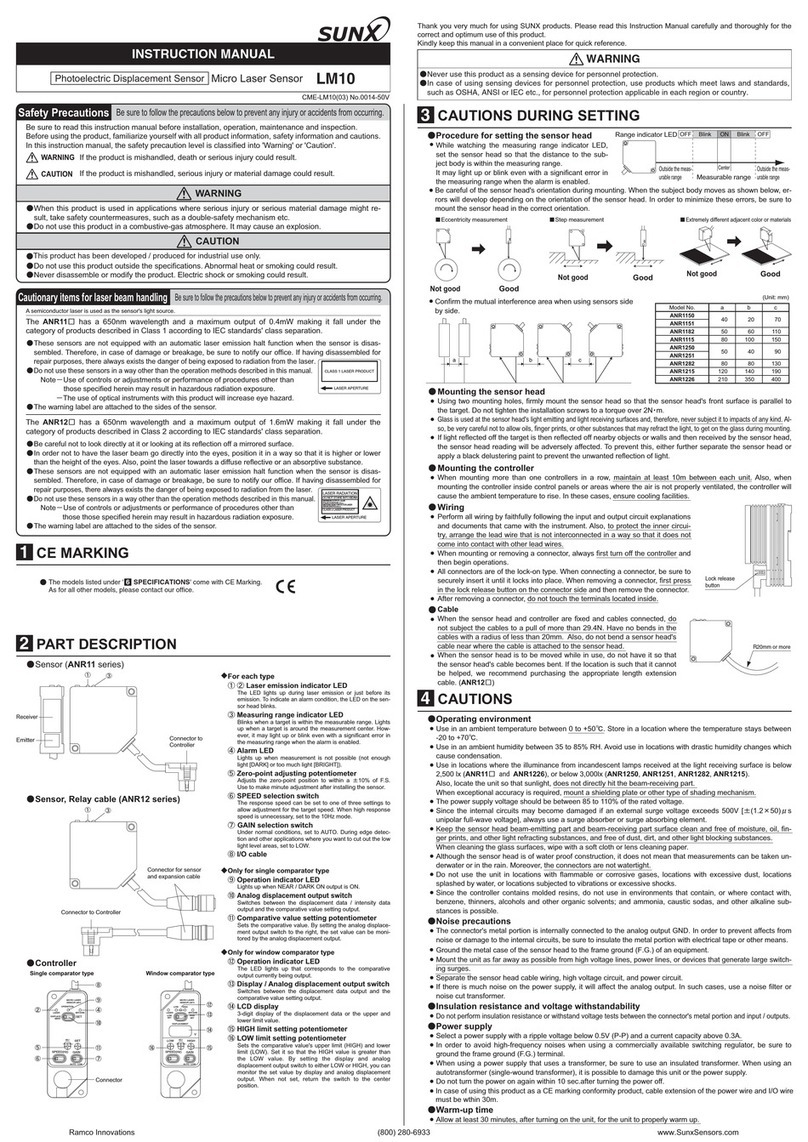

25mA or lessCurrent consumption 12 to 24V DCr10 %ޓRipple P-P10 % or lessSupply voltage

Type

Item GA-311

Output

NPN open-collector transistor

Maximum sink current: 100mA

Applied voltage:30V DC or less (between output and 0V)

Residual voltage:1V or less [at 100mA (Note 1) sink current]

18-turn potensiometerSensitivity adjuster

Orange LED (lights up when the output is ON)Operation indicator

Max. response frequency

3.3kHz

Normally open / closed Selectable with the operation mode switchOutput operation Incorporated

Short-circuit protection

Red LED (lights up when the sensor head is disconnected or mis-contacted)

Disconnection alarm indicator

Ambient temperature -10 to +60(if 4 to 7 units are connected in cascade: -10 to +50,

if 8 to 16 units are connected in cascade: -10 to +45) (No dew con-

densation or icing allowed), Storage: -20 to +70

Temp. characteristic

(Note 2)

Within r5%

35 to 85% RH, Storage: 35 to 85% RHAmbient humidity

Enclosure: Heat-resistant ABS, Case cover: Polycarbonate

Material 15g approx.

Weight

٨Amplifier

CAUTIONS

2

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

Make sure that the power supply is off while wiring or adding the units.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within the rating.

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground

(F.G.) terminal of the equipment to an actual ground.

If power is supplied from a commercial switching regulator, ensure that

the frame ground (F.G.) terminal of the power supply is connected to an

actual ground.

Do not use during the initial transient time (0.5 sec.) after the power

supply is switched on.

Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway.This can cause malfunction due to induction.

Be sure to use the optional quick-connection cable for amplifier

connection. Furthermore, extension up to 100m (50m: 5 to 8 units are

connected in cascade, 20m: 9 to 16 units are connected in cascade) is

possible with 0.3mm2or more, cable. However, in order to reduce noise,

make the wiring as short as possible.

Take care that when the cable is extended, the residual voltage rises.

Do not shorten or lengthen the sensor head cable.

This sensor is suitable for indoor use only.

Do not use the sensor at places having intense vibrations, as this can

cause malfunction.

Take care that the sensor does not come in direct contact with water, oil,

grease, organic solvents, such as, thinner etc., or strong acid, and alkaline.

Make sure that the sensing end is not covered with metal dust, scrap or

spatter. It will result in malfunction.

Take care that stress by forcible bending or pulling is not applied directly

to the sensor head cable joint.

MOUNTING

3

Be sure to use a sensor head and amplifier as a set.

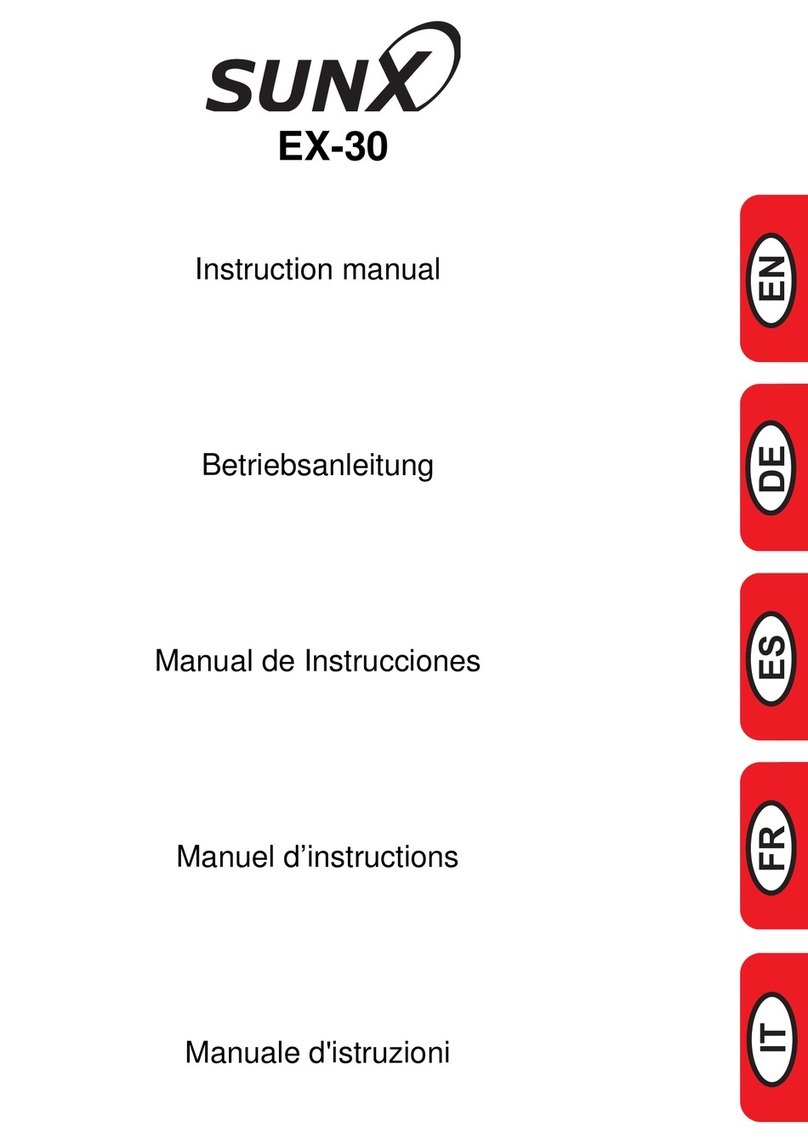

Disconnection method

Ԙ

Pressing the projection on the sensor

head connector, pull out the connector.

Note:

Take care that if the connector is pulled out without pressing the projection, the pro-

jection may break. Do not use a sensor head connector whose projection has bro-

ken.Furthermore, do not pull by holding the cable, as this can cause a cable-break.

Connection method

Ԙ

ԙ

Insert the the sensor head connector into

the connector inlet till a click is felt.

Fit the cover on the connector.

٨Connection of sensor head

Ԙ

Sensor head

connector part

Cover

ԙ

Projection

Ԙ

ԙ

Fit the rear part of the mounting section of the

amplifier on a 35mm width DIN rail.

Press down the rear part of the mounting section

of the unit on the 35mm width DIN rail and fit the

front part of the mounting section to the DIN rail.

How to mount the amplifier

Take care that if the front part is lifted without pushing the amplifier forward, the

hook on the rear portion of the mounting section is likely to break.

Note:

How to remove the amplifier

Ԙ

ԙPush the amplifier forward.

Lift up the front part of the amplifier to remove it.

٨Mounting of amplifier

Ԙ

35mm width DIN rail

ԙ

Ԙ

ԙ

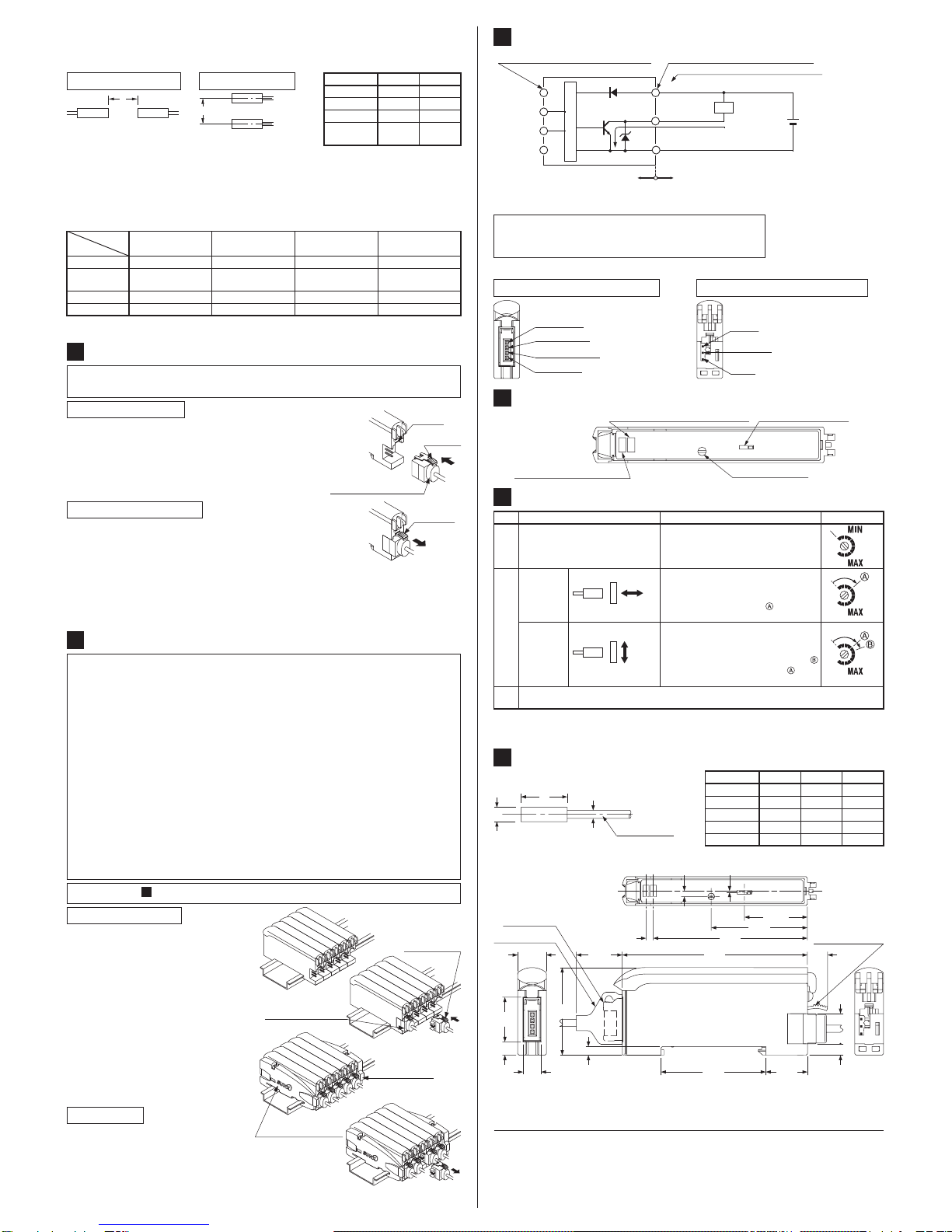

٨Mounting of sensor head

Do not tighten it with excessive strength.Note:

The tightening torque

for mounting should be

as given right.

Furthermore, be sure

to use a set screw with

a cup-point end.

0.17N㨯m

4 or more

0.78N㨯m

GH-3SE

5 or more

0.59N㨯m

GH-5SE

5 or more

GH-8SE

GH-F8SE

Model No. Amm

Tightening torque

3 or more

0.17N㨯mGH-2SE

Set screw (M3)

(Cup-point end)

A

Mounting with a set screw

Influence of surrounding metal

٨The surrounding metal

will affect the sensing

performance. Keep the

minimum distance

specified in the table

right.

4GH-3SE 5GH-5SE

9

GH-8SE

GH-F8SE

Model No. Bmm

3

GH-2SE

B

Background metal