6

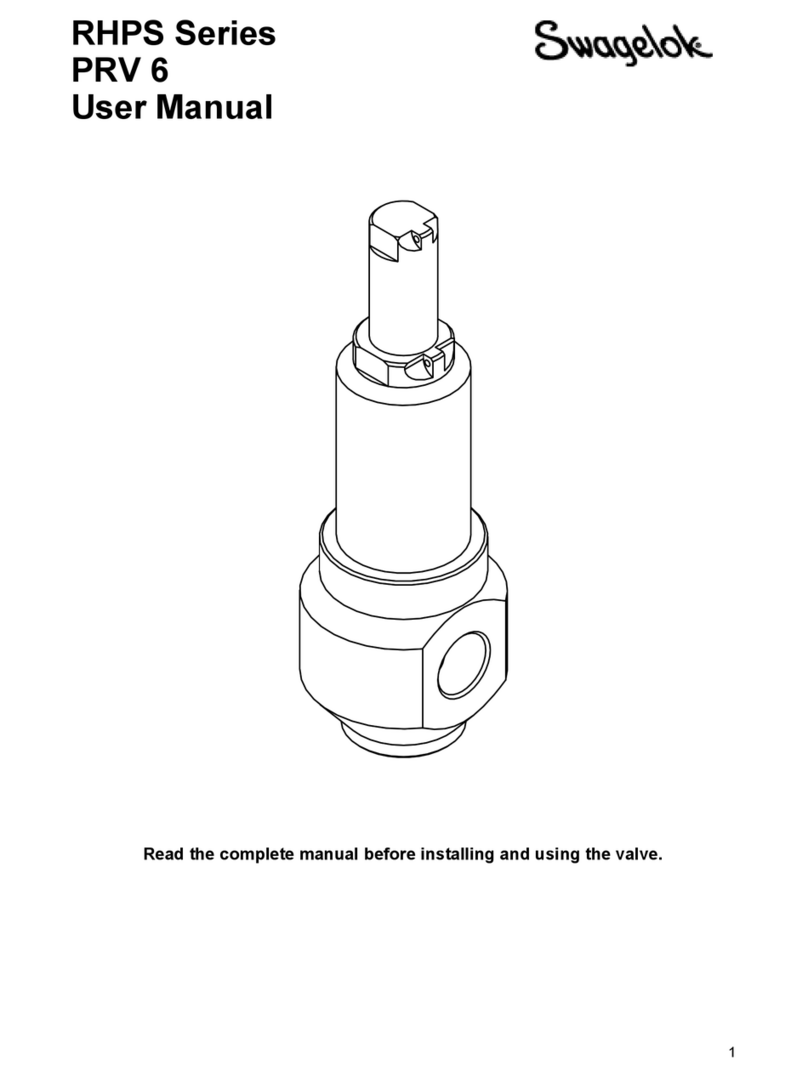

Maintenance

Annual maintenance is recommended under normal use.

More frequent maintenance may be required in heavy duty service.

Required tools for maintenance

vise, to place the PRV in a secure and steady position

wrench 10 mm

wrench 13 mm

wrench 22 mm

pincers in various (small) sizes to take out the O-rings

PRV2 O-ring cone (TF-4100)

PRV cover socket (AST001191)

PRV spring housing socket (AST001142)

PRV2 O-ring guide (AST001164)

Pressure venting

If no other means of venting pressure is provided, it is possible to turn the adjustment screw counter

clockwise.

Disassembly precautions

Do not try to unscrew the spring housing before taking out the set screw first.

Disassembly

Break the wire-lock seal.

Remove the anti-tamper cap cover.

Unlock locking nut.

Turn adjustment screw fully counter clockwise.

Loosen the spring housing.

Remove spring housing, set spring, spring guide (2x).

Remove valve housing and valve.

Remove seat.

Inspection of disassembled parts

With all parts taken out it is now possible to inspect the components for damage.

If there is any damage or significant wear the valve and seat must be replaced.

Besides the valve/seat combination there is also the valve/valve housing combination. Make sure the

valve is smoothly guided through the valve housing.

Assembly

Follow the instructions for disassembly in reverse order to assemble the valve. Use system appropriate

lubricant.

Recommended torque

Spring housing to body 50-55 N·m (445 in.·lb)

Anti-tamper cap to spring housing 30 N·m (265 in.·lb)