Tecsis E3907 User manual

Force Pressure Temperature SwitchService

Operating manual

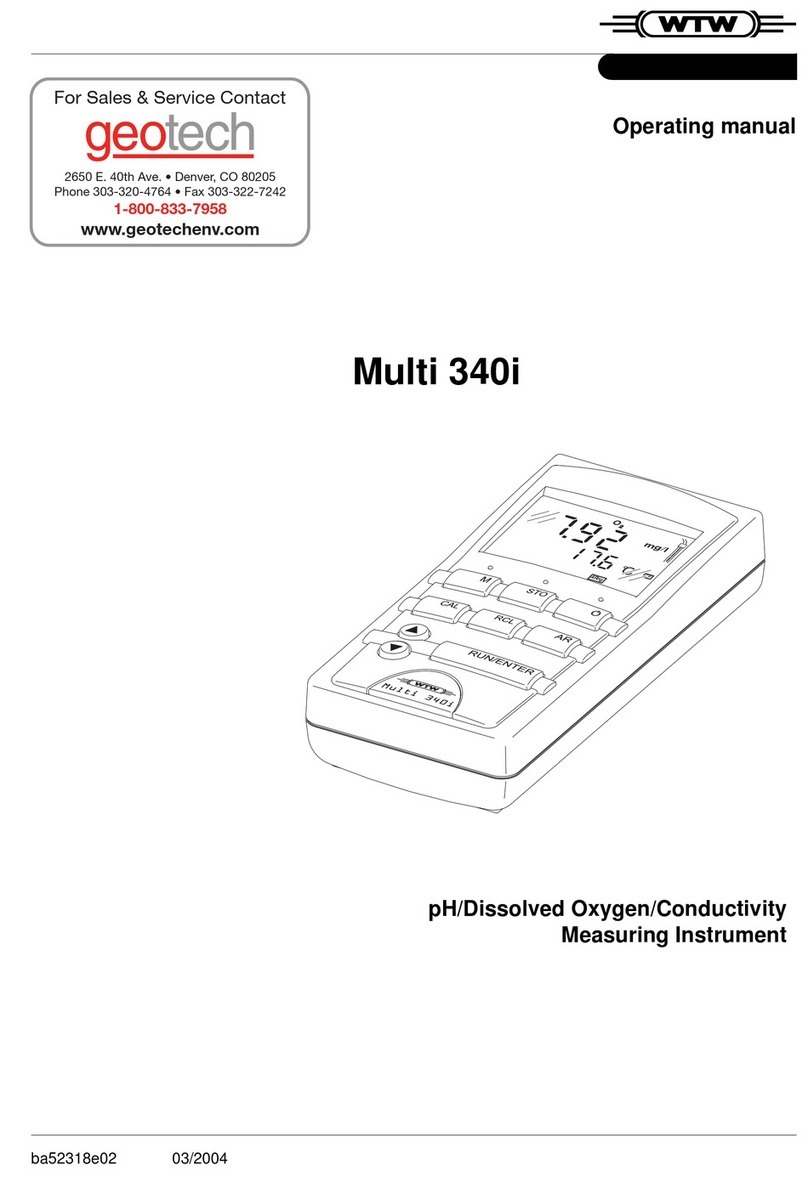

E3907

Universal handheld measuring device

with datalogger

BD 984 i 02/2013

Operating manual

E3907

Manufacturer, Location Tecsis GmbH, Germany-63073 Offenbach am Main

Valid for E3907 handheld measuring device with datalogger

Copyright © 2006 – 2015 tecsis GmbH, Offenbach, Germany

Reproduction prohibited Reproduction, in whole or in part, only with written permission

Change notice Subject to technical changes.

Operating manual

E3907

www.tecsis.de BE 984 i

1. Safety notes 1

1.1 General references ..........................................................................................1

1.2 Intended use.....................................................................................................2

1.3 General dangers............................................................................................... 2

1.4 Residual dangers.............................................................................................2

1.5 Notes identification..........................................................................................2

1.6 Health and safety rules.................................................................................... 2

1.7 Qualified personnel .........................................................................................3

1.8 Technical changes...........................................................................................3

2. References 3

3. Introduction 4

3.1 Brief description ..............................................................................................4

3.2 Power supply.................................................................................................... 4

3.3 Safe and proper use ........................................................................................5

3.4 Dimensions - Weight........................................................................................ 5

4. Instructions 6

4.1 Connection description...................................................................................6

4.2 Switching on the device..................................................................................8

4.3 Menu description .............................................................................................8

4.3.1 Brief handling overview E3907 8

4.3.2 Menu description 9

4.4 Operating example......................................................................................... 10

4.5 Measuring with the E3907............................................................................. 10

4.5.2 Parameters of a Sensor 11

4.5.3 Measuring with the E3907 11

4.6 Serial interface...............................................................................................11

4.6.1 Transfer rate / specification RS232 (V.24) / USB 11

4.6.2 Operation via the serial interface 11

4.6.3 Handling with serial interface / USB 14

4.6.4 Operation and function principle of the E3907-Data Logger 15

4.7 Calibration......................................................................................................16

4.7.1 Calibrate the active sensor with control (ACT wCON) 16

4.7.2 Calibrate the active sensor without control (ACT nCON) 16

4.7.3 Calibrate the passive sensor with control (ACT wCON) 16

4.7.4 Calibrate the passive sensor without control (ACT nCON) 16

4.7.5 Calibrate with current 4-20mA 17

4.8 Interface and Connectivity............................................................................17

4.8.1 Connection for strain gauge sensors: 17

4.8.2 Connection for active Sensors: 17

4.8.3 Visual evaluation: 17

4.8.4 Trigger input: 17

4.8.5 RS232 / USB: 17

5. Product phases 18

5.1 Transport........................................................................................................18

5.2 Commissioning and installation...................................................................18

5.3 Normal operation ...........................................................................................18

5.4 Maintenance and cleaning............................................................................ 19

5.5 Information for the safe disposal ................................................................. 19

Operating manual

E3907

BE 984 i www.tecsis.de

Operating manual

E3907

www.tecsis.de BE 984 i 1

1. Safety notes

1.1 General references

The enclosed operating instruction is intended for technically qualified personnel who has corresponding knowledge

in the field of measurement and industrial process & control technology.

The precise information about all safety notes contained in this operation manual and warnings, as well as its

technical implementation are precondition for the safe installation, the initiation, the secure operation and the

maintenance of tecsis devices. For this purpose it is absolutely necessary that all measures are carried out by

qualified personnel. All persons concerned with the project planning, installation and service of tecsis devices, must

be familiar to the security concepts in automatic control and should be qualified in this sense.

For clarity reasons, the enclosed operating instruction cannot represent complete details in all conceivable cases of

applications for the handling of tecsis devices. Further, we cannot consider the entire types of installation, handling

and maintenance. If you wish further information or if special problems occur, which were not ,or not at length

represented in this operating instruction, contact us, please..

The oblivion of the safety notes can and will lead to material damages, body injuries and death.

Tecsis devices may only be operated in accordance with the applications described in this operation

manual. Built-in devices may only be operated in appropriate installations.

With the connection and the initiation of the device, the customer accepts the general sale and delivery conditions

of tecsis GmbH. Further, he accepts eventually incomplete operation manuals. The information described is

without guarantee. Errors and changes are reserved.

Intended Purpose, Improper Usage

A tecsis device is used for displaying, processing and controlling or regulation of processes. It shall not be used as

the only tool for the prevention of dangerous states to machines and plants. Machines and plants must be

constructed in such a way, that erroneous states cannot lead to a dangerous situation for the staff (e.g. by

independent limit switches, mechanical locking devices). It must be guaranteed in particular that device-operating

errors, its malfunction or it’s breakdown do not lead to great property damages or danger for the staff.

Consequently, the device then can be used to prevent the machine or the technical installations from error

conditions.

It is also important that the use of devices does not endanger precautions for the safety of technical installations.

Emergency-off settings must remain effective in all operation modes.

Installation Notes

tecsis devices must be installed and connected by compliance with the relevant DIN- and VDE-norms. They must

be installed in such manner that an unintentional use is sufficiently excluded. The corresponding hardware and

software safety precautions are to be observed in such manner that an interruption of the supply and signal cables

cannot lead to an undefined or dangerous state. Supply and signal cables must be installed in such way, that

disturbing signals (e.g. inductive or capacitive intersperses) will not cause derogations to the function of tecsis

devices.

Disturbance, Maintenance and Repair Notes

The devices do not contain parts which can be maintained on the customer side. Repairs shall be carried out by

tecsis exclusively.

If assuming that a safe operation of the device is not possible anymore, it must be closed down and protected

against unintentional handling immediately. This, in particular, applies:

- If the device shows visible damages

- If the device is no longer operative

Operating manual

E3907

2 BE 984 i www.tecsis.de

- If parts of the device are loose or slack

- If the connection cables show visible damages

Furthermore, we point out that all obligations of tecsis exclusively result from the respective sales contract in which

the guarantee has been conclusively settled.

1.2 Intended use

Tecsis devices shall be used exclusively for measurement tasks and directly related control tasks. Any other usage

is considered as not intended.

1.3 General dangers

The equipment is state of the current safety requirements. Residual risks arising from the machine when it is

operated by untrained personnel and operated inappropriately. Any person who is in charge of installation,

operation, maintenance and repairs of the device has to read the manual and especially the safety instructions must

been read and understood.

1.4 Residual dangers

Safety engineering considerations of measurement technology have to be planned by the system designer /

equipment providers / operators to realize and take responsibility for that residual risks and to keep them as low as

possible. The relevant regulations and laws must be observed. Residual risks or dangers associated with the

measurement device should be noted.

1.5 Notes identification

Should there be any residual dangers in working with the device, this manual will refer to it with following signs:

Warning:

Possible risk of serious or life-threatening injuries. The accident prevention regulations have to be

recognized.

Attention:

Indicates a potential risk for damage to the product, process, person or environment.

Notation:

Additional information.

Important:

Reference to more detailed technical information.

1.6 Health and safety rules

To make sure our products cause no eventual risks or health threads, please mind the following health and safety

rules:

1. Please read all relevant sections of these instructions carefully before beginning work.

2. All warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and repair work may only be performed by trained personnel in accordance

with the instructions given. If one of these instructions is not met, the users of the product are solely responsible for

all consequences

Operating manual

E3907

www.tecsis.de BE 984 i 3

4. Before opening the equipment, it must be disconnected from any supply.

1.7 Qualified personnel

Qualified personnel are persons who are familiar with the installation, operation, maintenance and upkeep of the

equipment and have the necessary qualifications. The device may only be used by qualified personnel according to

the technical data in connection with the special safety rules and regulations.

1.8 Technical changes

The product may not be changed constructive without our. Any modification shall exclude our liability for any

resulting damages. Repairs and modifications to the circuit boards are prohibited.

2. References

The following documents contain reference information about the E3907 handheld measuring device:

-AE 984.pdf, Datasheet of the E3907

Operating manual

E3907

4 BE 984 i www.tecsis.de

3. Introduction

This manual describes the features and installation procedures for the E3907 with firmware version 3.

3.1 Brief description

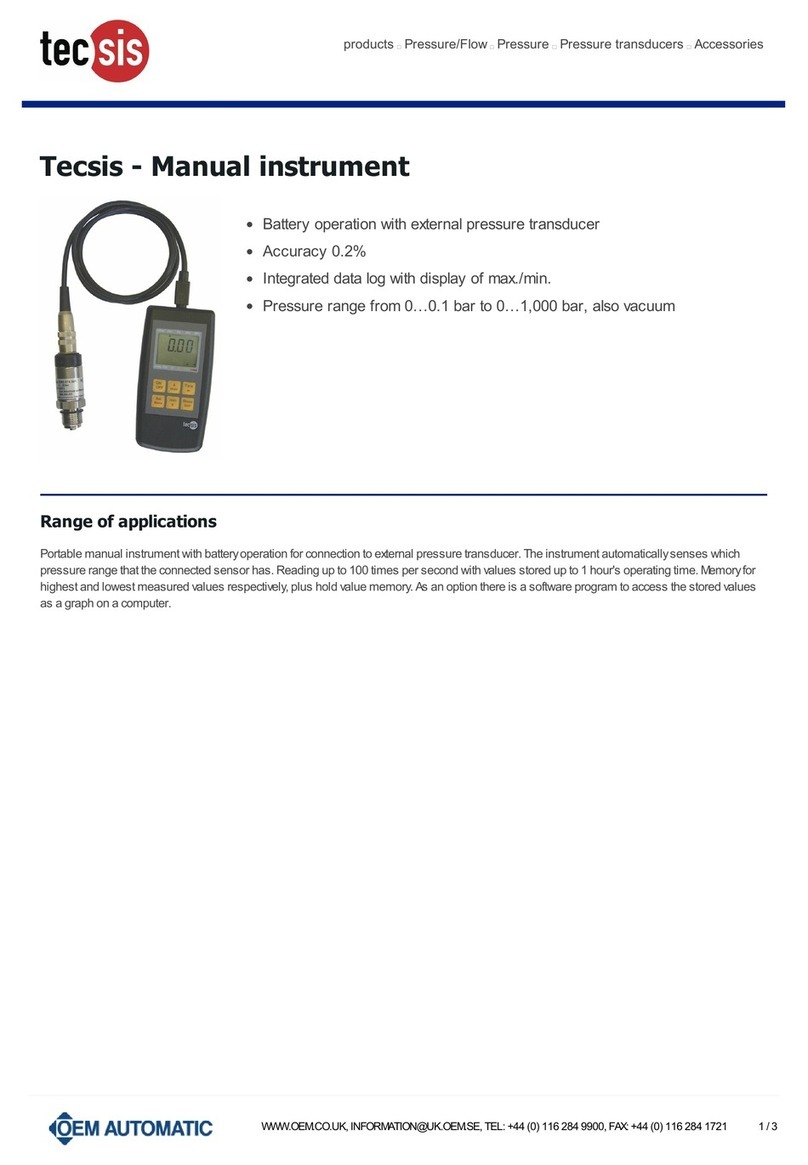

The E3907 is a DC measuring amplifier for passive or active sensors. A flexible data logger can store up to 3000

measured values with time and date. Mobile operation is possible by battery or accu operation, however, it can also

be operated with a power unit. Measuring or logging values are transmitted via an RS-232 interface to a pc or

printer. 10 parameter sets for sensors are available. There, in each case, the calibration data , the sensor

designation and the physical unit are being stored. Functions such as tare, min./max.-recall and min./max.-delete

are available during the measurement procedure. Via a trigger input the data logger or the interface can be

controlled externally.

If the E3907is being delivered with one or more sensors, these sensors will be in-calibrated to the E3907 and are

immediately ready for operation. An assignment of sensors to the corresponding parameter set is documented on

the rear of the device

3.2 Power supply

Mains operation:

Power supply: 6V DC, min. 1,8A

Fuse: Self-reset-able fuse 1,5A

Under-Overcut: Can cause measurement errors or defects.

Stress peaks: Be derived using protection components.

Voltage dropouts: Voltage dropouts up to 10ms are without consequences.

Warning:

Remove batteries when using external power supply!

The E3907 must only be used with ground reference voltage supplies, switching power supplies without earth

reference can cause measurement errors.

Battery Operation:

Battery operation: 4 x Typ: Mignon AA 1,5V

Accu operation: 4 x Typ: NiMH Mignon AA mit min. 1500mAh und 1,2V

The battery charging time for a battery capacity of 2.7 Ah approximately 9-10 hours. The constant charging current

for charging the battery is approximately 290mA. The end of charging process will be recognized with a minus delta

peak method (overcharge protection). For rapid charging of the batteries is an external battery charger (eg

Ansmann 4 - 6) recommended. The batteries can be charged at off, and while the E3907 is running.

Power supply: If the permissible battery voltage falls below the indicator starts blinking

Operating manual

E3907

www.tecsis.de BE 984 i 5

3.3 Safe and proper use

Attention:

- Protect the device from moisture, condensation, rain, snow...

- Protect the device from direct sunlight

- Protect the device from dust and dirt

- Protect the device from high or excessive ambient temperature

- Protect the device from excessive vibration.

3.4 Dimensions - Weight

Dimensions in mm: LxWxH: 200x100x40 Weight: 0,5kg

Operating manual

E3907

6 BE 984 i www.tecsis.de

4. Instructions

4.1 Connection description

Key assignment:

ENTER: Switch on the device

Confirm, one step forward in the menu

ESC: Switch off the device

Exit, one step back in the menu

:Scroll up

:Scroll down

USB: USB-Socket for: USB-Connector Type B

RS232: RS232-Socket for: 3,5mm jack 3pol.; front: GND; middle: RxD; outside: TxD

6V DC: Supply socket: 2,1mm supply connector; inside: +6V DC; outside: GND

Trig: Trigger jack for: 2,5mm Klinke 2pol.; Vorne: Trigger+; Außen: GND

SENSOR: Sensor socket for: SUB-D HD 15pol.

Operating manual

E3907

8 BE 984 i www.tecsis.de

4.2 Switching on the device

Press the ENTER button to switch on the device.

4.3 Menu description

4.3.1 Brief handling overview E3907

Operating manual

E3907

www.tecsis.de BE 984 i 9

4.3.2 Menu description

1 MEASURE Measuring mode

SENSOR__ Sensor selection for measuring mode, sensor 0-9

Here the sensor parameter set for the measurement is being selected.

The sensor parameter set must match the connected sensor.

2 SYSTEM All system parameters are being stored in this menu column.

2.1 LANG Language adjustment

The menu language can be chosen in German, English, French or Spanish

2.2 INFO Information query was configured factory-sided an is not variable

VERS NO. Software version

2.3 SCI Interface configuration

BAUD Baud rate adjustment must be conform with the receiver (pc or printer).

SCI MODE Interface configuration only refers to the measuring mode, not the logg mode!

OFF Interface off

HAND At key stroke ENTER the measured value is issued.

AUTO¹ Interval time, adjustable from 10ms to 1h (at high measuring rate only possible with highest baud

rate)

TRIGGER At impulse on trigger input the measured value is issued.

INTERFAC Auswahl der zu verwendenden Schnittstelle

USB USB interface is activated

RS232 RS232 interface is activated

2.4 RATE Measuring rate and average value

RATE Measuring rate adjustment can be chosen between 1/s and 1000/s. At fast courses (screw joint,

insert press...) always choose a fast measuring rate, e.g. 1000/s, at very slow courses a small rate,

e.g. 1/s.

AVERAGE Forming an average value, the numbers indicate by how many measurements an average value is

accumulated. Applicable at e.g. vibrations, control oscillations....

2.5 PASS Password query

After entering the password 9373 it is possible to enter menu 3 CALIB . There the sensor

parameters can be modified.

2.6 LCD LCD-contrast adjustment

If the LCD becomes unreadable by external influences e.g. solar radiation, heat or cold, the LCD-

contrast can be corrected here by using the or key

2.7 LOGG Data logger adjustments

LOGGMODE Data logger configuration.

OFF Off-switch for logger operation, by this the measuring mode is possible only.

HAND At each key stroke on ENTER a logg value is being taken over.

AUTO Adjustment of the measuring intervals.

DIAGRAM With each increasing flank of the trigger signal a logg value is being taken over.

WINDOW The window operation is being started by an increasing trigger flank and can only be finished by a

decreasing flank.

LOGGSEND Logger values are issued through the interface, press ENTER twice.

LOGGDEL Logger values are deleted, beforehand there will be a safety query whether the buffer should be

deleted.

2.8 DATE Date and time adjustment

DATE Date

TIME Time

3 CALIB Calibration menu

this is active only, if the password has been entered correctly

in 2.5PASS. For the calibration the sensor needs to be connected to the sensor socket.

¹If the SCI → AUTO interval is shorter than the set measuring rate, then the interface displays the same output until

a new value is recorded.

Sensor__ Sensor number or name of the sensor which is to be calibrated.

POINTDIS Measuring range with decimal indication of the sensor, e.g. 100,0; 200,0; 63,00;...

Operating manual

E3907

10 BE 984 i www.tecsis.de

Call menu "POINTDIS", after pressing ENTER the final value of the sensor can be entered, by

PLUS or MINUS the numeric character can be edited, by ENTER the next figure can be edited, if all

figures are edited, by PLUS and/or MINUS the comma will be shifted. For the completion of the

input press ENTER, thereafter the final value is being logged in the E3907

UNIT Input of the physical unit, e.g. Kg, Ncm, t, gr, kN, N•m, bar...

DESIG Name of the sensor e.g. sensor 1,2,3, silo, tank, mixer, balance1, motor, test1..

CALIB Selection of the sensor type (active, passive, 4-20mA, with or without calib. control..)

4.4 Operating example

- The E3907 is switched on by pressing ENTER

- Control time and date in SYSTEM menu or adjust if necessary

- Adjust language

Call menu 2 SYSTEM – 2.1 LANG. When ENTER button was pressed, the 3907 is in the selection mode. With keys

PLUS and/or MINUS the language can be selected. With ENTER the selected language will be stored. With ESC

the selected language will be discarded.

- Adjust time

Call menu 2 SYSTEM – 2.8 DATE. When ENTER button was pressed TIME will appear on the LCD. Press ENTER

again and the time can be adjusted. With PLUS and MINUS the hours can be adjusted. After ENTER the minutes

can be adjusted with PLUS and MINUS. With ENTER the selected time will be stored. With ESC the selected time

will be discarded

- Change to the measuring mode

From menu 1 MEASUR by pressing ENTER the list of all sensors is called. With PLUS and/or. MINUS a sensor

parameter set is being chosen. With ENTER the GM 80 is being adjusted to this sensor parameter set. With ESC it

is possible to switch back to menu 1 MEASUR from any mode.

- Change measuring rate by measuring mode

The measuring mode can be left by pressing ESC. After pressing ESC again, the GM 80 will be in menu 1

MEASUR. From there the menu 2 SYSTEM – 2.4 Rate can be called. Select RATE by key PLUS and/or INUS. By

pressing key ENTER the set measuring rate is being displayed first. By key PLUS and/or MINUS a new measuring

rate can be adjusted. By ENTER the new measuring rate will be taken over, by ESC the new measuring rate will be

discarded..

- Switch off E3907

E3907 is switched off, when ESC button is pressed >3 seconds.

4.5 Measuring with the E3907

4.5.1 Selected sensor

Force sensor with measuring range: 200KN

Sensitivity 2mV/V

Designation e.g.: Press

Parameter set: Sensor no.: 3

Option: 100% Calibration control

Operating manual

E3907

www.tecsis.de BE 984 i 11

4.5.2 Parameters of a Sensor

After entering the password (9373) in menu 2SYSTEM-2.5PASS, the sensor can be installed in the calibration

menu. Following parameters are possible:

Sensor__ Sensor no. 3 , Sensor 0 – 9 possible

POINTDIS 200,0 Match meas. range and decimal point (max. 9999)

UNIT _kN, 1 – 3 digit unit possible

DESIGN Press, up to 8 digit name (or numbers) arbitrary

CALIB PAS_wCON , Select Passive with cal. control. See data sheet of sensor

0% LOAD Unload sensor, 0% value of sensor is assigned to display

100% CON Autom. Calibration, 100% value of sensor is assigned to display for example 200,0 kN

SAVE ENTER or ESC , Confirm or discard

4.5.3 Measuring with the E3907

In order to be able to now measure with this sensor, the sensor " Press" is selected in the measuring mode. During

a measurement, a minimum and maximum value buffer can be called with the MINUS key. The respective

displayed minimum or maximum value can be deleted by ENTER.

If the measured value shall be sent through an interface to a pc or printer, the baud rate must be adjusted to the

receiver and at SCI-MODE the operating mode must be chosen. For example: HAND, a measured value with time

is displayed during every keystroke on ENTER while measuring.

For data logging, adjust operating mode in the logger mode, e.g. choose AUTO and interval time e.g. 10 sec and

change to measuring mode. A measured value with time is now stored every 10 sec. In mode LOGGSEND, these

data can then be sent through the interface.

Notation:

When running the device via USB port, the baud rate must be set correctly. This must match the

baud rate of the virtual com port on the receiving PC.

4.6 Serial interface

The E3907 handheld instrument uses for the serial data transfer either a RS232 or a USB interface.

The USB interface is managed on the PC as a virtual COM port. For the use of the USB port, the

PC must have a Windows operating system (2k, XP, Vista, 7) and it must be installed the USB

drivers from tecsis. After installing the drivers, the virtual COM port below can be used as described

below.

4.6.1 Transfer rate / specification RS232 (V.24) / USB

Parity: none

Number of data: 8 (1Byte) 8N1

Stoppbit: 1

Baudrate adjustable (2400; 4800; 9600; 19200; 38400; 115200 Baud)

Even in USB mode, the baud rate in the E3907 handheld device and the connected device must

match.

4.6.2 Operation via the serial interface

Through the serial interface, measurement values can be issued singly or automatically by the E 3907.

The commands can be sent to the E 3907 via a terminal program or PLC.

If the E3907 is in the measuring mode, following commands are available:

Operating manual

E3907

12 BE 984 i www.tecsis.de

4.6.2.1 Command overview

ASCII

HEX

Description

0

0x30

Query continuous measured value (signed integer)

1

0x31

Query maximal value (signed integer)

2

0x32

Query minimal value (signed integer)

3

0x33

Tare display

4

0x34

Reset maximal value

5

0x35

Reset minimal value

6

0x36

Actuate calibration control for sensors with 100 % control resistance

7

0x37

Switch off calibration control for sensors with 100 % control resistance

A

0x41

Read-Out datalogger

B

0x42

Delete datalogger

C

0x43

Read-Out current sensor parameter

D

0x44

Read-Out status

E

0x45

Read-Out complete status

g

0x67

Change protocol setup

k

0x6B

ENTER

l

0x6C

PLUS

m

0x6D

MINUS

n

0x6E

ESC

Outside of the measuring mode following commands are available:

ASCII

HEX

Description

A

0x41

Read-Out datalogger

C

0x43

Read-Out current sensor parameter

D

0x44

Read-Out status

E

0x45

Read-Out complete status

a

0x61

Write time

b

0x62

Read-Out time

c

0x63

Write company header

d

0x64

Read-Out company header

e

0x65

Write all sensor parameters

f

0x66

Read-Out all sensor parameters

g

0x67

Change protocol setup

k

0x6B

ENTER

l

0x6C

PLUS

m

0x6D

MINUS

n

0x6E

ESC

Operating manual

E3907

www.tecsis.de BE 984 i 13

4.6.2.2 Read-Out of current sensor parameters:

Sensor designation

8Byte

ASCII

Display final value

2Byte

packed BCD-figure

Unit

3Byte

ASCII

Sensor type and digit

1Byte

0xAB: A ... Sensor type, B ... digit of the dec. point (binary coded)

Sensor type:

0xXXXX XXXX

||||

0000 ... active with calibration control 0%load and 100% load calibration

0001 ... active without calibration control 0%load and 100% load calibration

0010 ... active without calibration control 0%load calibration and edit 100%load V

0011 ... active without calibration control edit 0%load V and 100%load V

0100 ... passive with calibration control 0%load and 100% load calibration

0101 ... passive without calibration control 0%load and 100% load calibration

0110 ... passive without calibration control 0%load calibration and edit 100% load in mV/V

0111 ... passive without calibration control edit 0%load and 100% load in mV/V

1000 ... current 0%load and 100% load calibration

1001 ... current 0%load calibration and edit 100%load in mA

1010 ... current edit 0%load mA and 100%load mA

Dec. point:

0xXXXX XXXX

||||

|000 ... _5000___

|001 ... _5,000__

|010 ... _50,00__

|011 ... _500,0__

|100 ... 5,000___

0%load

2Byte

HEX-value (MSB/LSB)

100% load

2Byte

HEX- value (MSB/LSB)

4.6.2.3 Read out status:

Status 2Byte, general error condition of the E3907

4.6.2.4 Read-Out complete status:

Status

2Byte

general error condition of the GM 80

Measuring rate

1Byte

0x01 … 1000/sec

0x02 … 100/sec

0x03 ... 10/sec

0x04 ... 1/sec

Average value

1Byte

0x01 ... x/1

0x02 ... x/2

0x04 ... x/4

0x08 ... x/8

0x10 ... x/16

0x20 ... x/32

SCI_MODE

1Byte

0x00 ... interface off

0x04 … hand mode

0x08 … automatic mode

0x0C … trigger mode

SCI_MODE_DELAY

1Byte

0x02 …10ms

0x03 … 100ms

0x04 … 1s

0x05 … 10s

0x06 ... 1min

0x07 ... 10min

0x08 ... 1h

LOGGMODE

1Byte

0x00 ... logger off

0x04 ... hand mode

0x08 ... automatic mode

0x0C ... graph mode

0x10 ... screen mode

LOGGMODE_DELAY

1Byte

0x01 … 1ms

0x02 …10ms

0x03 … 100ms

0x04 … 1s

0x05 … 10s

0x06 ... 1min

0x07 ... 10min

0x08 ... 1h

Language

1Byte

0x00 ... GERMAN

0x02 ... ENGLISH

0x04 ... FRENCH

0x06 ... SPANISH

Protocol status

1Byte

0xXXXX XXXX (binary coded)

|||| ||||

|||| |||1 ... do not send conclusion character

|||| ||1 ... send CR/LF

|||| |1 ... send CR

|||| 1 ... send LF

4.6.2.5 Read time

The writing is identically with the data block for receipt of time, however, the data block for writing is protected with a

checksum and the corresponding weighted checksum

Operating manual

E3907

14 BE 984 i www.tecsis.de

4.6.2.6 Read time

DAY.MONTH.YEAR

2xspace

HOURS:MINUTES:SECONDS

4.6.2.7 Write company header

The input is ended either if 256 characters are received or if the character ETX (0x03) Strg-C is contained in the

character string.

4.6.2.8 Read Company Header

With this command the company header, which is stored in the E3907, can be read.

4.6.2.9 Write all parameters

The write-data block for all sensors is identical to the received read all parameters-data block. However for the

writing of sensor parameters a checksum and the corresponding weighted checksum is required.

4.6.2.10 Read all parameters

The output of all parameters from sensor 1 to sensor 10 occurs in following sequence:

Sensor designation

Final display value

Unit

Sensor type (calibration type) / decimal place

Calibration values 0% load, 100% load with respectively 2 bytes

For this see command read-out of current sensor parameters.

4.6.2.11 Change protocol setup

Protocol status

1Byte

0xXXXX XXXX (binary coded)

|||| ||||

|||| |||1 ... no closing character is sent

|||| ||1 ... send CR/LF

|||| |1 ... send CR

|||| 1 ... send LF

4.6.2.12 Calculation of the Checksum (CS) and the Weighted Checksum (wCS)

The calculation takes place via all parameter bytes (without the command byte). At the CS all bytes are added

(overflows are not considered here). For the calculation of the wCS the CS is added to the wCS. At overflow the

wCS is incremented by 1.

4.6.3 Handling with serial interface / USB

Formatting the serial interface output:

Output format in SCI mode:

HAND:

Algebraic sign, measured value, unit, time and CRLF

AUTO:

10ms

Signed integer and CRLF

100ms

Signed integer and CRLF

1s

Algebraic sign, measured value, unit, time and CRLF

10s

Algebraic sign, measured value, unit, time and CRLF

1min

Algebraic sign, measured value, unit, time and CRLF

10min

Algebraic sign, measured value, unit, time and CRLF

1h

Algebraic sign, measured value, unit, time and CRLF

TRIGGER:

Signed integer and CRLF

Output Format in LOGG mode:

HAND:

Algebraic sign, measured value, unit, time and CRLF

AUTO:

Algebraic sign, measured value,unit and CRLF

DIAGRAM:

Algebraic sign, measured value,unit and CRLF

WINDOW:

Algebraic sign, measured value,unit and CRLF

Operating manual

E3907

www.tecsis.de BE 984 i 15

Adjustments in the SCI Mode

SCI OFF: At this adjustment a transfer of measured values from the E3907 is disabled. The E3907 can be

controlled however with the E3907-commands.

HAND: In this mode a measured value is issued via the serial interface when the Enter key is pressed at the E3907.

AUTO: In this mode a measured value is issued via the serial interface in the adjusted delay

TRIGGER: At a trigger event In this mode, a measured value is written in the logger. Since the trigger pulses may

occur in 10ms raster and additional time-logg is not possible. The flank of the trigger pulse must be on HIGH for at

least 4ms. Then it must be on LOW for at least 6ms.

WINDOW: This mode reacts to increasing, respectively decreasing flanks. With a decreasing flank the logging of

the measured values is started. Now the measured values are written in the data logger in 1ms raster. A decreasing

flank ends the recording.

4.6.4 Operation and function principle of the E3907-Data Logger

The data logger can, if the E3907 is not in the measuring mode, be read by the menu option 2,7 LOGG - SENDING

or by the command "A" via the interface. Outside of the measuring mode the data logger is deleted only by the

menu option 2,7 LOGG - DELETION.

If the E3907 is in the measuring mode, the data logger can be read with the command "A" and be deleted with the

command "B".

If the measuring mode is being switched on from the menu option 1MEASURING-sensor selection,

the starting time of the measurement, the current sensor designation, the final value of the measuring range, the

adjusted measuring rate and the logger mode (e.g.: AUTO 1ms) are saved in the logger.

NOTE: All previous measured values are deleted here!

With the read-out of the data logger via the serial interface different adjustments are sent from the E3907.

a) Company header

b) Starting time of the measurement

c) Sensor designation

d) Final display value

e) Adjusted measuring rate

f) Adjusted logger mode

g) Thereafter the measured values

In the HAND MODE the measured values are always logged with the time. The measured value is logged at the

data in the AUTOMODE. A time can be assigned to each measured value by the indicated starting time.

Since in GRAPHS and in the WINDOW MODE trigger events smaller than 1sec can occur, an additional time log is

not possible.

Adjustments in the Logg Mode

LOGG OUT: Here the data logger is switched off. The logg mode in the measuring mode is switched to "LOGG

OUT" as soon as the entire data logger has been edited.

HAND: In this mode a measured value is written into the data logger when the enter key was pressed at the

E3907. By an additional logg of time, there is a time assignment for each measured value.

AUTO : In this mode in the adjusted Delay a measured value is written into the data logger. By the stored

starting time there is a time assignment for each measured value.

GRAPH: In this mode at a trigger event a measured value is written into the logger. Since the trigger pulses

occur in 10ms raster, an additional logg of the time is not possible. The flank of the trigger pulse must

stand on HIGH for 4ms at least. Afterwards on LOW for at least 6ms.

Operating manual

E3907

16 BE 984 i www.tecsis.de

WINDOW: This mode reacts to increasing and/or decreasing flanks. At an increasing flank the logging of the

measured values is started. From now on the measured values are written in the data logger with

1ms raster. A decreasing flank ends the recording LOGG OUT.

4.7 Calibration

4.7.1 Calibrate the active sensor with control (ACT wCON)

Calibration possibilities:

- After pressing the ENTER key, the automatic calibration begins. The device will read the 0% Load value and

display WARM UP. After that the 100% Load value will be read and the device will display WARM UP. After the

WARM UP is finished the device will display SAFE?. Press ENTER to confirm or ESC to reject.

4.7.2 Calibrate the active sensor without control (ACT nCON)

Calibration:

- measure 0% Load and measure 100% Load

- measure 0% Load and enter the difference [100% Load in V – 0% Load in V]

- enter 0% Load in V and enter difference [100% Load in V – 0% Load in V]

Press key or and choose between 0% Load or Sensitivity

0% Load - Relieve sensor from load

or Sensitivity - Enter the value fort the sensitivity in V

Press Key or and choose between 100% Load or Sensitivity

100% Load -Calibrate with 100% Load

or Sensitivity - Enter the value for the sensitivity in V

SAFE - Accept calibration values

4.7.3 Calibrate the passive sensor with control (ACT wCON)

Calibration:

The device will read the 0% Load value and display WARM UP. After that the 100% Load value will be read and the

device will display WARM UP. After the WARM UP is finished the device will display SAFE?. Press ENTER to

confirm or ESC to reject.

4.7.4 Calibrate the passive sensor without control (ACT nCON)

Calibration:

- measure 0% Load and measure 100% Load

- measure 0% Load and enter 100% Load in mV/V

- enter 0% Load in mV/V and enter 100% Load in mV/V

Press key or and choose between 0% Load or Sensitivity

0% Load -Relieve sensor from load

or Sensitivity - Enter the value fort the sensitivity in V

Press Key or and choose between 100% Load or Sensitivity

100% Load -Calibrate with 100% Load

or Sensitivity - Enter the value for the sensitivity in mV/V

SAFE - Accept calibration values.

Table of contents

Other Tecsis Measuring Instrument manuals

Tecsis

Tecsis TM1 Series User manual

Tecsis

Tecsis E1999X500 User manual

Tecsis

Tecsis E3906 User manual

Tecsis

Tecsis P2107 User manual

Tecsis

Tecsis P27 Series User manual

Tecsis

Tecsis DC400 Series User manual

Tecsis

Tecsis E3904 User manual

Tecsis

Tecsis P3922 User manual

Tecsis

Tecsis P2600 User manual

Tecsis

Tecsis P2590 User manual

Popular Measuring Instrument manuals by other brands

Tecnosystemi

Tecnosystemi Toolsplit TSC200010 user manual

Watts

Watts HF scientific AccUView LED owner's manual

Calypso Instruments

Calypso Instruments Ultra-Low-Power Ultrasonic Wired Mini user manual

METREL

METREL MD 9272 instruction manual

Larson Electronics

Larson Electronics LZRWL-CRN-RED-100MW instruction manual

LI-COR

LI-COR 4300 manual