5

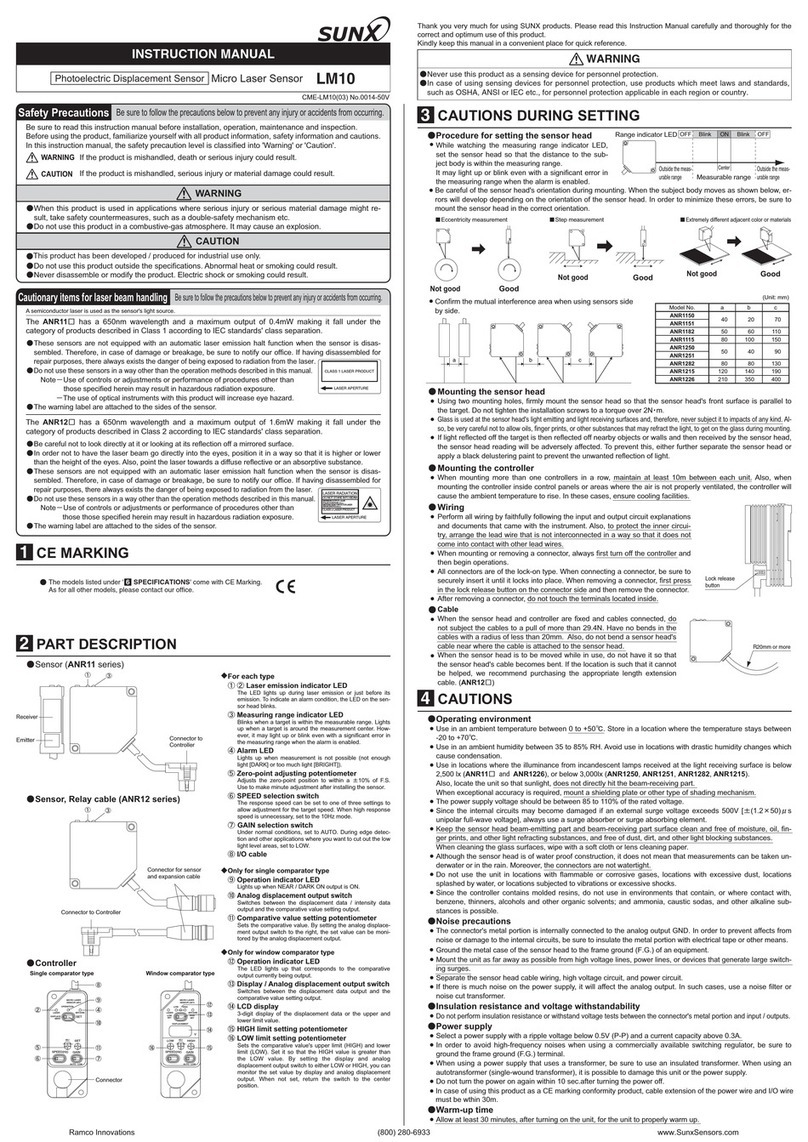

- Set the sensor head so that stray light such as sunlight or light with the same

wavelength, etc. does not enter the light receptor. If an extraordinary accuracy is

necessary, install a light shielding plate or the like at the sensor.

- The sensor head is a waterproof device, but this does not mean that it can be

mounted underwater or in places where rain falls. Also, due to their construction,

the controller and connectors are not dustproof, waterproof or corrosion resistant,

so do not use it in an environment where such characteristics are required.

- Do not use this product in places where flammable or corrosive gases are

generated, places where there is a lot of dust, where there is dripping water, where

it will be exposed to direct sunlight or where there are severe vibrations or impacts.

3. Noise Countermeasures

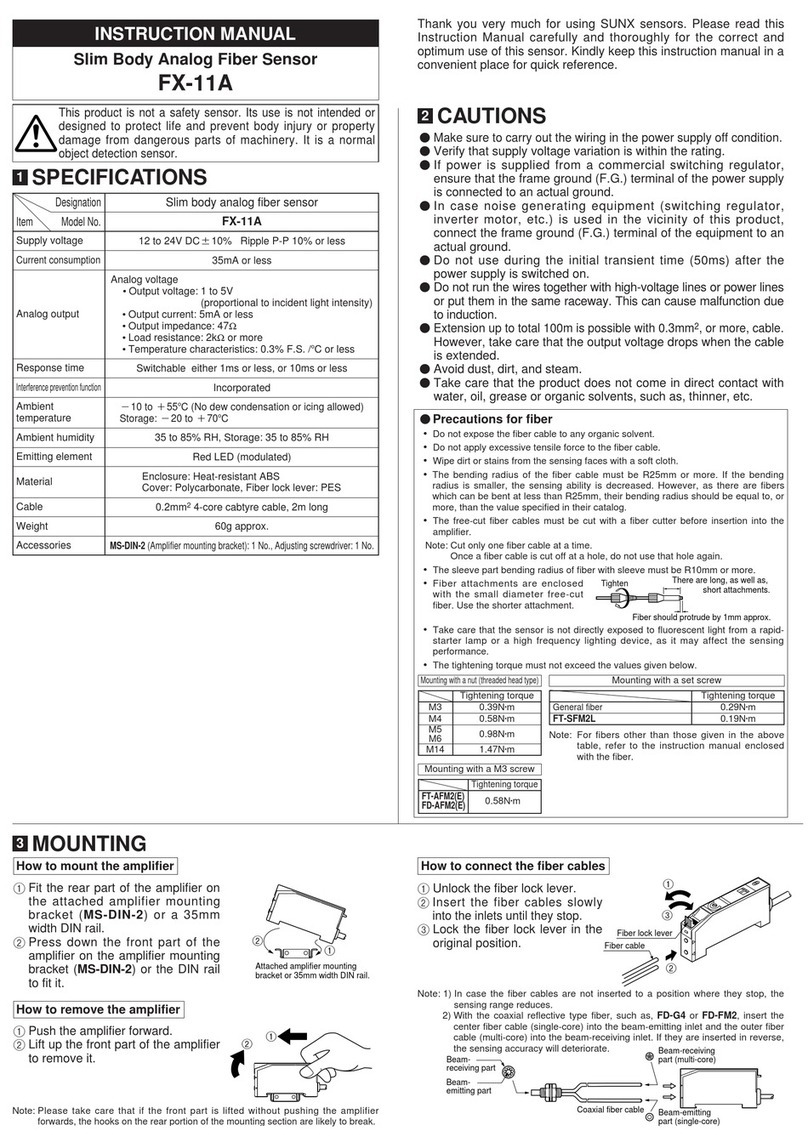

- Do not run the sensor cable along (bundled in parallel with) other wiring, and keep

it at least 100mm from other wires. Also run the cable so that it is separate from the

high voltage lines and power circuit lines. If running the lines in parallel cannot be

avoided, shield the cable by running it through a grounded electrical conduit, etc.

- For input signal lines and output signal lines, run them separately, not in parallel,

with power lines and power supply lines, keeping them at least 100mm apart. In

addition, keep all the various signal lines as short as possible when connecting

them.

- Install this product as far away as possible from high-voltage lines, power lines,

high voltage device, wireless devices and machines which generate a large

starting and stopping surge.

- If a large amount of electrical noise is generated in the power supply, the analog

outputs will be affected. In such a case, use a noise filter or a noise dampened

transformer.

- Use shielded cables for signal wires such as those for serial input and output and

I/O terminals to reduce electric noise, and connect the shielding wire to the frame

ground.

- It is easy for analog outputs to be influenced by noise, especially from external

sources, so use shielded wires, and keep the wiring as short as possible.

- Use an exclusive class D ground in accordance with the functional ground terminal,

and avoid grounding this device in common with other devices. If it is grounded in

common with other devices, the opposite effect may be obtained.