For additional information, see swagelok.com.

Swagelok — TM Swagelok Company

Christo-Lube — TM ECLI Products, LLC

Moly-Lit — TM Anti-Seize Technology

©2022 Swagelok Company

January 20222, Rev-

MS-CRD-0227

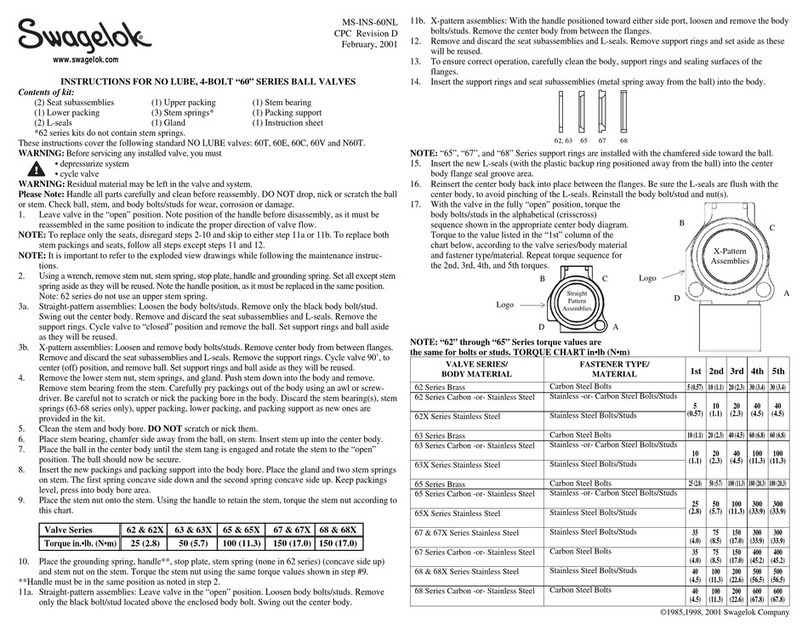

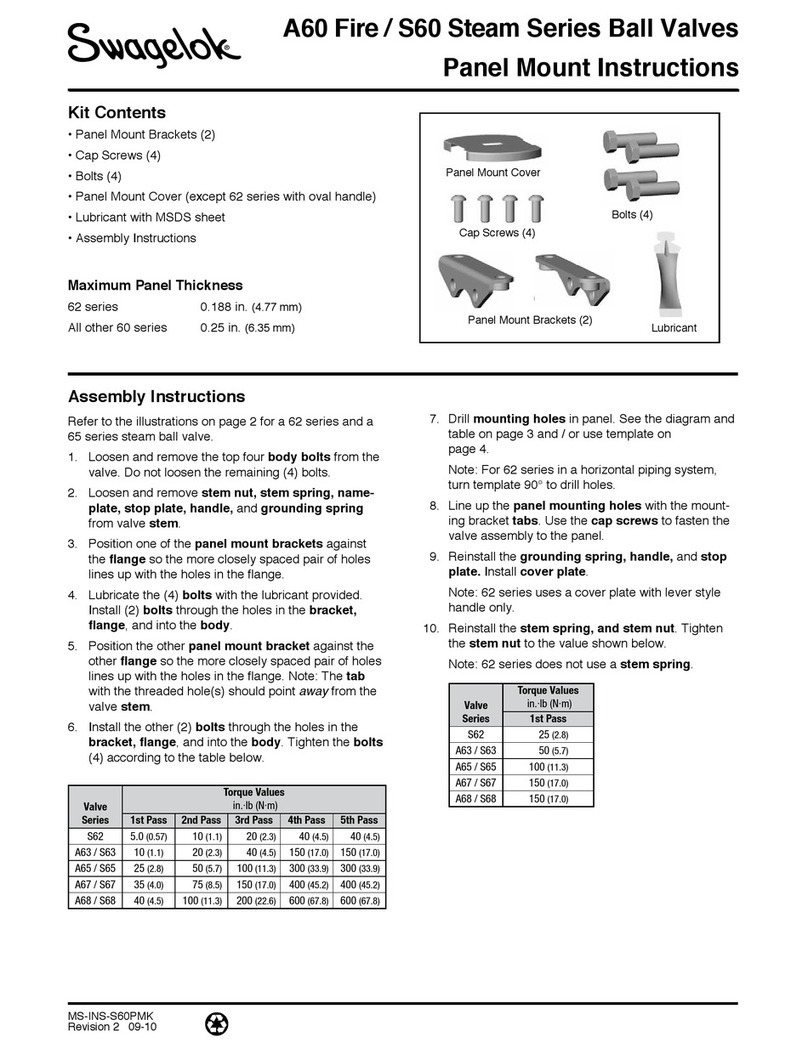

7. Lube the gland nut threads by applying Moly-Lit

anti-seize lubricant liberally. Assemble it nger-tight

into the body.

End

Connection

End

Connection

Size

(in.)

Gland Nut Torque Values

316➁and Alloy 2507

Required Torque

ft·lb (N·m)

Female Cone

and Thread

Medium-

Pressure

1/4 55 to 60 (74.5 to 81.3)

3/8 55 to 60 (74.5 to 81.3)

9/16 220 to 240 (298 to 325)➀

3/4 220 to 240 (298 to 325)

1 280 to 320 (380 to 434)

Female Cone

and Thread

High-Pressure

1/4 55 to 60 (74.5 to 81.3)

3/8 65 to 70 (88.1 to 94.9)

9/16 220 to 240 (298 to 325)

Female NPT

1/8 35 to 40 (47.5 to 54.2)

1/4 40 to 45 (54.2 to 61.0)

3/8 55 to 60 (74.5 to 81.3)

1/2 220 to 240 (298 to 325)

3/4 220 to 240 (298 to 325)

1 280 to 320 (380 to 434)

FK Series

1/4 40 to 45 (54.2 to 61.0)

3/8 190 to 210 (258 to 285)

1/2 190 to 210 (258 to 285)

9/16 190 to 210 (258 to 285)

3/4 280 to 320 (380 to 434)

Table 2

➀ For information on NACE material, contact your authorized Swagelok

sales and service center.

➁ Torque values do not apply to 316 stainless steel NACE material.

5. For assemblies with FK series end connection only:

Assemble the gasket onto OD of the cover.

6. Assemble the cover or cone ring into the body.

Ensure that the edge of the hole in the cover or

cone ring sits against the poppet ball (for ball-seal

design) or against the O-ring (for soft-seal design). 8. Torque the gland nut according to Table 2.

9. Using the dowel rod, tap the back of the poppet

assembly through the outlet in the body to properly

set the poppet.

10. Wipe off any excess lubricant.

Gasket

Cover

Cover Poppet

Liberal Moly-Lit anti-seize

lubricant

Gland nut

Gland nut

Dowel rod

Outlet