Valve Reassembly

1. Apply the supplied MS-LTK-NNS lubricant liberally

to the rst four outside diameter (OD) threads, the

bottom face of the bonnet, and to the OD threads

of the stem sleeve. Also apply the MS-LTK-NNS

lubricant lightly to the top face of the stem sleeve.

Apply the supplied MS-LTK-WL8-1 lubricant lightly

to the packing sequence area.

•WARNING

Before removing the valve from service,

to avoid personal injury, you must:

• Depressurize the system.

• Cycle the valve.

• Purge system to remove any residual

system media left in valve.

NOTICE

Do not scratch any sealing surfaces while

following these instructions. Scratches

on sealing surfaces may affect valve

performance.

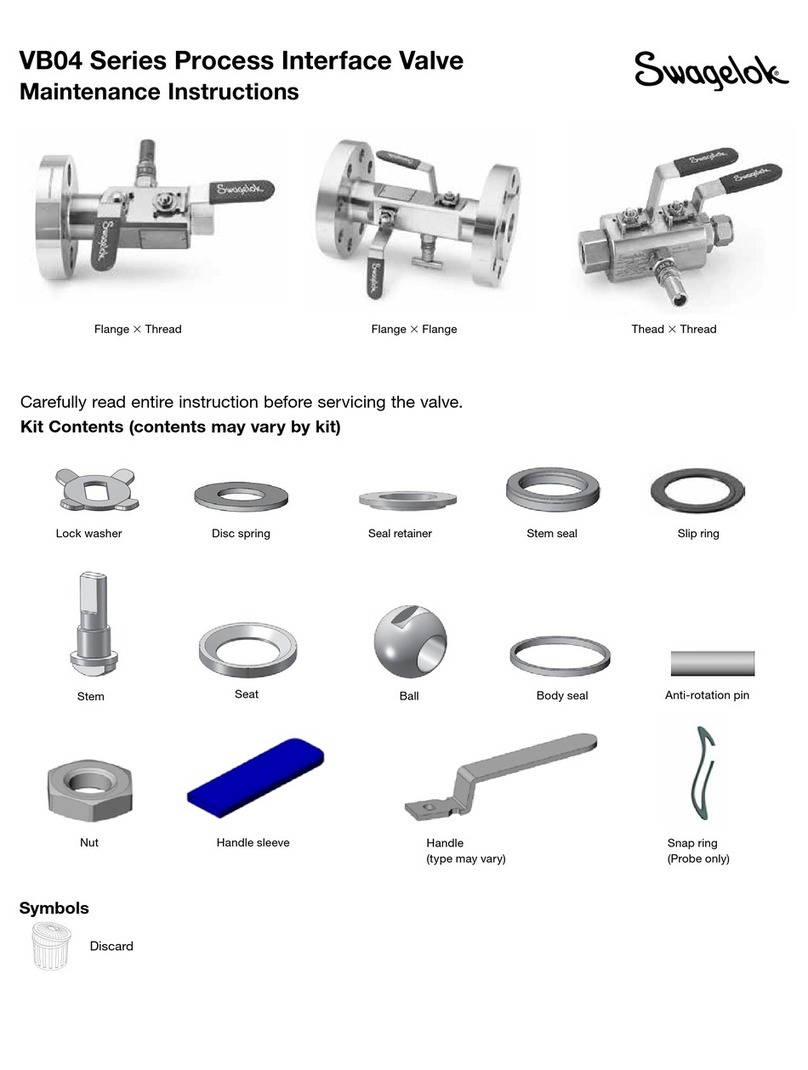

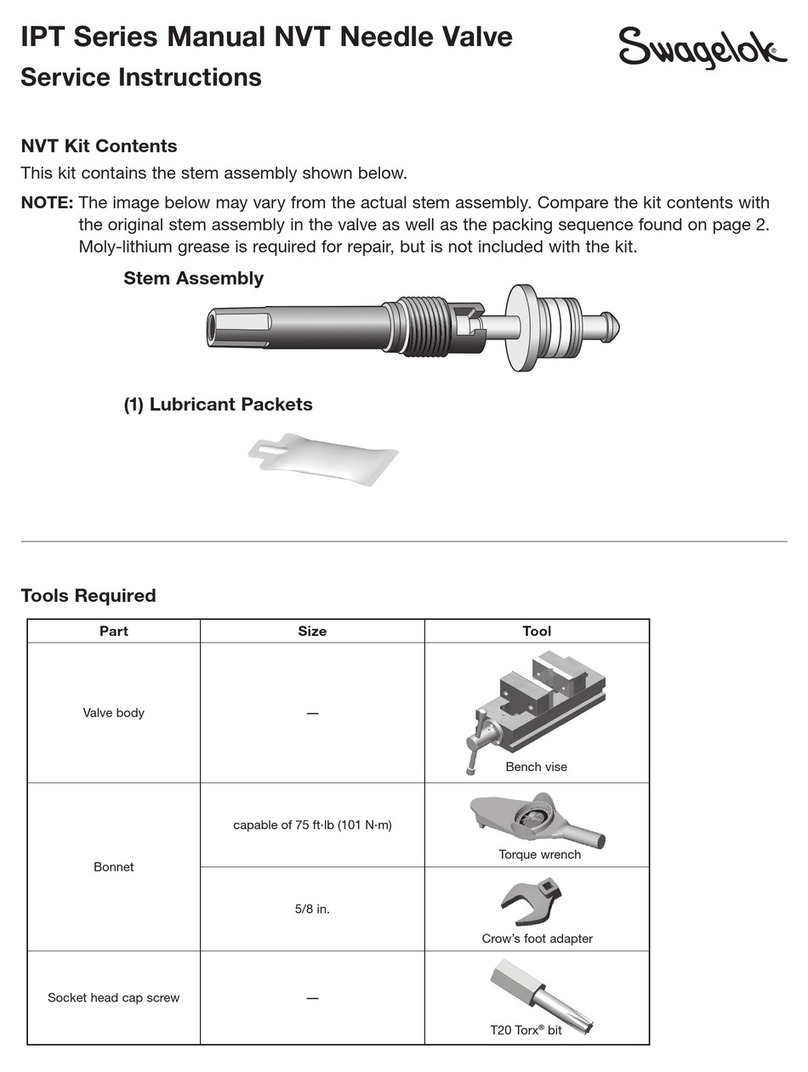

Disassembly

1. Remove the valve from the system.

2. Place the valve in a vise.

3. Loosen and remove the spring lock washers,

handle jam nuts, and set screws.

4. Remove the tee handle assembly.

5. Loosen and remove the locking device and socket

head cap screw.

6. Loosen and remove the bonnet, and remove the

stem assembly.

7. Discard the stem assembly.

8. Clean all remaining components: handle assembly,

bonnet, and valve body.

3

Instructions

Tee handle assembly

Bonnet

Stem assembly

Valve body

Handle

jam nut

Set screw

Spring lock

washer

Lock nuts and

upper bearing washer

Socket head

cap screw

Locking device

Bonnet

Stem assembly

Stem jam nuts and

upper bearing washer

2. Assemble the bonnet onto the stem sleeve until

bottomed.

NOTICE

To prevent damage to the sealing area during

reassembly, thread the stem to the fully open

position prior to insertion into the valve body.

NOTICE

The stem assembly ships with the stem jam

nuts and upper bearing washer appropriately

tightened. Do not tighten the stem jam nuts

and upper bearing washer any further; the stem

assembly needs to move freely.

Liberal MS-LTK-NNS

lubricant

Liberal MS-LTK-NNS

lubricant Light MS-LTK-WL8-1

lubricant

Bonnet

Stem sleeve

Packing

sequence

Light MS-LTK-NNS

lubricant