5/6

02-0-0205,02732020.9.29

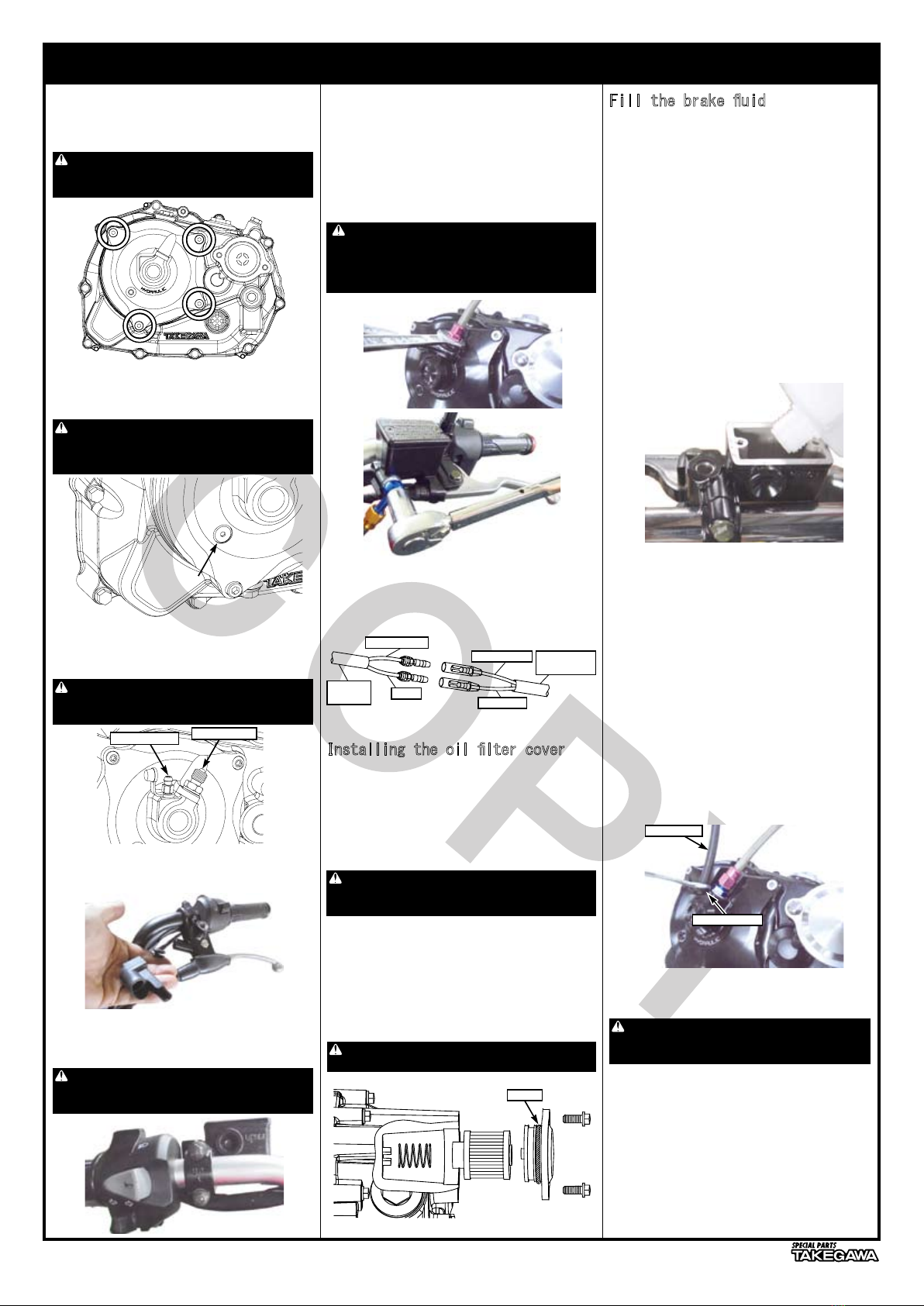

Installing the oil lter cover

O-ring

・Insert 6x8 hexagon socket head bolt

(extremely low head)with 6mm sealing

washer, attach to clutch cover, and

tighten with specied torque.

・With the“UP”mark on the bracket facing

upward, attach the master cylinder assembly,

and tighten the ange bolts(in the order of

upper and lower) with the specied torque.

■ Mounting procedure ※ Please refer to the Genuine Service Manual for detailed mounting methods and specied torques that are not

specically described.

Note:Be sure that you protect specied torque.

Hexagon socket head cap screw(low head),6x6

Torque:9.8N・m(.0kgf・m)

Note:Be sure that you protect specied torque.

Hexagon socket head cap screw

(extremely low head),6x8

Torque:6.3N・m(0.64kgf・m)

Note:Be sure that you protect specied torque.

Flange bolt

Torque:.8N・m(.2kgf・m)

Note:Be sure that you protect specied torque.

Flange bolt,6x6

Torque:9.8N・m(.0kgf・m)

・Place the oil lter spring in the R.crankcase

cover (t it into the guide of the case),

put the oil lter element, attach the

O-ring(40mm) to the oil lter cover, apply

engine oil,and attach the ange bolt(6x6),

Tighten with specied torque.

※ Make sure the oil lter element attached

the guide on the oil lter cover.

※ Caution:If the oil lter spring does not

t inside of the guide(of the oil lter

element), there will be a gap between the

oil lter cover and the R.crankcase cover.

This may cause the oil leaks.

・Attach the clutch cover to the R.crankcase

cover, install it with the Hexagon socket

head cap screw(low head)(6x6) and

tighten it to the specied torque.

・Attach the bleeder screw (with rubber

cap) temporarily, then attach the adaptor

with aluminum sealing washer(0mm) to the

clutch cover with the specied torque.

・Remove the connector and switch cover

from the clutch lever, and remove the

lever from the handle bar.

Bleeder screw Adaptor 0mm

Note:Be sure that you protect specied torque.

Adaptor 0mm

Torque:2.7N・m(.3kgf・m)

・Attach the brake hose (960 mm) with hold the

adaptor(by wrench as shown), and tighten

the hose tting to the specied torque.

Route the brake hose(960 mm) to the clutch

master cylinder,sealing washer(0 mm),banjo

(straight),sealing washer(0mm)in order,

install with banjo bolt(M0x.25,gold),and

hose. Tightening with the specied torque.

Note:Be sure that you protect specied torque.

Banjo bolt

Torque:4.7N・m(.5kgf・m)

Hose tting

Torque:5.9N・m(0.6kgf・m)

・Cut the wiring of the connector (removed

from the stock clutch lever) and the

wiring of the clutch master cylinder ASSY.

with electrical connector.

Master

cylinder

L.Handlebar

switch wire

Green White

Green Red

Green Yellow

Black

Note:Caution:O-ring is installed incorrectly,

the engine may be damaged.

Vinyl hose

・Remove the reservoir cap and check that

the bleeder screw and banjo bolt are well

tightened. Check and ll the brake uid

to the upper limit line of the reservoir

and operate the clutch lever to ll the

brake uid in the clutch system.

Repeat this until no air bubbles come out

from the primary port in the reservoir

(until the clutch lever feels some weight).

※ To prevent chemical reaction, do not mix

different brands of uid.

※ Caution:brake uid will damage the

painted surface, so do not let it adhere

to the parts.

If attached, wash with water.

Fill the brake uid

・Attach a vinyl hose to the bleeder screw

and receive it with an appropriate cup on

the other side of the tube. Grip the

bleeder screw about /2 turn until the

tip of the clutch lever hits the grip,

tighten it again, slowly release the

clutch lever, and leave it for a few

seconds as it is completely returned.

※ Do not release the lever with the

bleeder screw loosened.

・Repeat this until no bubbles come out

from the bleeder.

※ Caution: attention to the brake uid

level in the master cylinder, ll it

before lower limit line.

Bleeder screw

・Tighten the bleeder screw to the specied

torque.

・When air bleeding is completed, ll the

brake uid to the upper limit line of the

reservoir and attach the diaphragm and

cap.

・Secure the brake hose with a zip-tie

(200 mm) to avoid interfere with other

parts.

Note:Be sure that you protect specied torque.

Bleeder screw

Torque:7.8N・m(0.8kgf・m)