Standard Stall Instructions 2011 - Page 6

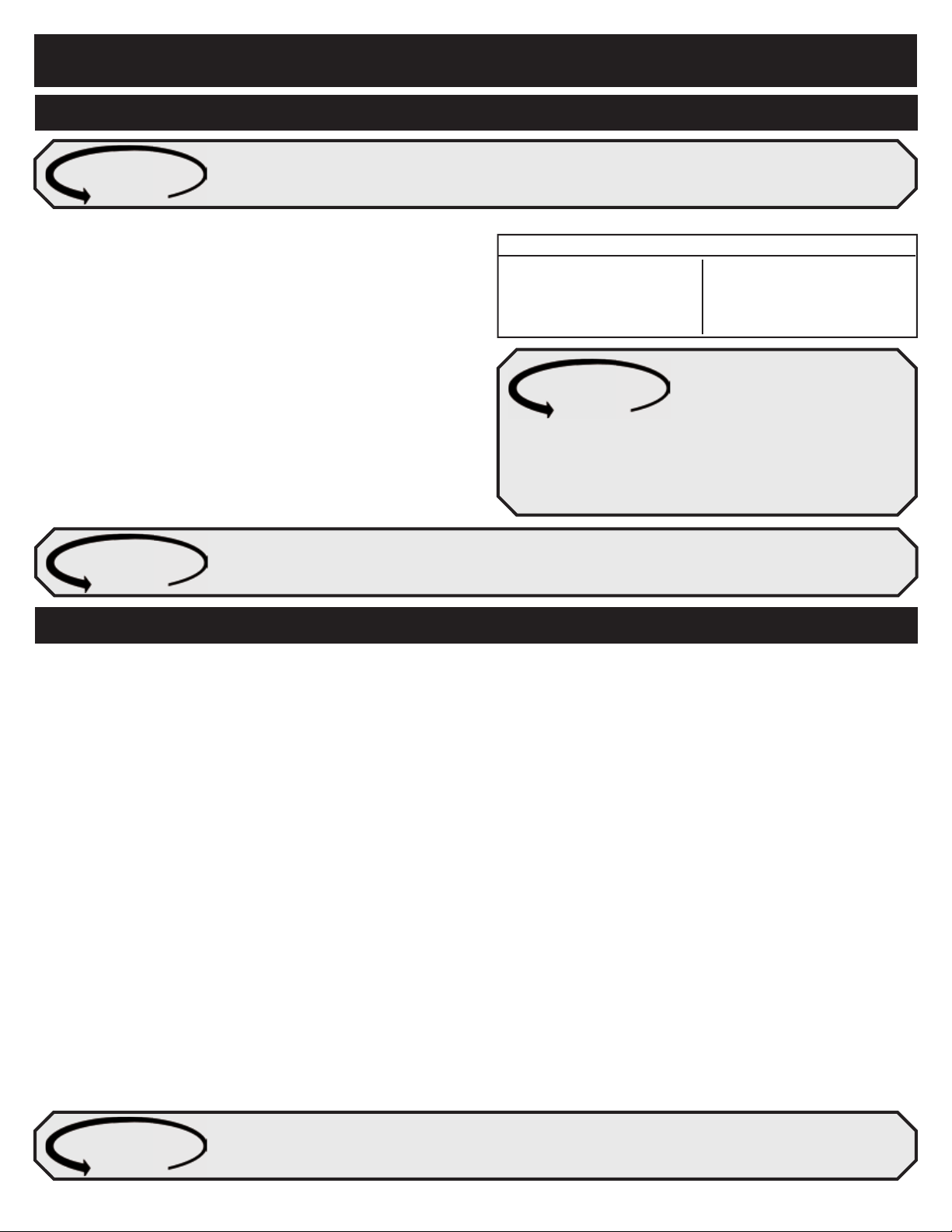

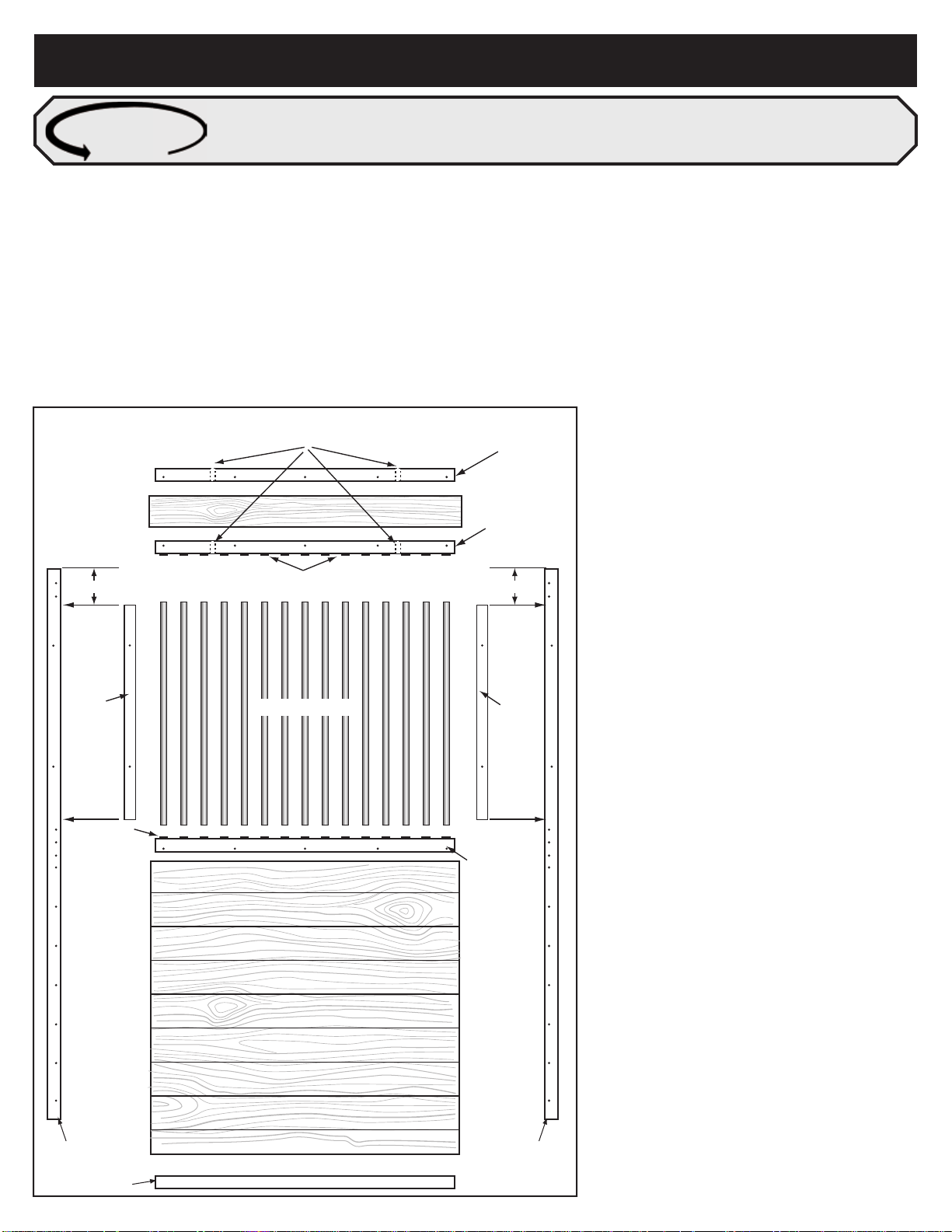

SIDE WALL ASSEMBLY (GRILLED & SOLID PARTITIONS)

NOTE:

The U-channel required for a solid wall partition is 94 1/2" long

The U-channel required for a grilled wall partition is 46" long

STEP 1

First, select the U-channel for the type of wall partition to be installed. Install

one U-channel in the center on either the corner or outside wall at + or - 1”

above the stall floor.

STEP 2

Cut all the necessary lumber to a length 1/4" to 3/8" less than the distance

measured between the inside faces of the U-channels.

STEP 3

Installing the lumber in the U-channels

3a. Slide the first board down the U-channels all the way to the floor and

ensure that it is level.

3b. Firmly secure with the screws provided.

NOTE: For solid partition walls

- Install all remaining boards and secure with the screws provided

- Install the two 94” wall braces (one each side) with the screws provided.

STEP 4 NOTE: Remaining steps are for grill partition walls.

Install all remaining boards ensuring that they come to a height of 1 1/8"

above the top of the U-channels. It may be required to rip cut a board to

achieve the correct height.

STEP 5

Install the rubber grommets as shown in Detail D on page 5 for both the

bottom grill channel and the corresponding top grill channel.

NOTE:

Use a soft face mallet or your fingers to install the rubber grommets into

place.

STEP 6

Install the bottom grill channel flush with the top of the U-Channels.

NOTE:

- For a 10' partition wall, two 6' and two 4' grill channel are utilized

- For a 12' partition wall, two 6' grill channels are utilized

- For a 14' partition wall, four 6' grill channels and two 21.5" channels are

utilized. NOTE: Wall sections that span over 12’ long will require a 4”

x 4” center support post.

- Install the 6' channel first by butting it flush with the face of the post. Install

the second channel for the appropriate distance. It may be necessary to

cut this component. Then attach channels with the screws provided.

STEP 7

At a height 36 3/8" install two 7" header U-channels above the top of the 46"

U-channel.

STEP 8

Place the 2” x 10” header board in the 7” U-channels allowing it to extend 1/2”

below the 7” U-channels. Use a screw at each end to hold the header board

in place for now. Put the top grill channel in position on the bottom of the

header board again hold in place with screws.

STEP 9

Insert the grill bars starting at one end. Place the grill bars in the top grill

channel then lower into the bottom grill channels, repeat until all bars are in

place. When all bars are in place, remove the screws used to hold the header

board and top grill channel. Push or pull down on the header board until it

seats evenly on the top of the grill bars. Now secure the header and top grill

channel in place with the screws provided.

STEP 10

Install the two wall braces, 46" for grilled walls or 94 1/2” for solid walls,

placing one on each side of the wall opposite each other and centred in the

partition.

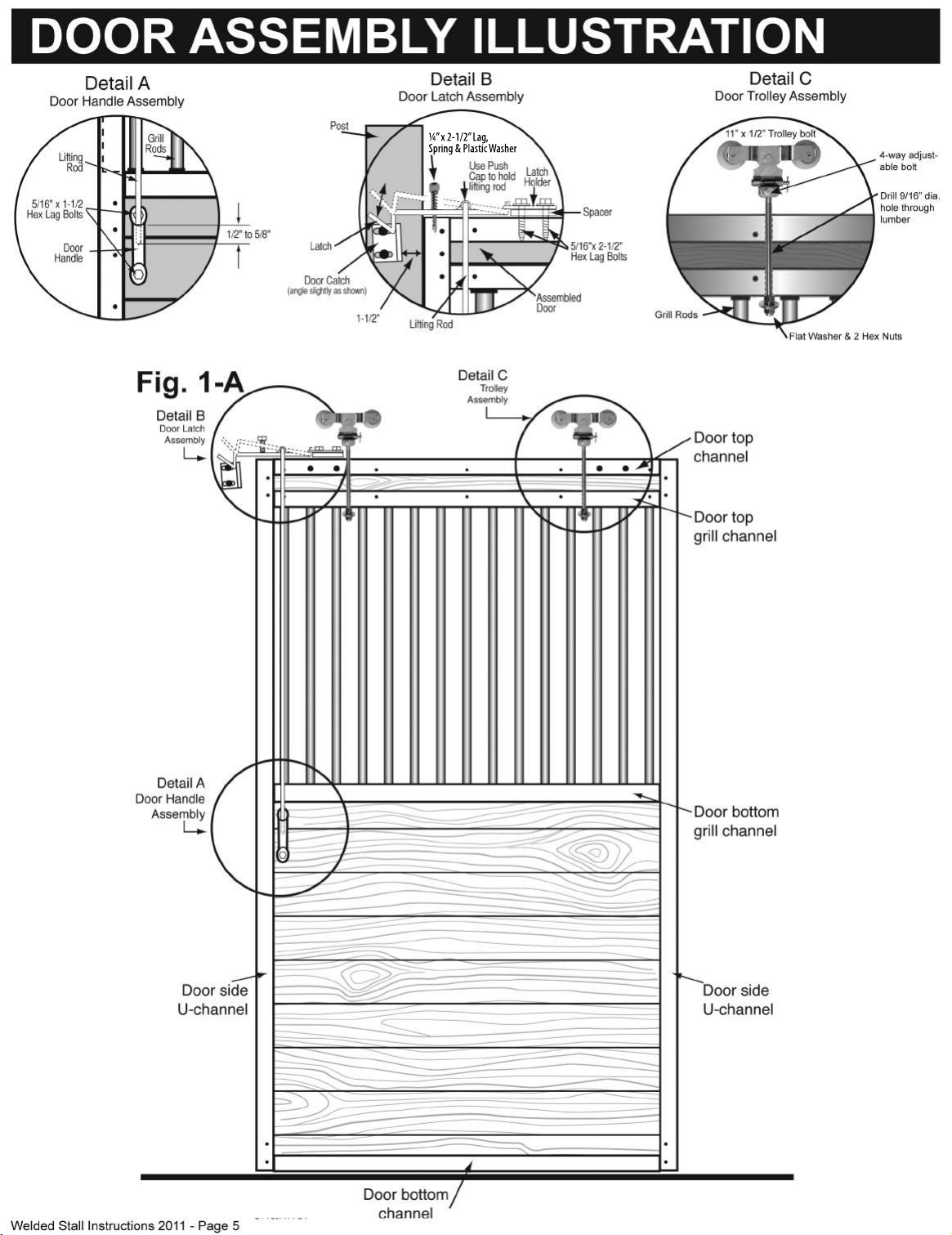

FEED DOOR STYLES

Hinge

Point

Pull down

& open

Hinge

Point

Swing-Out Feed

Door Installation

1. First decide where you want the

swing-out feed door located.

2. Omit 7 bars from the grill section

(Stay at least one bar from either

end of the grill section)

3. The swing-out feed door comes

completely assembled and ready

for installation and is installed in

the same way as the grill bars.

Feed Opening

Installation

1. First decide where you want the feed

opening.

2. Cut two bars to the desired length, 22”

long bars will leave approximately a 12”

opening.

3. Slide feed opening over the two outer

bars of the opening. Let the feed opening

plate rest on the bottom grill channel.

Insert the two cut bars in the top grill

channel and slide the feed opening up

until it is tight with the two bars. Use the

self-drilling self-tapping screws to hold

the feed opening plate in place. Note:

Screw through feed opening plates into

the outer bars of the opening. Place

screw at all four corners as shown.

FLIP DOWN V-DOOR

FliDr

V-Door

Installation

The V-Door grill section is delivered pre-1.

assembled as one-piece

Follow the Stall Door Assembly steps as2.

outlined on page 7 with Step 3 omitted

V-Door not exactly as shown.