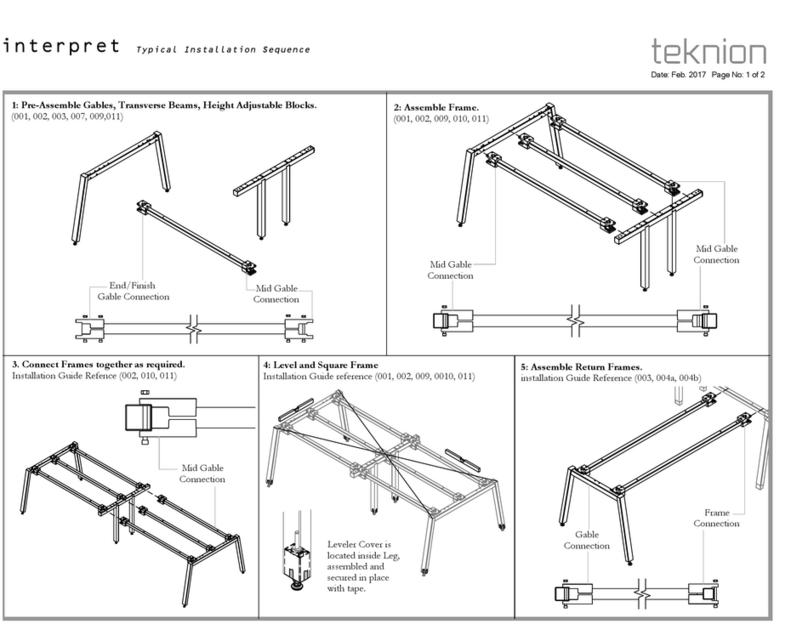

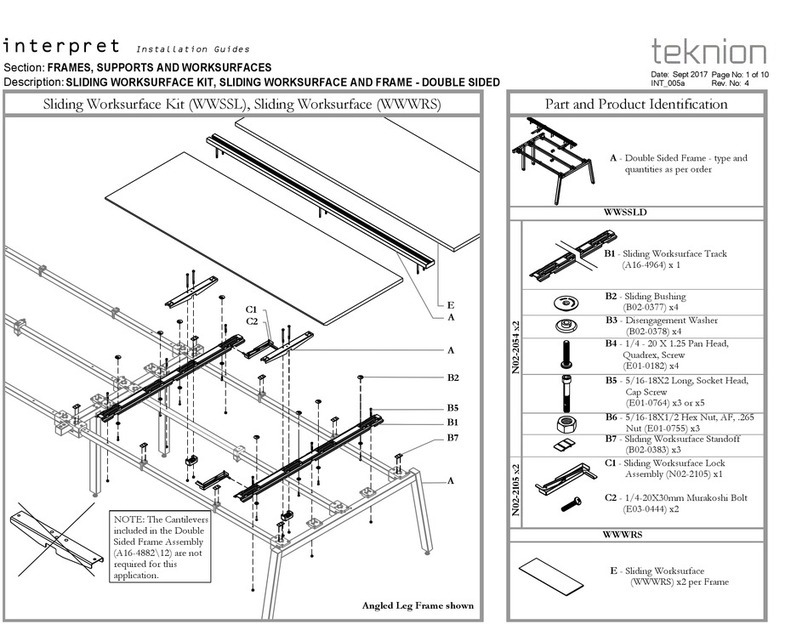

Teknion Interpret WWSSB Operating and maintenance instructions

Other Teknion Indoor Furnishing manuals

Teknion

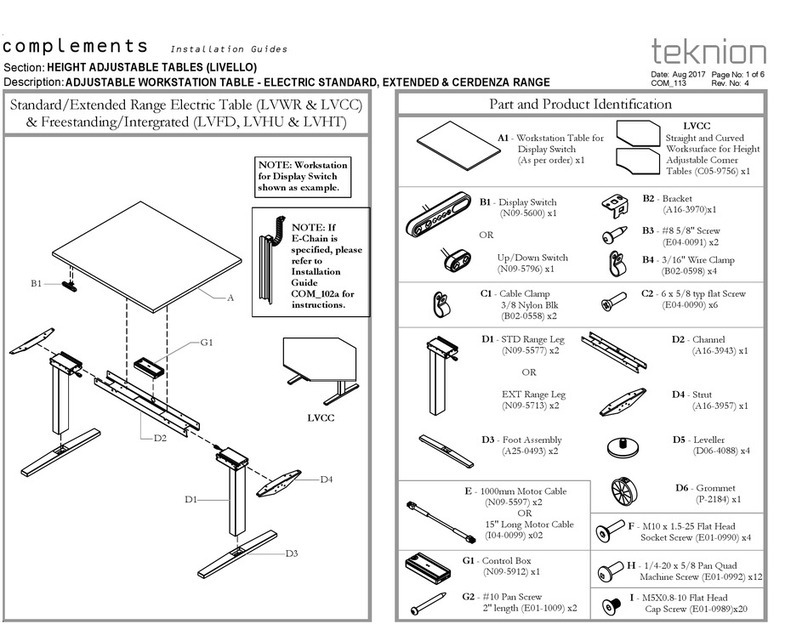

Teknion complements LIVELLO Operating and maintenance instructions

Teknion

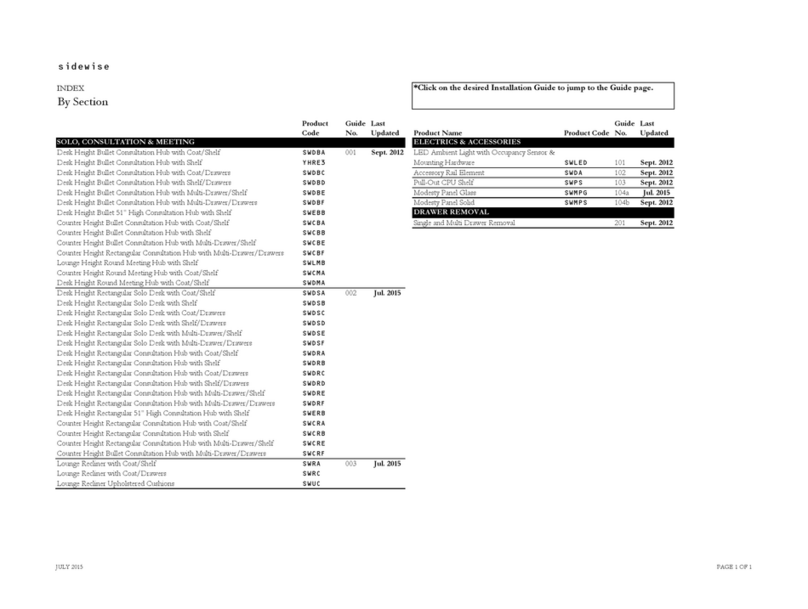

Teknion Sidewise Series Operating and maintenance instructions

Teknion

Teknion Sabrina Owner's manual

Teknion

Teknion Interpret User manual

Teknion

Teknion zones Operating and maintenance instructions

Teknion

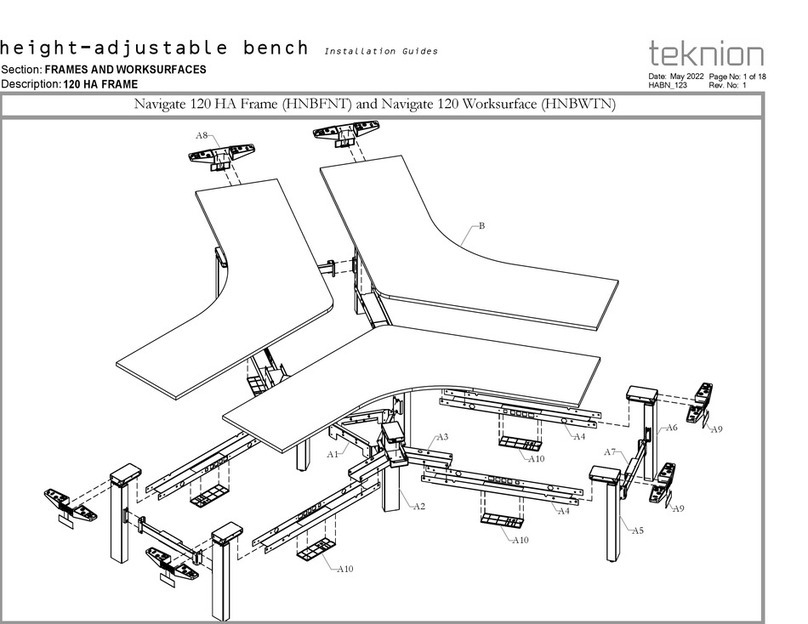

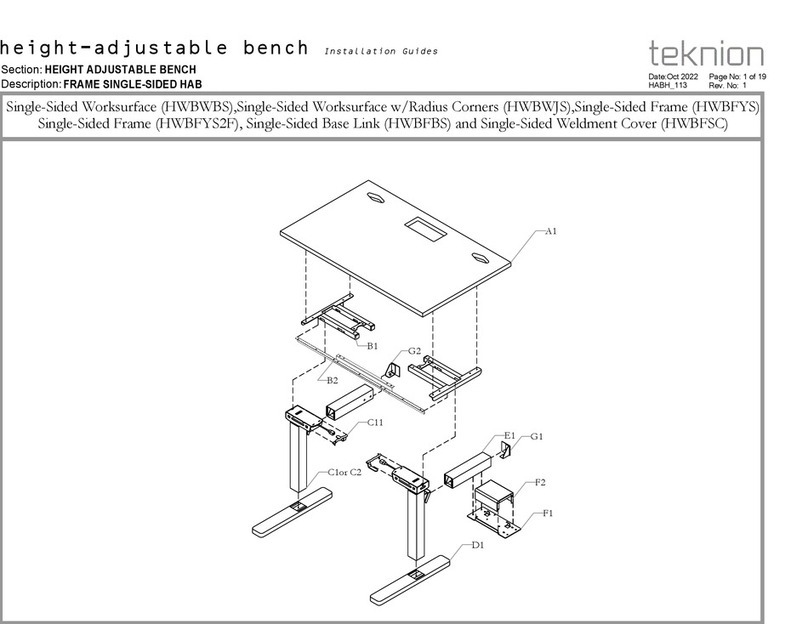

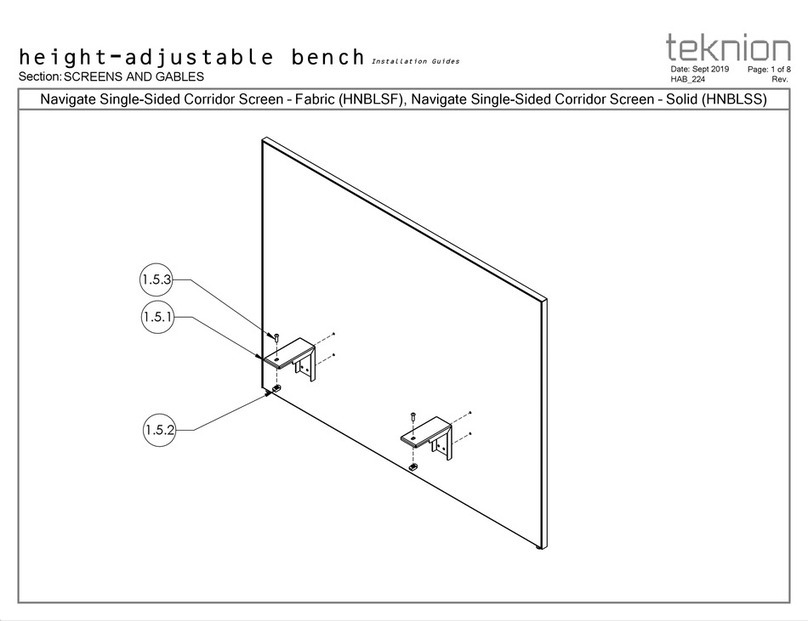

Teknion height-adjustable bench Operating and maintenance instructions

Teknion

Teknion HNBLSF Operating and maintenance instructions

Teknion

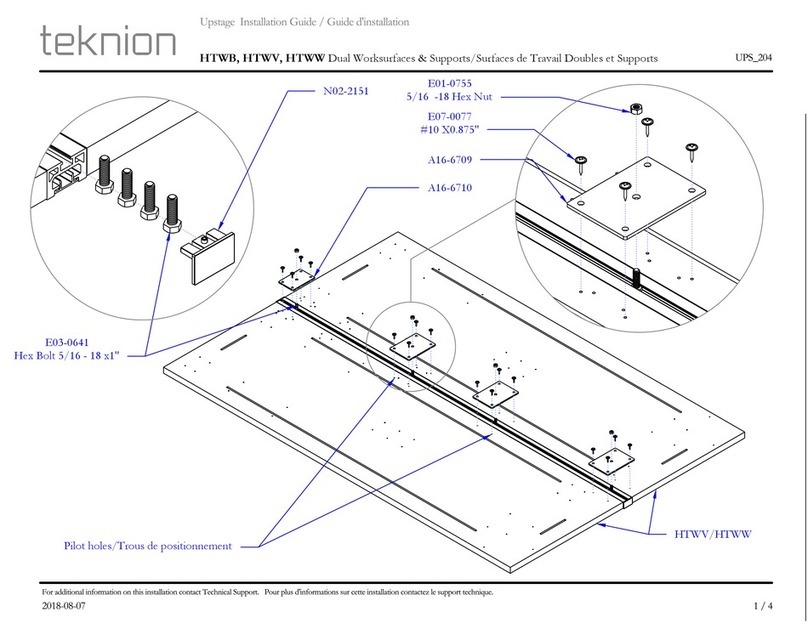

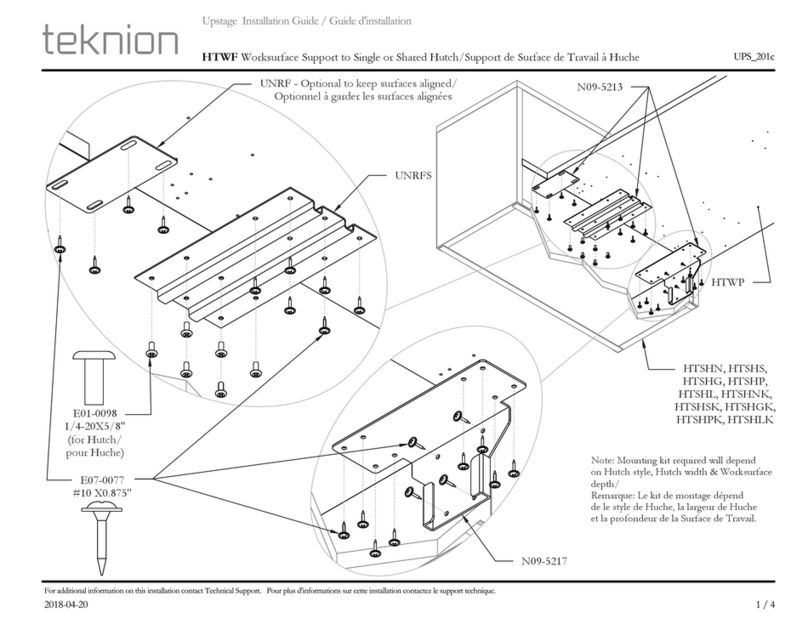

Teknion Upstage User manual

Teknion

Teknion District Series User manual

Teknion

Teknion JNSESH User manual

Teknion

Teknion Livello User manual

Teknion

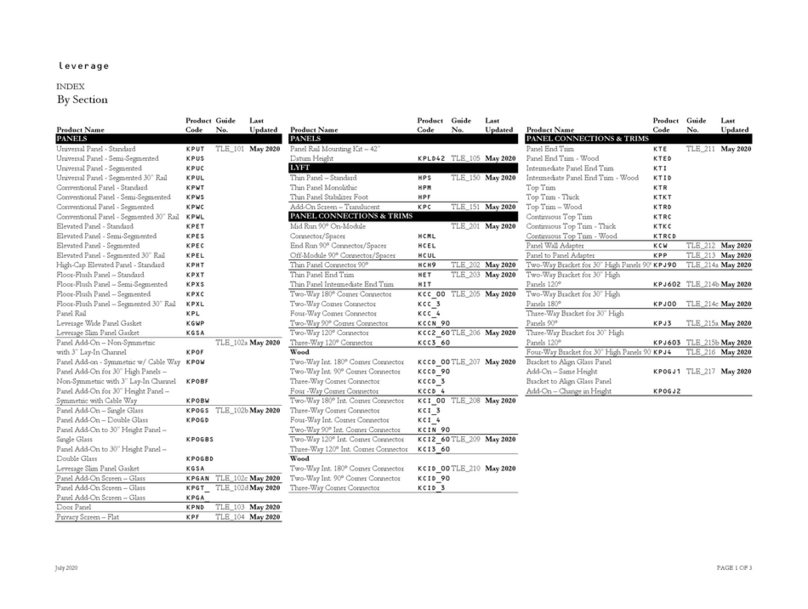

Teknion Leverage Operating and maintenance instructions

Teknion

Teknion north 56 User manual

Teknion

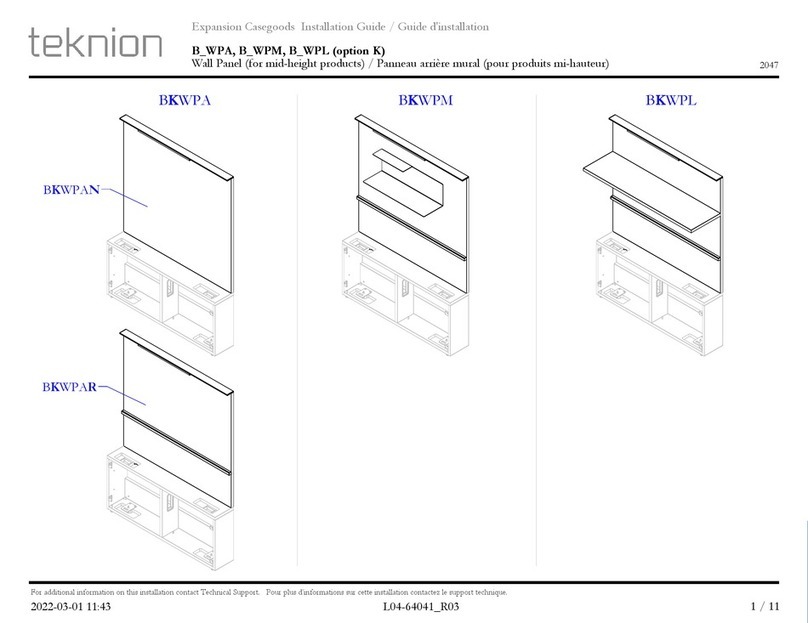

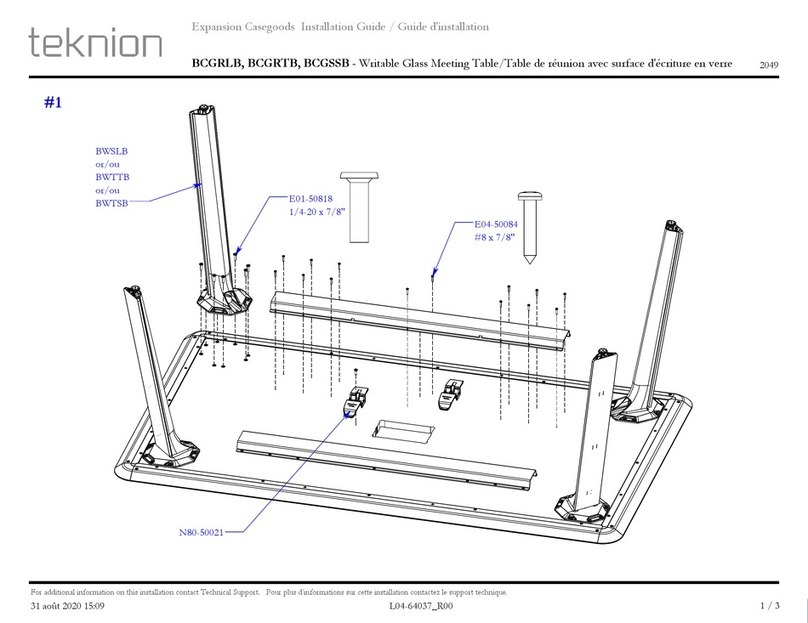

Teknion BCGRLB User manual

Teknion

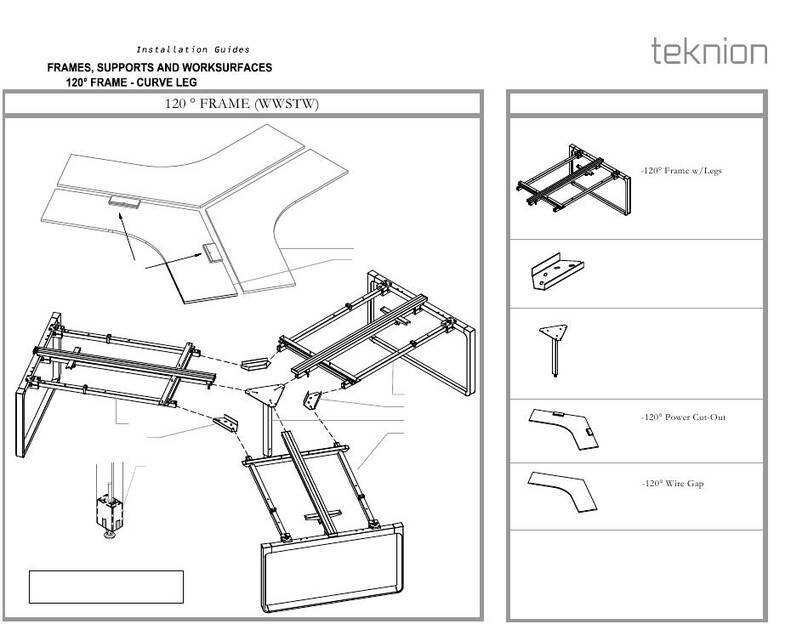

Teknion interpret 120 FRAME CURVE LEG WWSTW User manual

Teknion

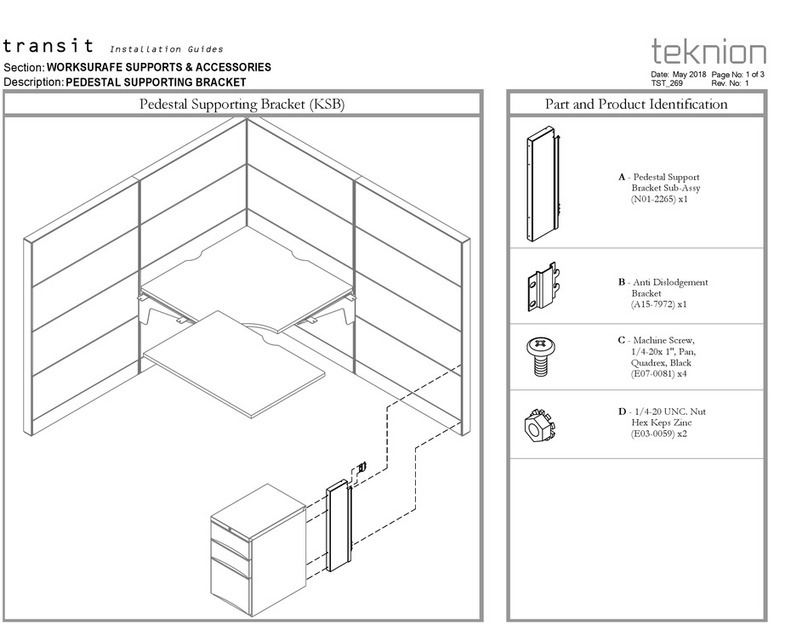

Teknion Transit KSB Operating and maintenance instructions

Teknion

Teknion Custom wood CWCT Series Operating and maintenance instructions

Teknion

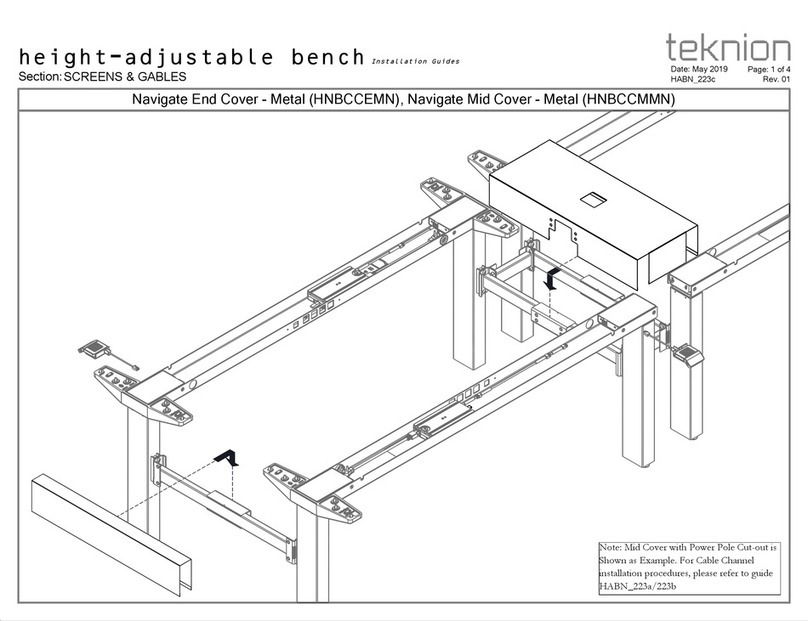

Teknion Navigate End Cover-Metal Operating and maintenance instructions

Teknion

Teknion XAFGM Series Operating and maintenance instructions

Teknion

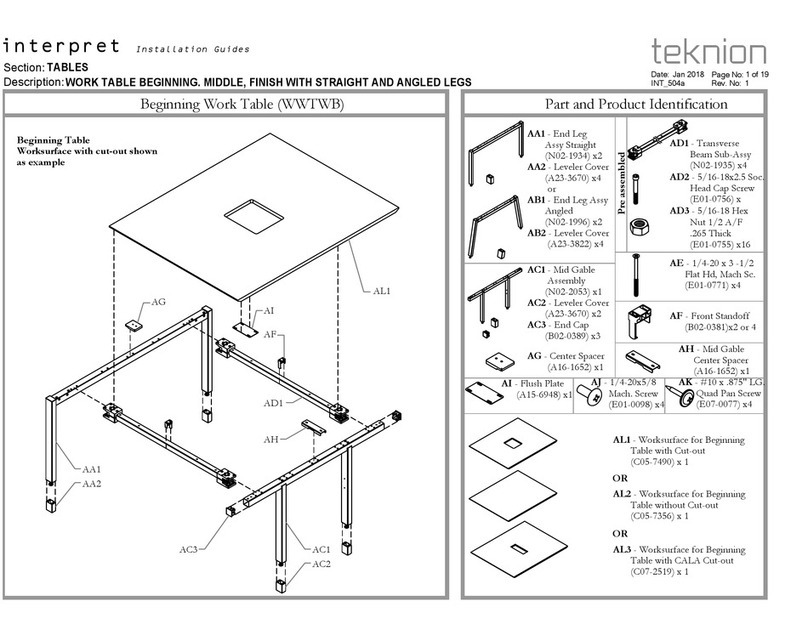

Teknion Beginning Work Table User manual

Popular Indoor Furnishing manuals by other brands

HAMPTON BAY

HAMPTON BAY EDINGTON 141-012-CLCB-KD-NF Use and care guide

Room & Board

Room & Board BERKLEY Assembly instructions

Simpli Home

Simpli Home WyndenHall Brooklyn + Max AXCART14-TB manual

Simpli Home

Simpli Home WyndenHall brooklyn + max AXCERN-12 manual

Smart Flex

Smart Flex SF-500 manual

HumbleCrew

HumbleCrew Bright CT376 Assembly instructions

Knape&Vogt

Knape&Vogt HM25 installation instructions

Little Seeds

Little Seeds Metal Bed with Casters 4395419LS Assembly manual

System Build

System Build 2484015COM Assembly instructions

Jason.L

Jason.L Quadro Wood A 2P Run workstation 1200 mm Assembly instructions

Happy Beds

Happy Beds Sanderson 6FT Velvet Fabric Bed Assembly instructions

WorkPro

WorkPro 12000 Series Assembly instructions and warranty information

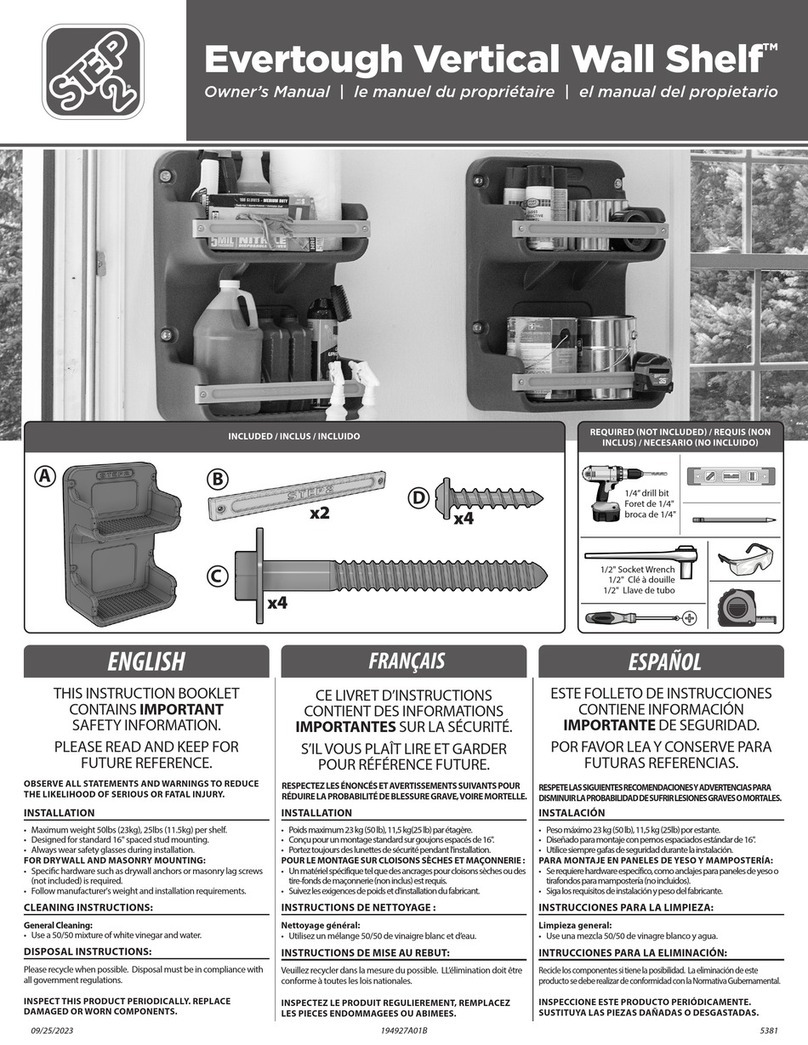

Step 2

Step 2 Evertough Vertical Wall Shelf owner's manual

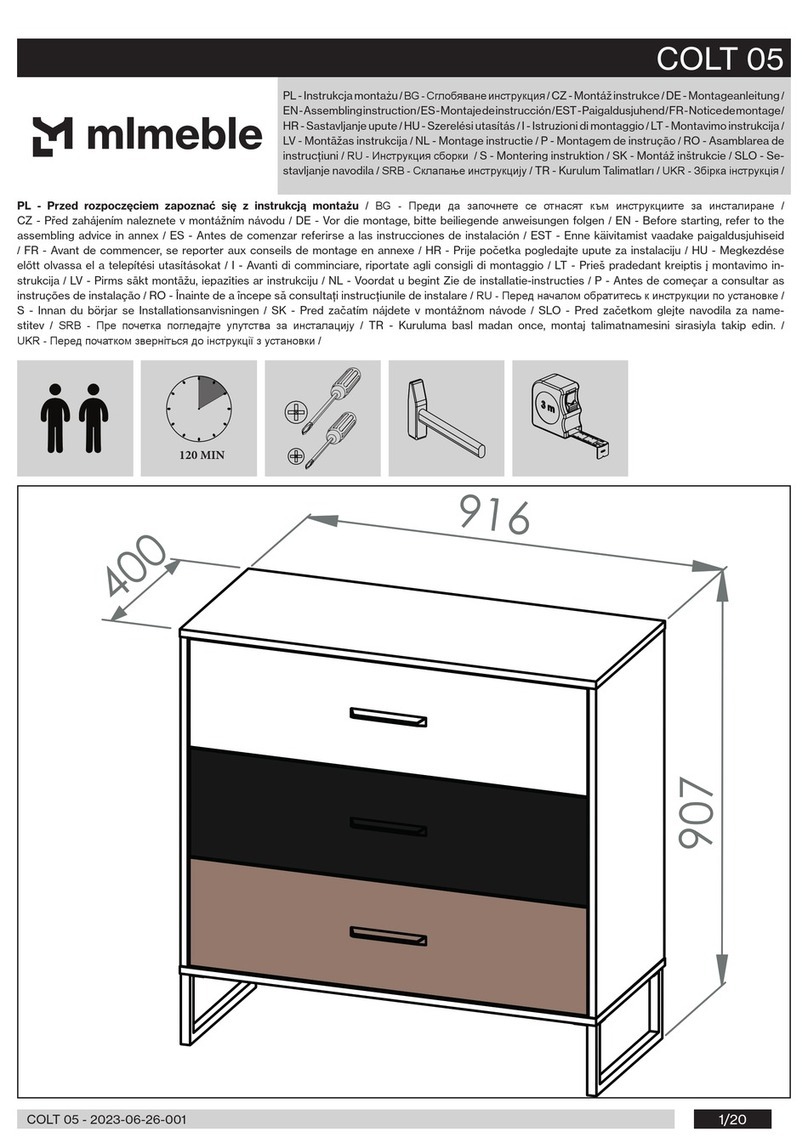

mlmeble

mlmeble COLT 05 Assembling Instruction

LOWE'S

LOWE'S 1954MR-22-278 manual

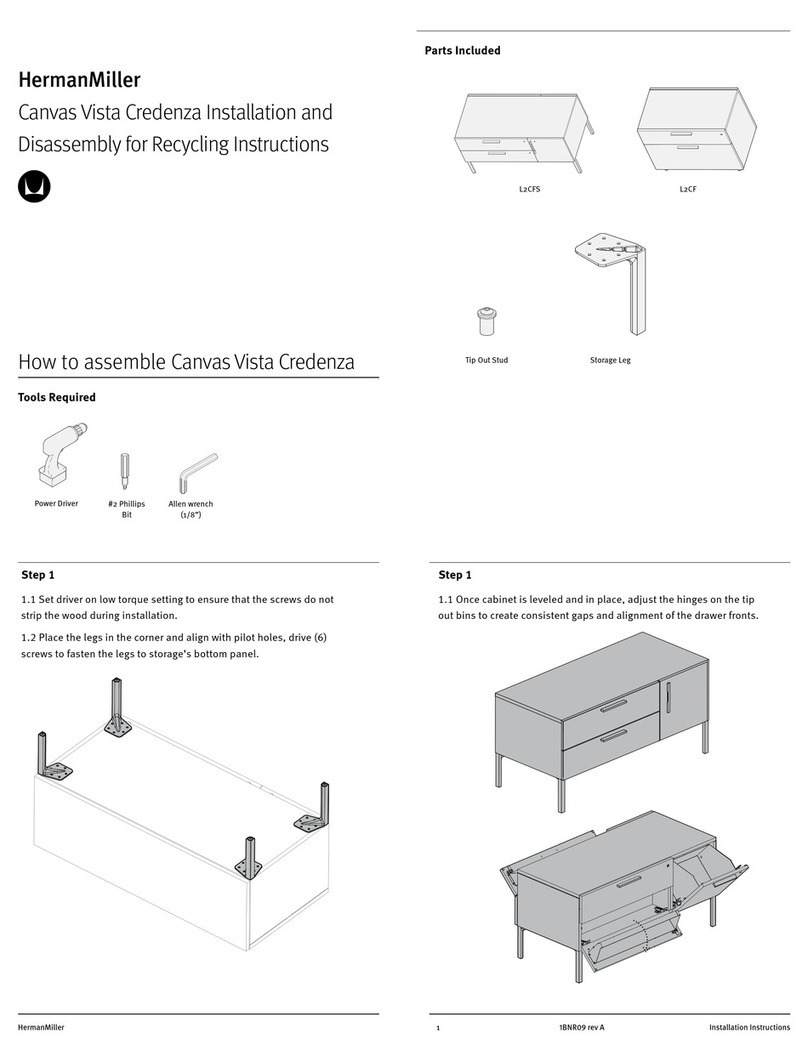

Herman Miller

Herman Miller Canvas Vista Credenza Installation and Disassembly for Recycling Instructions

HOMEDEPOT

HOMEDEPOT KF200189-01 manual

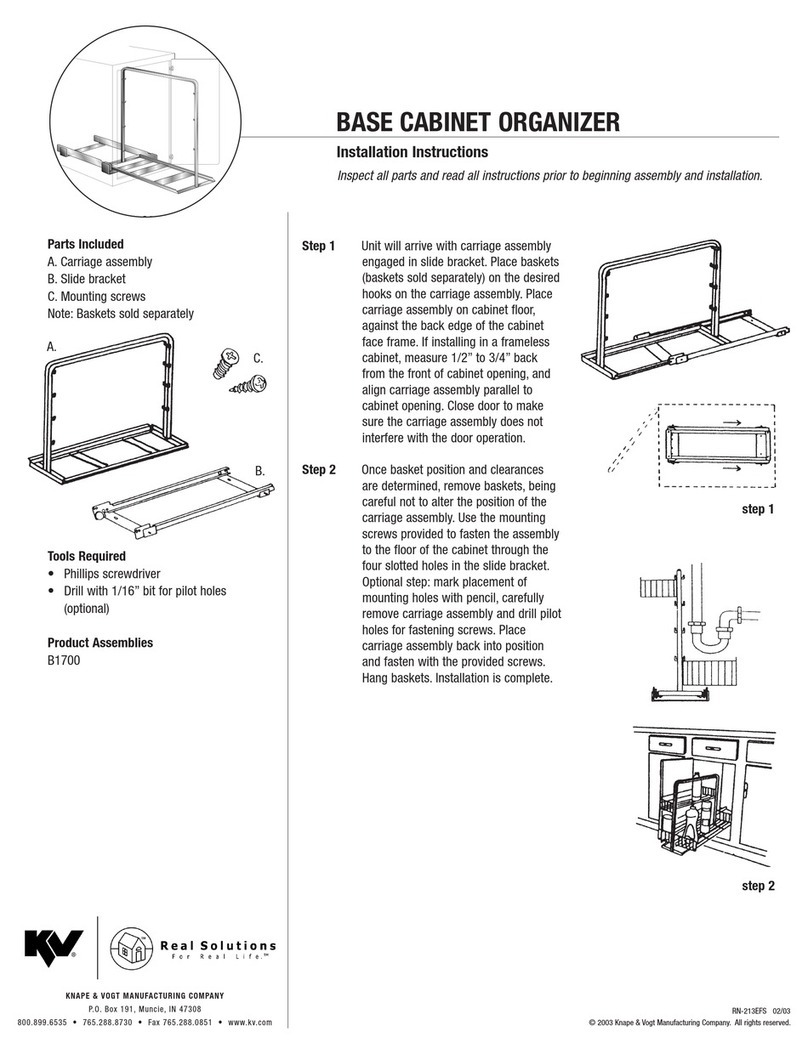

Knape&Vogt

Knape&Vogt B1700 installation instructions