Teledyne WORKHORSE II Quick reference guide

Other Teledyne Marine Equipment manuals

Teledyne

Teledyne WORKHORSE II Quick reference guide

Teledyne

Teledyne MB1 User manual

Teledyne

Teledyne WORKHORSE Quick reference guide

Teledyne

Teledyne SeaBat T Series User manual

Teledyne

Teledyne Everywhereyoulook WAYFINDER User manual

Teledyne

Teledyne RIVERPRO User manual

Teledyne

Teledyne Everywhereyoulook STREAMPRO Quick reference guide

Teledyne

Teledyne PINNACLE 45 Quick reference guide

Teledyne

Teledyne TASMAN Quick setup guide

Teledyne

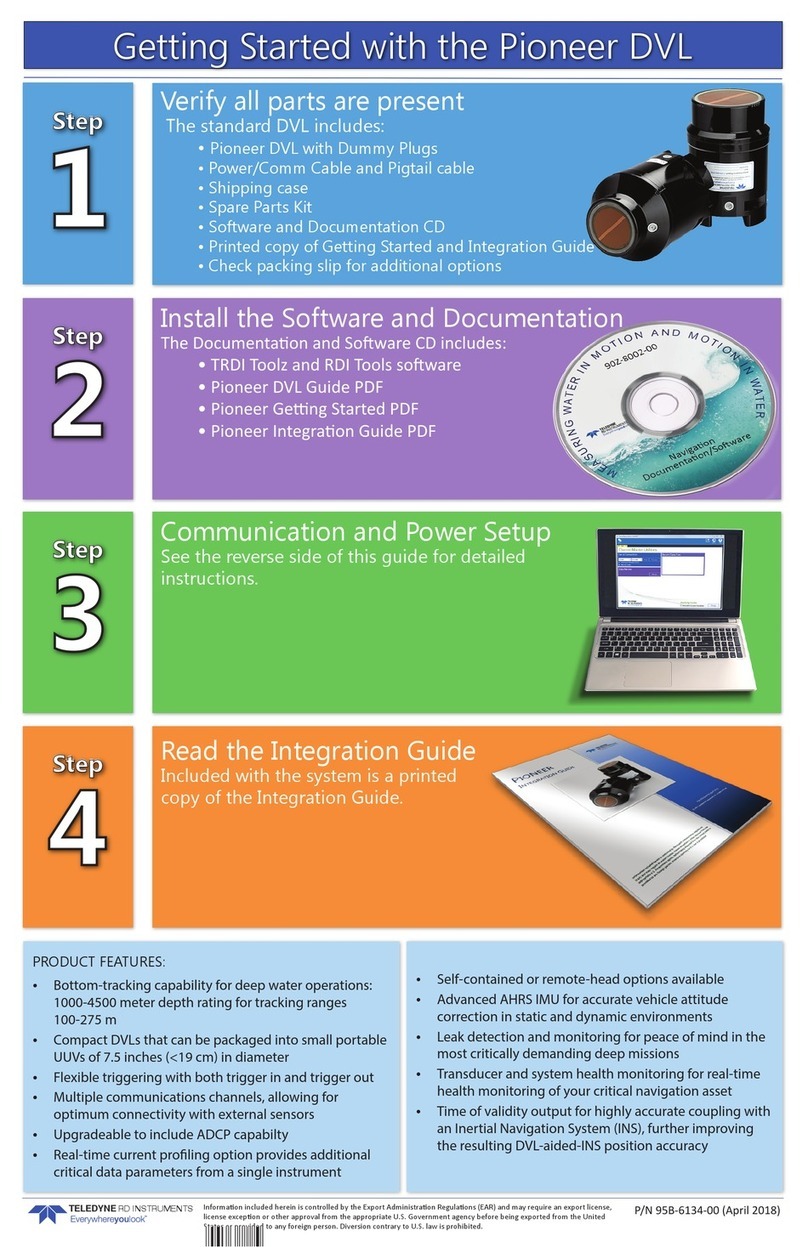

Teledyne Pioneer DVL User manual

Teledyne

Teledyne LONGRANGER Quick reference guide

Teledyne

Teledyne Everywhereyoulook SENTINEL V Quick reference guide

Teledyne

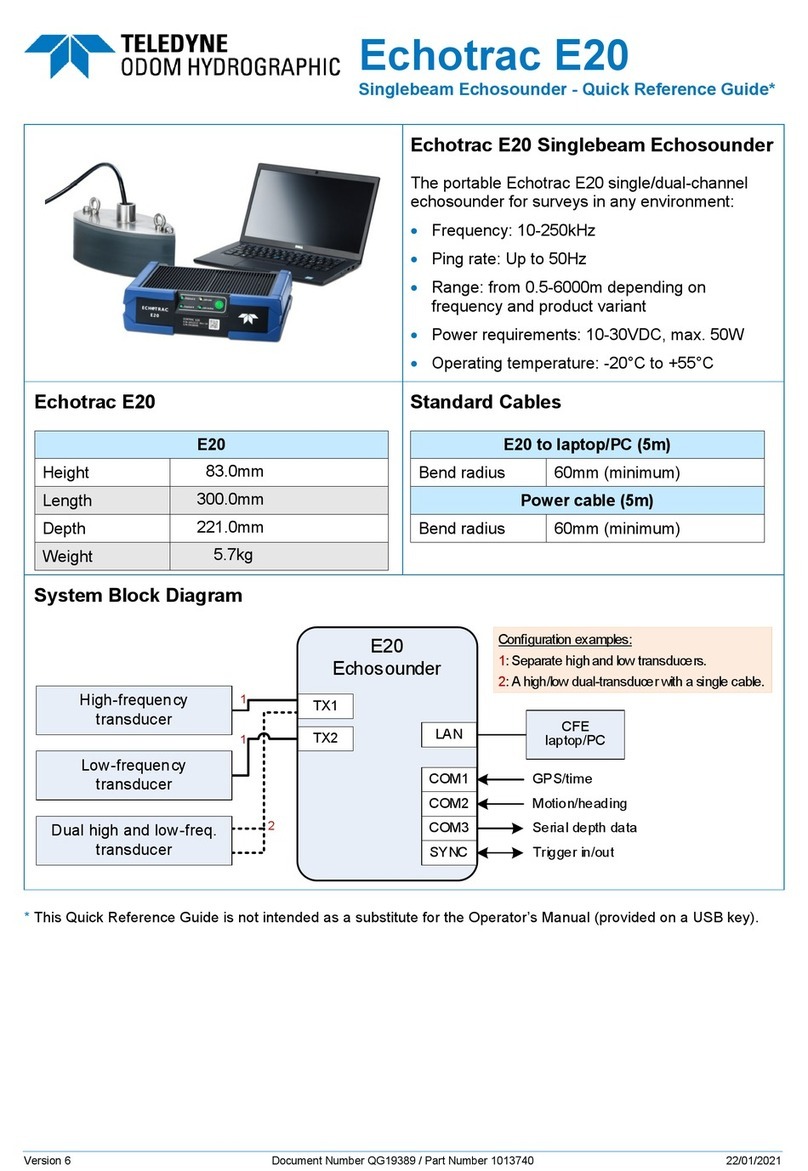

Teledyne Echotrac E20 User manual

Teledyne

Teledyne PINNACLE 45 Quick reference guide

Teledyne

Teledyne RAPIDCAST Quick reference guide

Teledyne

Teledyne WORKHORSE II User manual

Teledyne

Teledyne STREAMPRO User manual

Teledyne

Teledyne RIVERRAY Quick reference guide

Teledyne

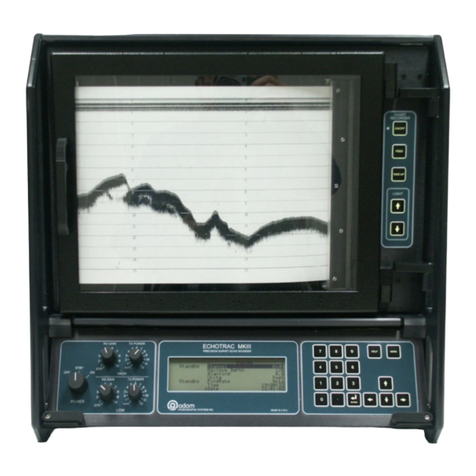

Teledyne Echotrac MKIII User manual

Popular Marine Equipment manuals by other brands

Raymarine

Raymarine Maxiview ST80 Owner's handbook

GUIDANCE MARINE

GUIDANCE MARINE 20- Series Installer's guide

Raymarine

Raymarine ST60 Tridata Owner's handbook

Sonic

Sonic 2024 Operation manual

Quicksilver

Quicksilver 88688A25 Installation, operation and maintenance instructions

Furuno

Furuno Navtex NX-700-A Operator's manual