5

Technical Data:

Available nozzle ________________________________________________1.3mm: No.59474

________________________________________________________________1.4mm: No.59528

________________________________________________________________1.5mm: No.59529

________________________________________________________________1.7mm: No.59530

________________________________________________________________2.1mm: No.59531

________________________________________________________________2.5mm: No.59532

Pressure required _____________________________________________ 1-2 bar (10-28 psi)

Air Consumption___________________________________________________150~280 l/min

Air connection________________________________________________________ 1/4” PS(M)

Net weight ________________________________________________________________ 450g

Safety

Never point the tool against people and animals - coating

materials or compressed air may be the cause of injuries. It is

forbidden to use any other gas instead of compressed air.

• The use of other gases can lead to serious injury, or threaten to cause a re hazard.

• When connecting the tool to the compressed air system should take into account

the space needed for the hose to prevent damage to the hose or ttings.

• At work should be ensured adequate ventilation. Lack of ventilation

can cause damage to health, or threaten to cause a re hazard.

• The tool should be used away from sources of heat and re, as

this could cause damage to or deterioration of functioning.

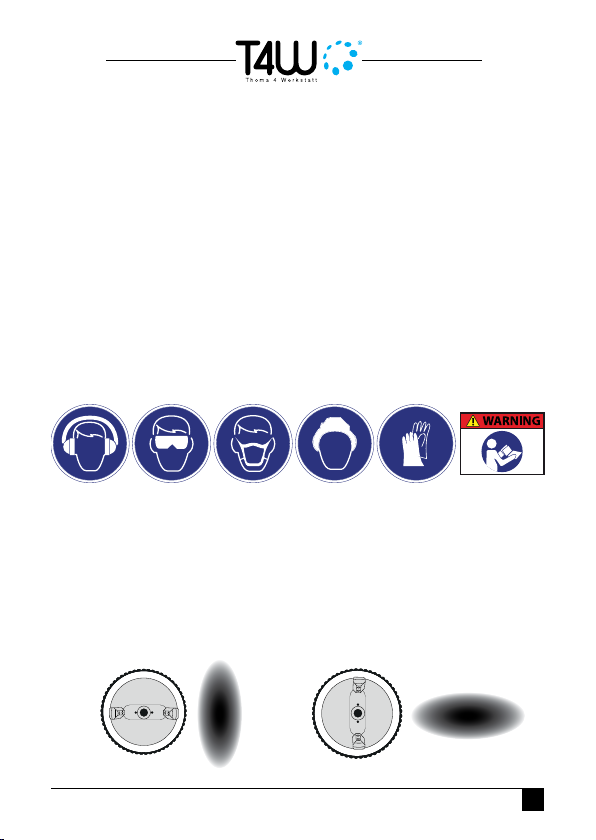

• Observe general safety rules when performing work of coating

materials and used appropriately selected personal protective

equipment such as goggles, masks, gloves and overalls.

• Never leave the assembled air system without the supervision of the person

entitled to maintenance. Do not allow children near the assembled air system.

• Supply compressed air under high pressure, can cause kickback

tool in a direction opposite to the direction of ejection of the coating

material. It should be especially careful, because the recoil forces

may, in certain circumstances, result in multiple injuries.

• It is recommended to try the tool before you start. It is recommended that

utility workers are properly trained. This will improve safety signicantly.

• Follow manufacturer of coating materials and use them in