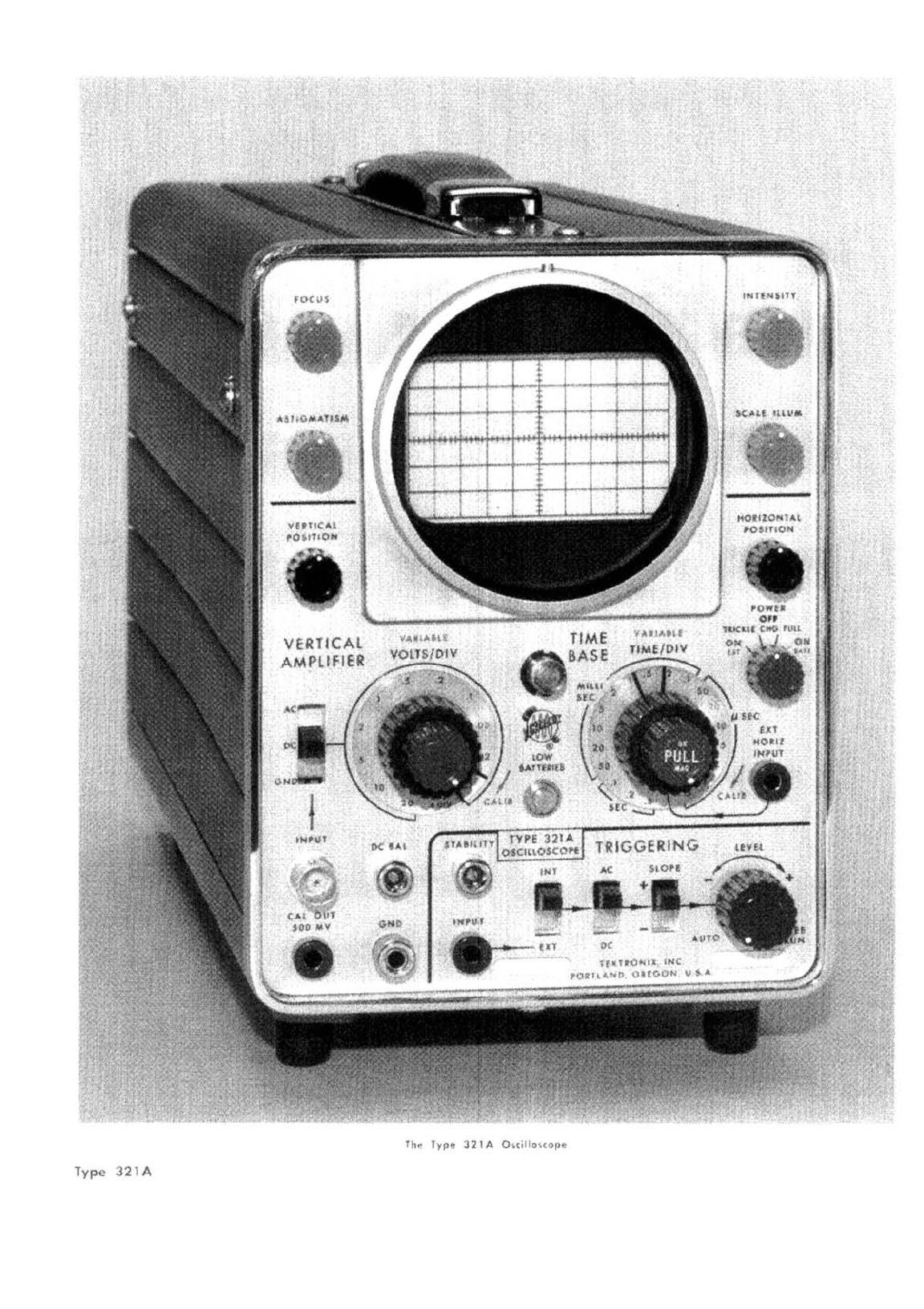

Tektronix 321 A User manual

Other Tektronix Test Equipment manuals

Tektronix

Tektronix TBS2000B Series User manual

Tektronix

Tektronix 212 User manual

Tektronix

Tektronix RM3000 User manual

Tektronix

Tektronix T202 User manual

Tektronix

Tektronix 2445B User manual

Tektronix

Tektronix P6042 PROBE User manual

Tektronix

Tektronix TBS1000B Series User manual

Tektronix

Tektronix 454A User manual

Tektronix

Tektronix 2445 User manual

Tektronix

Tektronix 2465 User manual

Tektronix

Tektronix MDO4000C Series User manual

Tektronix

Tektronix TMT4 Use and care manual

Tektronix

Tektronix 519 User manual

Tektronix

Tektronix TDS1000 Series User manual

Tektronix

Tektronix 575 series User manual

Tektronix

Tektronix 2215A Assembly instructions

Tektronix

Tektronix SD-24 User manual

Tektronix

Tektronix 2 Series Instruction manual

Tektronix

Tektronix TU-7 User manual

Tektronix

Tektronix 7603 User manual