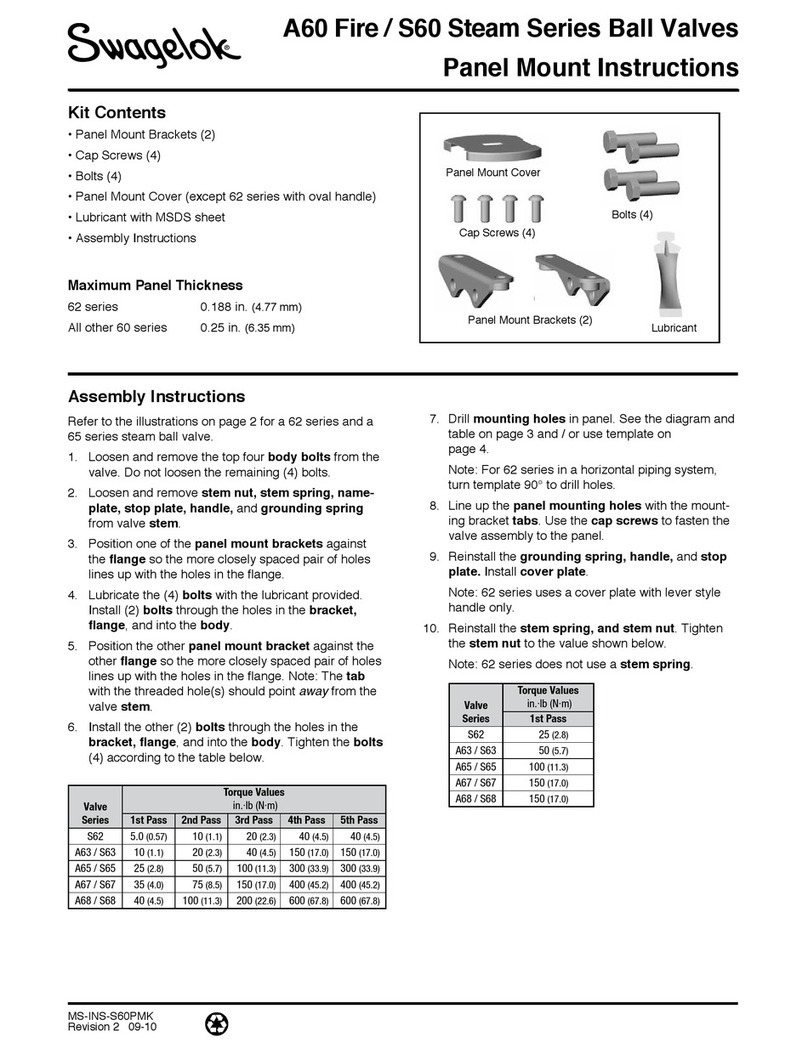

2.

3.

4.

Note :To replace seals only, skip to step 17

and continue.

www.swagelok.com

Swagelok—TM Swagelok Company

©1988 — 2016 Swagelok Company

November 2016, Rev L

MS-INS-S60P-1

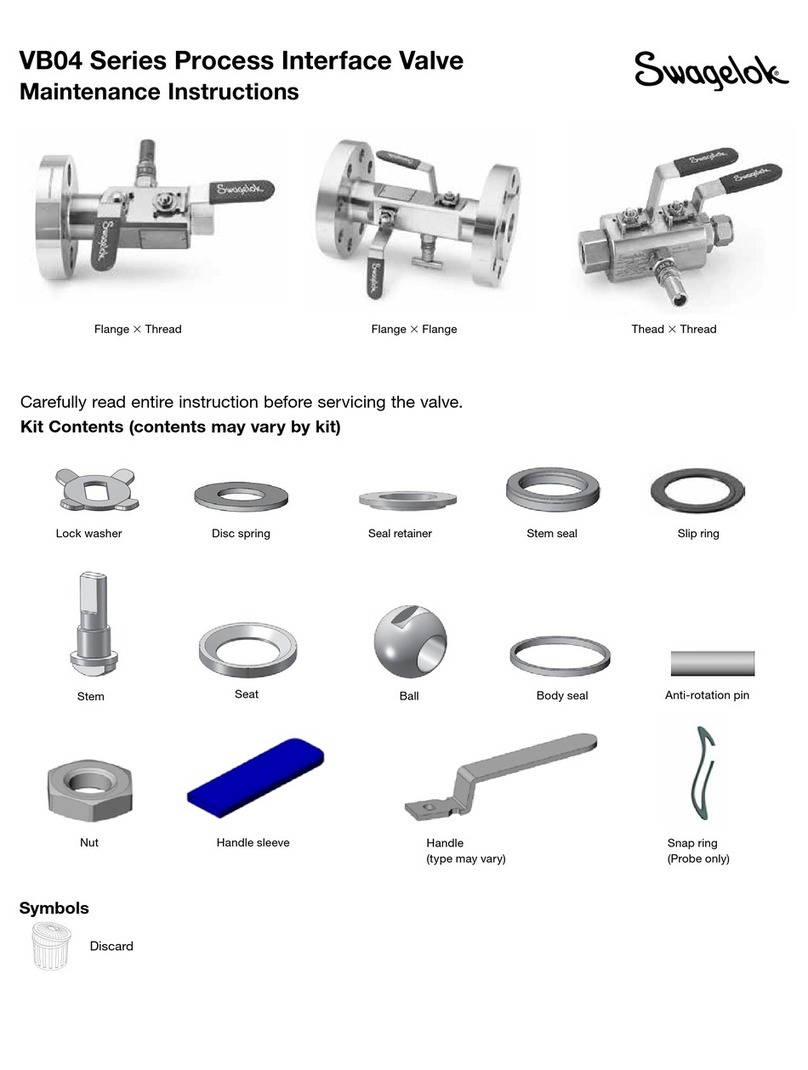

Kit contents are

bold and underlined

Maintenance Instructions

For S60P Steam Series Ball Valve

WARNING

Before servicing any installed valve, you

must

• depressurize system

• cycle valve

WARNING

Residual material may be left in the valve

and system.

CAUTION

• DO NOT remove ange seals from the

package until ready for use.

Note: Refer to exploded view while following

the maintenance instructions.

1.

Discard Clean Lubricate

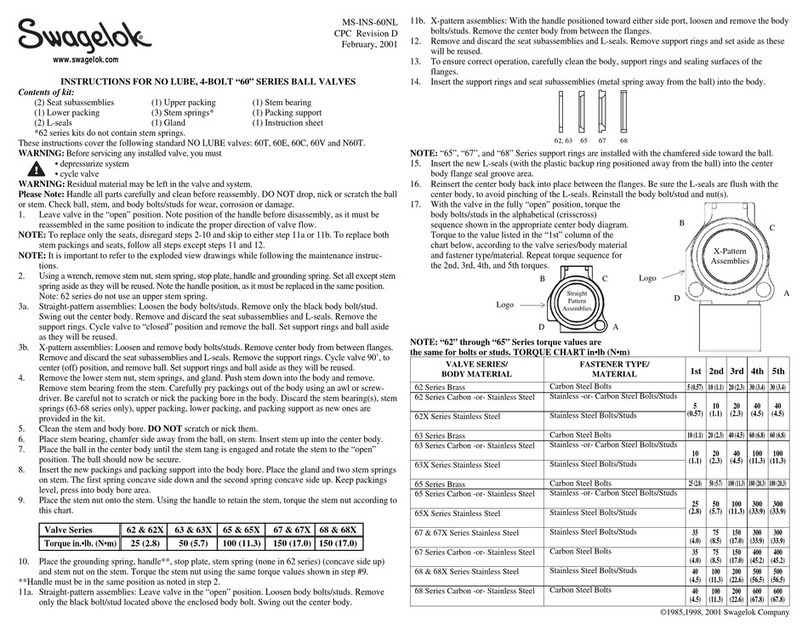

Body Bolt Torque Chart

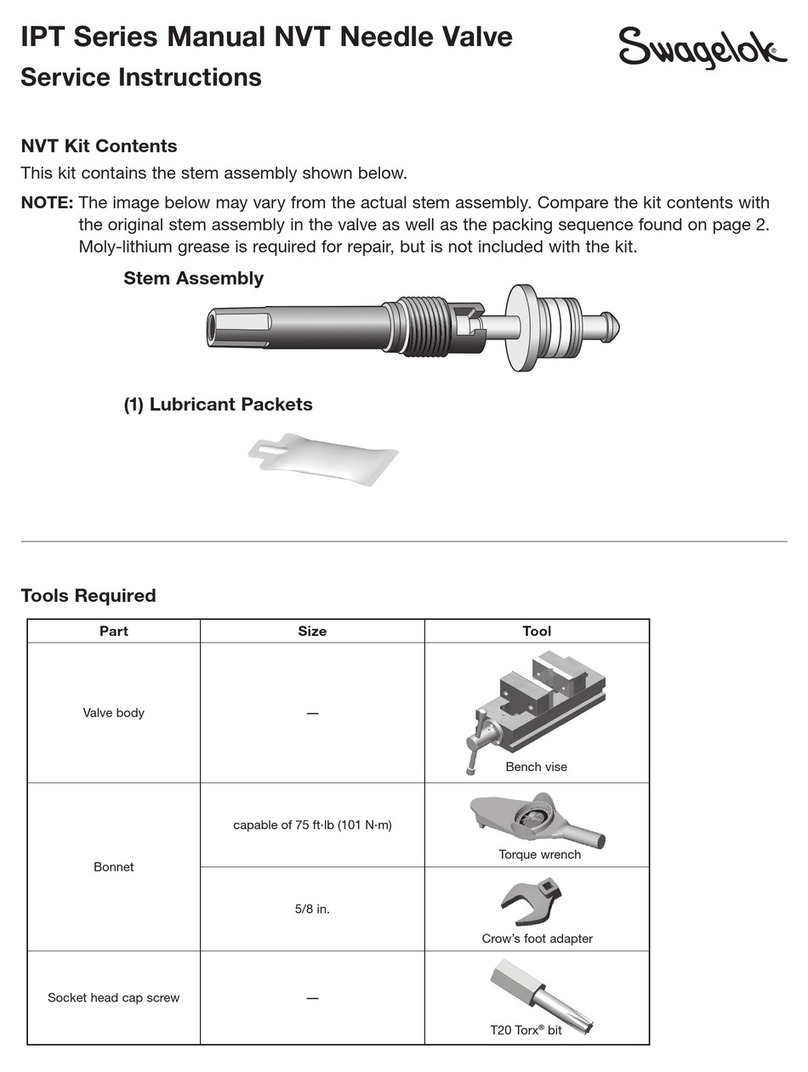

Part Tool Size

Stem nut

Crow's foot

7/16

Stem nut

Open-end wrench

7/16

Body bolt 5/16

Body bolt

Hex Socket

5/16

Stem nut

Torque wrench

Capable of

600 in.·lb

(67.8 N ·m)

Body bolt

Tools Required

Stem nut

Stem spring

Handle

Grounding spring

Stem nut

Gland

Packing support

Top packing

Bottom packing

Stem

Flange

Body bolts

Ball

Flange seal

Seat subassembly

Support ring

Body

Body bolts

Flange seal

Seat subassembly

Support ring

Stem bearing

Lubricant(s)

Stem spring

Flange

Remove all body

bolts.

Loosen all body

bolts.

center

body

×2

Use handle to

rotate the stem.

Remove ball from

the center body.

➀S62P series kits do not contain stop plate and

contain (2) stem springs.

➁Valves with a PEEK or Halar stem bearing

contain (1) stem bearing.

Valve

Series

Torque Value

in.·lb (N·m)

1st

pass

2nd

pass

3rd

pass

4th

pass

5th

pass

6th

pass

S62P 5.0

(0.57)

10

(1.1)

20

(2.3)

40

(4.5)

40

(4.5) —

S63P 10

(1.1)

20

(2.3)

40

(4.5)

100

(11.3)

150

(17. 0)

150

(17. 0)

S65P 25

(2.8)

50

(5.7)

100

(11.3)

300

(33.9)

300

(33.9) —

S67P 35

(4.0)

75

(8.5)

150

(17. 0)

400

(45.2)

400

(45.2) —

S68P 40

(4.5)

100

(11.3)

200

(22.6)

600

(67.8 )

600

(67.8 ) —

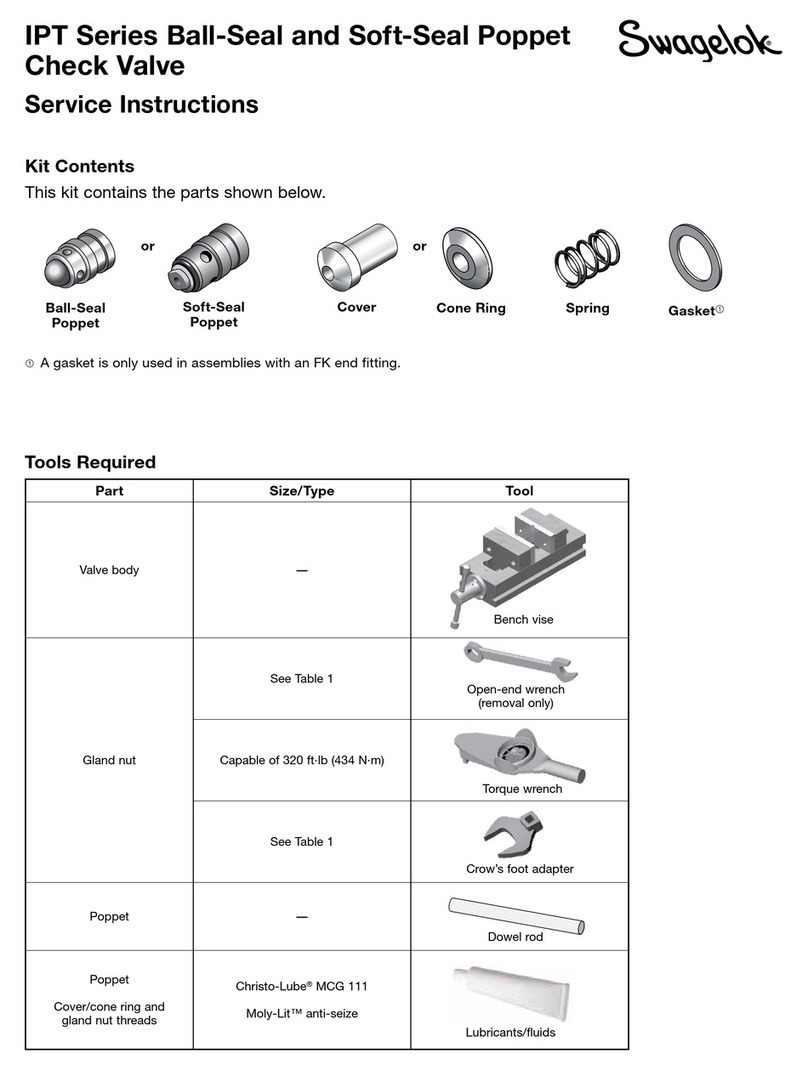

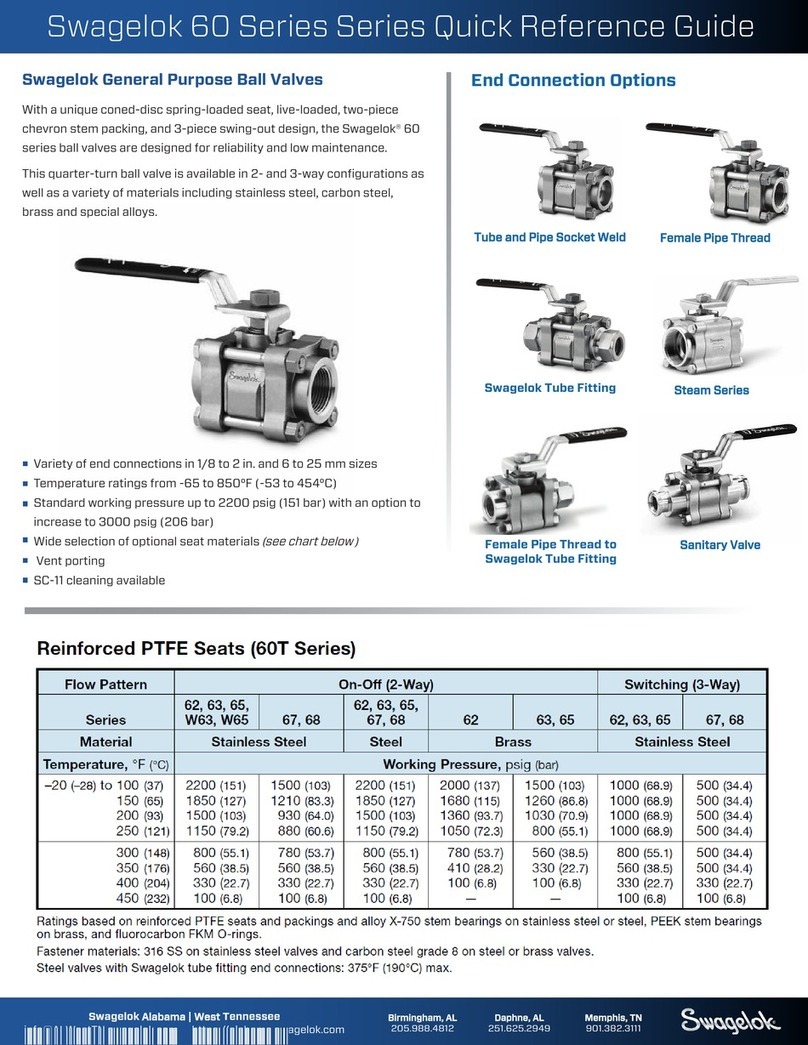

Parts Lubrication Details

Parts Lubricants

Stem bearing

MS-LT-WL8-1

Center body

(packing bore area)

Bottom packing

Top packing

Seat subassembly

Flange seal

(for S63P, S67P and S68P)

MS-LT-WL7

Body bolt MS-LT-NNS-1