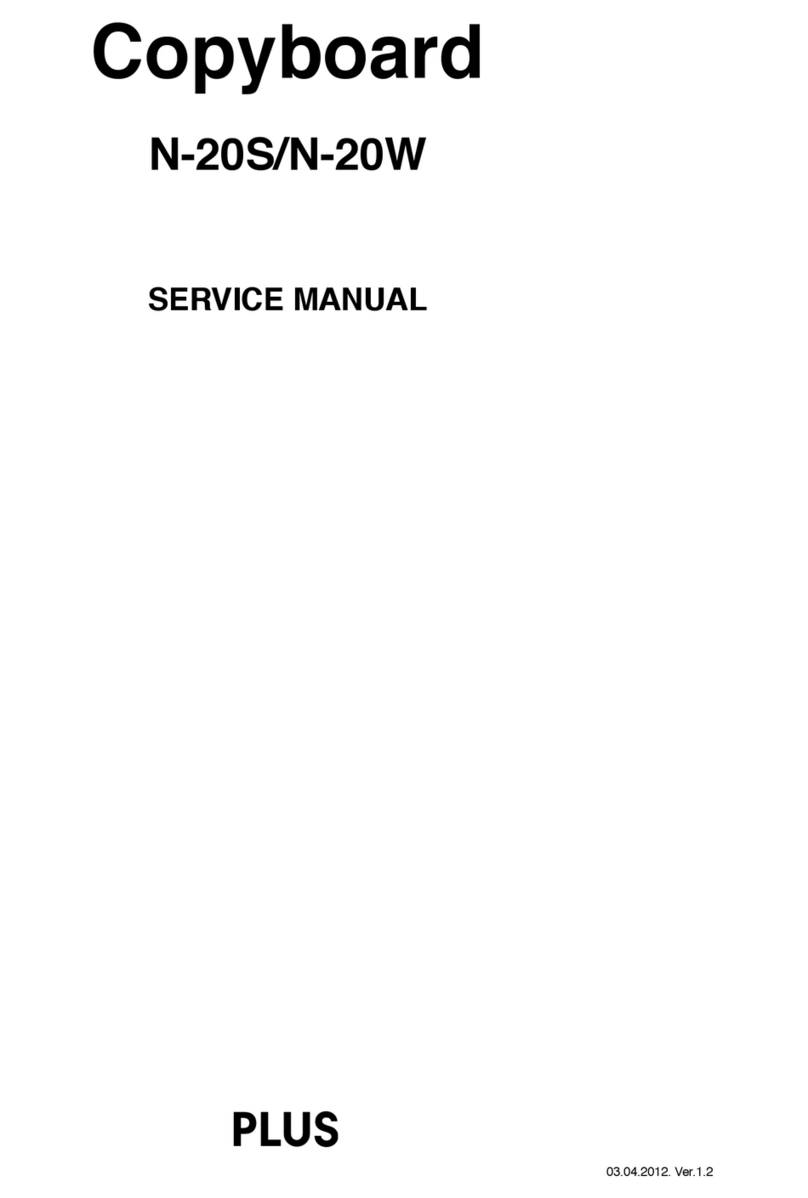

Teknion HABCGESL Operating and maintenance instructions

Section:

Description: Page No:

Date:

Rev. No: 06

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

Aug 2017 1 of 16

HABL_203b

height-adjustable bench

Installation Guides

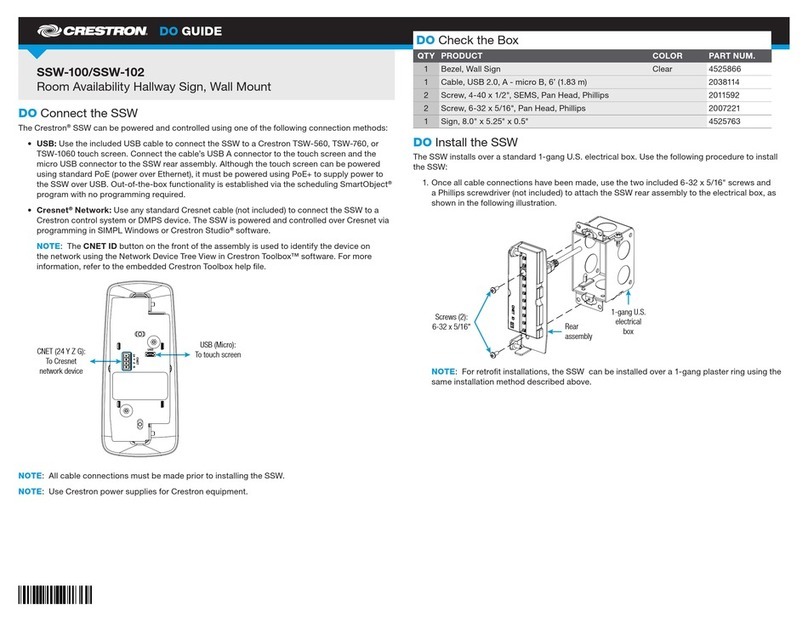

A - (HABCGESL) x2

A1 - Inside Cover Assembly

for Wood End Gable

(N09-5187) x1 or

(N09-5188) x1

A4 - Bottom Bracket

(A16-3020) x2

A2 - Cover for End Gable

(C05-8862) x1

B - (HABFCC) x2

B1 - Center Rail

Extrusion Cap

(A23-5200) x1

B2 - Center Rail

Extrusion

(A21-0888\98) x1

B3 - Cable Channel

Assembly

(N09-5019) x1

B4 - Support Bracket

- Screen Rail

(A16-3009) x2

B5 - Hex Bolt 5/16

-18x1" Long ZP

(E03-0641) x8

B6 - 5/16-18 Hex Nut, 1/2

A/F, .265 Thick

(E01-0755) x8

B7 - Communication

Cover Plate

(A16-3127) x1

B8 - #8-18x1/2" Cross

Square COMB. Self

(E07-0012) x6 or x10

B9 - Cable Channel Cover

Plate (Single Cable

Management only)

(A16-3220) x2

B11 - Wire Manager Clip

(B02-2007) xqty

varies

B10 - Hanger

(A16-2364) x2

C - (HABCGMSL) x1

C1 - Side Cover Assembly

(C05-8921)x1 &(C05-8863)x1

or (C05-9034)x1 &(C05-9033)x1

or (C05-8863) x2

or (C05-9033) x2

C3 - Front Hanging

Bracket

(A16-3028) x2

C2 - Front

Cover

(C05-8864) x2

B2 B3

B4

A1

A2

C1

C2

C9

NOTE: Mid Gable Without

Power Pole shown as an example.

Wire Manager E-Chain

(N09-5138) ships with HAB

Cable Channel (HABFCC).

Please refer to Installation

Guide HABL_301 for

assembly instructions.

A3 - Hanging Bracket

(A16-3021) x2

A5 - 1/4-20 UNCx0.5" 2A,

Cross/SQ. COMB.

Socket, Truss. Head.

Mach. Screw. Steel

ZN (E01-0110) x4

C7 - 1/4-20 UNCx0.5" 2A, Cross/SQ. COMB.

Socket, Truss Head. Machine Screw, Steel

Zinc (E01-0110) x12

C4 - Bottom Bracket

for Mid Gable

(A16-3027) x2

C5 - Hanging Bracket

for Mid Gable

(A16-3203) x4

C6 - Bottom Connecting

Bracket

(A16-3026) x4

C8 - Top Cover w/Cutout

for Mid Gable w/Power

Pole

(A16-3087) x1

& Top Cover for Wood Mid

Gable w/Power Pole

(A16-3088) x1

C9 - Top Cover for Wood Mid Gable

(A16-3029) x2

B12 - 1/4-20x3/4" Mach

Screw, Black

Quad, Truss

(E01-0113) x8

A6 - #10X1/2" Tap

Scr Quad Pan

(E01-0023)x2

A7 - Gable

Connecting Plate

(A16-3651) x2

C10 - #10X1/2" Tap Scr

Quad Pan (E01-0023)x4

C11 - Gable Connecting Plate

(A16-3651) x4

C12 - Mid Gabel Bottom Angle Bar

(A16-3655)x2

C11

C12

A7

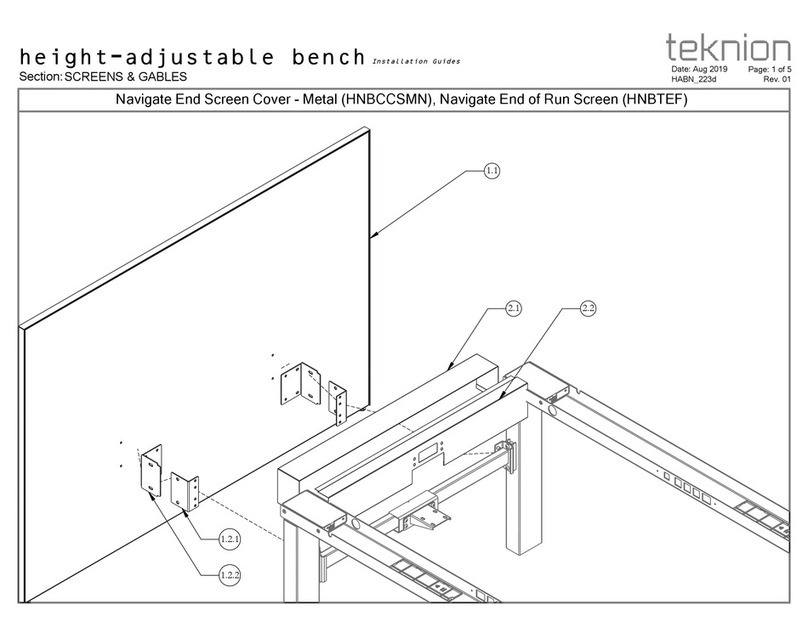

HAB End Gable-Solid (HABCGESL), HAB Cable

Channel (HABFCC) & HAB Mid Gable-Solid (HABCGMSL)

Part and Product Identification

C13- Cover Plate for

Basefeed Cut-Out

(A16-3690) x1

C14- Cover Plate for

Cable Cut-Out

(A16-3689) x4

C15- #6 Wood

Screw

(E04-0050)

xqty varies

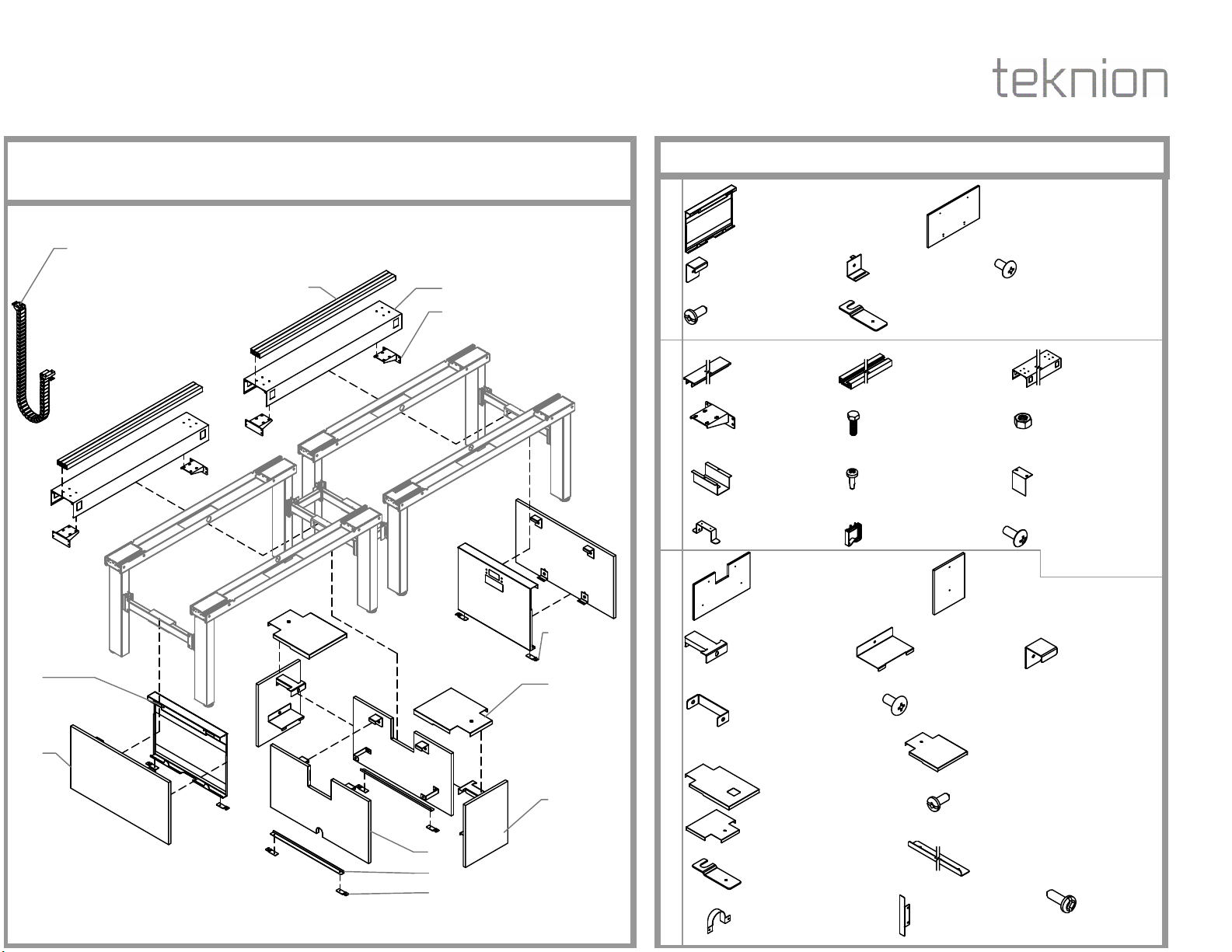

Section:

Description: Page No:

Date:

REMOVE SUPPORT BRACKETS AND COMMUNICATION PLATE COVER

Aug 2017 2 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

B3

B4

B6

B7 B8

STEP 1: Remove Support Brackets and Communication Plate Cover as shown.

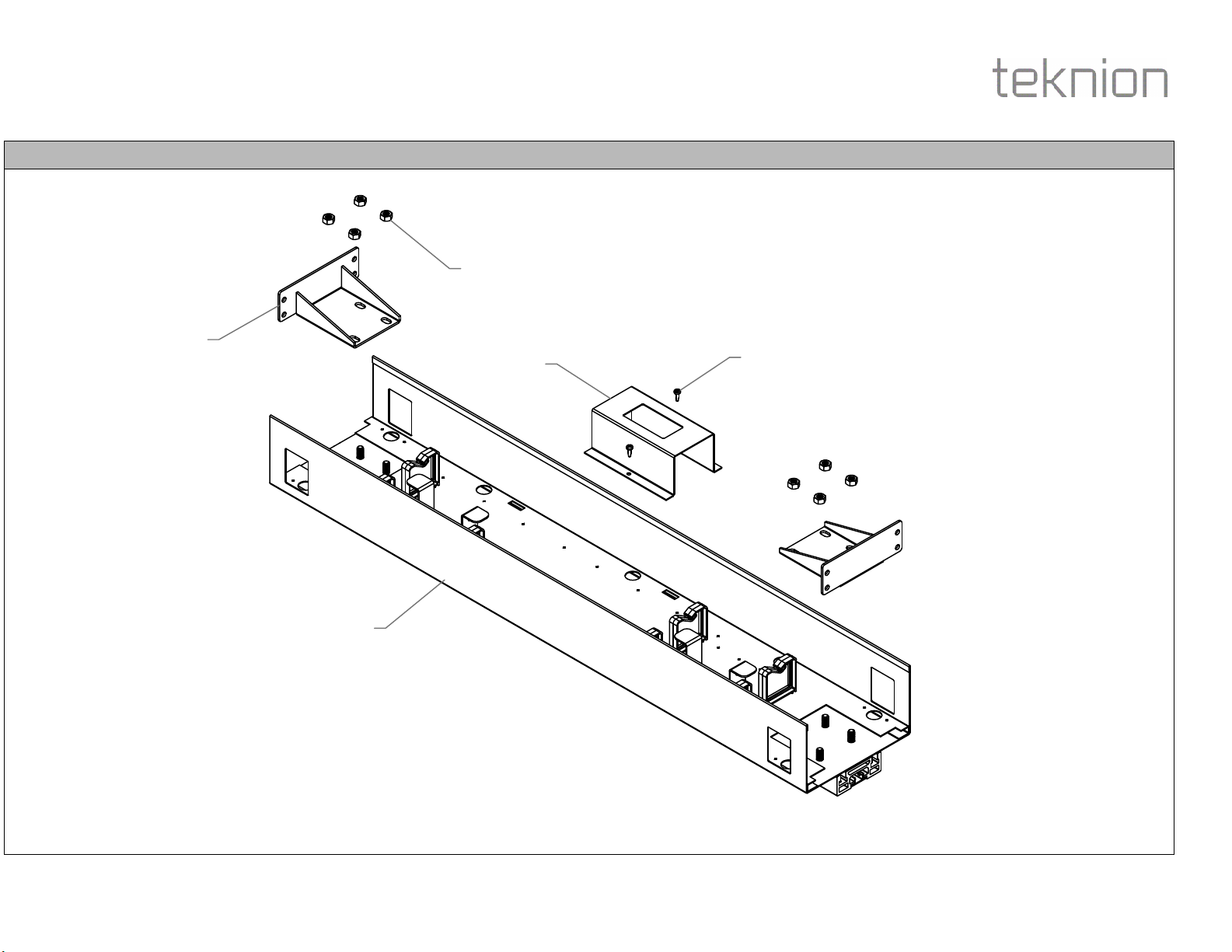

Section:

Description: Page No:

Date:

ATTACH SUPPORT BRACKET APPLY FOAM RUBBERS

HABL_203b

3 of 16

Aug 2017

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

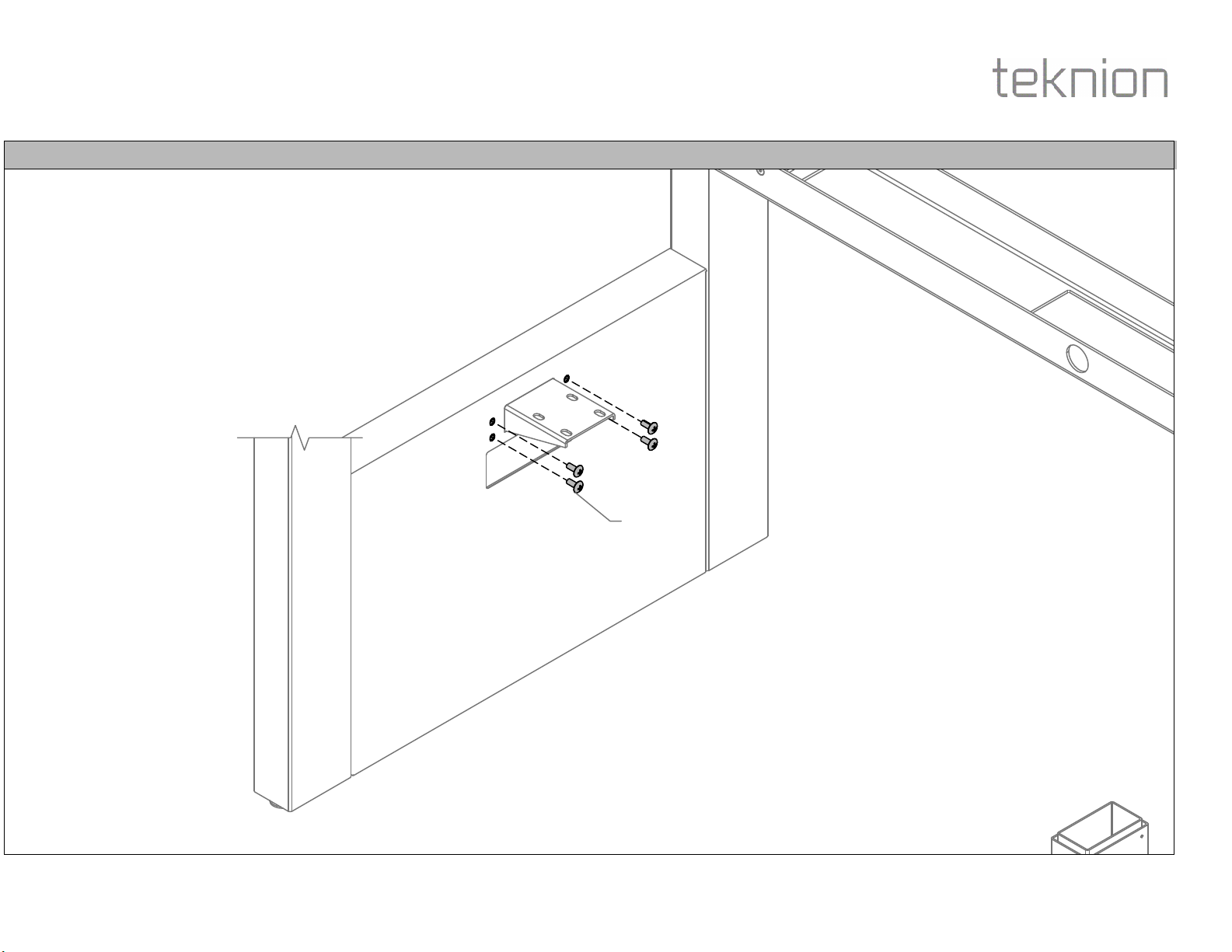

STEP 3: Insert Support Bracket through the cut-out on the Inside Cover Assembly as shown.STEP 2: Fasten Brackets to Outside Cover Assembly.

A2

A3

A1

B4

A4

A5

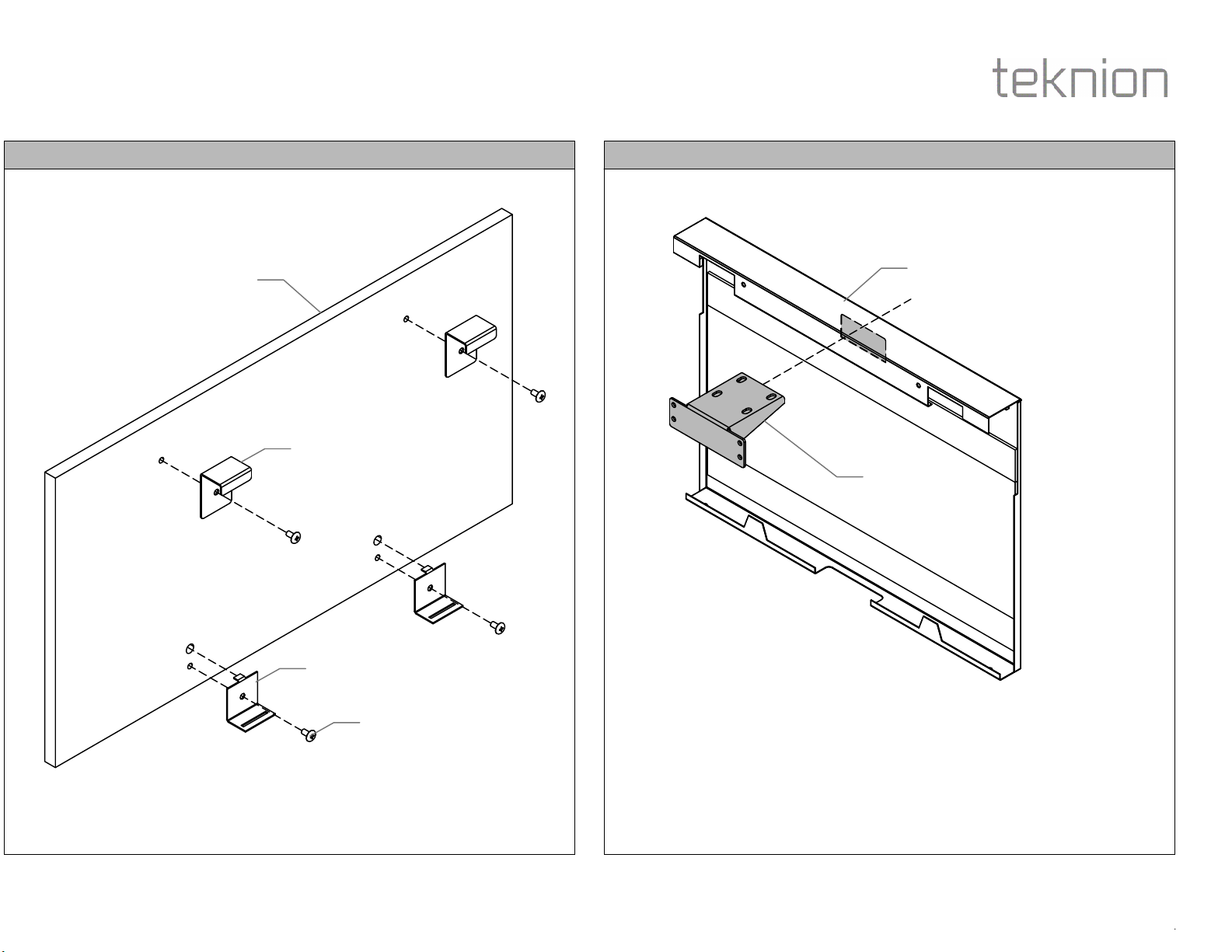

Section:

Description: Page No:

Date:

ATTACH CONNECTION PLATES TO FRAME LEGS

Aug 2017 4 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

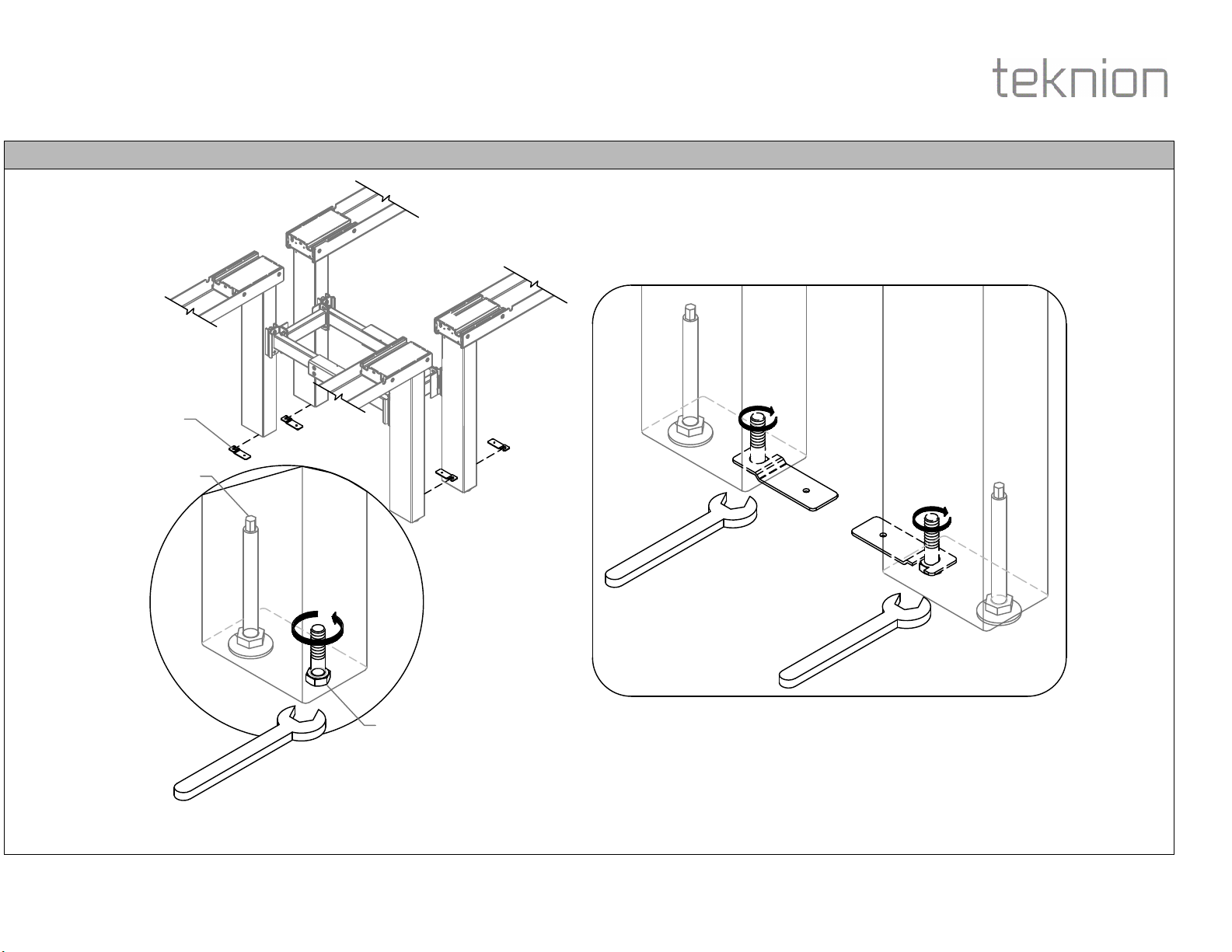

STEP 4: Loosen Legs Hex Bolt to allow enough room for Gable Connecting Plate. Fasten Gable Connecting Plates to Frame Legs.

A7

Leveler

Leg Hex Bolt

Please refer to Installation Guide

No. HABL_101a for

information.

Section:

Description: Page No:

Date:

MOUNT INSIDE COVER ASSEMBLY

Aug 2017 5 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 5: Mount Inside Cover Assembly onto Stretcher Bar. Make sure the face of the Inside Cover Assembly is flush with the Leg as shown in Section View. Secure Inside Cover Assembly to

Gable Connecting Plate on both sides using Tap Quad Pan screws provided.

Section View

A6

Section:

Description: Page No:

Date:

SECURE TO THE STRETCHER BAR

Aug 2017 6 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 6: Secure Inside Cover Assembly to Stretcher Bar with Bolts.

B12

Opposite Side

Section:

Description: Page No:

Date:

MOUNT OUTSIDE COVER ASSEMBLY

Aug 2017 7 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

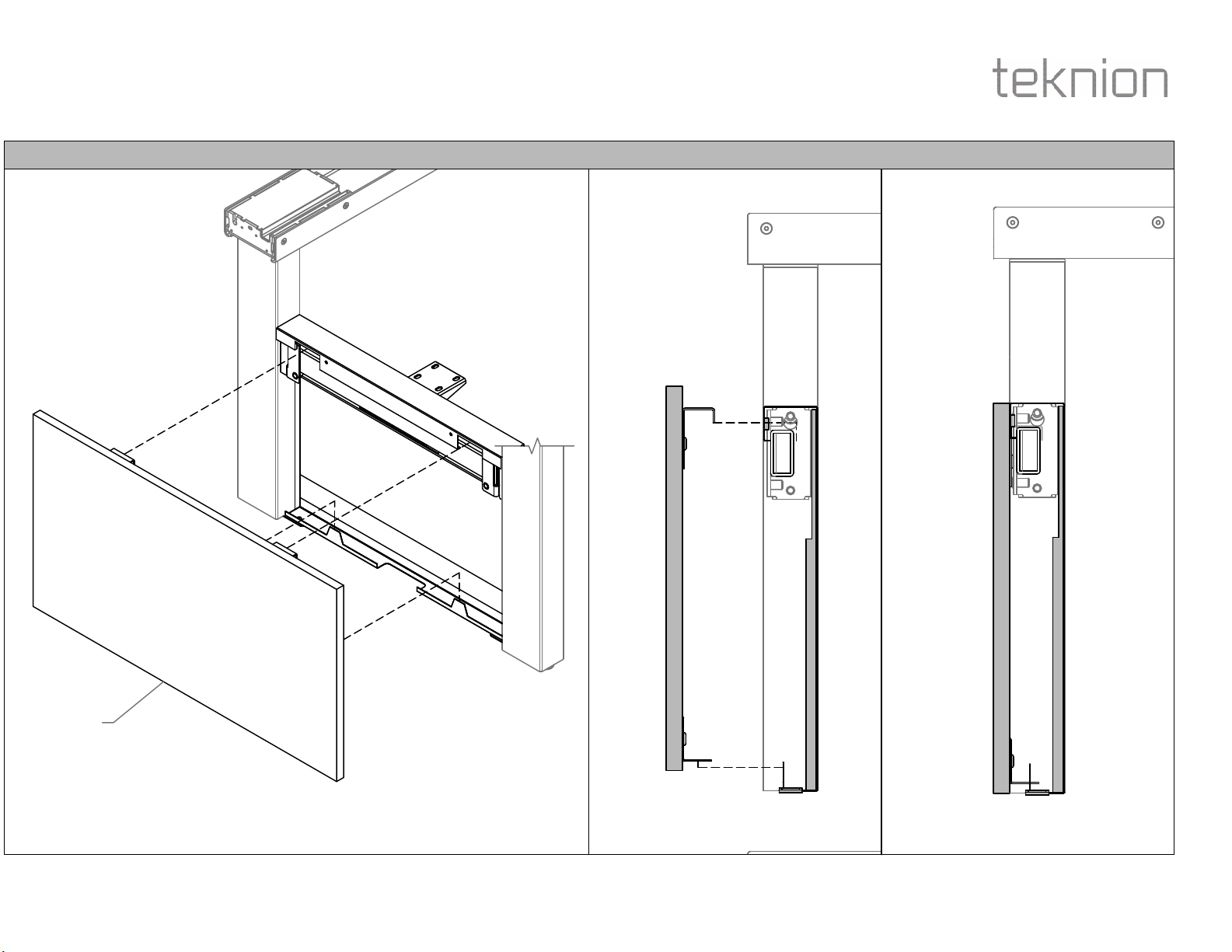

STEP 7: Mount Outside Cover Assembly to the highlighted part of the Inside Cover Assembly as shown.

A2

Section View Section View

Section:

Description: Page No:

Date:

ATTACH CONNECTING PLATES TO FRAME LEGS

Aug 2017 8 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 8: Loosen Legs Hex Bolt to allow enough room for Gable Connecting Plate. Fasten Gable Connecting Plates to Frame Legs.

C11

Leveler

Leg Hex Bolt

Section:

Description: Page No:

Date:

MOUNT BOTTOM ANGLE BAR

Aug 2017 9 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 9: Mount Bottom Angle Bar and secure to Gable Connecting Plate on both sides using Tap Quad Pan screws provided.

C10

C12

Section:

Description: Page No:

Date:

MID POWER POLE SUPPORT PLATE ATTACH SUPPORT BRACKET

HABL_203b

10 of 16

Aug 2017

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 10: Fasten Brackets and Cover Plates to Side Cover Assemblies and Front Covers as

shown.

Optional: If Mid Power Pole is specified. Please fasten Connecting Bracket to the underside of

the Stretcher Bars as shown.

C3

C2

C1

C4

C6

C5

C7

Connecting

Bracket

Hex Bolt 5/16-18x1"

Long ZP

NOTE: Please refer to installation

guide HABL_302b for detail.

Underside View

C13

C14

C15

C15

Section:

Description: Page No:

Date:

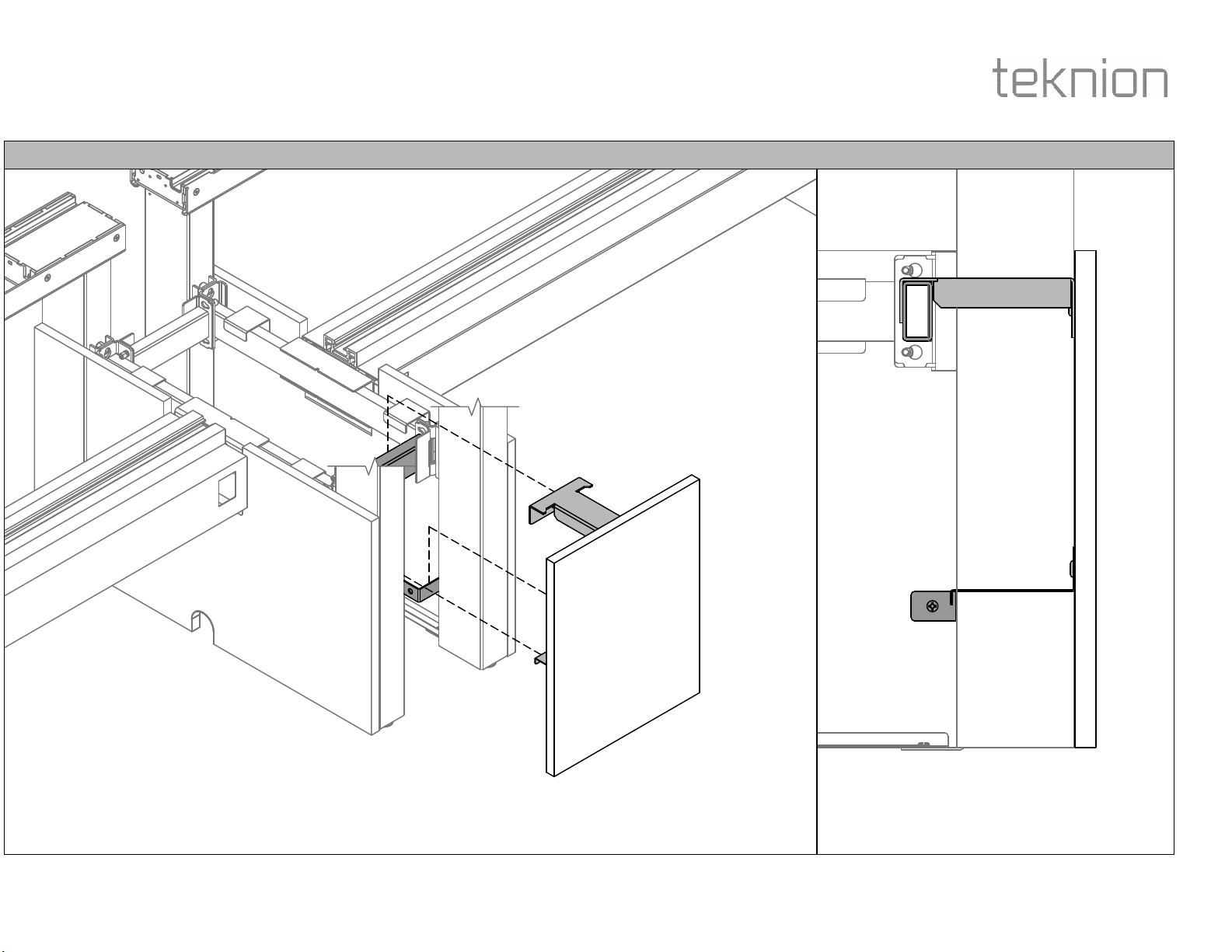

MOUNT SIDE COVER ASSEMBLY SECURE SIDE COVER ASSEMBLY

HABL_203b

11 of 16

Aug 2017

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

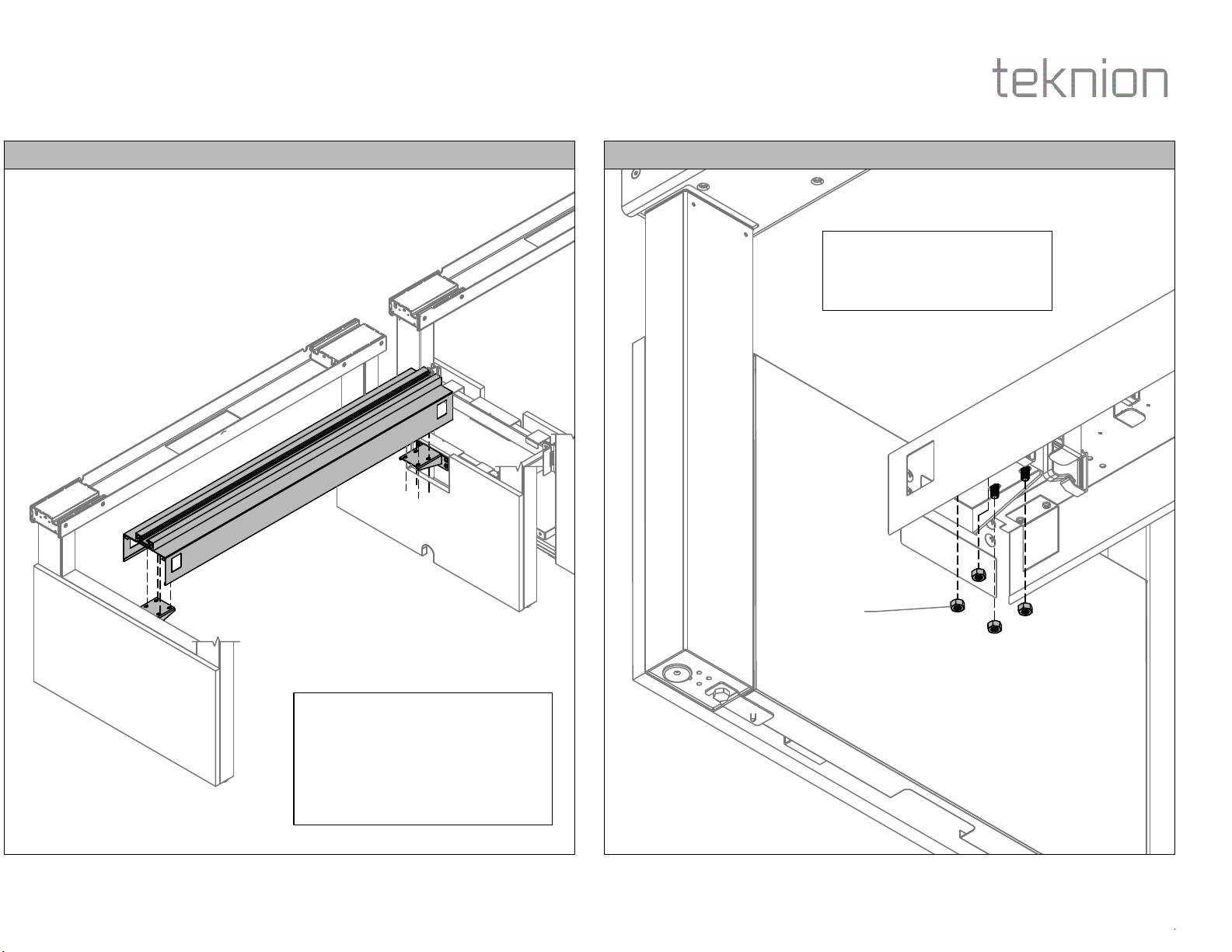

STEP 12: Secure Support Bracket to Stretcher Bar with Bolts.

STEP 11: Mount Side Cover Assembly onto the Stretcher Bar as shown.

NOTE: Side Cover with Base Feed

Cut-out shown as an example.

NOTE: Please refer to

Specification Drawing to

mount the correct Side

Cover Assembly.

Section:

Description: Page No:

Date:

CABLE CHAIN ASSEMBLY

Aug 2017 12 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

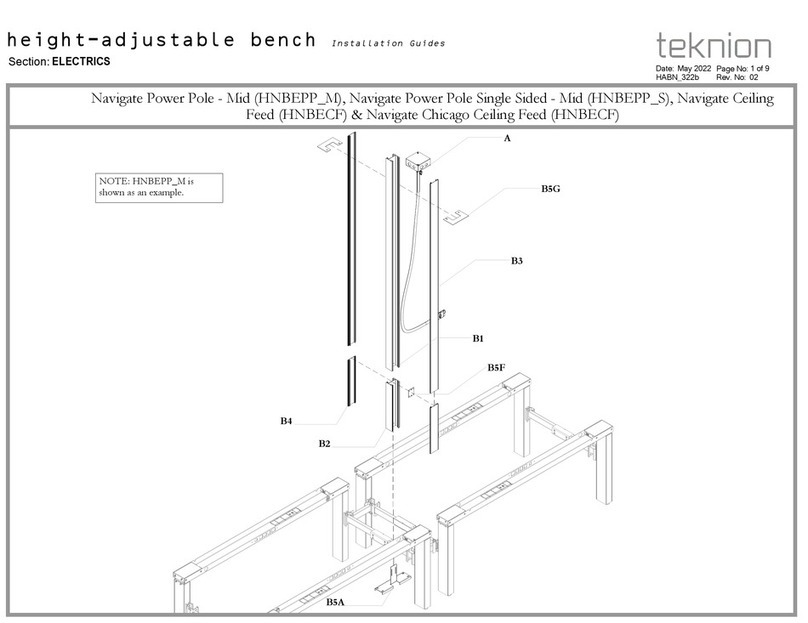

NOTE: Electrics

components have to

installed on Cable Channel

before connecting to

Support Bracket. Please

refer to Installation Guide

301, 302a or 302b for

corresponding Electrics

installation.

B3

B10

B7

B11

High Capacity

Power Module

Standard Power Module

Base Feed

Power Module

Cover

E-Chain

B9

B8

NOTE: Install Cable Channel

Cover Plate (B9) on Cable

Channel where E-Chain is not

specified or unused location.

Section:

Description: Page No:

Date:

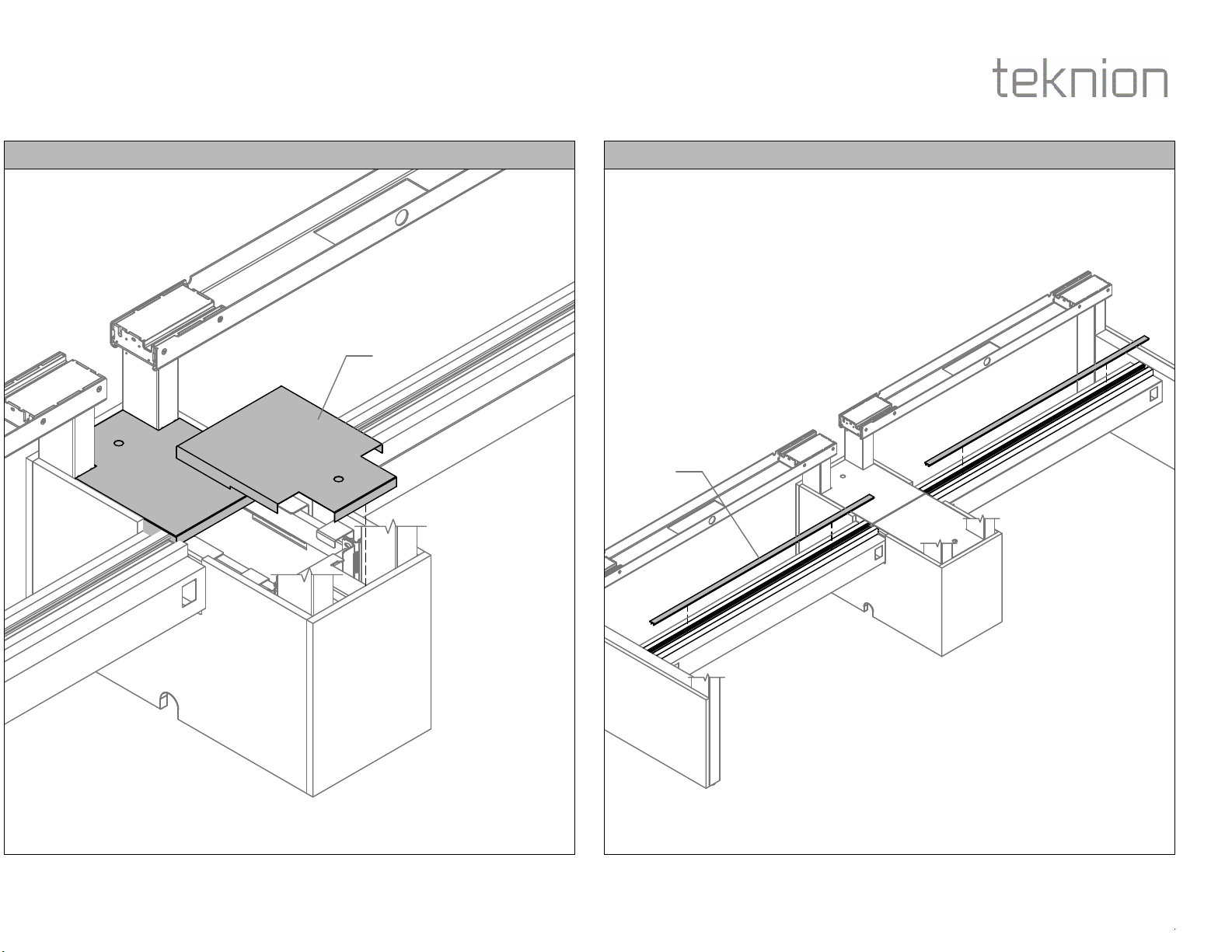

CABLE CHANNEL ASSEMBLY AND CENTER RAIL SECURE CABLE CHANNEL

HABL_203b

13 of 16

Aug 2017

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 14: Secure Cable Channel in place with Nuts.STEP 13: Align holes on Support Brackets, Cable Channel Assembly. Insert Bolts inside Center

Rail Extrusion through Cable Channel Assembly and Brackets as shown.

B6

Underside View

NOTE: Electrics components to be

installed on Cable Channel before

connecting to Support Bracket. Please

refer to Installation Guide 301a, 301b,

301c, 302a or 302b for corresponding

Electrics installation.

NOTE: Please repeat STEP 1 to

14 if second Cable Channel is

specified .

Section:

Description: Page No:

Date:

MOUNT FRONT COVER ASSEMBLIES

Aug 2017 14 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 15: Mount Front Covers onto the Frame Link and Bottom Connecting Brackets.

Section View

Section:

Description: Page No:

Date:

TOP COVER W/ POWER POLE CUTOUT (OPTIONAL)

Aug 2017 15 of 16

HABL_203b

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 16a: If Mid Gable Power Pole is specified. Attach Top Covers onto the highlighted extrusions on the Side and Front Cover Assemblies as shown.

Repeat Step 1-14 to install End Gable and Cable Channel on another side of the Table.

C5

Section:

Description: Page No:

Date:

ATTACH TOP COVER CENTER RAIL EXTRUSION CAP

HABL_203b

16 of 16

Aug 2017

SOLID GABLES & CABLE CHANNEL

SCREENS AND GABLES

height-adjustable bench

Installation Guides

STEP 17: Insert Center Rail Extrusion Caps onto Center Rail Extrusions as shown.STEP 16b: Rest Top Covers onto Gable structures as shown.

C5

B1

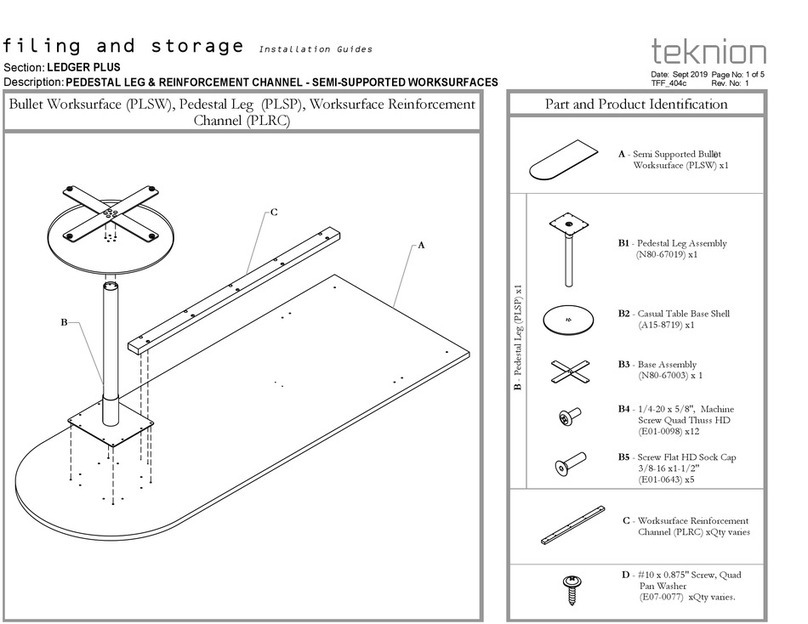

This manual suits for next models

2

Other Teknion Office Equipment manuals