T&D CM56 User manual

G16th Edition Testers

GAll-in-one’s

GCalibration Equipment

GContinuity Testers

GElectrician’s Kits

GFull Calibration & Repair Service

GFuse Finders

GDigital Clamp Meters

GDigital Multimeters

GMicrowave Leakage Detectors

GMotor Maintenance Equipment

GNon-trip Loop Testers

GPAT Testers & accessories

GPhase Rotation Units

GProving Units

GSocket Testers

GThermometers & Probes

GTest Leads

GVoltage Indicators

GSpecialist Metrohm Testers (4 & 5kV)

GSpecialist Drummond Testers

Other products from Martindale:

Martindale Electric Company Limited

Metrohm House, Penfold Trading Estate, Imperial Way, Watford, WD24 4YY, UK.

Tel: +44(0)1923 441717 Fax: +44 (0)1923 446900

E-mail: sales@martindale-electric.co.uk

Website: www.martindale-electric.co.uk

© Martindale Electric Company Ltd. 2006

Registered in England No. 3387451. Rev 1

CM56 CLAMP METER

INSTRUCTION

MANUAL

MARTINDALE

ELECTRIC

Trusted by professionals

CABLE JOINTS, CABLE TERMINATIONS, CABLE GLANDS, CABLE CLEATS

FEEDER PILLARS, FUSE LINKS, ARC FLASH, CABLE ROLLERS, CUT-OUTS

11KV 33KV CABLE JOINTS & CABLE TERMINATIONS

FURSE EARTHING

www.cablejoints.co.uk

Thorne and Derrick UK

Tel 0044 191 490 1547 Fax 0044 191 477 5371

Tel 0044 117 977 4647 Fax 0044 117 9775582

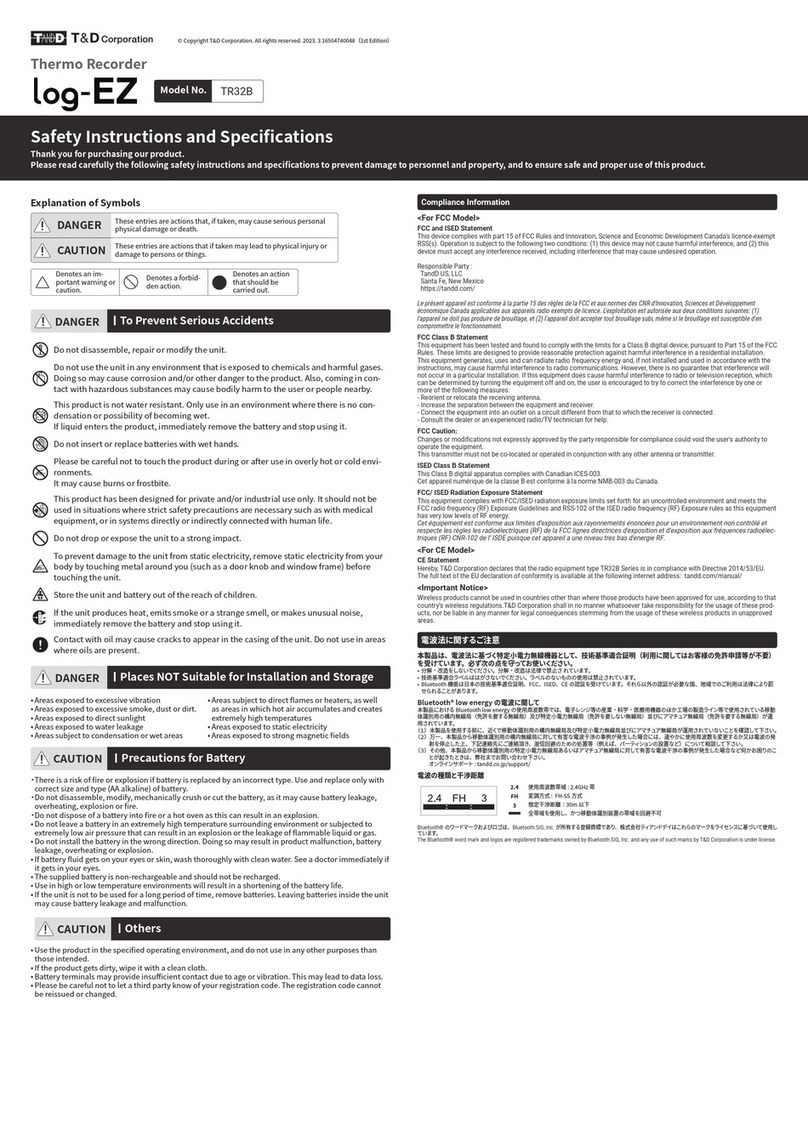

SAFETY INFORMATION: Always read before proceeding.

WARNING

This manual contains both information and warnings that are necessary for

the safe operation and maintenance of the clampmeter. It is recommended

that you read the instructions carefully and ensure that the contents are fully

understood. Failure to understand and to comply with the warnings and

instructions can result in serious injury, damage or even death.

In order to avoid the danger of electrical shock, it is important that proper

safety measures are taken when working with voltages exceeding 30V AC

rms, 42V AC peak or 60V DC.

The clampmeter must only be used under the conditions and for the

purposes for which it has been constructed. Particular attention should be

paid to these warnings, the precautions, the technical specifications and

the use of the CM56 in dry surroundings.

Always inspect your clampmeter, test leads and accessories for any sign of

damage before use. If any abnormal conditions exist (e.g: broken test

leads, cracked case, display not reading, etc.), do not attempt to use it. Do

not expose it to direct sunlight, excessive temperature or moisture.

Keep this manual for future reference. Updated instructions and

product information are available at: www.martindale-electric.co.uk

SYMBOLS:

Equipment complies with relevant EU Directives

AC (Alternating Current)

Ground

Direct Current

Equipment protected by Double Insulation (Class II)

Caution - refer to accompanying documents

Caution - risk of electric shock

End of life disposal of this equipment should

be in accordance with relevant EU Directives

!

CONTENTS

1 Introduction 2

1.1 Description 2

1.2 Unpacking & Inspection 4

1.3 Replacing the Battery 4

2 Safety Information 5

3 Operation 6

3.1 Voltage Measurement 6

3.2 Current Measurement 7

3.3 Resistance Measurement 8

3.4 Continuity Testing 9

3.5 Diode Testing 9

3.6 Frequency Measurements 9

4 Maintenance 10

4.1 Cleaning 10

4.2 Repair & Service 10

4.3 Storage Conditions 10

5 Warranty 10

Technical Specifications 11

1

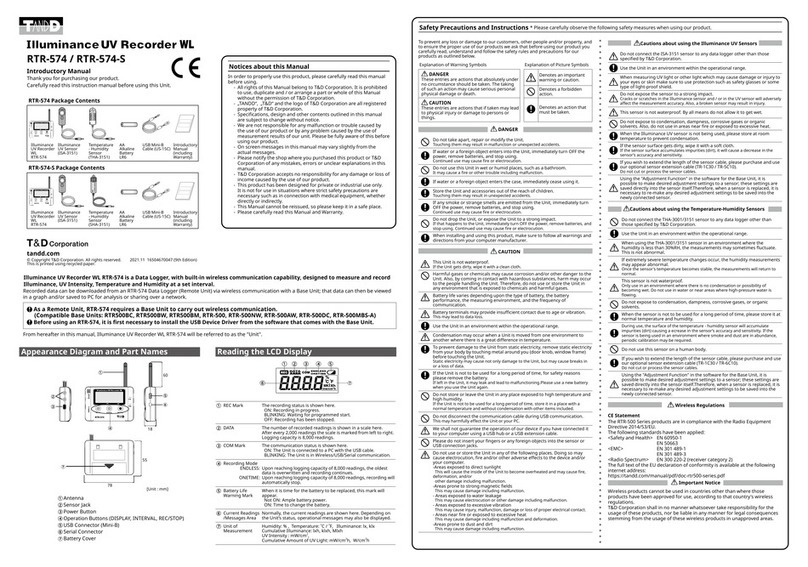

WARNING

READ "SAFETY INFORMATION" BEFORE USING THE METER

1

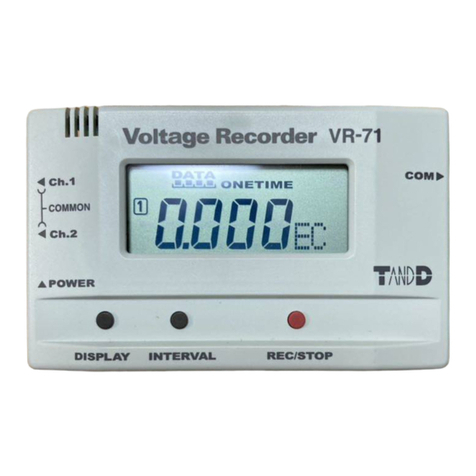

2

3

4

5

6

9

8

10

7

2

1. INTRODUCTION

This manual contains information and warnings which must be followed to ensure

safe operation of the clampmeter.

This clampmeter is a handheld 3200-count instrument that is designed for use in

the laboratory, field servicing and any circumstance where high current

measurement is required. The clampmeter incorporates a finger guard which

ensures the safety of the user whilst operating the instrument, a rugged case that

is shock resistant and fire retardant and electronic overload protection for all

functions and ranges. In addition, a protective carrying case is included for

protection of the meter whilst not in use.

1.1 Description

1. Volt - Input Terminal

This is the positive input terminal for VOLT measurements. Connection is made

to it using the red test lead.

2. COM - Common Terminal

This is the negative (Ground) input terminal for all measurement modes except

current. Connection is made to it using the black test lead.

3. HzΩFrequency, Ohms, Diode Input Terminal

This is the positive input terminal for frequency, Ohms and diode

measurements. Connection is made to it using the red test lead.

4. Display

The display indicates the measured value of signal, function mode, low battery,

range, peak and hold settings.

5. Function / Range selector rotary switch

The rotary switch selects the function and desired range

6. PEAK - Peak recording mode

This function is used to measure the peak value of an AC current signal. To use

this function select the current range and press the PEAK button. The "PEAK"

indicator will appear on the display. When the instrument detects current, the

peak value will be displayed and held in the internal memory. To cancel the

function, press the PEAK button once again.

7. RANGE Button

Press the RANGE button to select the manual ranging mode. The " " indicator

will be displayed. In the manual ranging mode, each time the RANGE button is

pressed, the range and the input indicator change. To exit the manual ranging

mode and return to autoranging, press and hold the RANGE button for 2

seconds. The " " indicator clears from the display.

When the rotary switch is set to or , press the RANGE button to toggle

between audible continuity and diode test modes.

8. Hold Button

Press (HOLD) to toggle in and out of data hold mode. In the data hold mode, the

"HOLD" indicator is displayed and the last reading is frozen on the display. Press

the (HOLD) button again to exit and resume taking readings.

3

9. Clamp Jaws

Detect AC current flowing through the conductor on test.

10. Trigger

Press the lever to open the clamp jaws. When the lever is released, the jaws will

close.

11. Other Functions

Auto Power Off

Automatic power-off extends the life of the battery by turning the meter off after

approximately ten minutes of inactivity. To Turn the meter back on, simply push

the range button, or turn meter off then back on.

1.2 Unpacking and Inspection

Before unpacking the clampmeter, examine the shipping carton for any sign of

damage. Unpack and inspect the clampeter and any associated leads for dam-

age. If there is any damage then consult your distributor immediately.

Upon removing your new Digital Clamp Meter (DCM) from its packaging, you

should have the following items:

1. Digital clampmeter

2. Test lead set (one black, one red)

3. 9-Volt battery (installed in meter)

4. Instruction manual

5. Protective carry case

If any of the above items are missing, please contact your distributor immediately.

1.3 REPLACING THE BATTERY

WARNING

To avoid electrical shock, disconnect the test leads

and any input signals before replacing the battery.

Replace only with same type of battery.

4

AC Volts (Average sensing RMS indicating)

Frequency Response: 50Hz to 300Hz

Overload protection: 1000V DC or 750V AC rms

AC Current (Average sensing RMS indicating)

Overload Protection: 1200A for 60 seconds Maximum

Continuity Test

Overload Protection: 500V DC or AC rms

Range Resolution Accuracy Input Impedance

3.2V

32V

320V

750V

1mV

10mV

100mV

1V

±(1.5% rdg+4d)

±(1.5% rdg +1d)

±(1.5% rdg +1d)

±(1.5% rdg +1d)

11MΩ/ 20PF

10MΩ/ 20PF

10MΩ/ 20PF

10MΩ/ 20PF

Range Resolution Accuracy (50Hz-60Hz)

32A

320A

1000A

10mA

100mA

1A

0-600A±(1.5% rdg+5d)50-60Hz

>600A±(2.0% rdg+5d)50-60Hz

0-600A±(3.0%rdg+5d)61-400Hz

>600A±(3.5%rdg+5d)61-400Hz

Range Audible Threshold Response Time Test Current

320ΩLess than 20ΩApprox. 500ms <0.7mA

This meter is powered by a NEDA type 1604 or equivalent 9-volt battery. When

the meter shows the " " the battery must be replaced to maintain correct

operation. Follow the procedure below to replace the battery.

1. Disconnect the test leads from any live source, turn the rotary switch to off

and remove the test leads from the input terminals

2. The battery cover is secured to the bottom case by a screw. Using a Phillips

head screwdriver, remove the screw from the battery cover. The cover will now

come away from the instrument.

3. Replace the battery with a new equivalent 9-volt one observing correct polarity.

4. Replace the battery cover and re-install the screw.

2 SAFETY INFORMATION

The instrument complies with class II overvoltage CAT III 1000V of the

IEC1010-1 (EN61010-1) ; UL3111-1; and CAN/CSA C22.2 #1010.1-92

standards, pollution degree 2 in accordance with IEC-664 indoor use. If the

equipment is used in a manner not specified, the protection provided by the

equipment may be impaired.

This product complies with the requirements of the following European

Community Directives: 89/336/EEC (Electromagnetic Compatibility) and

73/23/EEC (Low Voltage) as amended by 93/68/EEC (CE Marking).

Electrical noise or intense electromagnetic fields in the vicinity of the equipment

may disturb the measurement circuit. Measuring instruments will also respond to

unwanted signals that may be present within the measurement circuit. Users

should exercise care and take appropriate precautions to avoid misleading

results when taking measurements in the presence of electromagnetic

interference.

5

* Accuracy is given as ± ([% of reading]+[number of least significant digits]) at

18°C to 28°C with relative humidity up to 70%.

Resistance

Overload Protection: 500V DC or RMS AC

Diode Test

Overload Protection: 500V DC or RMS AC

Frequency

Range: 320Hz. 3200Hz, 32KHz

Resoloution: 0.1Hz

Accuracy: ±(1.0% rdg + 4dgts) on all ranges

Sensitivity: 3.5V rms min at >20% and <80% duty cycle

Effect Reading: More than 100 digits at pulse width >2µsec

Overload Protection: 500V DC or RMS AC

DC Volts

Overload protection: 1000V DC / 750VRMS on all other range

Range Accuracy

320Ω

3.2kΩ

32kΩ

320kΩ

3.2MΩ

30MΩ

0.1Ω

1Ω

10Ω

100Ω

1kΩ

10kΩ

±(1.0% rdg+3d)

±(1.0% rdg+3d)

±(1.0% rdg+3d)

±(1.0% rdg+3d)

±(1.5% rdg+3d)

±(2.5% rdg+5d)

<0.7mA

<0.13mA

<13µA

<1.3µA

<0.13µA

<0.13µA

Range Resolution Accuracy Test Current Open Circuit

Volts

3.2V 1mV ±(10% rdg + 2d) 0.6mA 3.0VDC typical

Test CurrentResoiution

Range Resolution Accuracy Input Impedance

320mV

3.2V

32V

320V

1000V

100µV

1mV

10mV

100mV

1V

±(0.5% rdg +1d)

±(0.5% rdg +1d)

±(0.5% rdg +1d)

±(0.5% rdg +1d)

±(0.5% rdg +1d)

>1000MΩ

11MΩ

10MΩ

10MΩ

10MΩ

3. OPERATION

3.1 VOLTAGE MEASUREMENTS

1. Turn off power to the circuit/device under test and discharge all capacitors.

2. Plug the black test lead into the COM input jack on the meter and connect the

test lead tip to a grounded point (the reference point for measured voltage).

3. Select the desired AC voltage range (V ), or DC voltage range (V ). If the

magnitude of the voltage to be measured is unknown, always start with the

highest range.

4. Plug the red test lead into the volt input jack on the meter and connect to the

circuit where a voltage measurement is required. Voltage is always measured in

parallel across a test point.

5. Energise the circuit or device under test and make the voltage measurements.

Reduce the range setting if set too high until a satisfactory best resolution read-

ing is obtained.

6. After completing the measurement, turn off the power to the circuit / device

under test, discharge all capacitors and disconnect the meter test leads.

6

WARNING

To avoid possible electric shock, instrument damage and / or equip-

ment damage, do not attempt to take any voltage measurements

if the voltage is above 1000V DC or 750VAC. These are the maximum

voltages that this instrument is designed to measure. The "COM"

terminal potential should not exceed 500V measured to ground.

Display: 3½ 17mm large LCD, maximum reading 3200 with function and units

sign annunciators. Display update rate 2 times per second, nominal.

Analogue bar graph: 34 segments with measurements 12 times per second

Polarity Indication: Automatic, positive implied, negative indicated.

Overrange Indication: (OL) is displayed.

Low Battery Indication: The " " is displayed when the battery voltage drops

below accurate operating level

Auto Power Off: Clampmeter automatically shuts down after approx 10 minutes

of inactivity.

Operating Environment: 0°C to 50°C at <70% Relative Humidity.

Storage Environment: -20°C to 60°C at <80% Relative Humidity with battery

removed from meter.

Temperature Coefficient: 0.1 X (specified accuracy) / °C (<18°C or >28°C)

Altitude: 6561.7 Feet (2000M)

Power: Standard 9-volt battery, NEDA 1604, IEC 6F22, JIS 006P PP3.

Battery Life: 300 hours typical with alkaline battery.

Jaw Opening Capability: 57mm conductor, 70 X 18mm bus bar.

Size (H x W x D): 10.9 x 4.0 x 1.9 inches (277 x 102 x 49mm)

Weight: Approx: 18.9 OZ/ 540grams (including battery).

Specification

CM56 Clamp Meter

3.2 CURRENT MEASUREMENTS

1. Set the rotary function switch to ACA 1000A Range.

2. Press the trigger to open the clamp jaws and clamp them around a conductor.

Jaws should be completely closed before taking a reading.

3. The most accurate reading will be obtained by keeping the

conductor across the centre of the clamp jaws.

4. The reading will be indicated on the display

5. Reduce the range if set too high until a satisfactory best resolution

reading is obtained.

Peak Button

This function is used to measure the peak value of an AC current signal. To use

this function, select the current range and press the PEAK button. The "PEAK"

indicator will appear on the display. When the instrument detects current, the

peak value will be displayed and held in the internal memory. To cancel the

function, press the PEAK button once again.

Hold Button

Press (HOLD) to toggle in and out of data hold mode. In the data hold mode, the

"HOLD" indicator is displayed and the last reading is frozen on the display. Press

the (HOLD) button again to exit and resume taking readings.

4. MAINTENANCE

Maintenance consists of periodic cleaning and battery replacement.

The exterior of the instrument can be cleaned with a dry clean cloth

to remove any oil, grease or grime. Never use liquid solvents or

detergents.

Repairs or servicing not covered in this manual should only be

performed by qualified personnel.

4.1 Cleaning

The CM56 may be cleaned using a soft dry cloth. Do not use abrasives,

solvents, or detergents, which can be conductive. Allow to dry completely

before using.

4.2 Repair & Service

There are no user serviceable parts in this unit. Return to Martindale Electric

Company Ltd if faulty. Our service department will quote promptly to repair any

fault that occurs outside the guarantee period.

Before the unit is returned, please ensure that you have checked the unit and

associated leads thoroughly for flat batteries (check & replace), blown fuses

(check & replace) and other poor connections.

4.3 Storage Conditions

The clampmeter should be kept in warm dry conditions away from direct sources

of heat or sunlight, and in such a manner as to preserve the working life of the

unit. It is strongly advised that the unit is not kept in a tool box where other tools

may damage it.

5. WARRANTY

The CM56 is guaranteed against faults in manufacture and materials for 24

months from date of invoice and will be rectified by us free of charge, provided

the unit has not been tampered with and is returned to us with its housing

unopened. Damage due to dropping, abuse or misuse is not covered by this

guarantee. Batteries and fuses are not covered by this guarantee.

7

10

WARNING

The clamp jaws are designed to take current measurements on circuits

with a maximum voltage difference of 500VAC between any conductor

and ground potential. Using the clamp jaws for current measurements

on circuits above this voltage may cause electric shock, instrument

damage and / or damage to the equipment under test. Before

measuring current, make sure that the test leads are removed from the

instrument.

The clamp jaws are overload protected up to 500VAC for up to 1 minute.

Do not take current readings on circuits where the maximum current

potential is not known. Do not exceed the maximum current that the

instrument is designed to measure.

3.3 RESISTANCE MEASUREMENTS

1. Isolate any power which may be present at the resistance to be measured and

discharge any capacitors. Any voltage that may be present during a resistance

measurement will cause inaccurate readings and could damage the meter if the

voltage exceeds the overload protection of 500V DC or AC.

2. Insert the black & red test leads into the COM and Ωinput terminals

respectively.

3. Select the desired ohms (Ω) range

4. Connect the black & red test probe tips to the circuit or device under test,

making sure it is de-energised first.

5. Open circuits will be displayed as an overload condition.

6. Test lead resistance can affect low resistance measurements and should be

subtracted from resistance measurements for accuracy. Select the lowest

resistance range and short the test leads together. The value displayed is the

test lead resistance which should subtracted from the resistance measurement.

7. After completing the measurement, disconnect the test leads.

3.4 CONTINUITY TESTING

1. Select the ( ) / ) position by turning the rotary selector switch and

press the "range" button to enter continuity testing.

2. Follow steps 2 & 4 as for resistance measurements

3. The clampmeter emits a tone when measuring resistance of approximately

20Ωor less. After measurements have been carried out, disconnect the test

leads from the circuit and from the input terminals of the clampmeter.

3.5 DIODE TESTING

1. Set the ( / ) position by turning the rotary switch and press the

RANGE button to enter Diode testing.

2. Follow steps 2 & 4 as for resistance measurements.

3. The RED lead should be connected to the anode and the black lead to the

cathode. For a silicon diode, the typical forward voltage should be about 0.6V

silicon diode or 0.3V for germanium diode.

4. If the diode is reverse biased or there is an open circuit, the display shows

"OL"

3.6 FREQUENCY MEASUREMENTS

1. Set the rotary selector switch to the desired position

2. Plug the black and red test leads into the "COM" and "Hz" input terminals

respectively

3. Determine that the amplitude level of the signal to be measured is not greater

than the input voltage limit (500Vac/Vdc). The signal amplitude must also be

greater than the sensitivity level.

4. Attach the probe tips to the points across which the frequency is to be

measured, and read the result directly from the display.

5. Disconnect the test leads.

8 9

WARNING

Attempting resistance or continuity measurements on live circuits can

cause electrical shock, damage to the instrument and damage to the

equipment under test. Resistance measurements must be made on

de-energised (DEAD) circuits only, for maximum personal safety. The

electronic overload protection installed in this instrument will reduce

the possibility of damage to the instrument but not necessarily avoid

all damage or shock hazards.

CAUTION

Measurements must only be made with the circuit power OFF

Table of contents

Other T&D Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Memosens Wave CKI50 operating instructions

Thermokon

Thermokon LCF02 5DO RS485 Modbus manual

Hantek

Hantek HTM200 Series user manual

Starrett

Starrett 3752 Series user guide

Milltronics

Milltronics MultiRanger Plus PL-513 instruction manual

Kompernass

Kompernass KH 4038 operating manual