Nedap SmartFlow User manual

Instruction Manual

Nedap SmartFlow

Installation manual

Version 01.001 / 2021 / EN

Original instructions

Dairy Farming

Copyright

Copyright © Nedap N.V. All rights reserved. The information in this document is subject to change without

notice, it is not to be reproduced in any way, in whole or in part, without the written consent of Nedap N.V. All

trademarks referenced belong to their respective owners.

Disclaimer

Nedap N.V. has made every effort to ensure the accuracy of the information contained in this document.

However, Nedap N.V. makes no representations or warranties whatsoever whether express or implied as

to the accuracy, correctness, completeness or fit-for-purpose or suitability for the purpose of this product.

You use the products at your own risk. Nedap N.V. excludes any liability to the maximum extent permitted by

applicable law for the damages caused by errors or failures made during the installation or improper use of

this product or by not applying the instructions stated in this document. Nedap N.V. reserves the right to make

improvements or amendments to this document and/or the products described therein at any time without any

notification. The latest version of this document can be found on the Nedap Livestock Management business

portal (www.nedap.com/livestockmanagement-portal). Please download the latest version of this document (by

yourself or reseller) and keep a copy for your own records. This document can be published in various languages

but only the English language version will prevail. Nedap N.V. assumes no responsibility for any errors caused for

the translations into another language.

Warranty and spare parts

Please consult the Nedap products dealer from whom you purchased this product, in regards to the applicable

warranty conditions. This product cannot be used for any other purpose as described in this document. If

the product is not installed according to this document; the warranty provided is not applicable. At the sole

discretion of Nedap N.V., Nedap N.V. may decide to change the conditions of the warranty policy. You agree

that Nedap N.V. is able to compensate you the pro-rata value of the warranty involved rather than replacing

or repairing the product depending on the technical or economical value of the product. Prior to applying the

warranty, please verify if you comply with the warranty conditions of the warranty policy, whether you can

successfully apply for the replacement or repair of a defective part. Parts can only be replaced with original

Nedap parts, otherwise the warranty policy will not be applicable on the product. If the warranty is applicable,

please contact the dealer or send the defective parts to the dealer.

Additional information

For any information or questions regarding the product, please contact your own dealer.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

1

Dairy Farming

Nedap SmartFlow

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

2

Dairy Farming

Content

1 Safety .................................................................................................. 4

2 SmartFlow overview ............................................................................. 6

2.1 SmartFlow introduction .................................................................................................. 6

2.2 Components .................................................................................................................... 7

2.3 SmartFlow and MPCU in the milking parlor .................................................................. 9

3 Installation ......................................................................................... 10

3.1 Requirements for installation ...................................................................................... 10

3.1.1 Electrical requirements .................................................................................................. 10

3.1.2 Network requirements ................................................................................................... 11

3.1.3 Electromagnetic requirements ...................................................................................... 11

3.2 Additional documentation ........................................................................................... 12

3.3 Installation overview .................................................................................................... 12

3.4 Unpack the SmartFlow components ........................................................................... 13

3.5 Place the SmartFlow components .............................................................................. 13

3.6 Mount the components ................................................................................................ 13

3.6.1 Mount the VP8002 VPU and VP2001 power supply ..................................................... 14

3.6.2 Mount the VP4102 reader and antenna ....................................................................... 14

3.6.3 Mount the SmartFlow .................................................................................................... 14

3.6.4 Prepare the Float ........................................................................................................... 21

3.7 Mount the cleaning installation ................................................................................... 25

4 Configuration ...................................................................................... 27

4.1 Configure the VP8002 VPU and VP4102 reader ......................................................... 27

4.2 Configure the Velos software ...................................................................................... 28

4.3 Zero Point test .............................................................................................................. 28

4.4 Calibrate the SmartFlow .............................................................................................. 30

4.4.1 Auto calibration .............................................................................................................. 30

4.4.2 Milk test .......................................................................................................................... 31

5 Commissioning ................................................................................... 33

5.1 Before startup .............................................................................................................. 33

5.2 Inform the end user ..................................................................................................... 33

6 Routine checks ................................................................................... 34

6.1 Check status auto calibration ...................................................................................... 34

6.2 Check the Zero Point test ............................................................................................ 35

7 Cleaning ............................................................................................. 38

7.1 Clean the SmartFlow .................................................................................................... 38

7.2 Cleaning requirements ................................................................................................. 38

7.2.1 Cleaning agents .............................................................................................................. 39

7.2.2 Water temperature and flow rate .................................................................................. 39

7.2.3 Mechanical aspects ........................................................................................................ 39

7.2.4 Cleaning cycle ................................................................................................................ 40

7.2.5 Water usage ................................................................................................................... 40

7.2.6 Cleaning program settings ............................................................................................. 40

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

3

Dairy Farming

8 Maintenance ....................................................................................... 41

8.1 Maintenance scheme ................................................................................................... 41

8.2 Replace the SmartFlow Float ...................................................................................... 41

9 Troubleshooting .................................................................................. 45

9.1 Malfunctions ................................................................................................................. 45

10 Handling instructions .......................................................................... 46

11 Glossary ............................................................................................. 47

12 Technical specifications ...................................................................... 48

13 Compliance ........................................................................................ 49

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

4

Dairy Farming

1 Safety

Read this manual before using this product. Failure to follow the instructions and safety precautions in this

manual may result in serious injury or death. Keep this manual in a safe location for future reference.

Symbols used in the manual

Danger

Indicates a hazardous situation that, if not avoided, will result in death or serious

injury.

Warning

Indicates a hazardous situation that, if not avoided, could result in death or serious

injury.

Caution

Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury.

Indicates important information but not hazard related.

Suggestions and advice to perform certain tasks more easily.

General safety instructions

Warning

Always turn off the mains power supply when working on the electrical installation.

Warning

Always wear proper protection when installing and maintaining the Nedap SmartFlow.

Caution

Installation and service should only be done by locally qualified personnel.

Caution

Install the system according to the local rules and regulations.

Caution

We advice to install and maintain the Nedap SmartFlow with at least 2 persons.

Working environment

Caution

The installation area must be free from any obstacles, including animals.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

5

Dairy Farming

Caution

Make sure all components are installed out of reach of animals.

Caution

Make sure all cables are properly concealed, and form no danger for stumbling.

Animal welfare and safety

The automated actions of the Nedap Livestock Management systems do never discharge the installer and the

user of the system from his/her responsibility to assure and to take care of the well-being of the animals.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

6

Dairy Farming

2 SmartFlow overview

2.1 SmartFlow introduction

The Nedap SmartFlow milk meter measures and registers the milk yield and flow rate of individual cows during

each milking. The mechanical geometry and electronic recording principle of the Nedap SmartFlow are designed

for a continuous and optimally free milk and air flow. No flow obstruction or interruption occurs that could cause

a vacuum drop, vacuum fluctuation or rough treatment of the milk. As a result, cows are milked more gently and

completely and udder health improves. It also leads to higher milk quality with less free fatty acids.

The SmartFlow is completely wireless. The Float inside the device and the Velos Process Unit (VPU) form the

intelligent brains and the heart of the system. They combine advanced technologies that make power supply, the

measuring principle and data communication completely wireless. The Float is equipped with state-of-the-art

technologies for the most accurate and reliable measurements. It has smart functionalities on board such as a

data-memory and a control system that monitors whether the device is correctly installed, functions properly,

cleans properly and has a data connection.

Data communication between the SmartFlow and Nedap's dairy management system takes place via Ultra

High Frequency (UHF) communication. All data that is measured and recorded by the Nedap SmartFlow is

sent real-time and wirelessly, collected by an antenna and processed by the VPU. Information and insights are

immediately available via the web-interface (on desktop, tablet or smartphone) and/or via the display of the

milking parlor control unit. Automated actions, such as automatic cluster take-off, are executed immediately as

needed.

Figure1:SmartFlow system overview

1. SmartFlow with Float 4. PC or smartphone with performance insights in Velos

2. V-box with VP4102 UHF reader and antenna (922 MHz) 5. UHF connection (CAN or Ethernet)

3. V-box with VP8002 VPU 6. Ethernet connection

The Nedap SmartFlow milk meter is delivered together with the Nedap Milking Point Control Unit (MPCU). The

MPCU is installed on each milking point to control the milking and cleaning process. For more information

see the MPCU Installation Manual.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

7

Dairy Farming

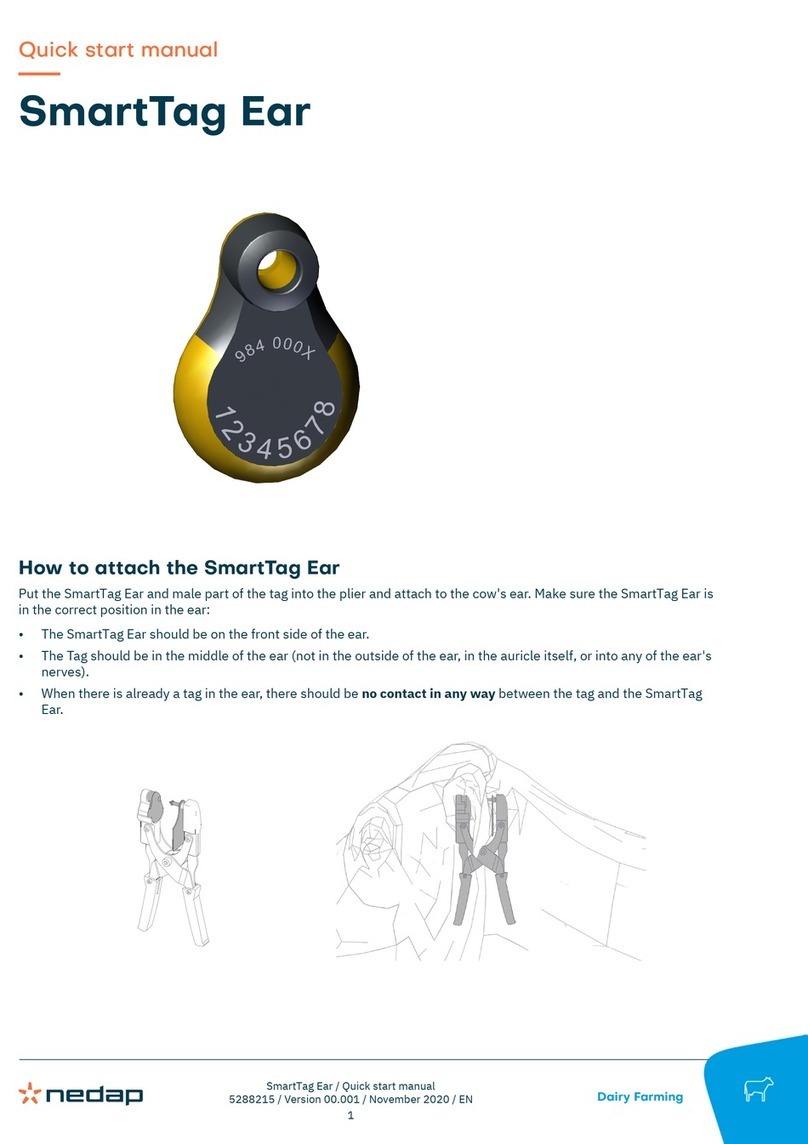

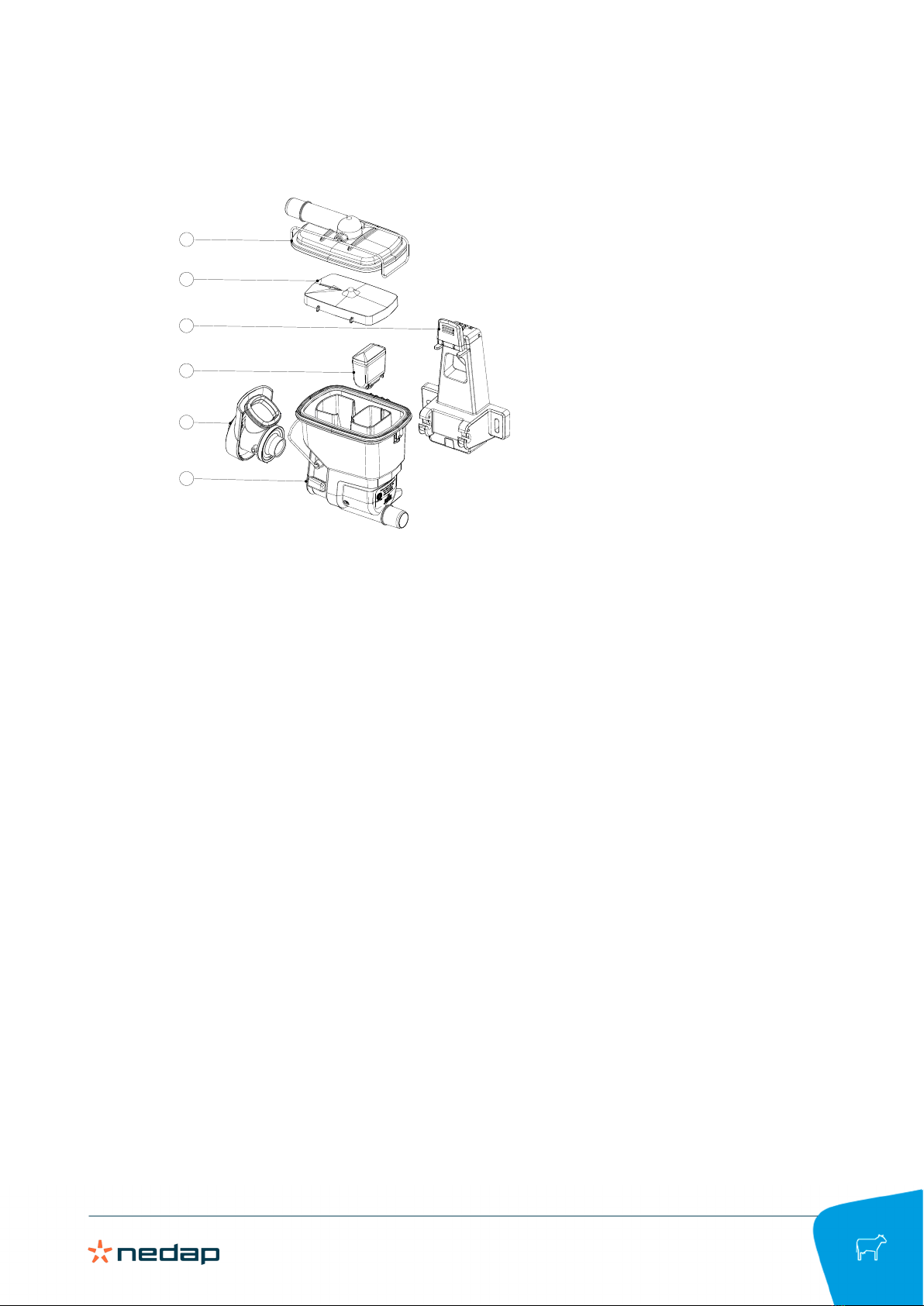

2.2 Components

6

4

5

2

3

1

Figure2: SmartFlow components

1. Cover 4. Main volume

2. Spreader plate 5. Valve module

3. Float 6. Mounting bracket

1. The cover with the inlet ensures a continuous milk and air flow.

2. The spreader plate spreads the milk and air into the main volume for a free milk and air flow.

3. The Float measures the milk yield and milking process.

4. The main volume collects the milk and ensures a free air flow during milking.

5. The valve module makes sure the milk or cleaning fluid flows through the SmartFlow. The SmartFlow

cleaning valve has 2 positions:

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

8

Dairy Farming

a. Milking mode.

When the SmartFlow cleaning valve is in the milking position, the milk cannot flow away from the right

side of the valve. The milk level in the main volume rises, and the Float starts floating on the milk flow,

and measures the amount of milk in the SmartFlow.

b. Cleaning mode.

When the SmartFlow cleaning valve is in the cleaning position, only a bit of the liquid can flow through

the flow column. This will completely fill the rest of the SmartFlow with cleaning liquid, which ensures

proper cleaning of the SmartFlow.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

9

Dairy Farming

6. The mounting bracket ensures the SmartFlow can be mounted firmly to the wall.

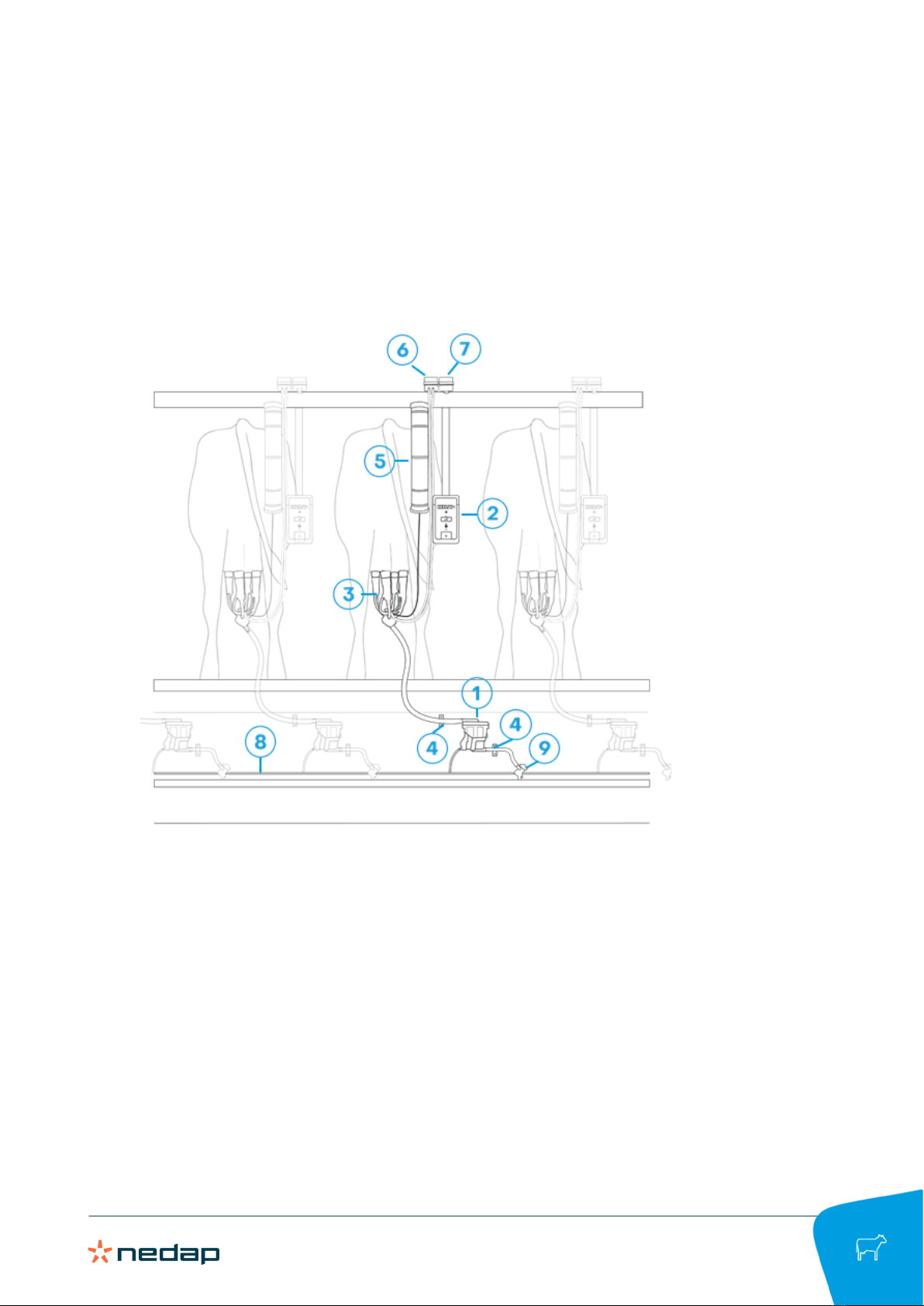

2.3 SmartFlow and MPCU in the milking parlor

The Nedap SmartFlow milkmeters and Nedap Milking Point Control Units (MPCU) are mounted in milking parlors

to measure the milk flow and control the milking process. The location of the SmartFlows and MPCUs in the

milking parlor are indicated in the following illustration. The other parts indicated in the illustration are not

delivered by Nedap.

1. Nedap SmartFlow 6. Pulsator

2. Nedap MPCU 7. Take off/Vacuum valve

3. Milk cluster 8. Vacuum line for cleaning

4. Milk hose bracket 9. Vacuum valve

5. Take off cylinder

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

10

Dairy Farming

3 Installation

Do not operate the product without first reading this chapter and the safety section at the beginning of this

manual.

Warning

Failure to follow safety precautions in this chapter could result in serious injury or death.

3.1 Requirements for installation

3.1.1 Electrical requirements

Mains power

Make sure the mains power supply for the system is easily accessible and not too far away from the barn

in which the units are placed. The power sockets shall be installed near the equipment and must be easily

accessible.

Caution

Nedap power supplies must be connected to a power socket with protective earth (PE). Always use a 3-pole

connector with a PE contact.

If there is no PE available, create a PE next to the power socket to be used for each power supply. The

properties of a correct PE depend on local circumstances and legislation. Always comply with local rules and

regulations when installing earth electrodes.

Network

Use a fiberglass network between the VPUs (VP8002) if

• the power supplies have different power sources with a separate PE;

• the distance between two VPUs or the distance between one VPU and a router/switch exceeds 100 m (330

ft.);

• there is often lightning in the area.

Cabling

Install Velos CAN cable(s) and Ethernet cable(s) inside a plastic (PVC) conduit.

• Do NOT install cables directly to metal ceiling, trusses and feed lines.

• Install fiberglass cables inside a plastic (PVC) conduit with an inner diameter of at least Ø 25 mm (1 in.).

Surge protection and UPS

Caution

Always use surge protectors with Ethernet surge protection.

Install an Uninterruptible Power Supply (UPS) that is connected to the VP2001 when the power source is not

reliable and constant. The UPS is intended to correctly power down the VP8002 and will also run the other V-

packs in the Nedap system for a brief period.

The VP8002 has internal backup power that will shut down the VP8002 correctly when the power is

interrupted. The internal backup power will not run the other V-packs in the Nedap system.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

11

Dairy Farming

Lightning protection

It is important to follow closely the guidelines that are described in this section, in order to minimize risk of

damage on Velos systems in case of lightning. Nedap does, however, not accept any responsibility for damage

caused by high voltage (such as lightning), as described in the Warranty Policy.

Protective Earth (PE)

PE is meant for safety related issues such as electric shocks to humans or animals. PE will not protect devices

(sufficiently) when they are struck by lightning. Normally PE is situated next to the main power source only.

Grounding

Grounding is a connection to the ground, but not Protective Earth, for example a metal roof that is connected to

different earth electrodes in order to lead high peak currents (such as lightning) to the earth.

3.1.2 Network requirements

Basic network requirements

• Router to connect the VPU (VP8002) to the Internet.

• Use of DHCP (Dynamic Host Configuration Protocol) advised.

• LAN Ethernet cable UTP minimum cat 5.

• Minimum upload speed: 1 MB/s

Wi-Fi requirements

To experience all the benefits of the Nedap system, a full covering Wi-Fi installation is crucial in the area

where the system is applied. A functional Wi-Fi connection offers easy access to the mobile interface, allowing

operation by smartphone or tablet. Because of the wide variation in barn designs, we recommend to make use of

local Wi-Fi specialists to plan, install and service such a Wi-Fi installation.

In order to install single wireless networks, we advise you to consider the following conditions. These conditions

are set up for a so-called single wireless network.

General recommendations regarding setting up a Wi-Fi installation

• Always follow local circumstances and legislation regarding wireless network configurations.

• Never use powerful Wi-Fi transmitters; powerful transmitters will generate more noise.

• Do not use dual band or the 5 GHz band; only use the 2,4 GHz band.

• Never use (multiple) ordinary consumer electronics Wi-Fi routers.

• Only use professional access points to create a wireless network.

• Only use a single wireless network configuration, also called "roaming network".

• Use splash and dust proof plastic housings (IP65) to install professional access points.

Wi-Fi bridge requirements for point-to-point connection

• 5GHz to minimize interference (recommended 5.18GHz ~ 5.825GHz).

• High-Power Output to ensure long distance coverage.

• Connection rate of 300 Mbps or higher.

• Internal High-Gain Directional Antenna (10 dBi to 13 dBi or higher).

• Supports WPA2 Wi-Fi Security.

Nedap can never be kept responsible for incorrect functioning of networks or any damage arising from the

recommendations mentioned in this document.

3.1.3 Electromagnetic requirements

Nedap Animal Identification uses radio waves in compliance with ISO 11784/11785 standard and local

regulations.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

12

Dairy Farming

Notwithstanding all due precaution by Nedap, Nedap Animal Identification may not function optimally due

to devices that emit radio waves, such as (but not limited to) variable frequency drives, electronic ballasts of

lighting systems, power supplies, electronic converters of solar panels/windmills and (long) wave radio stations,

which may cause interference with Nedap Animal Identification.

No claims, representations or warranties, whether expressed or implied, are made by Nedap as to the

performance, reliability, durability and safety of Nedap Animal Identification used in conjunction with

abovementioned or other devices.

In order to achieve optimal performance of Nedap Animal Identification, the electrical installation on the farm

needs to meet the conditions that are shown below.

• Maximum allowed environmental noise level: 10 dBµA/m quasi peak, according to CISPR 16-1-1.

• Maximum allowed conducted noise: according to EN55032: 2015.

3.2 Additional documentation

The following additional documentation is required for the proper installation of the SmartFlow system.

This documentation can be obtained from your dealer or on our Business portal: http://www.nedap.com/

livestockmanagement-portal.

Document

VP8002 Installation Manual or VP8002 set Installation Manual

VP4102 Installation Manual or VP4102 set for dairy farming Installation Manual

VP2001 Installation Manual

Antenna Installation Manual

Antenna mounting bracket Quick Start Manual (delivered with the product)

SmartFlow E-learning module

3.3 Installation overview

Assemble and install the system according to the steps below. Each step will be fully explained in the next

sections.

1. Unpack the SmartFlow components (page 13).

2. Place the SmartFlow components (page 13).

3. Mount the components (page 13).

4. Mount the cleaning installation (page 25).

5. Configure the VP8002 VPU and VP4102 reader (page 27).

6. Configure the Velos software (page 28).

7. Calibrate the SmartFlow (page 30).

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

13

Dairy Farming

The SmartFlow can be mounted in two configurations: The milk outlet is positioned either on the right side or

the left side of the Smartflow. The mounting procedure only shows illustrations of the right side configuration,

but is applicable for the left side configuration as well.

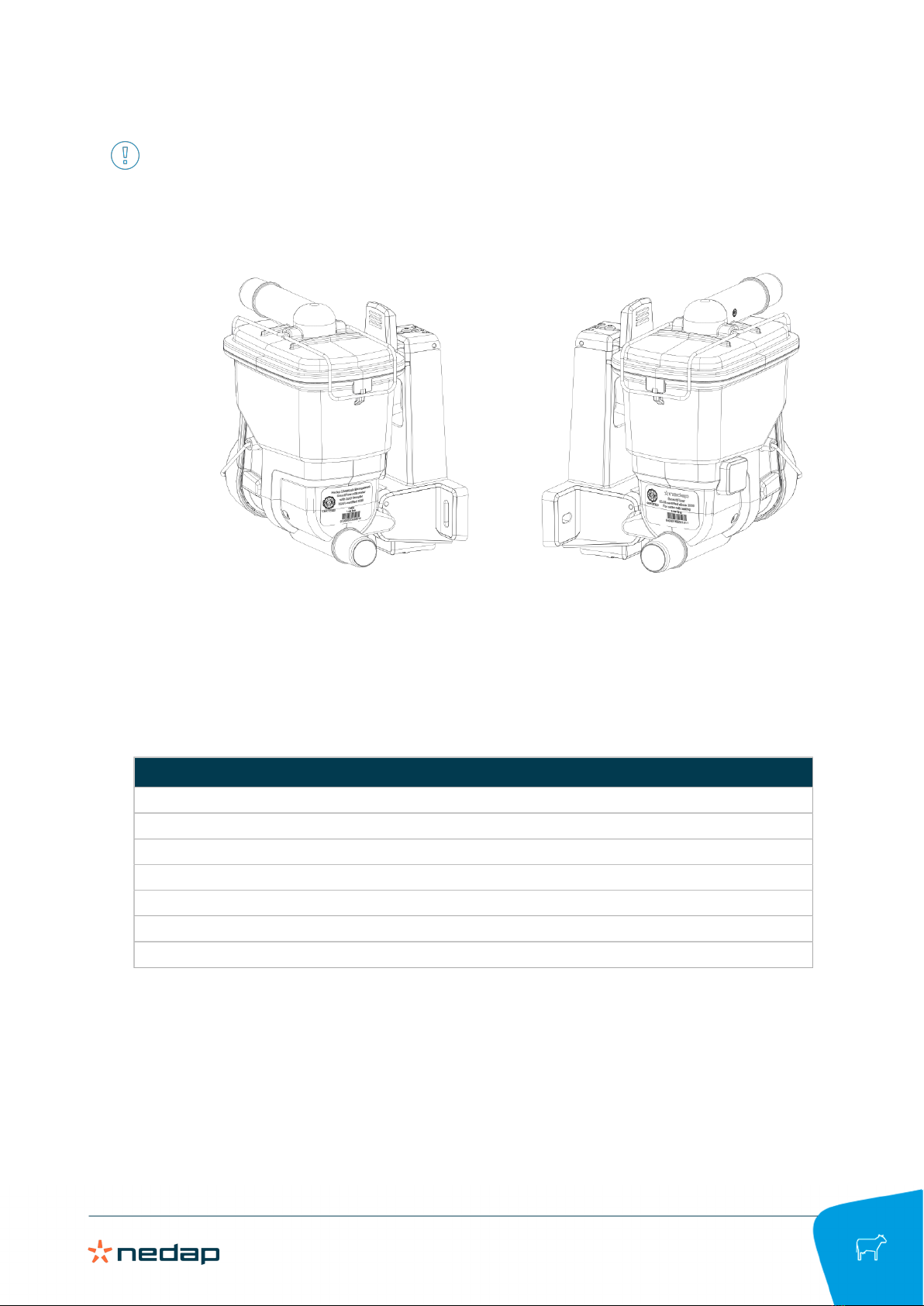

Figure3:Right and left side configuration of the milk outlet on the SmarttFlow

3.4 Unpack the SmartFlow components

1. Check if all parts and components are present:

Item

SmartFlow milk meters

SmartFlow floats

VP8002 VPU or VP8002 VPU set

VP4102 reader or VP4102 reader set

VP2001 power supply (for VP8002 VPU)

Indoor antenna 922 MHz

Antenna mounting bracket (optional)

2. Check the content of the delivery for visible damage.

3. Report any missing or damaged part or component immediately to your supplier.

3.5 Place the SmartFlow components

Place the SmartFlow components on the locations indicated in the Installation Plan.

3.6 Mount the components

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

14

Dairy Farming

3.6.1 Mount the VP8002 VPU and VP2001 power supply

The VP8002 VPU is powered by a VP2001 power supply:

1. Consult the installation plan where the VP8002 VPU and the VP2001 power supply must be mounted. The

VP2001 power supply must be placed near the VP8002.

2. Mount and wire the VP8002 VPU following the instructions in the VP8002 Installation Manual (see

Additional documentation (page 12)).

3. Mount and wire the VP2001 power supply following the instructions in the VP2001 Installation Manual (see

Additional documentation (page 12)).

Caution

– The VP2001 power supply is for indoor use only.

– The VP2001 power supply must be wall mounted and the wires must enter and exit at the bottom

only.

– Do NOT place the V-box with VP2001 power supply inside another box!

Caution

Make sure to always close the V-boxes with the V-box covers.

3.6.2 Mount the VP4102 reader and antenna

The antenna (922 MHz) of the VP4102 reader is preferably mounted with an antenna mounting bracket:

1. Consult the installation plan where the VP4102 reader with antenna must be mounted.

2. Mount and wire the VP4102 reader following the instructions in the VP4102 Installation Manual (see

Additional documentation (page 12)).

3. Mount the antenna mounting bracket following the instructions delivered with the mounting bracket.

4. Mount and wire the antenna (922 MHz) following the instructions in the Antenna Installation Manual (see

Additional documentation (page 12)).

Caution

Make sure to always close the V-box with the V-box cover.

3.6.3 Mount the SmartFlow

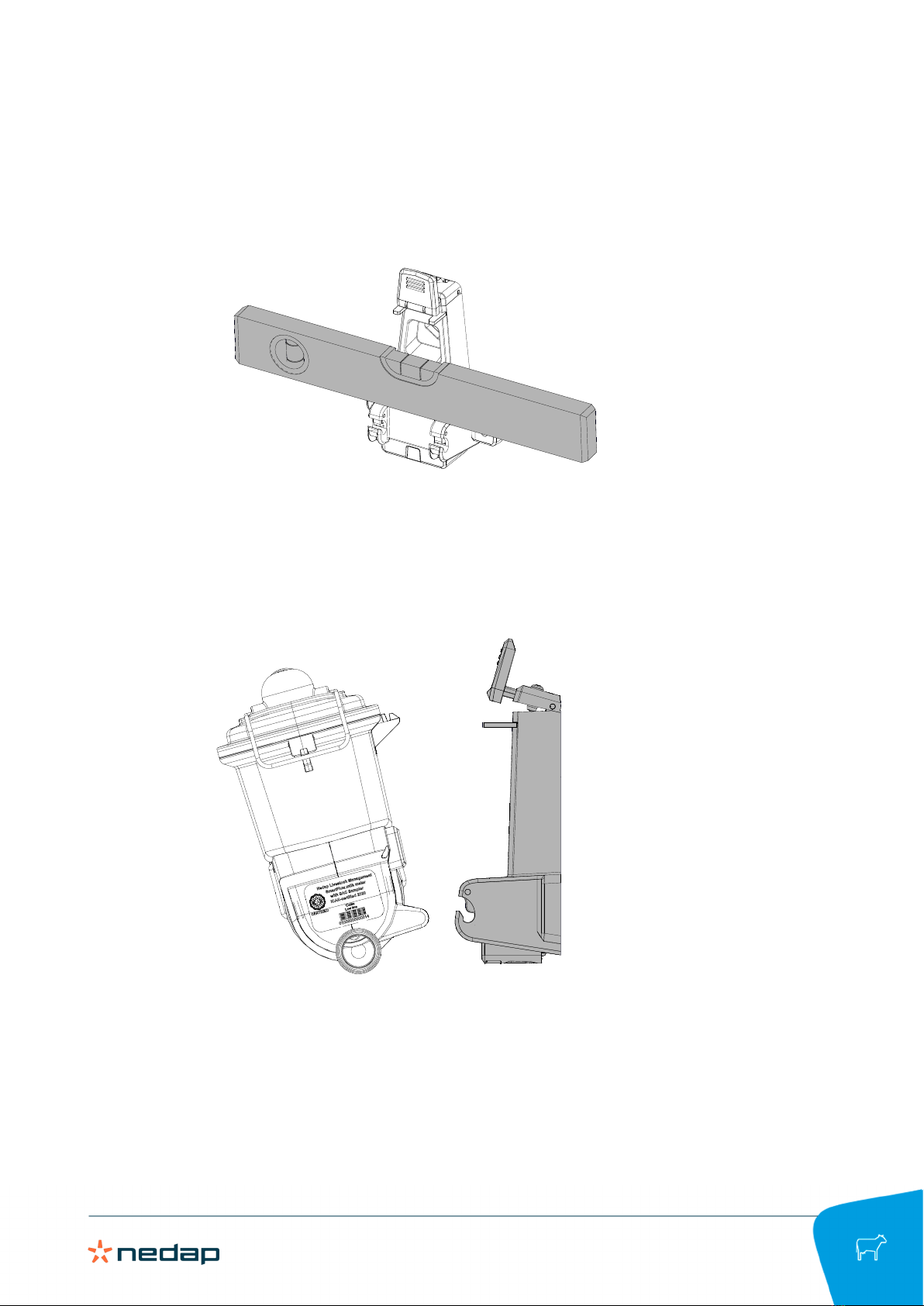

1. Mount the bracket on a flat surface, for example a wall or a plate. Use appropriate mounting material.

Make sure there is at least 10 cm free space above the bracket.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

15

Dairy Farming

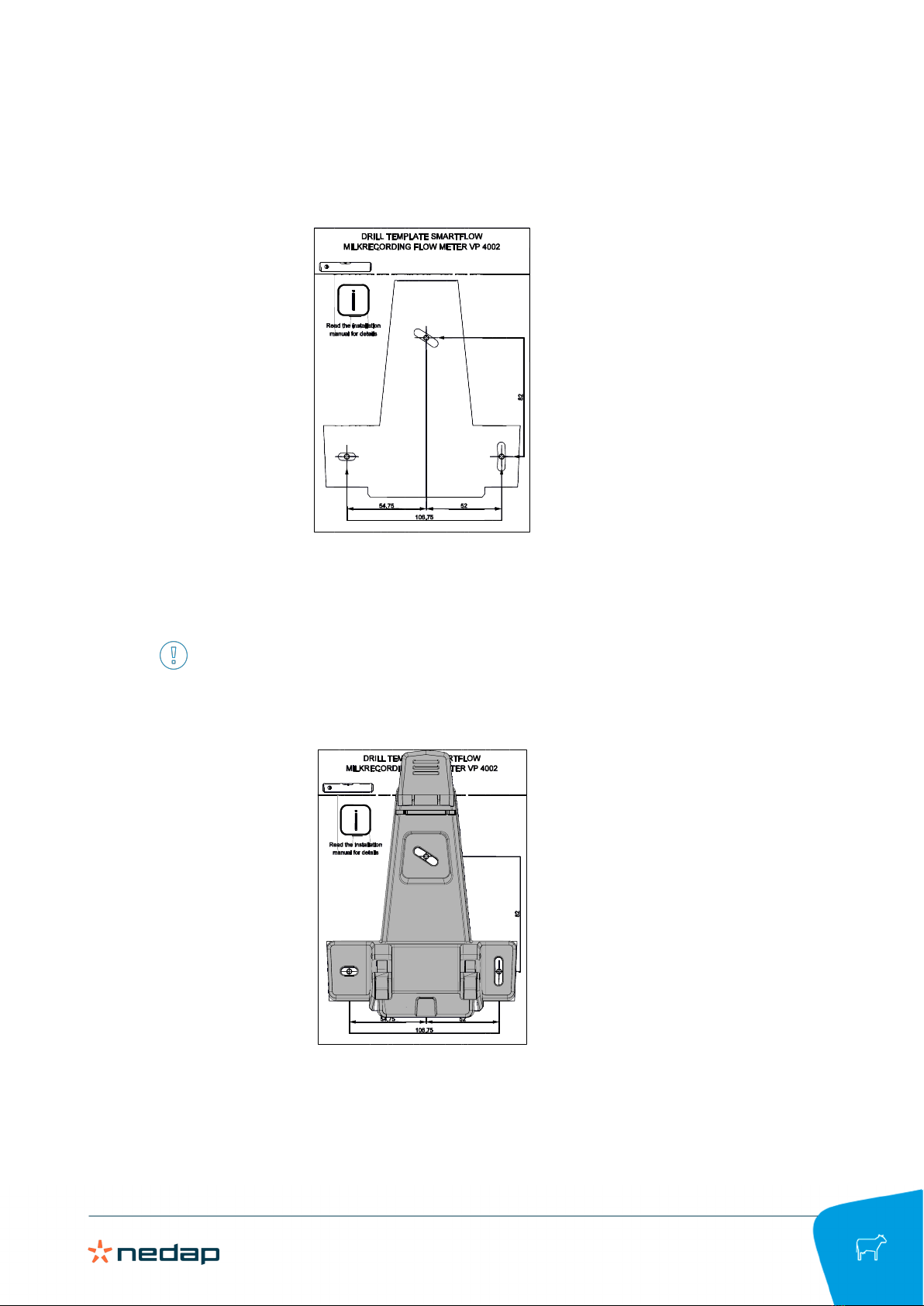

a. Use the drilling template that is delivered with the SmartFlow to mark 3 drilling holes on the wall or

panel.

b. Drill the holes.

c. Mount the bracket using 3 hex bold screws or hex head lag wood screws (M6, at least 20 mm length)

with washers.

Tighten the 2 lower screws hand-tight. These screws are used to level the SmartFlow.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

16

Dairy Farming

d. Use the two lower screws of the bracket to level the bracket in the sidewards direction (left or right).

e. Tighten the 2 lower screws to lock the bracket.

2. Place the SmartFlow in the bracket as follows:

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

17

Dairy Farming

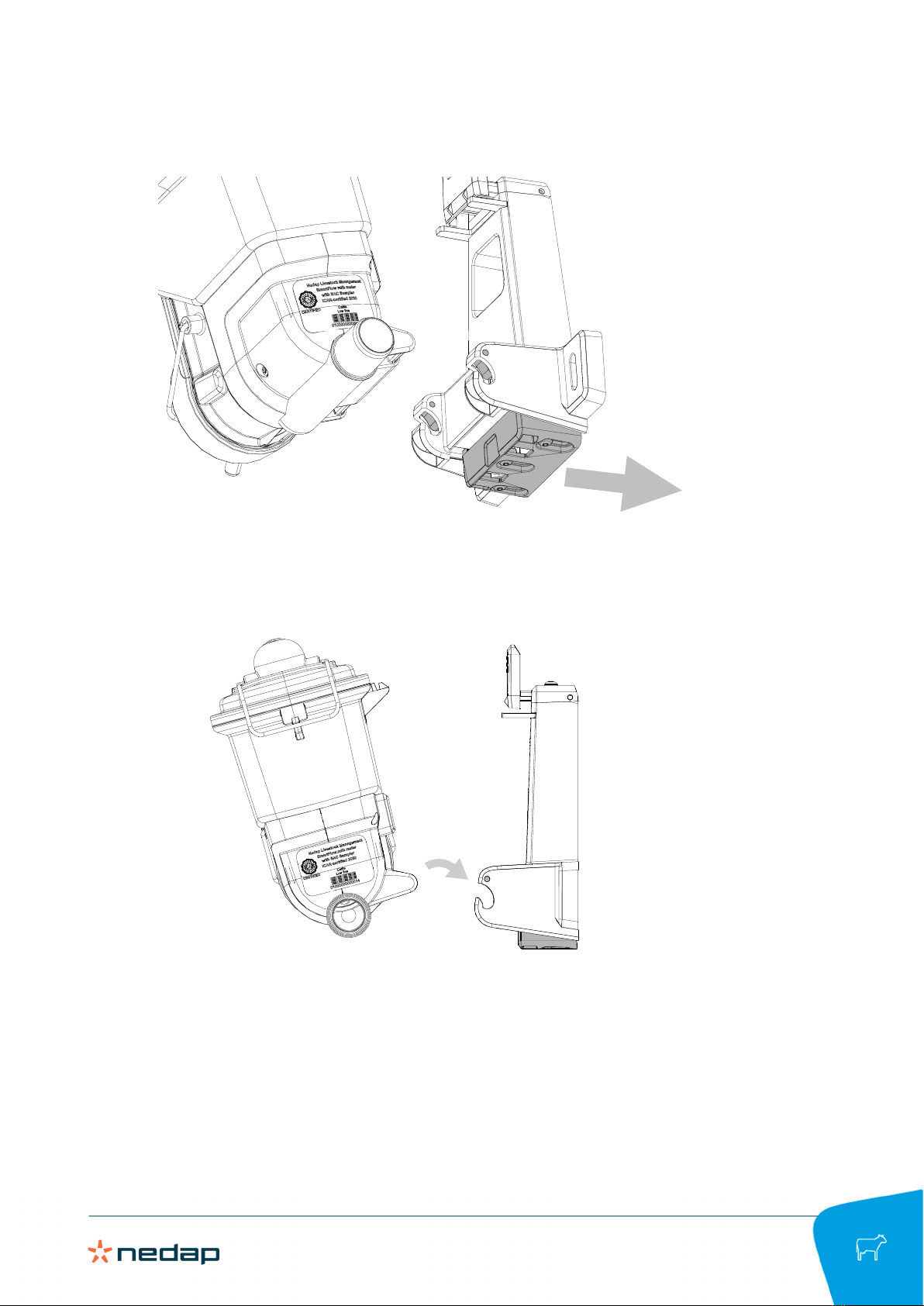

a. Press the push button at the bottom of he bracket backwards to open the hinges.

b. Slide the lower part of the SmartFlow in the hinges and release the push button.

Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

18

Dairy Farming

c. The hinges are closed and the lower part of the SmartFlow is now fixed in the bracket.

d. Press the lever at the top of the bracket and slide the ridge of the SmartFlow under the lever.

Other manuals for SmartFlow

2

Table of contents

Other Nedap Farm Equipment manuals

Popular Farm Equipment manuals by other brands

De Heus

De Heus BOXER AGRI PI 135 user manual

Alpego

Alpego DELTA Series Use and maintenance manual

Landoll

Landoll Brillion LSP5 Operator's manual

Fullwood

Fullwood Revolution II Stage 3 Installation instruction

Agria

Agria Bison 5900 Series Translation of the original operating instructions

H&S

H&S HDII RAKE Operator's manual and parts list