6

Chapter 3 Notice for wiring

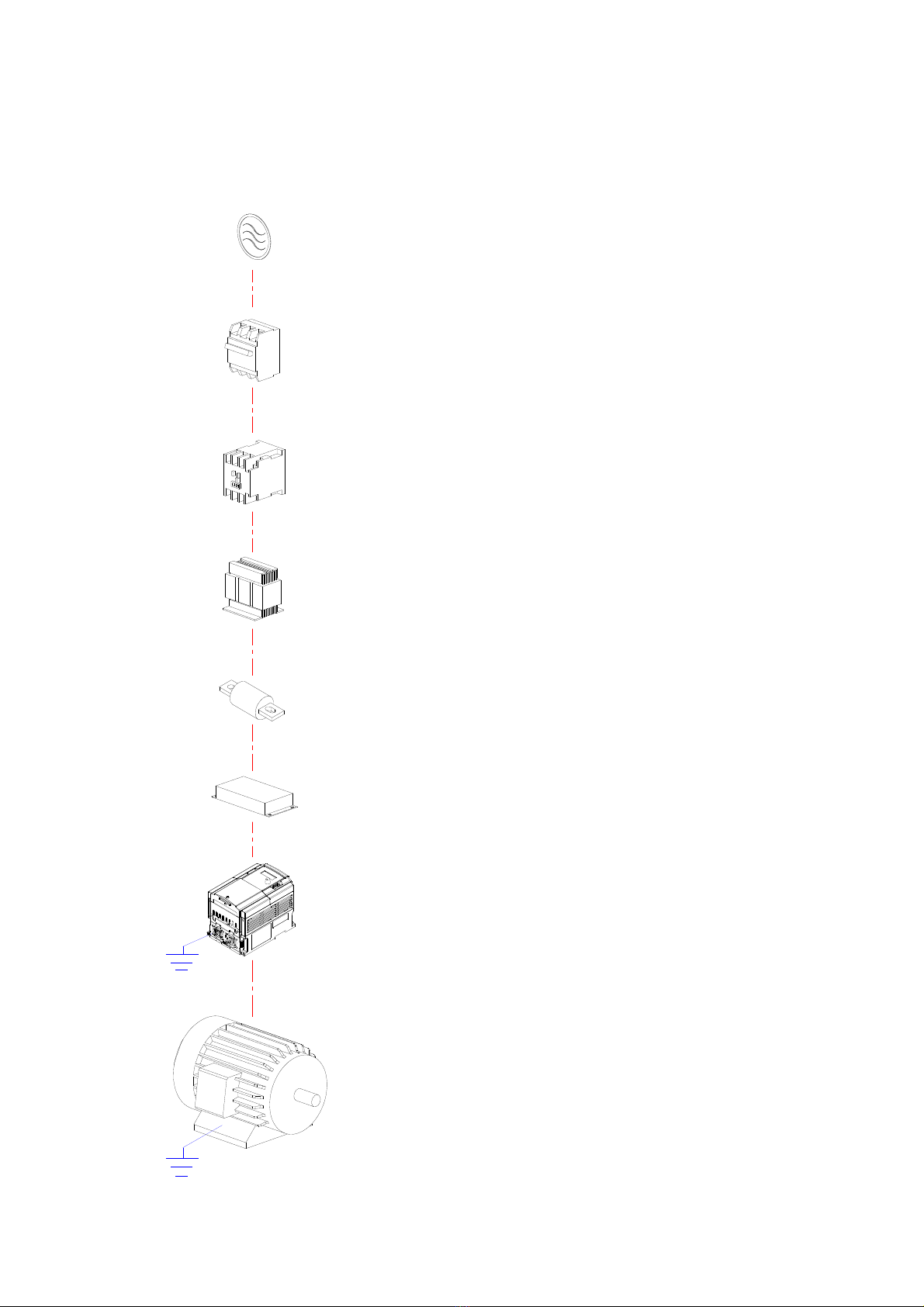

3.1 Precautions for Peripheral Applications

Power supply:

zMake sure the voltage applied is correct to

avoid damaging the inverter.

zA molded-case circuit breaker must be

installed between the AC source and the

inverter

Molded-case circuit breaker:

zUse a molded-case circuit breaker that

conforms to the rated voltage and current of

the inverter to control the power ON/OFF and

protect the inverter.

zDo not use the inverter as the switch for

run/stop switch.

Leakage breaker:

zInstall a leakage breaker to prevent error

operation caused by electric leakage and to

protect operators

zSetting current should be 200mA or above and

the operating time at 0.1 second or longer to

prevent malfunction.

Magnetic contactor:

zNormal operations do not need a magnetic

contactor. But a contactor has to be installed in

primary side when performing functions such

as external control and auto restart after power

failure, or when using brake controller.

zDo not use the magnetic contactor as the

run/stop switch of the inverter.

AC reactor for power improvement:

zWhen inverters below 200V/400V 15KW are

supplied with high capacity (above 600KVA)

power source or an AC reactor can be

connected to improve the power performance.

Install fast action fuse (If necessary):

zTo ensure the safety of peripheral devices,

please install the fast action fuse. Regarding

the specification, please refer to P7.

Input noise filter:

zA filter must be installed when there are

inductive load around the inverter

Inverter:

zInput power terminals L1, L2, and L3 can be

used in any sequence regardless of phases.

zOutput terminals T1, T2, and T3 are connected

to U, V, and W terminals of the motor. If the

motor is reversed while the inverter is forward,

just swap any two terminals of T1, T2, and T3.

zTo avoid damaging the inverter, do not connect

the input terminals T1, T2, and T3 to AC

power.

zConnect the ground terminal properly. 200 V

series: class 3 grounding, <100Ω; 400 V

series : <10Ω.

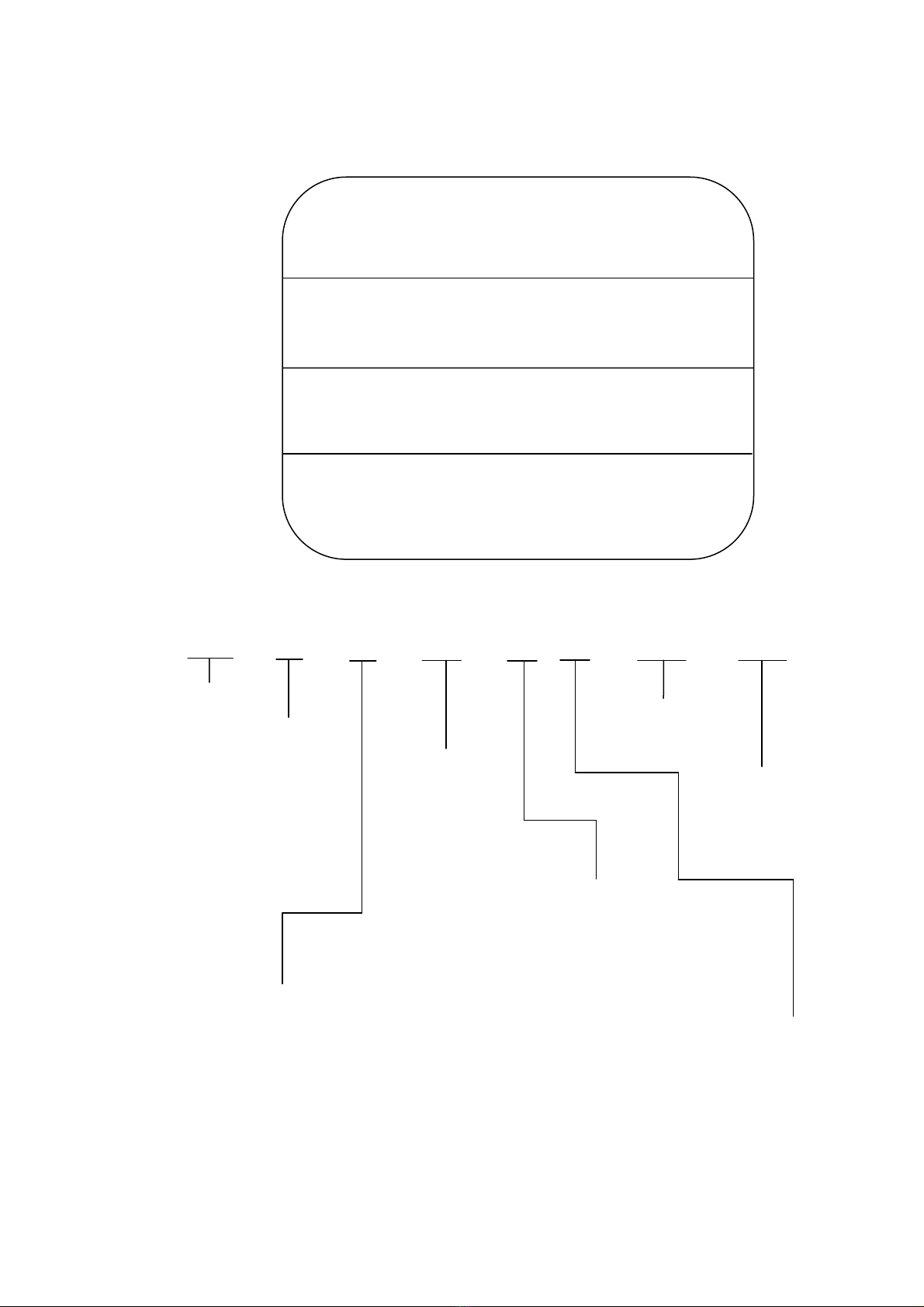

Power

Molded-case

circuit breaker

Magnetic

contactor

C reactor for

power

improvement

Install fast

action fuse

(If necessary)

Input noise

filter

CVP inverter

Ground

Three-phase

cage motor

Ground