Operator’s manual

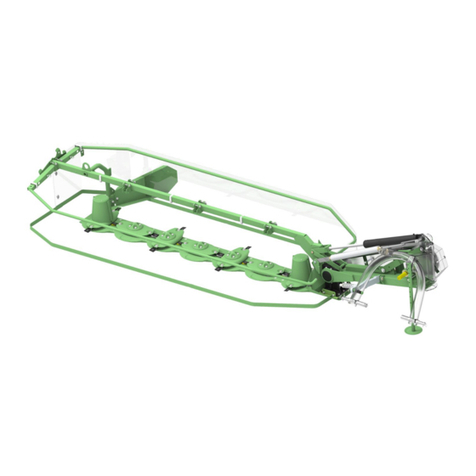

Double-sided disc mowers

with central suspension

- 1 -

Contents page

1.

IDENTIFYING THE MACHINE ....................................................................... 3

2.

INTRODUCTION................................................................................................. 3

3.

PROPER AND INTENDED USE........................................................................ 4

3.1.

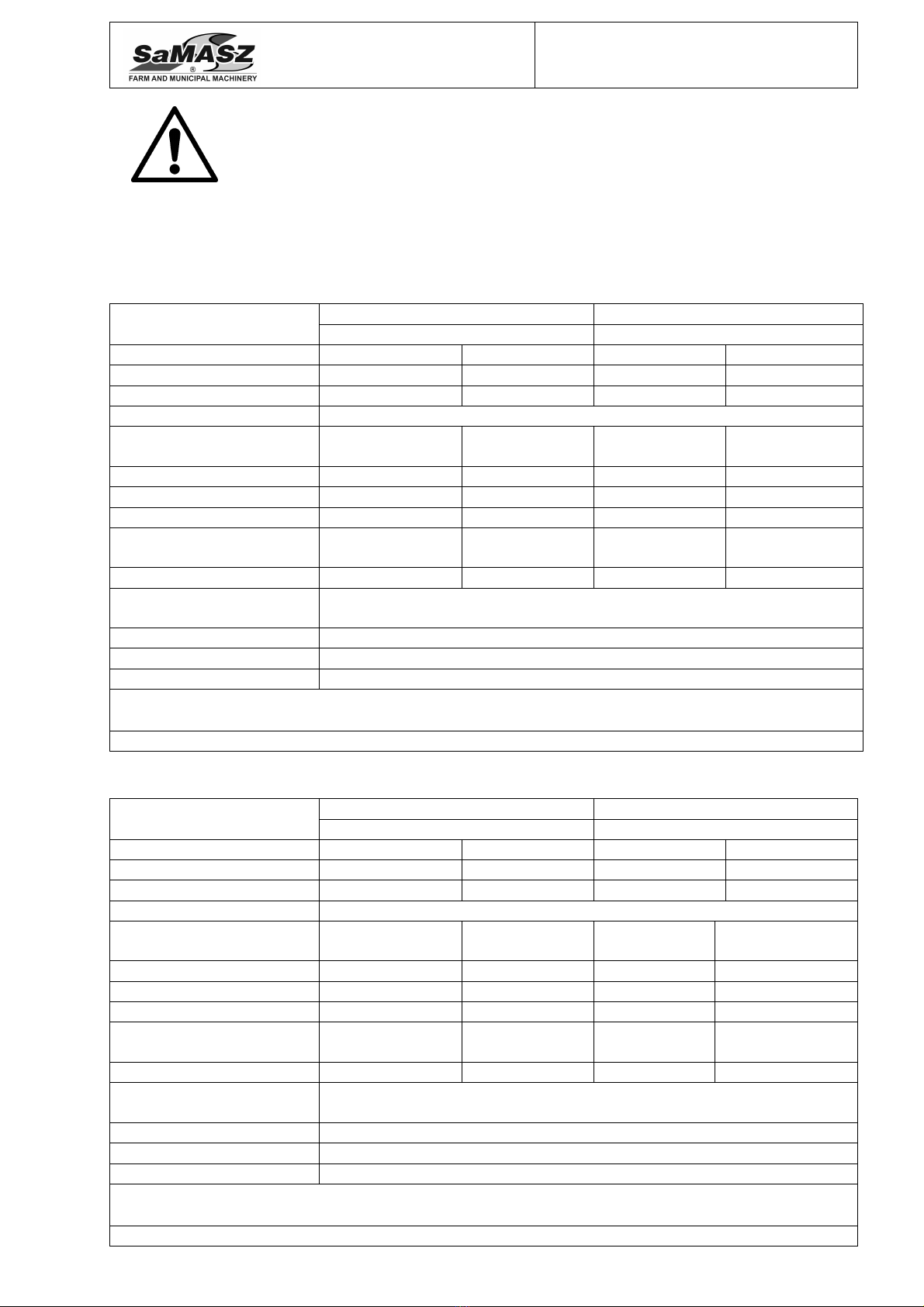

Technical data...........................................................................................................................5

3.2.

Design and working principle ..................................................................................................7

3.2.1.

Double-sided disc mowers without swath conditioner/rollers ..........................................7

3.2.2.

Double-sided disc mowers with tine conditioner..............................................................8

3.2.3.

Double-sided disc mowers with roller conditioner. ..........................................................9

3.2.4.

Belt conveyors...................................................................................................................9

3.3.

Standard equipment and spare parts.......................................................................................10

4.

SAFETY PRECAUTIONS................................................................................. 12

4.1.

General safety rules and regulations.......................................................................................12

4.2.

Conditions of mounting mower on tractor .............................................................................14

4.3.

Transport.................................................................................................................................14

4.3.1.

Putting the mower onto another vehicle for transport.....................................................14

4.4.

Working parts.........................................................................................................................16

4.5.

PTO shaft................................................................................................................................16

4.6.

Hydraulic assembly................................................................................................................16

4.7.

Safety curtains........................................................................................................................17

4.8.

Residual risk...........................................................................................................................17

4.8.1.

Danger of machine entanglement....................................................................................17

4.8.2.

Danger of cutting injury ..................................................................................................17

4.8.3.

Danger of injury from liquid ejection out of hydraulic system.......................................18

4.8.4.

Forbidden actions............................................................................................................18

4.8.5.

Residual risk assessment .................................................................................................18

4.9.

Safety labels and their meaning..............................................................................................18

4.10.

Design and operation of safety breakaway device...............................................................23

5.

OPERATION....................................................................................................... 24

5.1.

Attaching the mower to the tractor.........................................................................................24

5.1.1.

Connecting hydraulic hoses.............................................................................................25

5.1.2.

Mounting PTO shaft........................................................................................................26

5.2.

Control panel..........................................................................................................................27

5.2.1.

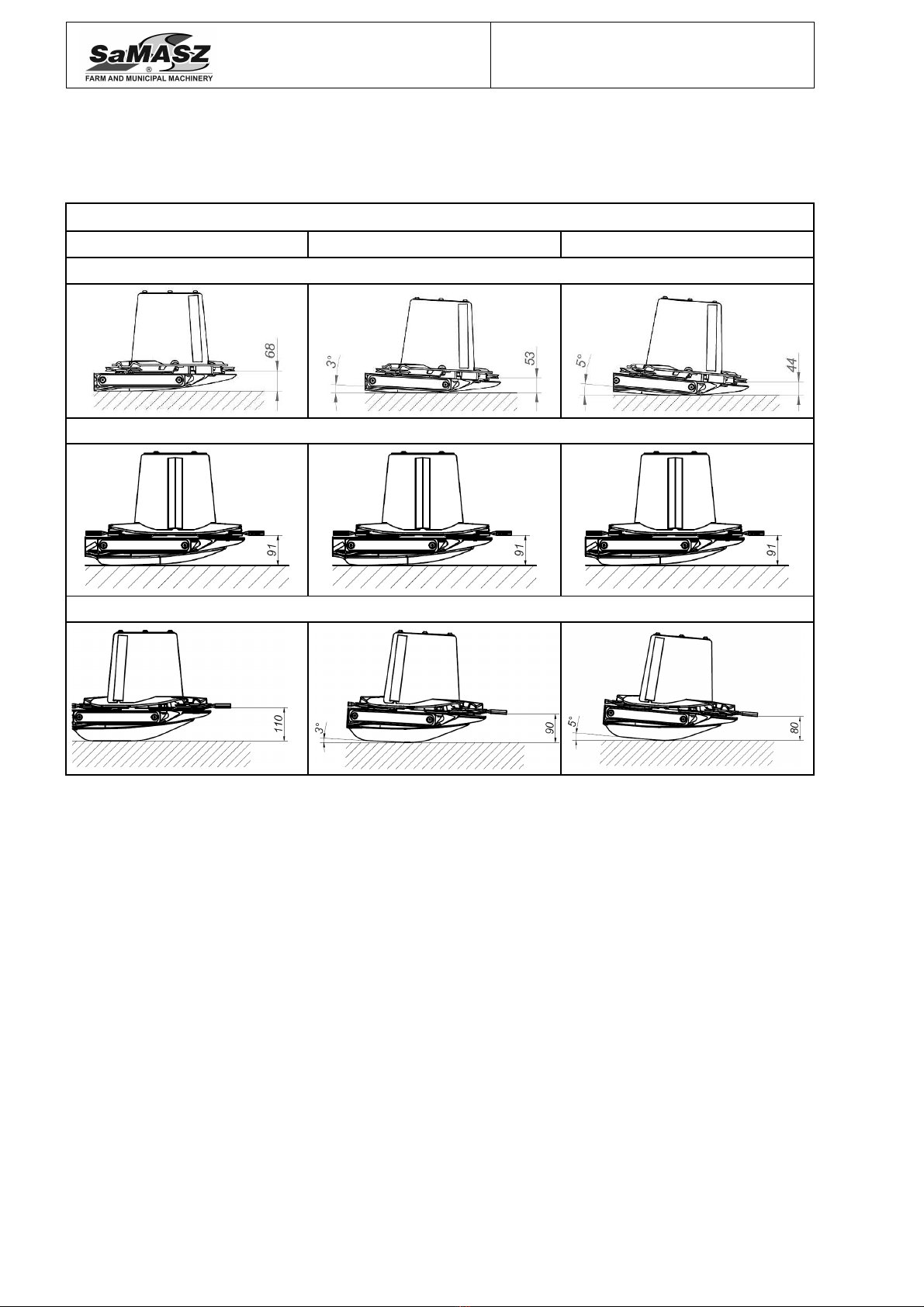

Setting mower in transport position on headlands ..........................................................28

5.2.2.

Setting mower in vertical transport position ...................................................................28

5.2.3.

Starting the conveyer’s belt.............................................................................................29

5.3.

Preparing the mower for transport..........................................................................................29

5.4.

Preparing the mower for transport on public roads................................................................30

5.5.

Moving from transport to operating position .........................................................................31

5.6.

Preparing mower for operation – mower with hydro-pneumatic support..............................31

5.7.

Preparing the mower for work................................................................................................32

5.7.1.

Regulation of cutterbar's pressure on the ground by means of support springs..............33

5.8.

Operation (mowing) ...............................................................................................................34

5.8.1.

Essential information concerning mowing......................................................................34

5.8.2.

Mower clogging ..............................................................................................................35

5.8.3.

Taking turns on headlands...............................................................................................35

5.9.

Storing ....................................................................................................................................36

6.

MOUNTING AND ADJUSTMENTS............................................................... 36

6.1.

Mounting and timing of the knives ........................................................................................36

6.2.

Replacing the knives...............................................................................................................37

6.3.

Adjusting the cutterbar ...........................................................................................................37