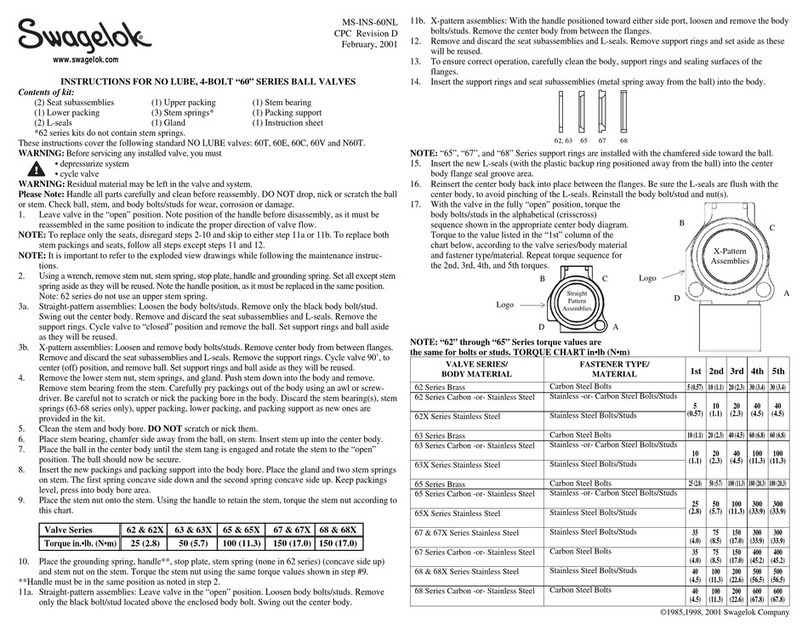

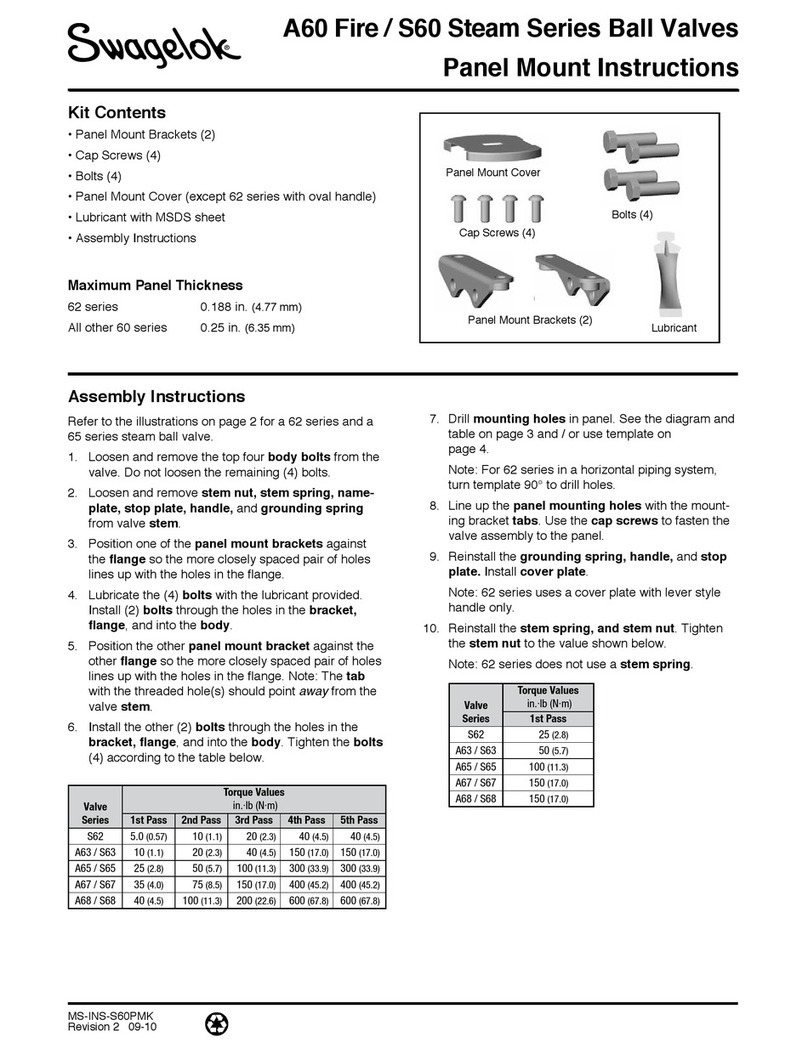

Refer to the Fig. 1 while following these instructions.

Complete the maintenance on one end screw assembly

before proceeding to the other end screw assembly.

from the system. Actuate the

in a vise or use a 1 1/2 in. wrench to

end screw assembly from end screw assembly

. (The use of a small, non-

metallic pick or similar tool is optional.)

removed components except the

Reassembly if not replacing Reassembly

9. Remove the stem assembly from the packing bolt.

Clean all lubricant and contaminants from the

2. Apply a thin film of the pro

Note: The chamfer on the stem back

Note: Be careful not to pi

components when inserting into the packin

valve body and torque to valve body

to 700 in.·lb (68 to 79.1 N·m) (692 to 806 cm·kg).

dy by aligning the ball slot with

8. Apply a thin film of the pro

into the end screw as shown.

end screw assembly into the body. end screw assembly

Torque the end screw to 600 to 700 in.·lb (68 to

Torque the end screw to 600 to 700 in.·lb (68 to

79.1 N·m) (692 to 806 cm·kg).

79.1 N·m) (692 to 806 cm·kg).

12. Repeat the procedure on the other end screw

12. Repeat the procedure on the other end screw

13. Replace handle and thread set screw into the

13. Replace handle and thread set screw into the

(9.0 to 12.4 N·m) (92.1 to 123 cm·kg).

(9.0 to 12.4 N·m) (92.1 to 123 cm·kg).

for proper operation and leak-tight

for proper operation and leak-tight