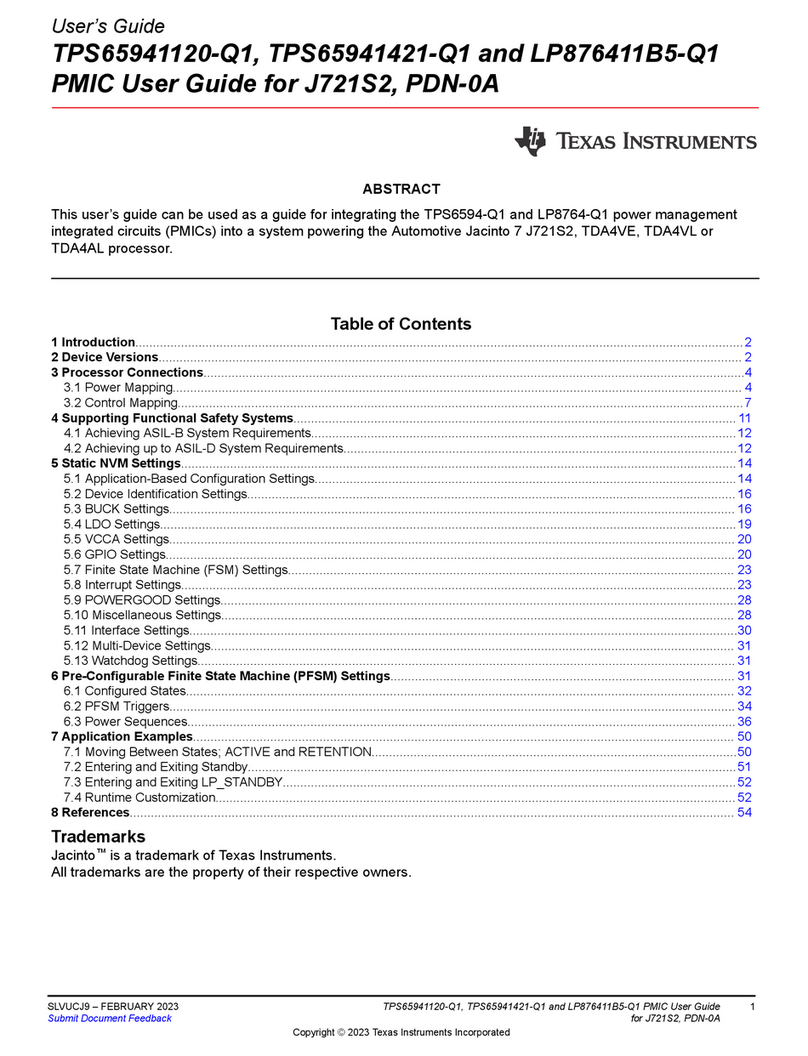

User’s Guide

Dual TPS6594-Q1 PMIC User Guide for Jacinto 7 DRA829

and TDA4VM Automotive PDN-0B

ABSTRACT

This User’s Guide can be used as a guide for integrating the TPS6594-Q1 power management integrated circuit

(PMIC) into a system powering the DRA829 or TDA4VM processor.

Table of Contents

1 Introduction.............................................................................................................................................................................2

2 Device Versions...................................................................................................................................................................... 2

3 Processor Connections..........................................................................................................................................................4

3.1 Power Mapping.................................................................................................................................................................. 4

3.2 Control Mapping.................................................................................................................................................................7

4 Supporting Functional Safety Systems..............................................................................................................................10

4.1 Achieving ASIL-B System Requirements......................................................................................................................... 11

4.2 Achieving up to ASIL-D System Requirements................................................................................................................11

5 Static NVM Settings..............................................................................................................................................................13

5.1 Application-Based Configuration Settings........................................................................................................................13

5.2 Device Identification Settings........................................................................................................................................... 14

5.3 BUCK Settings................................................................................................................................................................. 14

5.4 LDO Settings....................................................................................................................................................................16

5.5 VCCA Settings................................................................................................................................................................. 17

5.6 GPIO Settings.................................................................................................................................................................. 17

5.7 Finite State Machine (FSM) Settings............................................................................................................................... 20

5.8 Interrupt Settings..............................................................................................................................................................20

5.9 POWERGOOD Settings...................................................................................................................................................23

5.10 Miscellaneous Settings.................................................................................................................................................. 24

5.11 Interface Settings............................................................................................................................................................25

5.12 Multi-Device Settings..................................................................................................................................................... 26

5.13 Watchdog Settings......................................................................................................................................................... 26

6 Pre-Configurable Finite State Machine (PFSM) Settings.................................................................................................. 26

6.1 Configured States............................................................................................................................................................ 27

6.2 PFSM Triggers................................................................................................................................................................. 28

6.3 Power Sequences............................................................................................................................................................ 29

7 References............................................................................................................................................................................ 47

Trademarks

Jacinto™ are trademarks of Texas Instruments.

All trademarks are the property of their respective owners.

www.ti.com Table of Contents

SLVUC32 – JUNE 2021

Submit Document Feedback

Dual TPS6594-Q1 PMIC User Guide for Jacinto 7 DRA829 and TDA4VM

Automotive PDN-0B

1

Copyright © 2021 Texas Instruments Incorporated