Azbil MY6050A1001 User manual

Other Azbil Controllers manuals

Azbil

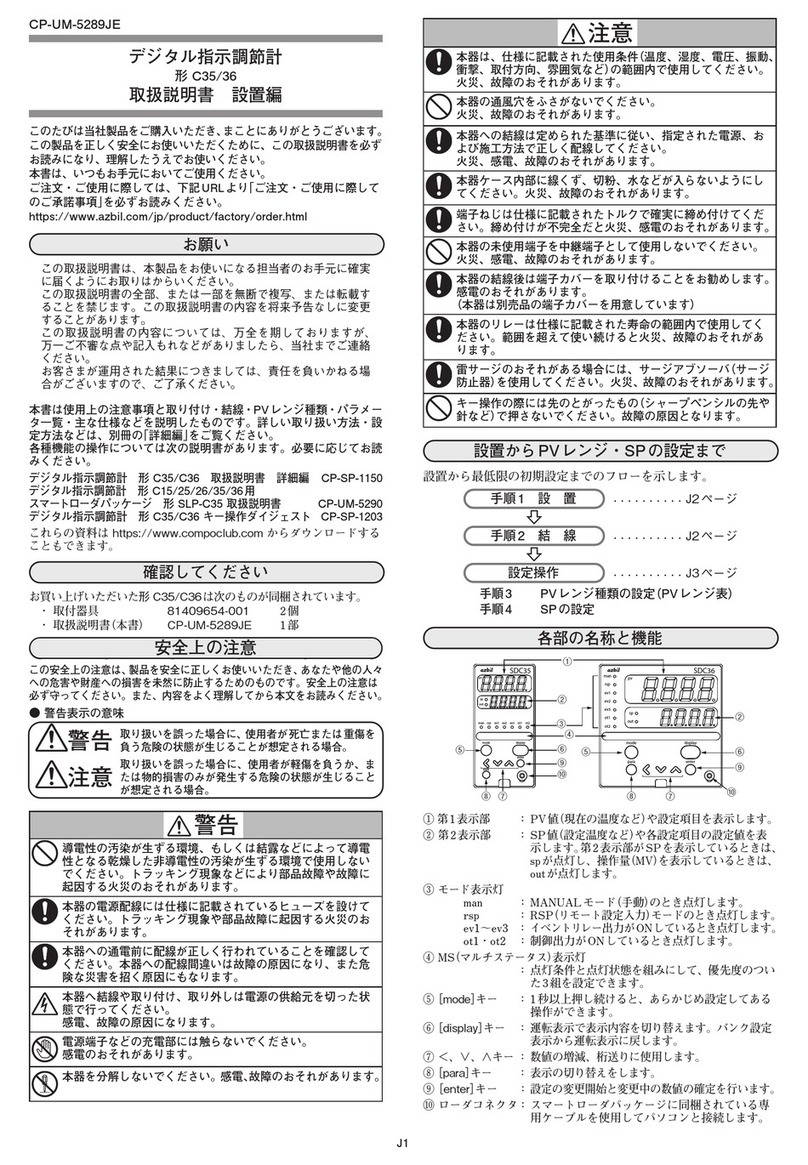

Azbil C35 User manual

Azbil

Azbil AUR890 Series User manual

Azbil

Azbil AUR890 Series User manual

Azbil

Azbil BH-101G0W0000 User manual

Azbil

Azbil SDC35 Instruction Manual

Azbil

Azbil DCP31 User manual

Azbil

Azbil FRS100 User manual

Azbil

Azbil Infilex BC WY5610 User manual

Azbil

Azbil Infilex ZM WY5322 User manual

Azbil

Azbil C26 User manual

Azbil

Azbil KZ03 Series User manual

Azbil

Azbil C1M User manual

Azbil

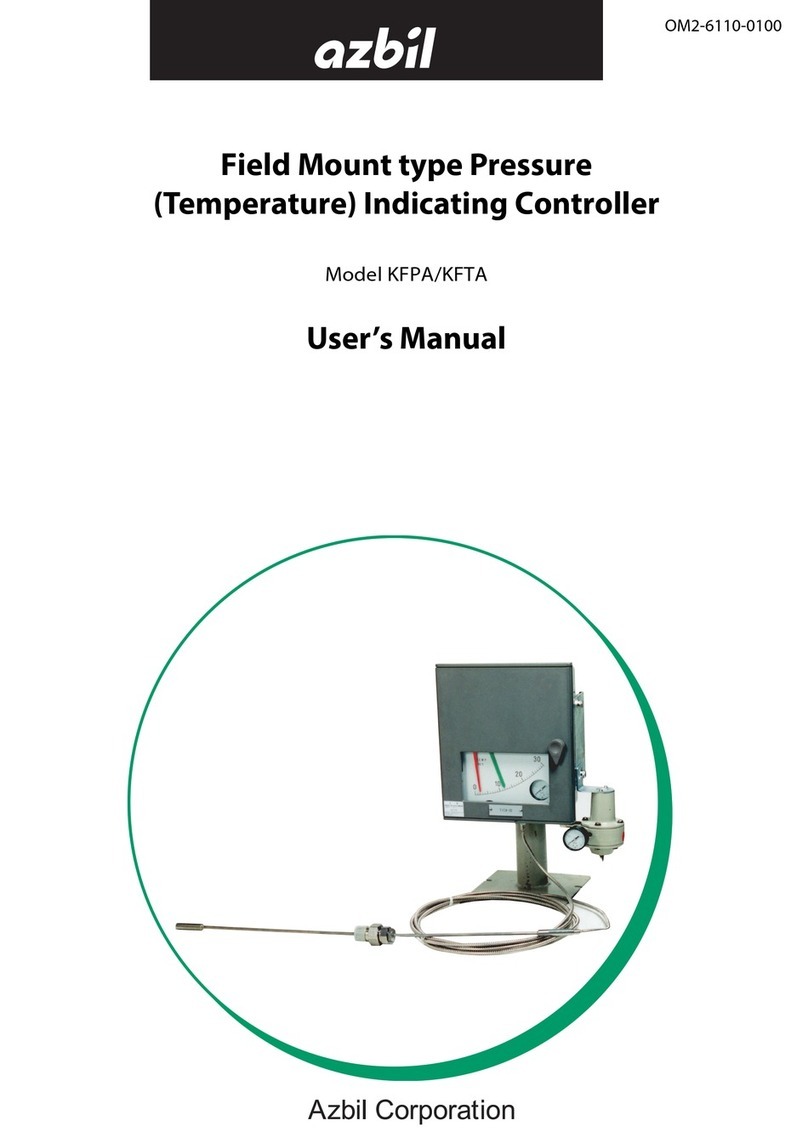

Azbil KFPA User manual

Azbil

Azbil Infilex ZM WY5122 User manual

Azbil

Azbil SDC26 Instruction Manual

Azbil

Azbil RA890G User manual

Azbil

Azbil C7G Manual

Azbil

Azbil Infilex FC Series User manual

Azbil

Azbil MPC0002 User manual

Azbil

Azbil AUR455 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions