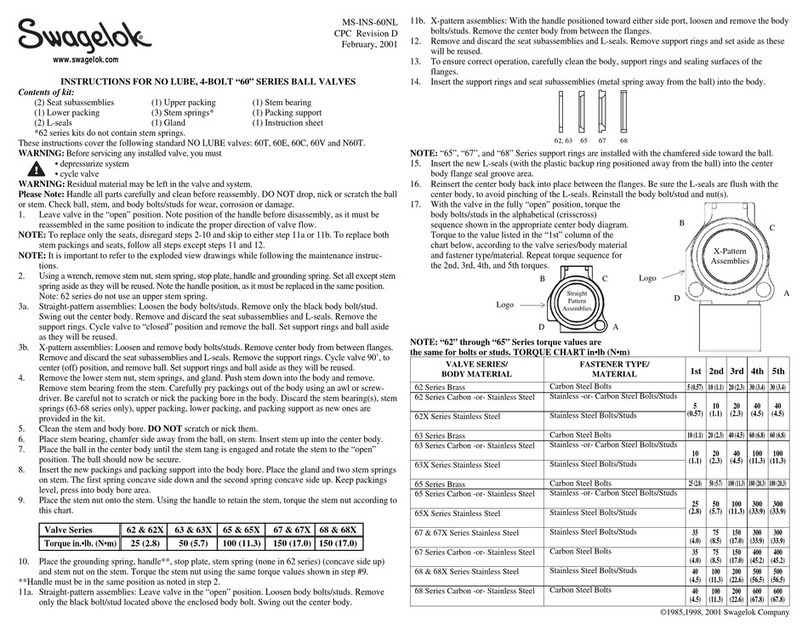

5

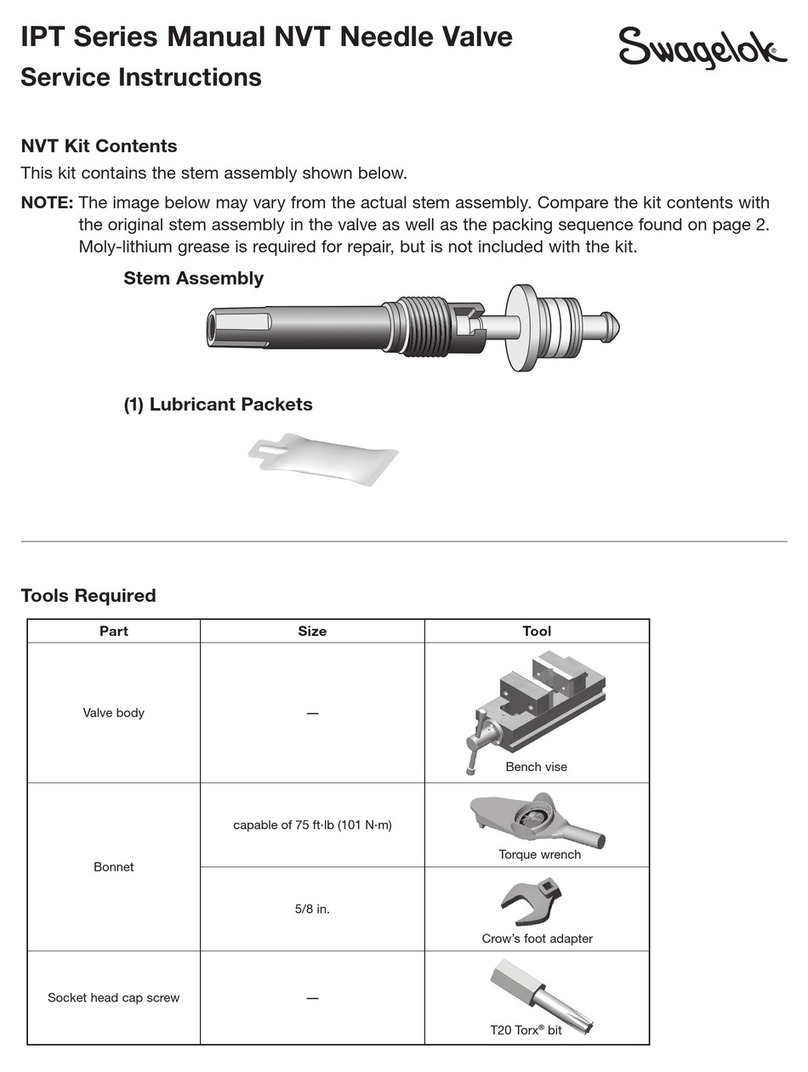

Stem Seal Maintenance

Reassembly

6. Wipe packing bolt and stem clean with a lint-free

cloth.

7. Apply a thin film of lubricant to the stem thrust

washer and stem O-ring. Place parts on stem in

order and orientation shown.

8. Insert the stem assembly into the packing bolt.

CAUTION

Do not pinch the stem assembly components

when inserting into the packing bolt. The

components could be damaged and leakage

result.

9. Remove the valve assembly from the vise and tilt to

remove the ball. Rotate stem if necessary.

10. Place the packing bolt gasket into the body.

11. Thread packing bolt/stem assembly in valve body and

tighten by hand until it meets resistance.

12. Torque the packing bolt to 200 to 250 in.·lb (22.6

to 28.2 N·m, 230 to 290 cm·kg). Put the stem in the

closed position.

13. Pull stem up and install ball. Make sure the stem tang

is aligned with the slot on the ball. Push down on the

stem and rotate to the open position.

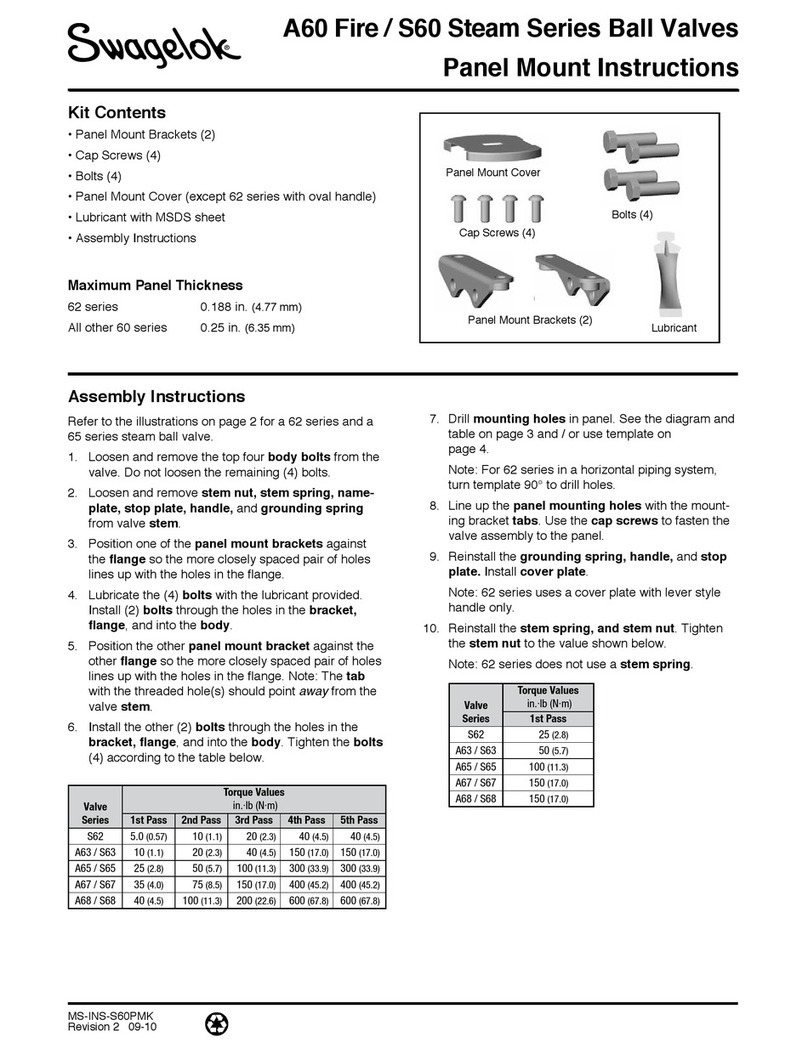

Packing bolt

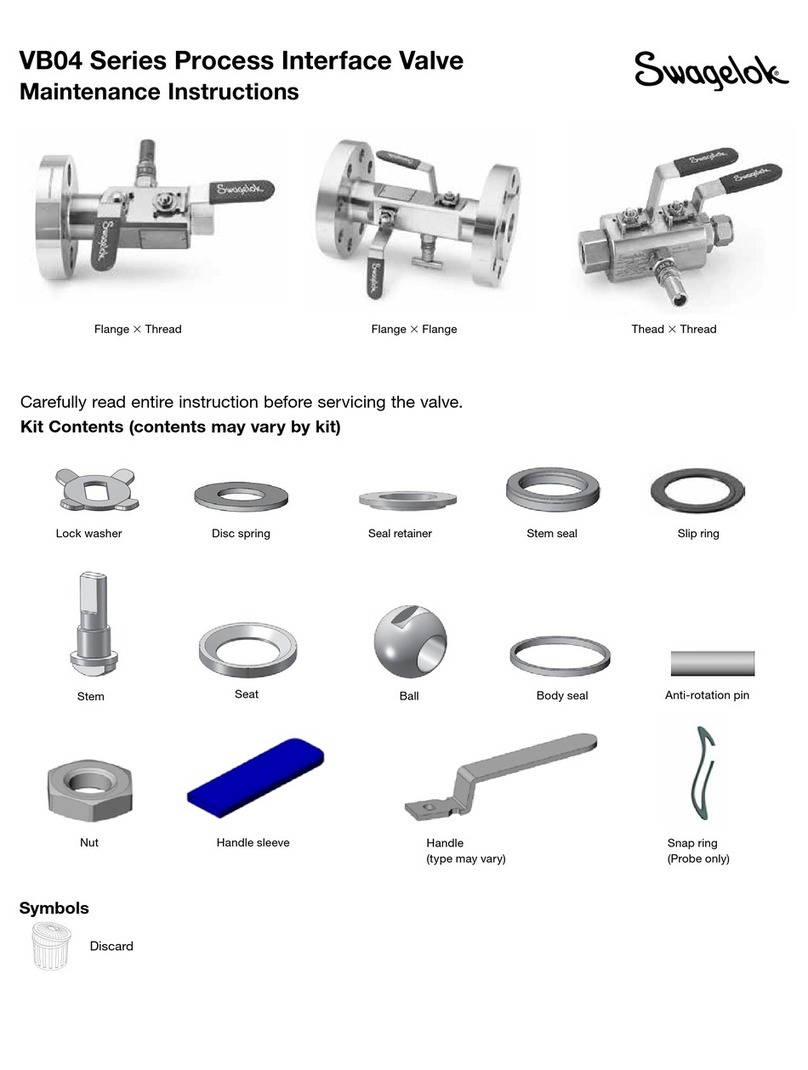

Stem assembly

Stem O-ring

Stem backup ring

Chamfered backup ring

(chamfer side up)

Stem thrust washer Note: If also performing seat seal maintenance on the

removed end screw, follow step 5 of Seat Seal

Maintenance, Disassembly and steps 6 through

11 of Reassembly before proceeding with stem

seal maintenance.

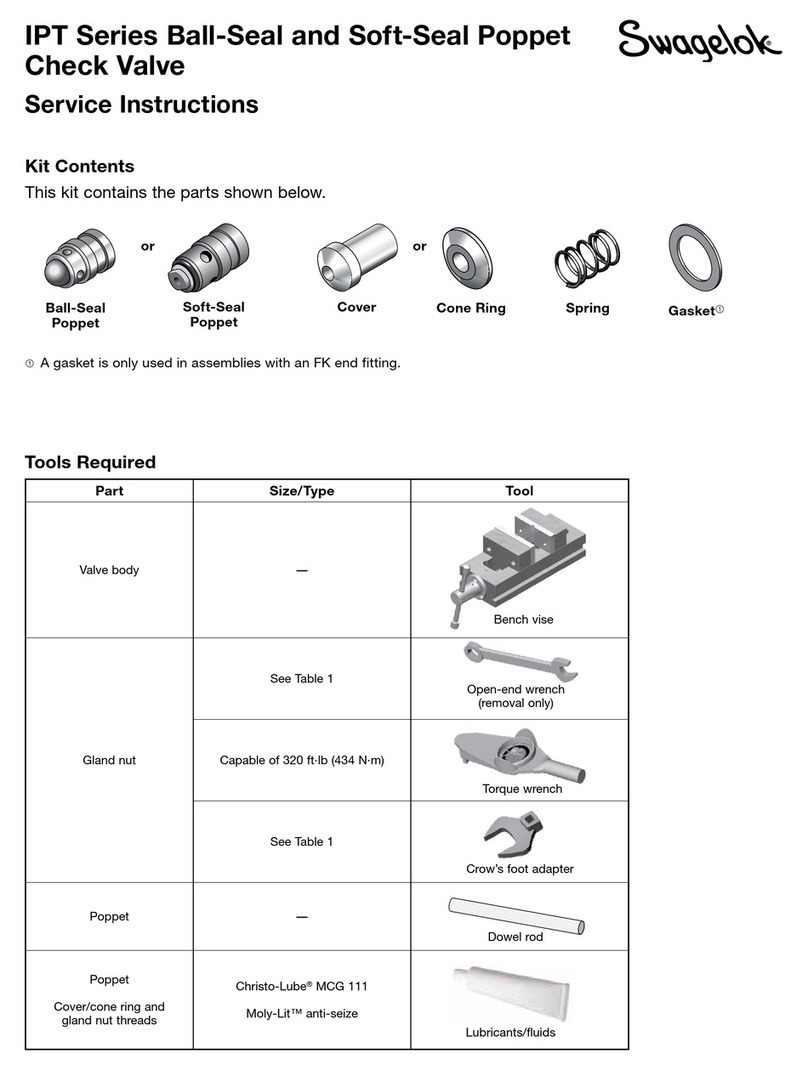

14. Ensure the end screw gasket is resting on the

sealing surface of the end screw. Orient the end

screw assembly as shown and screw into the valve

assembly until no threads are visible.

15. Place the valve assembly into the vise. Torque the end

screwn to 300 to 350 in.·lb (33.9 to 39.5 N·m, 345 to

403 cm·kg).

NOTICE

Ensure end screw gasket remains on sealing

surface or damage to the gasket could result.

16. Place the handle on the valve stem, aligning the larger

stem flat and set screw hole, with the set screw hole

opposite the logo side of the valve. Tighten set screw

with a hex key.

17. Test the fully assembled valve for proper operation

and leak-tight integrity.

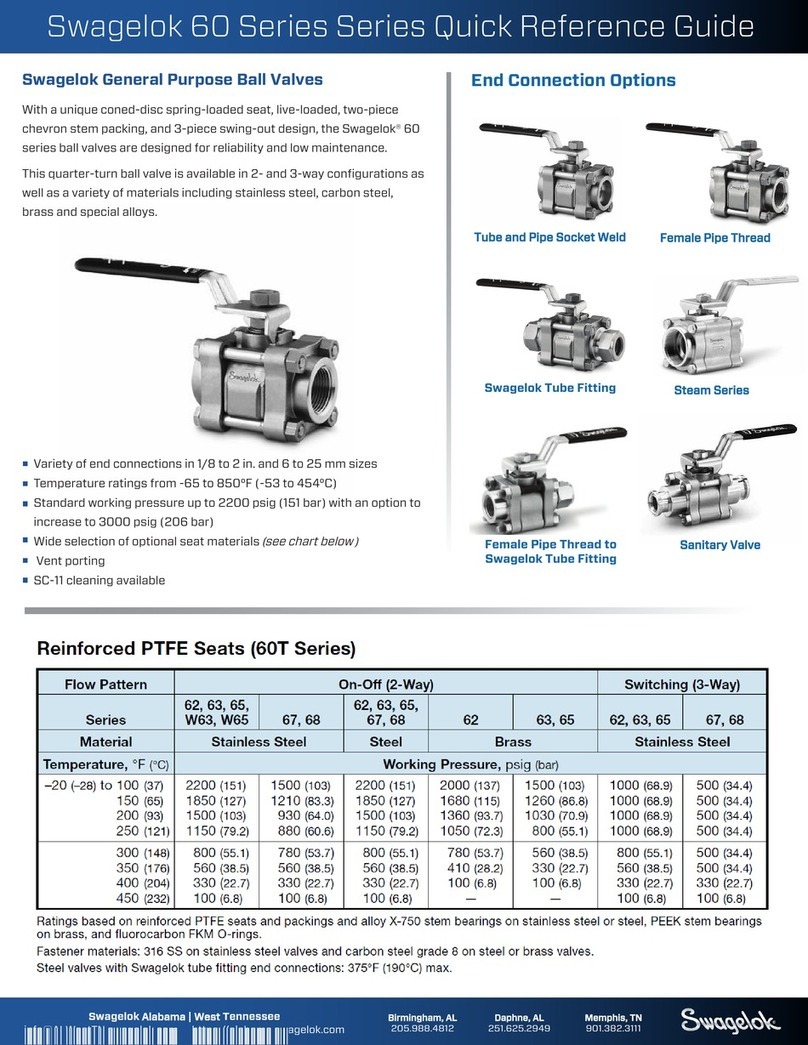

Stem tang Ball slot

End screw assembly

Valve assembly

Sealing surface

Stem step

Stem

step