TEST INPUT (EMISSION HALT) FUNCTION

5

When the test input (emission halt input) is turned ON (+1.5V or less,) all

LEDs stop emission, generating the wafer sensed condition, and output

transistors of all channels become ON.

The output circuit of the sensor can be checked by using the test input

(emission halt input.)

Ɣ

Ɣ

ON

OFF

Emission

Emission

halt

ON

[Emitting LED]

[Output]

Normal Error

OFF

Test input

(Emission halt input)

OUTPUT INVALID (EXTERNAL SYNCHRONIZATION) FUNCTION

6

If the output invalid input is turned ON (+1.5V or less,) the output transistors of

all channels stay in the OFF state irrespective of the wafer detection condition.

Several sensors can be used in parallel by using the output invalid inputs,

thereby reducing the required PLC input points.

Ɣ

Ɣ

Output

Output invalid

input 1

Output invalid input 2

Sensor 1Sensor 2

Switch position Sensor operation

1

2Only Sensor 2 is operative

1

2Only Sensor 1 is operative

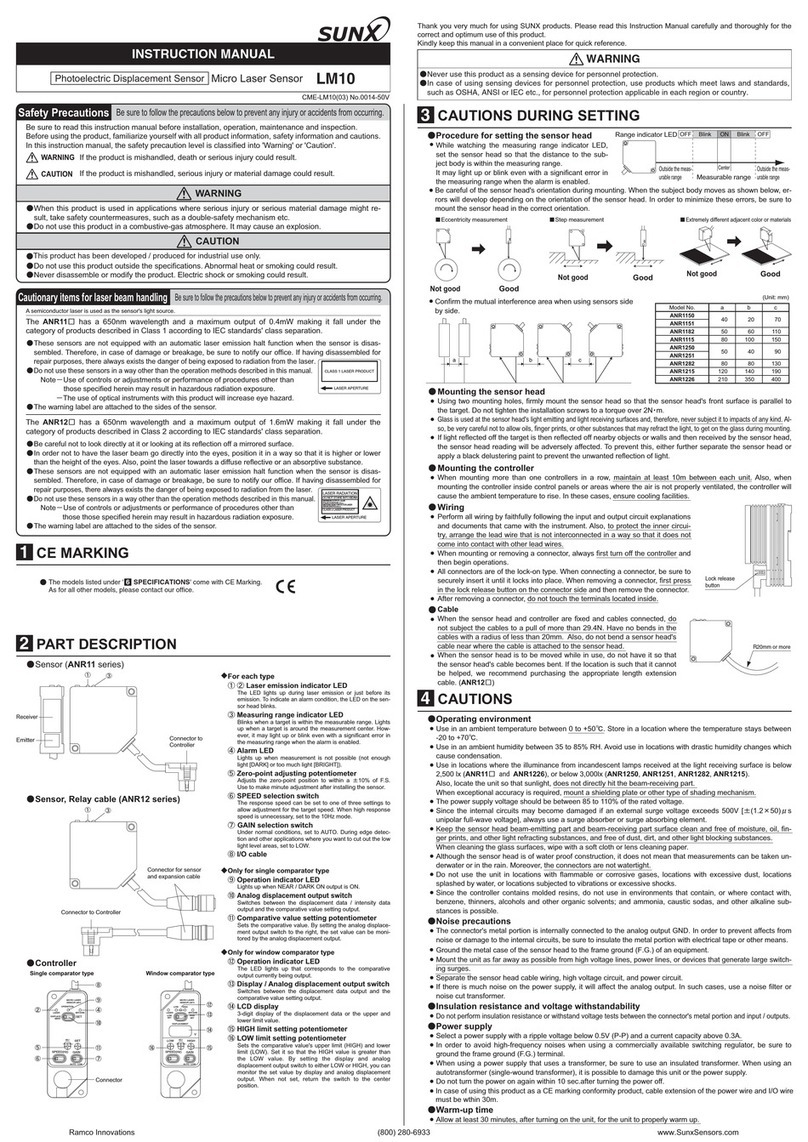

Connector pin positionƔ

2927252321191715131197531

30282624222018161412108642

Orientation mark

Recommended mating connector

HIF3BA-30D-2.54R

[Manufactured by Hirose Electric Co., LTD.]

Connector

HIF3BA-30PD-2.54R-MC

[Manufactured by Hirose Electric Co., LTD.]

Terminal No.

Description

Terminal No.

Description

1 0V 16 OUT 14

2 +V 17 OUT 15

3 OUT 1 18 OUT 16

4 OUT 2 19 OUT 17

5 OUT 3 20 OUT 18

6 OUT 4 21 OUT 19

7 OUT 5 22 OUT 20

8 OUT 6 23 OUT 21

9 OUT 7 24 OUT 22

10 OUT 8 25 OUT 23

11 OUT 9 26 OUT 24

12 OUT 10 27 OUT 25

13 OUT 11 28

OUT 26 (Note)

14 OUT 12 29

Output invalid input

15 OUT 13 30

Test input (Emission halt input)

Note: Terminal No.28 of M-825 and M-625 is

assigned 0V.

PRINTED IN JAPAN

Overseas Sales Dept. (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

Europe Headquarter: Panasonic Electric Works Europe AG

Rudolf-Diesel-Ring 2, D-83607 Holzkirchen, Germany

Phone: +49-8024-648-0

US Headquarter: Panasonic Electric Works Corporation of America

629 Central Avenue New Providence, New Jersey 07974 USA

Phone: +1-908-464-3550

URL : sunx.com

SUNX Limited

SPECIFICATIIONS

7

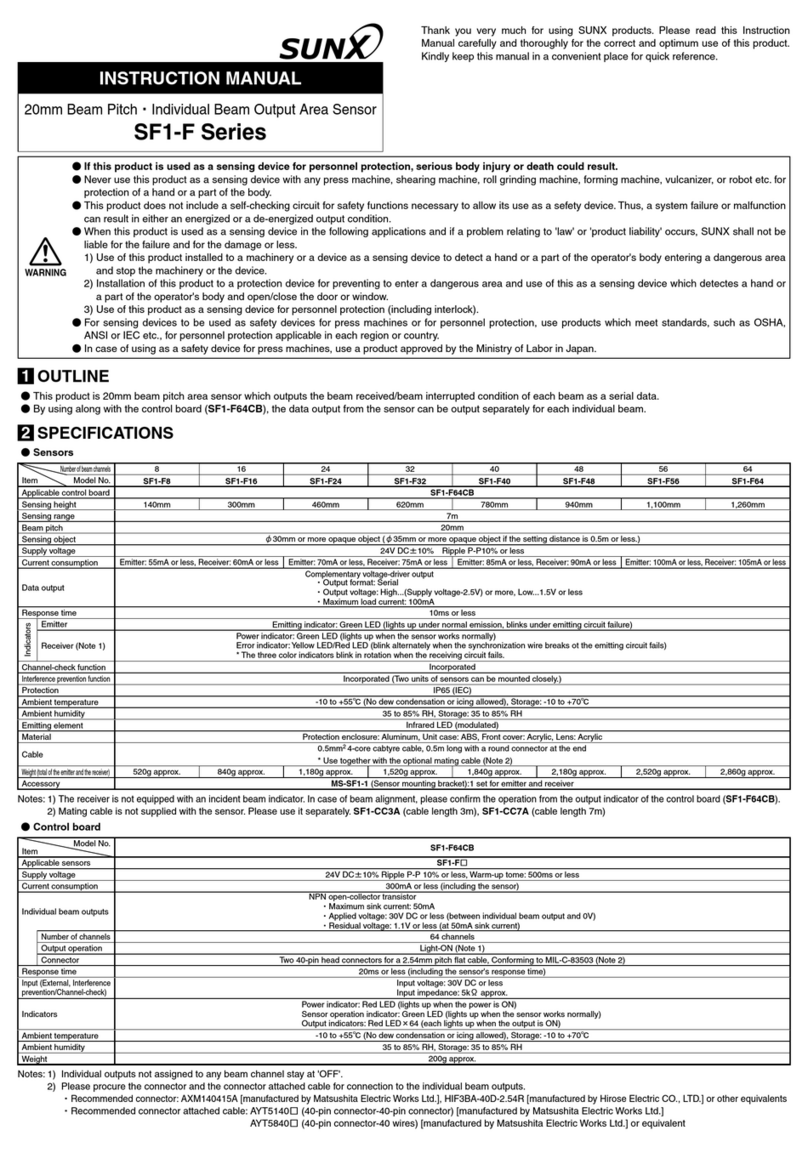

Type For 8 inch wafer

For 6 inch wafer

25 pieces 26 pieces 25 pieces

Item

Model No.

M-825 M-826 M-625

Wafer pitch 6.35mm 4.76mm

Supply voltage 20 to 26.4V DC Ripple P-P 10% or less

Current consumption 200mA or less

Sensing output

NPN open-collector transistor

Maximum sink current: 20mA

Applied voltage: 30V DC or less

(between sensing output and 0V)

Residual voltage: 1V or less (at 20mA sink current)

•

•

•

Number of channels

25 channels 26 channels 25 channels

Output operation Dark-ON

Response time 1ms or less

Power indicator Red LED (lights up when the power is ON)

Ambient temperature

0 to +40

Û&

(No dew condensation,) Storage: -25 to +60

Û

C

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Emitting element Infrared LED (modulated)

Material Enclosure: ABS, Sensing probe: PPS, Connector: PBT

Cable PPSLWFKFRUHÀH[LEOHÀDWFDEOHPPORQJZLWK

clamp connector

Weight 150g approx.

Accessory Spacer: 2 pcs.

CAUTIONS

8

This product has been developed / produced for industrial use only.

Make sure that the power supply is off while wiring.

Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway. This can cause malfunction due to induction.

Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that

the frame ground (F.G.) terminal of the power supply is connected to an

actual ground.

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

Do not use during the initial transient time (100ms.) after the power sup-

ply is switched on.

([WHQVLRQXSWRWRWDOPLVSRVVLEOHZLWKDQHTXLYDOHQWÀDWFDEOH

Make sure that stress by forcible bend or pulling is not applied directly

to the sensor cable joint.

Take care that the sensor is not directly exposed to fluorescent lamp

from a rapid-starter lamp, a high frequency lighting device or sunlight

etc., as it may affect the sensing performance.

Before use the product, make sure to eliminate the static electricity of

the wafer.

Make sure that stress is not applied to the sensor probe.

Wafer which transmits infrared light cannot be detected, since the infra-

red LED is used for the emitting element.

This sensor is suitable for indoor use only.

Avoid dust, dirt, and steam.

Take care that the product does not come in contact with water, oil,

grease, organic solvents, such as thinner, etc., strong acid or alkaline.

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

Ɣ

INTENDED PRODUCTS FOR CE MARKING

9

The models listed under “ SPECIFICATIONS” come with

CE Marking.

$VIRUDOORWKHUPRGHOVSOHDVHFRQWDFWRXURI¿FH

Ɣ