Thermo Scientific HyPerforma DynaDrive 500 L User manual

Other Thermo Scientific Laboratory Equipment manuals

Thermo Scientific

Thermo Scientific Dionex TCC-100 User manual

Thermo Scientific

Thermo Scientific RVT5105 Programming manual

Thermo Scientific

Thermo Scientific 1300 Series User manual

Thermo Scientific

Thermo Scientific 2870 Operating instructions

Thermo Scientific

Thermo Scientific MEGA-PURE 11A Water Still 677 Series User manual

Thermo Scientific

Thermo Scientific Multidrop Combi+ User manual

Thermo Scientific

Thermo Scientific SHKE8000 Series User manual

Thermo Scientific

Thermo Scientific SL40 F User manual

Thermo Scientific

Thermo Scientific 88882011 User manual

Thermo Scientific

Thermo Scientific Sorvall RC-4 User manual

Thermo Scientific

Thermo Scientific SimpliAmp Quick start guide

Thermo Scientific

Thermo Scientific HM525 NX Series Manual

Thermo Scientific

Thermo Scientific STERI-CYCLE i160 LK User manual

Thermo Scientific

Thermo Scientific 3767A User manual

Thermo Scientific

Thermo Scientific Dionex Integrion HPIC Manual

Thermo Scientific

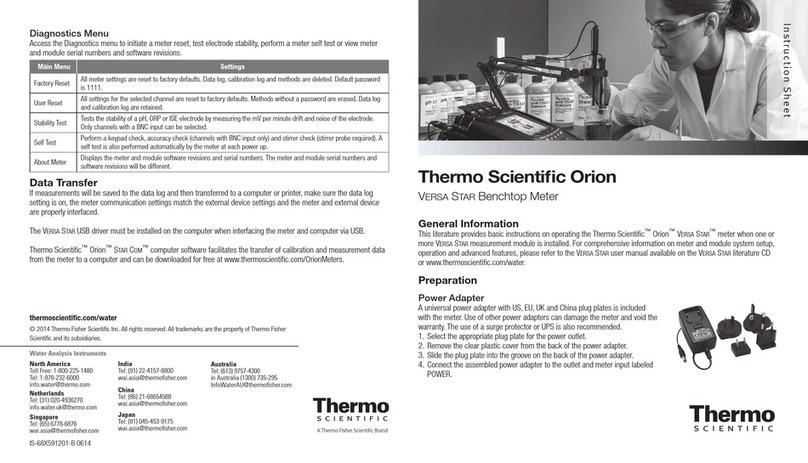

Thermo Scientific Orion Versa Star User manual

Thermo Scientific

Thermo Scientific AI 3000 User manual

Thermo Scientific

Thermo Scientific Microm HM355S User manual

Thermo Scientific

Thermo Scientific TSE Series Operating instructions

Thermo Scientific

Thermo Scientific Sorvall ST40 User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

VWR

VWR SAS Super IAQ instruction manual

illumina

illumina MiSeqDx reference guide