2

Contents

Introduction .................................................................................................................................3

Initial operation of instrument ....................................................................................................4

Description of instrument ...........................................................................................................6

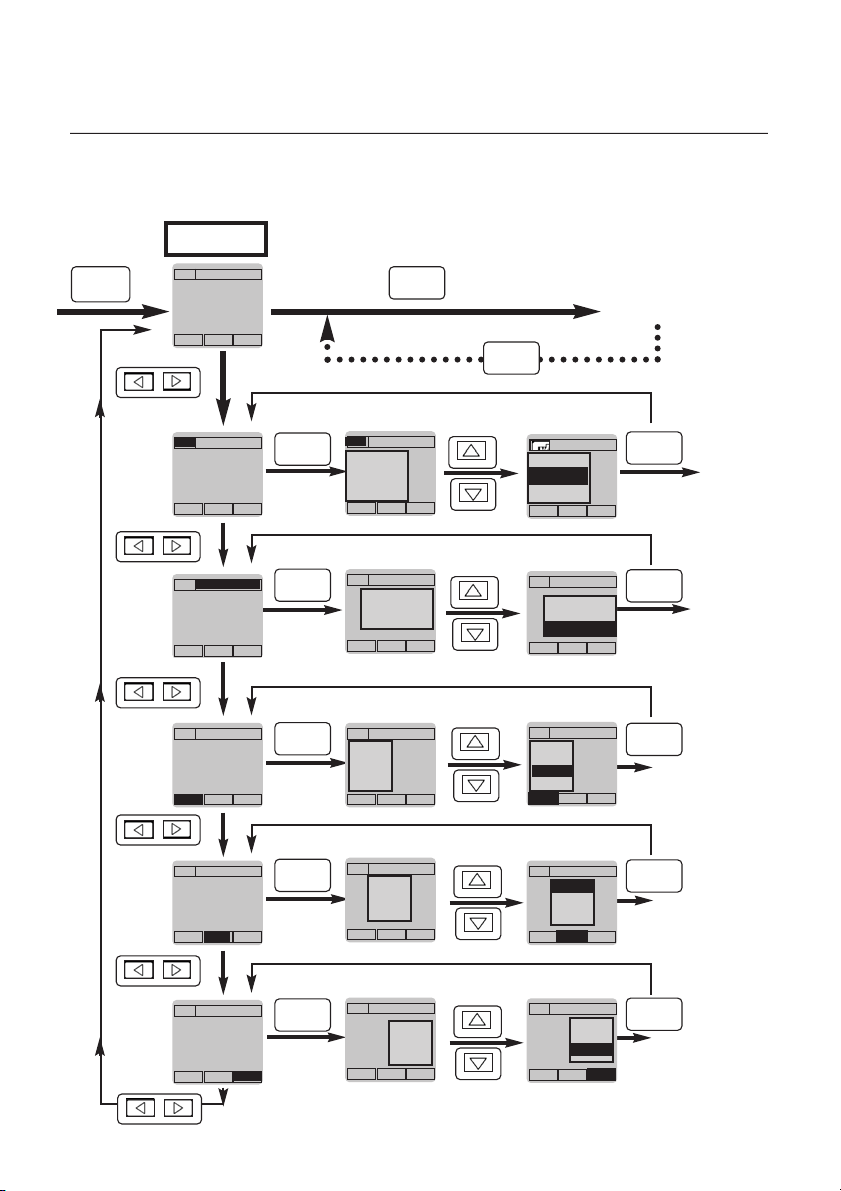

Function fields .......................................................................................................................8

Menu overview / Configuration..............................................................................................9

Allocation options of function buttons ........................................................................10

Initial operation of printer

Attachable printer 0554.0570..............................................................................................12

Instrument and error messages ...............................................................................................15

Resetting instrument data ........................................................................................................16

Data management.....................................................................................................................17

Working with the barcode.........................................................................................................18

Examples of measuring tasks

Temperature measurement ..............................................................................................19

Humidity measurement ....................................................................................................24

aw value measurement.....................................................................................................28

Automatic storing..............................................................................................................30

Velocity measurement.......................................................................................................37

WBGT measurement.........................................................................................................44

NET measurement.............................................................................................................45

Pressure measurement .....................................................................................................46

rpm measurement .............................................................................................................46

Current/voltage measurement..........................................................................................47

Barometric measurement .................................................................................................48

Leak detection probe........................................................................................................49

CO measurement/ CO2measurement .............................................................................50

Power supply.............................................................................................................................51

Update on disk ..........................................................................................................................52

Technical data ...........................................................................................................................53

Ordering data.............................................................................................................................55

Index ...................................................................................................................................64

The conformity certificate confirms that the instruments meet

89/336/EWG guidelines.

©2002 Copyright Testo AG

The software and software structure included in the product testo 400 are protected by

copyright laws worldwide.