408- 4452

Rev B2 of 4

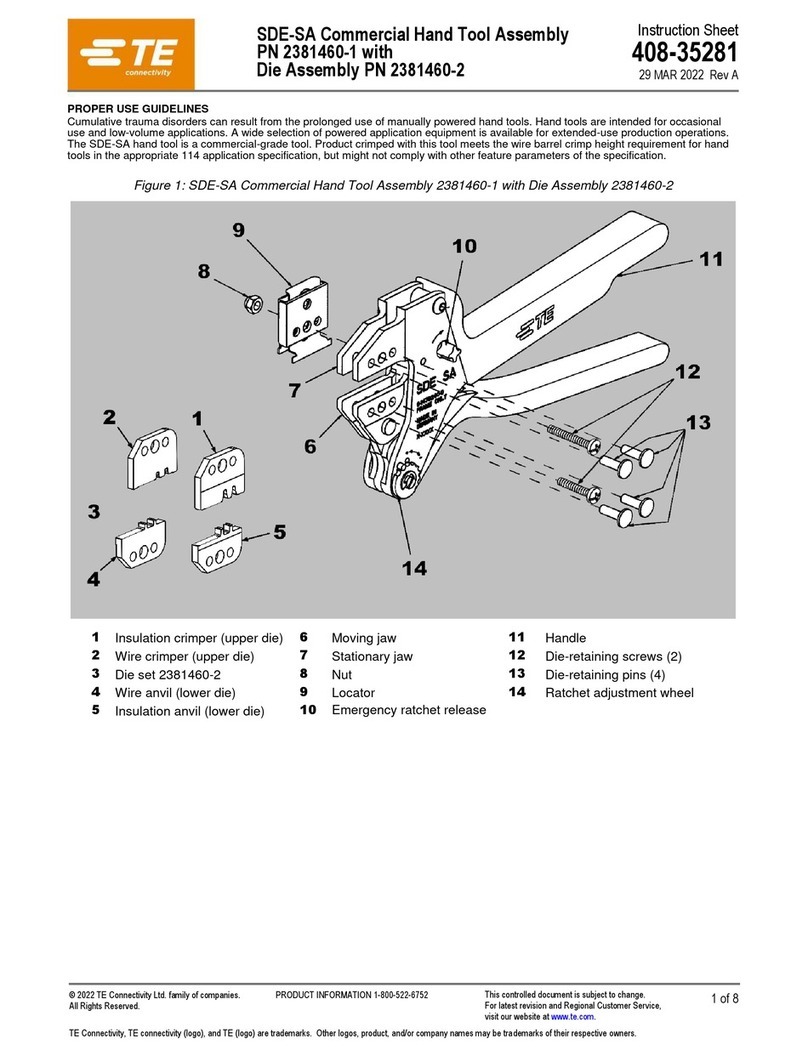

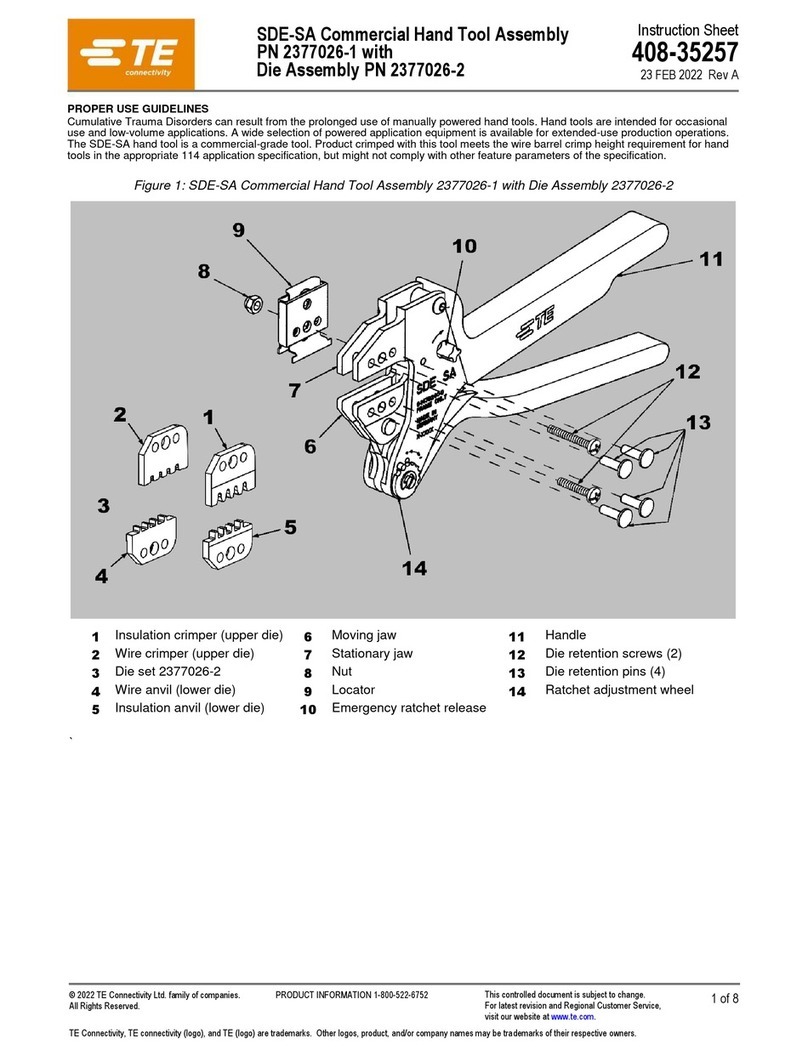

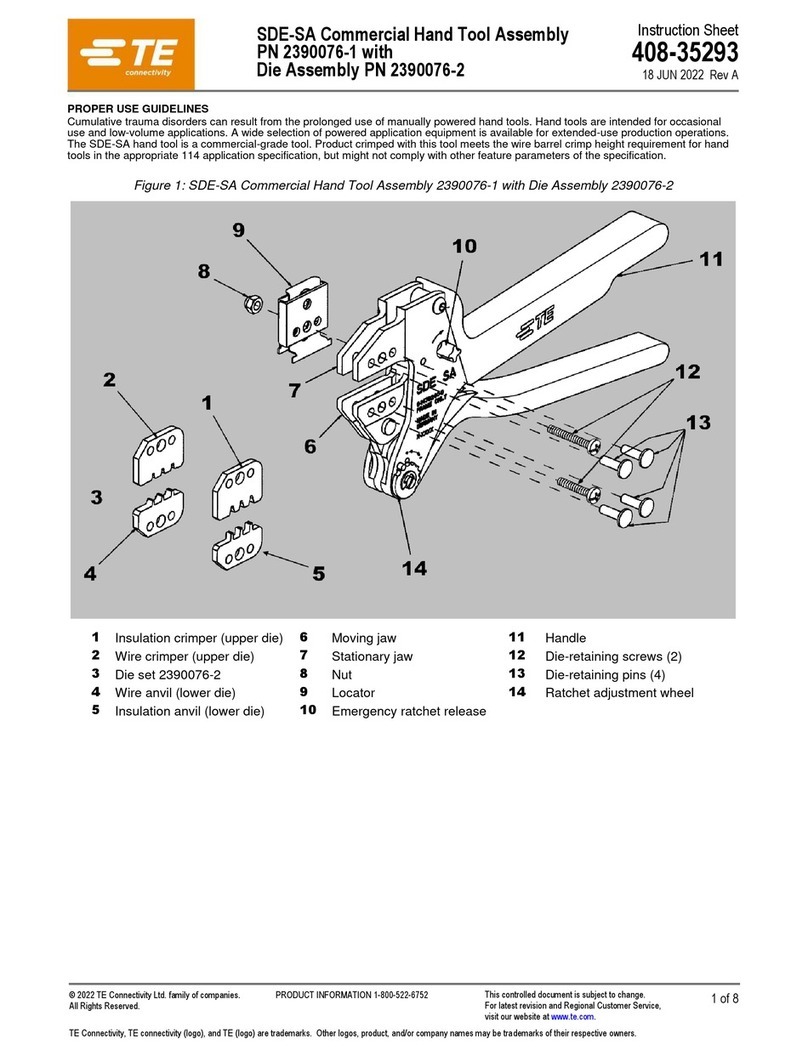

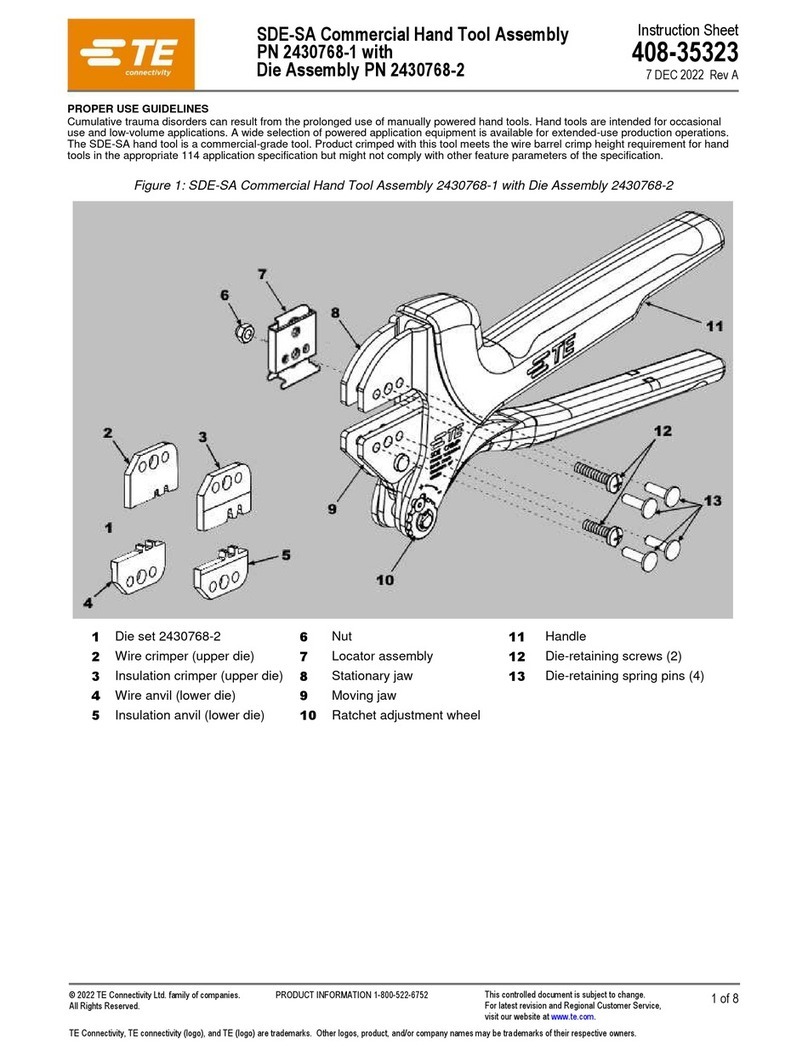

Figure 2

Tool Frame

Die Retaining

Screws

Crimper Die

Anvil Die

Crimping Chamber

Wire Size Markings

Die Retaining Pin

(4 Places)

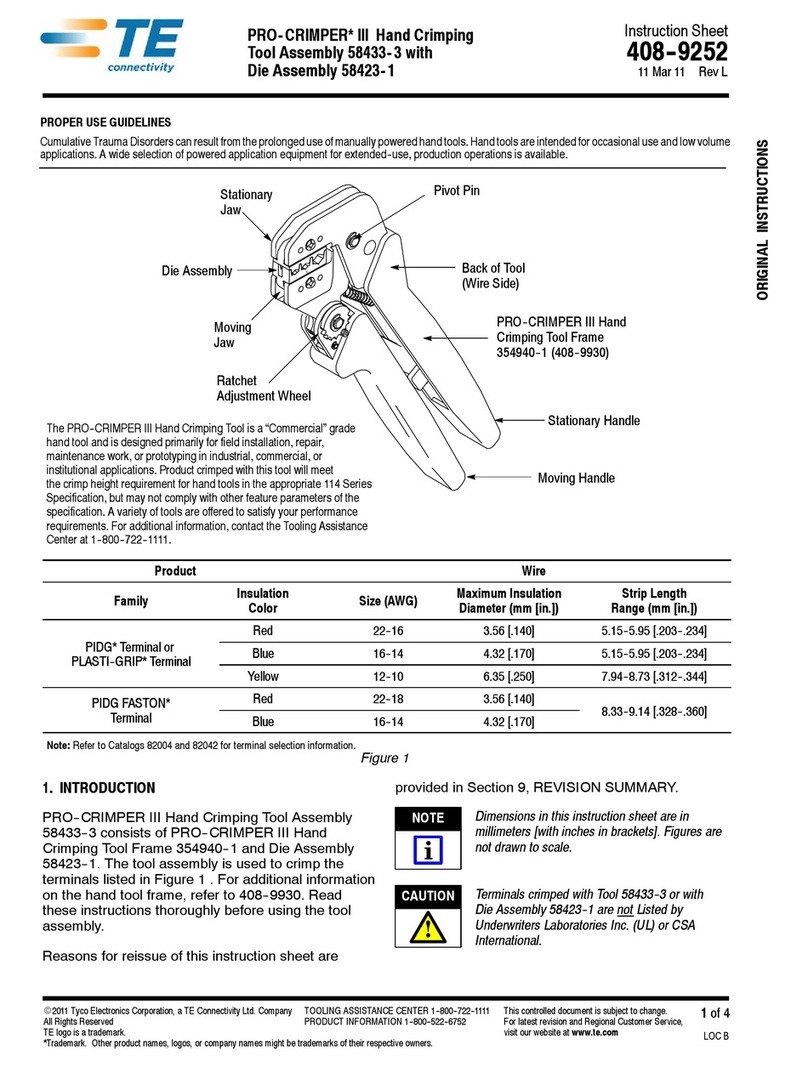

2. DESCRIPTION (Figures 1 and 2)

The tool features a tool frame with a stationary jaw

and handle, a moving jaw, a moving handle, and an

adjustable ratchet that ensures full crimping. The tool

frame holds a die assembly with three crimping

chambers.

The die assembly features an anvil die and a crimper

die. Die retaining pins and die retaining screws are

used to position and secure the dies in the tool frame.

3. INSTALLATION AND REMOVAL OF

DIE ASSEMBLY (Figure 2)

1. Open the tool handles and remove the two die

retaining screws from the tool jaws.

2. Place the anvil die so that the chamfered edge

faces outward when mounted in the moving jaw of

the tool frame. Place the crimper die so that the

chamfered edge faces outward when mounted in

the stationary jaw.

3. Insert the die retaining screws and die retaining

pins through each jaw and into each die. Tighten

the die retaining screws just enough to hold the

dies in place. Do not tighten the screws completely

at this time.

4. Carefully close the tool handles, making sure

that the anvil die and crimper die align properly.

Continue closing the tool handles until the ratchet

in the tool frame has engaged sufficiently to hold

the dies in place, then tighten both die retaining

screws.

5. To disassemble, open the tool handles, remove

the four die retaining pins and two die retaining

screws, and slide the dies out of the tool jaws.

4. CRIMPING PROCEDURE

Initially, the crimping chambers and tool ratchet

should be inspected as specified in Section 5,

CRIMP HEIGHT INSPECTION, and Section 6,

RATCHET ADJUSTMENT, to verify reliability

before using the tool.

Refer to Figure 1 and select wire of the specified size.

Strip the wire to the length indicated, taking care not

to nick or cut wire strands. Select an applicable

receptacle and identify the appropriate crimping

chamber according to the wire size markings on the

dies. Refer to Figure 3 and proceed as follows:

1. Squeeze tool handles together until the ratchet

releases and then allow the tool jaws to open fully.

2. Insert the receptacle (mating end first) into the

BACK of the tool in the appropriate crimping

chamber so that the flat side of the receptacle

faces the anvil die. Make sure that the wire barrel

is centered in the crimping chamber.

3. Hold the receptacle in position and squeeze the

tool handles together until ratchet engages

sufficiently to hold the receptacle in position. Do

NOT deform the wire barrel.

4. Insert the stripped wire into the wire barrel of the

receptacle.

5. Holding the wire in place, squeeze tool handles

together until ratchet releases. Allow tool handles

to open and remove crimped receptacle.

NOTE

i