Thinkcar TK-IMT602 User manual

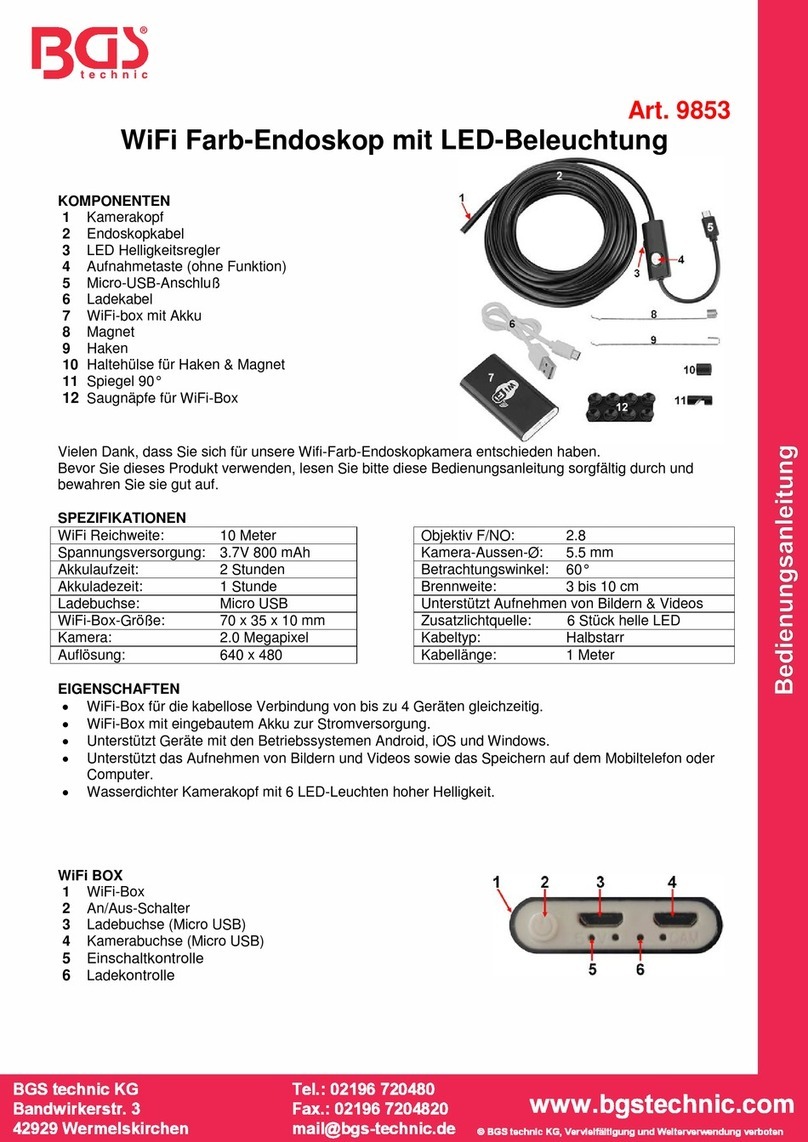

TK-IMT602 Fuel Injector Cleaner & Tester

User Manual

Thinkcar Tech Inc

Follow us on

@thinkcar.official @ObdThinkcar

THINKCAR

www.thinkcar.com

Content

1 Introduction.............................................................................................................1

2 Function & Specifications......................................................................................1

2.1 Main functions........................................................................................................................1

2.2 Main Features........................................................................................................................1

2.3 Working environment & Technical parameters ....................................................................2

3 Structural composition...........................................................................................2

3.1 Overview ...............................................................................................................................2

3.2 Control Panel ........................................................................................................................3

3.3 Tool drawer description..........................................................................................................4

4 Operating Procedures.............................................................................................4

4.1 Ultrasonic Cleaning................................................................................................................4

4.1.1 Preparation...................................................................................................................4

4.1.2 Method and Steps........................................................................................................5

4.2 Test Function..........................................................................................................................5

4.2.1 Preparation...................................................................................................................5

4.2.2 Method and Steps........................................................................................................6

4.3 Reverse Flushing...................................................................................................................9

4.3.1 Preparations.................................................................................................................9

4.3.2 Methods and steps......................................................................................................10

4.4 No disassembly cleaning......................................................................................................11

4.4.1 Preparations...............................................................................................................11

4.4.2 Methods and Steps....................................................................................................11

5 Maintenance...........................................................................................................12

5.1 Organization.........................................................................................................................12

5.2 Maintenance.........................................................................................................................13

6 General Notice........................................................................................................13

7 Warranty Service....................................................................................................13

8 Warranty Terms......................................................................................................14

9 Packing list of TK-IMT602 Injector Cleaner & Tester.......................................15

THINKCAR THINKCAR

www.thinkcar.com www.thinkcar.com

1 Introduction

Thinkcar TK-IMT602 Injector Cleaner & Tester is an electronic mechanical product which

combining ultrasonic clean technology and microcomputer control simulation automobile fuel

injection technology. The product uses efficient ultrasonic and the solubility of the cleaning

liquid to clean the surface of injectors to recover its original characteristics. At the same time,

the product simulates various working conditions of the engine, and tests injectors of various

cars. The products is necessary for the automobile maintenance, repair shops, research and

teaching and training departments.

2 Function & Specifications

2.1 Main functions

· Ultrasonic Cleaning: To perform simultaneous cleaning on one or several injectors and to

remove the carbon deposits on the injector completely.

· Reverse Flushing: to remove the dirt inside the injector and attached to the filter.

· No disassembly cleaning: The unit is equipped with various adaptors and couplers that

facilitate cleaning on the injectors on vehicle (additional tools and special liquids).

· Atomization observation: to carefully observe the spray atomization of the fuel injectors

under background lamp.

· Sealing test: test the sealing and leakage of injectors under high pressure.

· Uniformity test: detect the uniformity of each injector.

· Automatic cleaning detection: real simulation of injectors test under various conditions.

· Injection Detection: the injection fuel amount of injectors under specific operating

parameters ( for example in the same time or the same times) can be detected.

2.2 Main Features

· Ultrasonic powerful cleaning technology has strong cleaning ability.

· Electronic pressure regulating control technology, stable oil pressure, wide adjustable range.

· BOSCH oil pump can ensure long-term and stable use.

· High-definition digital tube display makes the operation clear and easy to learn.

· Fuel tank level is visually displayed, and the test liquid can be recycled.

· Bright background light for a clear view of the injector operation.

· Applicability wide, It can work for different types of injector with compound adapters.

· Allow arbitrary adjustment the test time, operating frequency, oil injection times, minimum

switching cycle of the injectors within the allowable range.

2.3 Working environment & Technical parameters

Power supply AC 220 V/ 110 V ± 10%

Frequency 50 Hz / 60 Hz ± 0.5

Relative humidity < 90 %

Ambient temperature 0℃~ + 50℃

Notice No open fire is allowed around.

External magnetic field strength < 400 A/m

Oil tank volume 1500 ml

Measuring cylinder volume 125 ml

Speed 0 ~ 7500 r/ min

Injection times 0~7500, steps 100 ms

PWM width 0~20.0 ms, step 0.1 ms

System pressure 0~72 psi (adjustable)

Timiming 0~20 min (adjustable)

Input power 250 W

Ultrasonic cleaning power 70 W (intermittent operation)

Ultrasonic cleaning frequency 28 KHz ± 0.5 KHz

Dimensions (L x W x H) 380 mm × 485 mm × 470 mm

Net weight 16 Kg

3 Structural composition

3.1 Overview

1 2

Working panel

Glass measuring cylinder

(add test liquid)

Oil drain handle

Tool drawer

Power interface

Test wire interface

Oil inlet pipe

Lock nut

Ultrasonic tank

(add cleaning liquid)

Injector

THINKCAR THINKCAR

www.thinkcar.com www.thinkcar.com

3.2 Control Panel

FUNCTIONS/PULSE WIDTH

Four - bit red tube displays selected functions. Select the function【FUNCITONS MENU】in

order by【+】and【-】.【01】means the top one,【13】means the last one. When the

machine is in startup, press【+】and【-】can change the pulse width ratio, affecting the

amount of oil injected.

WORKING/INJECTING TIMES

Four - bit red tube displays time, each function runs with the default time. When it needs to be

increased, it can change the working time by pressing【+】and 【-】before clicking

【START】.

PRESSURE REGULATING

The pressure gauge is used to display the working pressure ( 0 ~ 72psi ). The pressure of the

test fluid is increased or decreased by【+】and 【-】icons to simulate the pressure of

automobile fuel injection.

FUNCITONS MENU

The function list is detailed and needs to be selected by the【+】and 【-】buttons of

【FUNCTIONS / PULSE WIDTH】.

START

Press to execute the functions selected in【FUNCTIONS/PULSE WIDTH】.

PAUSE

Stop the selected function temporarily and press 【START】again to continue.

STOP

Stop the selected function immediately and return the selected function item.

3.3 Tool drawer description

(1) Adaptors for reverse cleaning

(2) 10-13.6 mm conical adaptor for spray testing

(3) 11mm Japanese Automotive Fittings for Jet Testing

(4) Round plug, need to be used when not testing all 6 cylinders

(5) Special oil nozzle gasket, some oil nozzles are small, used for fixing

(6) The oil rail, the joint is screwed on this groove, the nozzle is connected to the head,

and it is pressed tightly.

(7) Adapter cable, used to solve some special nozzle electronic interface

(8) The cleaning fluid drain valve is installed on the back of the machine after

disassembly. In order to prevent liquid leakage, it must be covered with sealant

(9) The fuel injector locks the screw nut for pressing the fuel rail and the nozzle.

4 Operating Procedures

4.1 Ultrasonic Cleaning

Ultrasonic cleaning is the penetration and cavitation shock wave generated by the ultrasonic

wave propagating in the medium. The object with complex shape, inner cavity and fine pores is

strongly cleaned to completely remove the stubborn carbon on the injector.

4.1.1 Preparation

1)Remove the injector from the vehicle and carefully check the rubber seal of the injector for

damage. If it is damaged, replace the same type of seal before the cleaning test, in order to

avoid leakage during the test. Put the nozzle into gasoline or detergent, carefully remove

the external oil and wipe it with a soft cloth.

2)Turn on the power. Plug the end of the power cord into the socket of the equipment and the

other end into the AC 220 V power outlet. Turn on the power switch at the side of the main

unit.

3)Take out the cleaning bracket from the accessory box, put it into the ultrasonic tank, and

place the outside cleaned injector on the positioning hole of the cleaning bracket in the

ultrasonic tank.

4.1.2 Method and Steps

【01】Ultrasonic Cleaning

1) Add an right amount of cleaning liquid to the ultrasonic tank. Generally, the cleaning liquid

can be immersed over the cleaning bracket.

2) Insert the injector pulse signal line into the injector separately. (Special injectors need to be

connected with an adapter cable)

3) Press the【+】and【-】keys of【FUNCTIONS/PULSE WIDTH】to select【01】,

corresponding to the【Ultrasonic Cleaning】option, then press the【+】and【-】keys of

【WORKING/INJECTING TIMES】to set the time. (The system defaults to 10 minutes.

Please use the up and down keys for modification if needed)

4) Press【START】. (Press【PAUSE】to suspend or press【STOP】to exit during working)

5) The working time is counting down. When it is 0, the system automatically stops.

6) Take the nozzle from the ultrasonic tank and clean the cleaning liquid with a soft cloth to

prepare for the next job.

! Note:

· During the cleaning process, you can hear the intermittent (approximately 5 seconds)

vibrating sound when you take the injector out and put it next to your ear, to judge whether

the injector is working properly.

· In the case that the ultrasonic tank is not filled with cleaning liquid, don’t perform ultrasonic

cleaning, otherwise the ultrasonic equipment will be damaged.

4.2 Test Function

This function is to detect the atomization, dripping, blockage, fuel injection angle status of the

injector, and the size and balance of the fuel injection volume of each injector at different

speeds.

4.2.1 Preparation

1)Add test liquid,as shown below.

Add test liquid

(Right amount is 1200 ML, and the liquid level should not be lower than 1000 ML normally)

1 2 3 4 5

6

7

8

9

25 125

150

10

8

6

4

2

0

psi

kg/cm2

50

75

100

0

8.8.8.8.

8.8.8.8.

3 4

THINKCAR THINKCAR

www.thinkcar.com www.thinkcar.com

4 Operating Procedures

4.1 Ultrasonic Cleaning

Ultrasonic cleaning is the penetration and cavitation shock wave generated by the ultrasonic

wave propagating in the medium. The object with complex shape, inner cavity and fine pores is

strongly cleaned to completely remove the stubborn carbon on the injector.

4.1.1 Preparation

1)Remove the injector from the vehicle and carefully check the rubber seal of the injector for

damage. If it is damaged, replace the same type of seal before the cleaning test, in order to

avoid leakage during the test. Put the nozzle into gasoline or detergent, carefully remove

the external oil and wipe it with a soft cloth.

2)Turn on the power. Plug the end of the power cord into the socket of the equipment and the

other end into the AC 220 V power outlet. Turn on the power switch at the side of the main

unit.

3)Take out the cleaning bracket from the accessory box, put it into the ultrasonic tank, and

place the outside cleaned injector on the positioning hole of the cleaning bracket in the

ultrasonic tank.

4.1.2 Method and Steps

【01】Ultrasonic Cleaning

1) Add an right amount of cleaning liquid to the ultrasonic tank. Generally, the cleaning liquid

can be immersed over the cleaning bracket.

2) Insert the injector pulse signal line into the injector separately. (Special injectors need to be

connected with an adapter cable)

3) Press the【+】and【-】keys of【FUNCTIONS/PULSE WIDTH】to select【01】,

corresponding to the【Ultrasonic Cleaning】option, then press the【+】and【-】keys of

【WORKING/INJECTING TIMES】to set the time. (The system defaults to 10 minutes.

Please use the up and down keys for modification if needed)

4) Press【START】. (Press【PAUSE】to suspend or press【STOP】to exit during working)

5) The working time is counting down. When it is 0, the system automatically stops.

6) Take the nozzle from the ultrasonic tank and clean the cleaning liquid with a soft cloth to

prepare for the next job.

! Note:

· During the cleaning process, you can hear the intermittent (approximately 5 seconds)

vibrating sound when you take the injector out and put it next to your ear, to judge whether

the injector is working properly.

· In the case that the ultrasonic tank is not filled with cleaning liquid, don’t perform ultrasonic

cleaning, otherwise the ultrasonic equipment will be damaged.

4.2 Test Function

This function is to detect the atomization, dripping, blockage, fuel injection angle status of the

injector, and the size and balance of the fuel injection volume of each injector at different

speeds.

4.2.1 Preparation

1)Add test liquid,as shown below.

2)Installation of injector

Installation of up-inlet injector

Installation diagram of up-inlet injector

a) Select the fuel injection assembly and oil separator plug from the accessory box, and install

them into the oil separator.

b) Install the injector in the forward direction (apply a small amount of grease on the “O” ring of

the injector).

c) Horizontally put the oil separator and the injector on the upper plate base, and tighten the

two ends with the locking rod, to prepare for the test. (Special injectors must use extension

rods, for example, micro-faces must also use extension pads or backing plates)

4.2.2 Method and Steps

【02】Idling Test (0-20 ms)

Add test liquid

(Right amount is 1200 ML, and the liquid level should not be lower than 1000 ML normally)

1)Connect the quick connector of the black oil outlet pipe on the machine with the male end

connector on the oil separator, and plug the fuel injector drive line.

2)Press the【+】and【-】buttons of 【FUNCTIONS/PULSE WIDTH】to select 【02】

Idling Test.

3)Press up and down keys of working time to set the time. (Generally set to 2 minutes)

4)Press【START】to start working.

5)Press【+】and【-】keys of 【PRESSURE PE GULATING】to adjust the pressure to

36-45 psi. (In the electronic injection system, the general oil pressure works at 36-45 psi)

6)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select the

corresponding pulse width.(Default system set is 3MS, normal adjustment is 3MS). Press

the oil drain handle in order to observe the level of the oil.

7)The working time is counting down until 0, the system will automatically stop.

8)When the test completed, uplift the oil drain handle and put the test liquid back to the oil

tank.

【03】Medium Speed

1) Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【03】

Medium Speed test mode.

2)Press 【START】key.

3)The following operation procedures is same with the 02 item.

【04】High speed Test(0-4 ms)

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【04】High

Speed Test mode.

2)Press START key

3)The following operation procedures is same with the 02 item.

【05】Accelerating Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select 【05】

Accelerating Test mode.

2)Press 【START】key.

! Note:

· The system will set the fuel pressure, working time and pulse width systems automatically,

default time is 10s as one circulation period. User’s setting is unnecessary.

· The system will automatically simulate the working status and oil inject value of injector at

700-7500 rpm constant accelerate condition in three times.

【06】Shifting Speed Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select 【06】

Shifting Speed Test mode.

Oil Separator

Up-inlet Composite

Assembly

Up-inlet Injector

5 6

【09】Medium Speed Spray Value Test

1)Press the【+】and【-】key of 【FUNCTIONS/PULSE WIDTH】to select the 09 Medium

Speed Spray Value Test mode.

2)The following operation procedures is same with the 08 item.

【10】High Speed Spray Value Test

1)Press the【+】and【-】key of 【FUNCTIONS/PULSE WIDTH】to select the 10 High

Speed Spray Value Test mode.

2)The following operation procedures is same with the 08 item.

! Note:

· Flow equilibrium: Test the flow equilibrium under different rmp, when the test liquid level

at 2/3 of the counting instrument, it will pause or stop work. The deviation of the inject

value should not exceed 2% for all the nozzle of one vehicle. Please refer to the relative

tech-manual of injector nozzle, in order to observe the flow equilibrium.

· Injector shape observation: Observe the injection shape, angle uniformity of all the

injector nozzle of one vehicle. And adjust the injector nozzle open pulse width

simultaneously, observe the uniformity of the minimum open pulse width.

· Leakage test: Detect the nozzle valve seal under system high pressure.(Observe the

nozzle seal, it should not has the leakage in one minute normally.

4.3 Reverse Flushing

Reverse Flushing, The test liquid from the outlet to the inlet, it can wash the dirt out from the

internal parts of the nozzle and filter mesh.

4.3.1 Preparations

1) Add test liquid, reference to 4.2.1.

(Approximately fill about 1800 ml. The liquid level should not be lower than 1000 ml normally)

2) Reverse flushing installation of the top-injection nozzle.

THINKCAR THINKCAR

www.thinkcar.com www.thinkcar.com

2)Installation of injector

Installation of up-inlet injector

Installation diagram of up-inlet injector

a) Select the fuel injection assembly and oil separator plug from the accessory box, and install

them into the oil separator.

b) Install the injector in the forward direction (apply a small amount of grease on the “O” ring of

the injector).

c) Horizontally put the oil separator and the injector on the upper plate base, and tighten the

two ends with the locking rod, to prepare for the test. (Special injectors must use extension

rods, for example, micro-faces must also use extension pads or backing plates)

4.2.2 Method and Steps

【02】Idling Test (0-20 ms)

1)Connect the quick connector of the black oil outlet pipe on the machine with the male end

connector on the oil separator, and plug the fuel injector drive line.

2)Press the【+】and【-】buttons of 【FUNCTIONS/PULSE WIDTH】to select 【02】

Idling Test.

3)Press up and down keys of working time to set the time. (Generally set to 2 minutes)

4)Press【START】to start working.

5)Press【+】and【-】keys of 【PRESSURE PE GULATING】to adjust the pressure to

36-45 psi. (In the electronic injection system, the general oil pressure works at 36-45 psi)

6)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select the

corresponding pulse width.(Default system set is 3MS, normal adjustment is 3MS). Press

the oil drain handle in order to observe the level of the oil.

7)The working time is counting down until 0, the system will automatically stop.

8)When the test completed, uplift the oil drain handle and put the test liquid back to the oil

tank.

【03】Medium Speed

1) Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【03】

Medium Speed test mode.

2)Press 【START】key.

3)The following operation procedures is same with the 02 item.

【04】High speed Test(0-4 ms)

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【04】High

Speed Test mode.

2)Press START key

3)The following operation procedures is same with the 02 item.

【05】Accelerating Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select 【05】

Accelerating Test mode.

2)Press 【START】key.

! Note:

· The system will set the fuel pressure, working time and pulse width systems automatically,

default time is 10s as one circulation period. User’s setting is unnecessary.

2)Press 【START】key.

! Note:

· The system will set the fuel pressure, working time and pulse width systems automatically,

default time is 10s as one circulation period. User’s setting is unnecessary.

· The system will automatically simulate the working status and oil inject value of injector at

Idle Speed (700rpm), Medium Speed(4,500rpm) and High Speed (7,500rpm) working

condition in three times.

【07】Leak checking Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【07】

Leakage checking Test mode.

2)Press the【+】and【-】key of the【WORKING TIMES】to set time. (General setting is

one minute)

3)The following operation procedures is same with the 02 item.

! Note:

· Default pulse width system is 3 ms.

· Simulate the system pressure under 45 psi and test whether the injector has dripping.

【08】Idling Spray Value Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【08】Idling

Spray Value Test mode.

2) Press the【+】and【-】key of the【WORKING/INJECTING TIMES】to set times.

(General time is 2,000)

3)The following operation procedures is same with the 02 item.

! Note:

Simulate the working status and inject value under the idle speed of engine in several times.

· The system will automatically simulate the working status and oil inject value of injector at

700-7500 rpm constant accelerate condition in three times.

【06】Shifting Speed Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select 【06】

Shifting Speed Test mode.

7 8

3) The system default time is 1 minute. Press【START】to start working.

4) Adjust the pressure to 36 - 45 psi.

5) The remaining working time reduces gradually. When it goes to 0, the system automatically

stops.

6) After the test, raise the drain handle and put the test agent back into the fuel tank.

! Note:

· Reverse flushing is applicable to top-injection nozzles only.

· In reverse flushing, the pulse width parameter of the fuel injector has been automatically

set in the program, and users do not need to set it separately.

· Test liquid must be clean in the tank, to avoid clogging injector nozzle.

4.4 No disassembly cleaning

After the engine fuel supply system has been used for a period of time, the dust in the air and

the impurities in the gasoline will make the fuel path unsmooth or blocked. In addition, the

carbon deposits and gums produced during the combustion process will adhere to injector

nozzle, fuel inlet, exhaust valve, throttle valve and combustion chamber. Therefore, it is

necessary to clean the engine fuel supply system, combustion chamber and fuel injection

nozzles in time.

4.4.1 Preparations

1 ) Open the oil drain screw at the bottom of the main engine to release all the test liquid in the

oil tank.

2) Open the hood of the car to find the fuel inlet and return pipes of the fuel supply system of

the car.

4.4.2 Methods and Steps

【12】No disassembly cleaning (need to purchase additional accessories)

* This function requires Special cleaning fluid and tools, please use it with caution.

1) Connect the male end of the red non-dismantling pipe to the oil return pipe of the fuel

supply system (choose a suitable connector from the accessory box), and the other end to

the male end on the upper right side of the equipment.

2) Start the engine to extract 600ml-800ml gasoline from the car tank through the oil return

pipe (watching through the right window of the machine), and then turn off the engine.

3) Connect the male end of the blue non-dismantling pipe to the oil inlet pipe of the fuel supply

system, (choose the right connector from the accessory box), and the other end to the black

high-pressure oil pipe of the equipment.

4) Unplug the car oil pump fuse or oil pump relay in the condition of not affecting the work of

other systems, or find a suitable connector from the accessory box to connect the oil inlet

【09】Medium Speed Spray Value Test

1)Press the【+】and【-】key of 【FUNCTIONS/PULSE WIDTH】to select the 09 Medium

Speed Spray Value Test mode.

2)The following operation procedures is same with the 08 item.

【10】High Speed Spray Value Test

1)Press the【+】and【-】key of 【FUNCTIONS/PULSE WIDTH】to select the 10 High

Speed Spray Value Test mode.

2)The following operation procedures is same with the 08 item.

! Note:

· Flow equilibrium: Test the flow equilibrium under different rmp, when the test liquid level

at 2/3 of the counting instrument, it will pause or stop work. The deviation of the inject

value should not exceed 2% for all the nozzle of one vehicle. Please refer to the relative

tech-manual of injector nozzle, in order to observe the flow equilibrium.

· Injector shape observation: Observe the injection shape, angle uniformity of all the

injector nozzle of one vehicle. And adjust the injector nozzle open pulse width

simultaneously, observe the uniformity of the minimum open pulse width.

· Leakage test: Detect the nozzle valve seal under system high pressure.(Observe the

nozzle seal, it should not has the leakage in one minute normally.

4.3 Reverse Flushing

Reverse Flushing, The test liquid from the outlet to the inlet, it can wash the dirt out from the

internal parts of the nozzle and filter mesh.

4.3.1 Preparations

1) Add test liquid, reference to 4.2.1.

(Approximately fill about 1800 ml. The liquid level should not be lower than 1000 ml normally)

2) Reverse flushing installation of the top-injection nozzle.

2)Press 【START】key.

! Note:

· The system will set the fuel pressure, working time and pulse width systems automatically,

default time is 10s as one circulation period. User’s setting is unnecessary.

· The system will automatically simulate the working status and oil inject value of injector at

Idle Speed (700rpm), Medium Speed(4,500rpm) and High Speed (7,500rpm) working

condition in three times.

【07】Leak checking Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【07】

Leakage checking Test mode.

2)Press the【+】and【-】key of the【WORKING TIMES】to set time. (General setting is

one minute)

3)The following operation procedures is same with the 02 item.

! Note:

· Default pulse width system is 3 ms.

· Simulate the system pressure under 45 psi and test whether the injector has dripping.

【08】Idling Spray Value Test

1)Press the【+】and【-】key of the【FUNCTIONS/PULSE WIDTH】to select【08】Idling

Spray Value Test mode.

2) Press the【+】and【-】key of the【WORKING/INJECTING TIMES】to set times.

(General time is 2,000)

3)The following operation procedures is same with the 02 item.

! Note:

Simulate the working status and inject value under the idle speed of engine in several times.

THINKCAR THINKCAR

www.thinkcar.com www.thinkcar.com

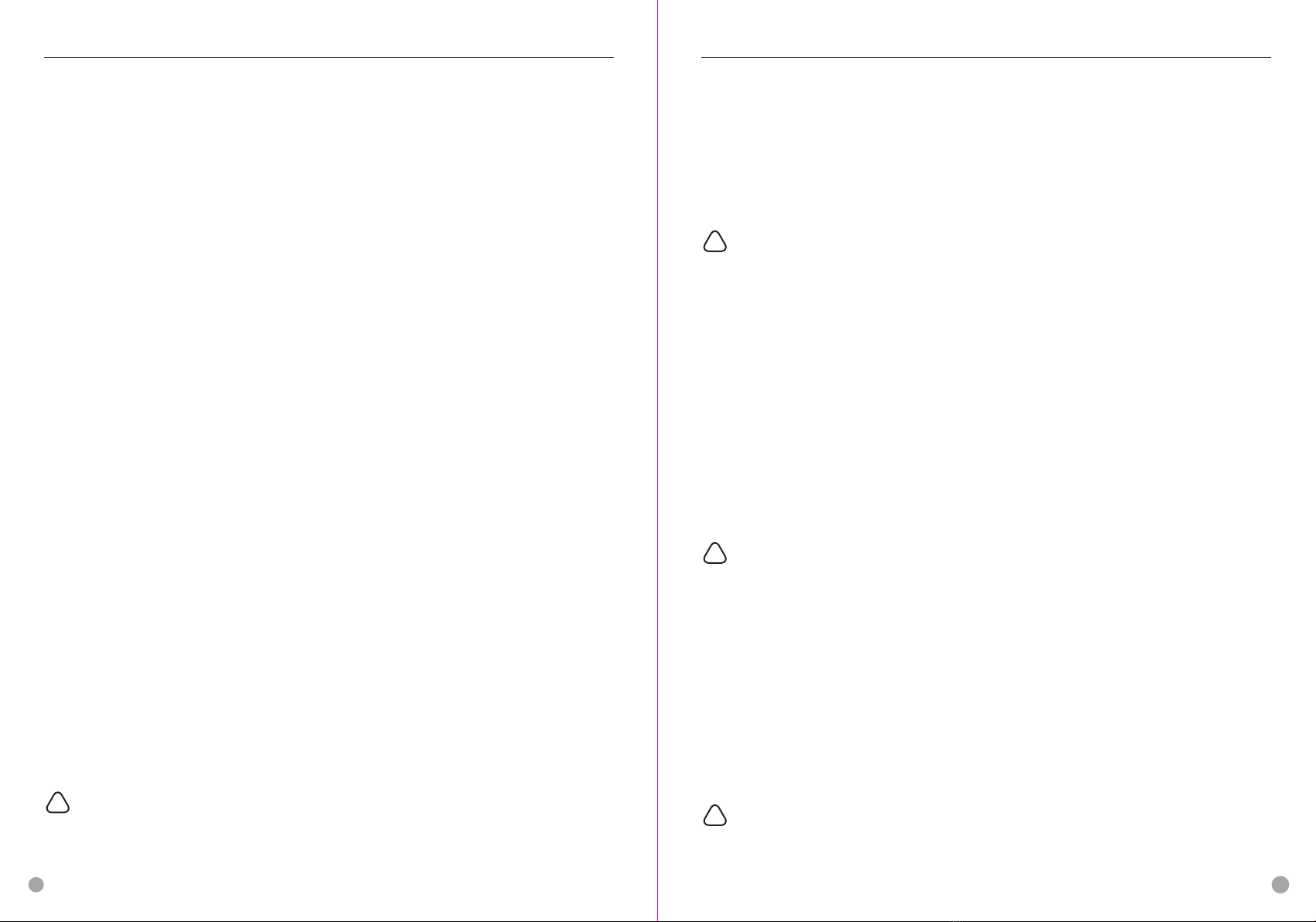

a. Select the upper recoil coupler (part 5) and the oil separator end cap to plug into the oil

separator (part 4) from the accessory box.

b. Put the recoil seal ring (part 6) on the fuel injection nozzle, (as shown in the figure), and

then install the fuel injection nozzle in the opposite direction. (The oil outlet is facing

upwards and the oil inlet is facing downwards)

c. Select the lower recoil coupler (part 9) from the accessory box and place it on the oil inlet of

the upper plate base (part 10).

d. Place the oil separator 4 and the horizontal end of the fuel injector on the lower recoil

coupler (part 9), and tighten the two ends with the extension rod 8 and the locking rod 2.

Ready to test.

4.3.2 Methods and steps

【11】Reverse Flushing

1) Connect the quick connector of the black oil outlet pipe on the machine with the male end

connector on the oil separator, and insert the fuel injector drive line.

2) Press the【+】and【-】key of 【FUNCTIONS/PULSE WIDTH】to select item 11 “Reverse

Flushing".

1

2

3

4

5

6

7

8

9

10

11

and return pipes of the original car to make it a loop. (Note: The fuel tank cap must be

opened, otherwise it is dangerous.)

5) Turn on the power of the equipment, press the item selection key to select item 12 “No

disassembly cleaning", and press the time adjustment key to adjust the time to 20

minutes-30 minutes.

6) Set the pressure according to the technical requirements of the car. (Generally,

0.25-0.3MPa is suitable to most car models).

7) Press 【START】key. Wait a few seconds to start the engine.

8) After engine starts, pour the disassembly-free cleaning liquid from any round hole above the

glass tube of the equipment. (The ratio of disassembly-free liquid and fuel is about 1:4.

Normally 1/2 bottle for four-cylinder cars, 3/4 bottle for six-cylinder cars, and 1 bottle for

eight-cylinder cars)

9)Adjust the car throttle. (1-10 minutes idling operation, 10-15 minutes medium and

high-speed operation, the rest of the time idling operation)

10)The time gradually decreases, and when it is reduced to 0, the system automatically

stops. Remove the non-dismantling device, and recovery the car's oil inlet and return pipes

and insurance.

11)Start the engine and run the car at high speed for 2-3 minutes to discharge the washed

carbon deposits in the exhaust pipe. At the same time, check whether there is leakage at

the oil pipe interface of the vehicle's fuel supply system.

! Note:

· The cleaning liquid is flammable, so pay attention to safety when cleaning.

· Before cleaning, it must be confirmed that all pipelines are connected well and there is no

leakage.

【13】Device Information

Remark the the equipment serial number and date of manufacture

If the model or function is changed, operate according the operation panel description.

5 Maintenance

5.1 Organization

1)Turn off the power and unplug the power.

2)Put all the even parts and free-disassembly connectors back into the accessory box for

storage.

3)Put the ultrasonic cleaning liquid back into the original bottle and seal it, and wipe the

equipment clean with a dry soft cloth.

4)If it is not used for a long time, open the oil drain screw at the bottom of the main unit and

put the test liquid in the oil tank back into the original bottle for sealed preservation.

Schematic diagram of reverse flushing installation

1. Oil outlet pipe quick connector

2. Locking Lever

3. Oil Separator Joint

4. Oil rail

5. Upper Recoil Coupler

6. Recoil Seal Ring Φ24

7. Reverse installation of jacking oil injector

8. Extension Rod

9. Lower Recoil Coupler

10. Upper Plate Base

11. Measuring Cylinder

910

3) The system default time is 1 minute. Press【START】to start working.

4) Adjust the pressure to 36 - 45 psi.

5) The remaining working time reduces gradually. When it goes to 0, the system automatically

stops.

6) After the test, raise the drain handle and put the test agent back into the fuel tank.

! Note:

· Reverse flushing is applicable to top-injection nozzles only.

· In reverse flushing, the pulse width parameter of the fuel injector has been automatically

set in the program, and users do not need to set it separately.

· Test liquid must be clean in the tank, to avoid clogging injector nozzle.

4.4 No disassembly cleaning

After the engine fuel supply system has been used for a period of time, the dust in the air and

the impurities in the gasoline will make the fuel path unsmooth or blocked. In addition, the

carbon deposits and gums produced during the combustion process will adhere to injector

nozzle, fuel inlet, exhaust valve, throttle valve and combustion chamber. Therefore, it is

necessary to clean the engine fuel supply system, combustion chamber and fuel injection

nozzles in time.

4.4.1 Preparations

1 ) Open the oil drain screw at the bottom of the main engine to release all the test liquid in the

oil tank.

2) Open the hood of the car to find the fuel inlet and return pipes of the fuel supply system of

the car.

4.4.2 Methods and Steps

【12】No disassembly cleaning (need to purchase additional accessories)

* This function requires Special cleaning fluid and tools, please use it with caution.

1) Connect the male end of the red non-dismantling pipe to the oil return pipe of the fuel

supply system (choose a suitable connector from the accessory box), and the other end to

the male end on the upper right side of the equipment.

2) Start the engine to extract 600ml-800ml gasoline from the car tank through the oil return

pipe (watching through the right window of the machine), and then turn off the engine.

3) Connect the male end of the blue non-dismantling pipe to the oil inlet pipe of the fuel supply

system, (choose the right connector from the accessory box), and the other end to the black

high-pressure oil pipe of the equipment.

4) Unplug the car oil pump fuse or oil pump relay in the condition of not affecting the work of

other systems, or find a suitable connector from the accessory box to connect the oil inlet

THINKCAR THINKCAR

www.thinkcar.com www.thinkcar.com

a. Select the upper recoil coupler (part 5) and the oil separator end cap to plug into the oil

separator (part 4) from the accessory box.

b. Put the recoil seal ring (part 6) on the fuel injection nozzle, (as shown in the figure), and

then install the fuel injection nozzle in the opposite direction. (The oil outlet is facing

upwards and the oil inlet is facing downwards)

c. Select the lower recoil coupler (part 9) from the accessory box and place it on the oil inlet of

the upper plate base (part 10).

d. Place the oil separator 4 and the horizontal end of the fuel injector on the lower recoil

coupler (part 9), and tighten the two ends with the extension rod 8 and the locking rod 2.

Ready to test.

4.3.2 Methods and steps

【11】Reverse Flushing

1) Connect the quick connector of the black oil outlet pipe on the machine with the male end

connector on the oil separator, and insert the fuel injector drive line.

2) Press the【+】and【-】key of 【FUNCTIONS/PULSE WIDTH】to select item 11 “Reverse

Flushing".

and return pipes of the original car to make it a loop. (Note: The fuel tank cap must be

opened, otherwise it is dangerous.)

5) Turn on the power of the equipment, press the item selection key to select item 12 “No

disassembly cleaning", and press the time adjustment key to adjust the time to 20

minutes-30 minutes.

6) Set the pressure according to the technical requirements of the car. (Generally,

0.25-0.3MPa is suitable to most car models).

7) Press 【START】key. Wait a few seconds to start the engine.

8) After engine starts, pour the disassembly-free cleaning liquid from any round hole above the

glass tube of the equipment. (The ratio of disassembly-free liquid and fuel is about 1:4.

Normally 1/2 bottle for four-cylinder cars, 3/4 bottle for six-cylinder cars, and 1 bottle for

eight-cylinder cars)

9)Adjust the car throttle. (1-10 minutes idling operation, 10-15 minutes medium and

high-speed operation, the rest of the time idling operation)

10)The time gradually decreases, and when it is reduced to 0, the system automatically

stops. Remove the non-dismantling device, and recovery the car's oil inlet and return pipes

and insurance.

11)Start the engine and run the car at high speed for 2-3 minutes to discharge the washed

carbon deposits in the exhaust pipe. At the same time, check whether there is leakage at

the oil pipe interface of the vehicle's fuel supply system.

! Note:

· The cleaning liquid is flammable, so pay attention to safety when cleaning.

· Before cleaning, it must be confirmed that all pipelines are connected well and there is no

leakage.

【13】Device Information

Remark the the equipment serial number and date of manufacture

If the model or function is changed, operate according the operation panel description.

5 Maintenance

5.1 Organization

1)Turn off the power and unplug the power.

2)Put all the even parts and free-disassembly connectors back into the accessory box for

storage.

3)Put the ultrasonic cleaning liquid back into the original bottle and seal it, and wipe the

equipment clean with a dry soft cloth.

4)If it is not used for a long time, open the oil drain screw at the bottom of the main unit and

put the test liquid in the oil tank back into the original bottle for sealed preservation.

11 12

THINKCAR THINKCAR

www.thinkcar.com www.thinkcar.com

5.2 Maintenance

1)Test liquid replacement

When the test liquid is used for a period of time, a lot of impurities will accumulate. The test

agent containing dirt cannot be used, otherwise it will easily block the fuel injector. When

replacing the test agent, first unscrew the oil drain nut to release the test agent. After draining

it, inject a little clean test agent to clean the interior. After cleaning, re-tighten the oil drain nut

and pour two bottles of new test agent.

2)Selection of cleaning agent and test agent

When choosing cleaning agent and test agent, choose one that does not contain any acid and

alkali components, otherwise it will easily burn the oil pump, the core component of the

equipment, or cause corrosion to the oil supply pipeline; pay attention to the test solvent used

for spray calibration Its environmental protection, efficient dispersion, anti-precipitation, high

temperature stability and oxidation resistance.

! Special attention: cleaning liquid and test liquid cannot be mixed.

6 General Notice

1. Since the test device is part of quartz glass, it is easy to break, so do not place other objects

around the equipment to avoid bumps and breaks.

2. If there is no digital display after power-on, please check whether the power supply has

power; if so, check whether the plug is connected firmly, or whether the fuse is blown. If it is

uninterrupted, and the switch is still invalid after pressing the switch several times, please

contact the local dealer and do not disassemble it by yourself, otherwise our company will

not provide the warranty.

3. When no cleaning liquid is added to the ultrasonic tank, it is strictly forbidden to open the

ultrasonic cleaning item to avoid damage to the ultrasonic system due to empty driving.

4. Every time the test liquid is changed, it must be cleaned, and then about 1200 ml of test

agent is added.

5. Use of unqualified test agent will cause corrosion of the oil pump, oil supply pipeline and

malfunction of the pressure gauge.

6. It is strictly forbidden to use kerosene, gasoline, sina water and other testing agents and

cleaning agents as testing agents and cleaning agents for this machine. Otherwise, the "O"

ring and pipeline rubber parts in the equipment will be damaged, causing leakage.

7 Warranty Service

Thank you for choosing our products, we will provide you with the following services and

promises:

1. This product is guaranteed for three years and maintained for life.

2. After the warranty period expires, only the cost of replacement parts and other direct

expenses will be charged for repairs.

3. For machine upgrades, only cost is charged.

4. After the failure, please contact your local dealer, we will give you the most complete service

in the shortest time.

5. The following items are not covered by the warranty:

a) Wearing parts are not covered by the warranty, including: glass test tube, drive line,

control panel, sealing ring, pressure gauge.

b) Consumables are not covered by the warranty, including: testing liquid, cleaning liquid,

and disassembly-free liquid.

c) When there is not cleaning liquid is added to the ultrasonic tank, the ultrasonic system is

damaged by turning on the ultrasonic cleaning air blower, which is not covered by the

warranty.

d) If the test liquid is not replaced in time after long-term using, the filter screen of the oil

pump is blocked and the oil pump is burned out of the warranty.

e) If the cleaning liquid is used as a injector test liquid.

f) Man-made faults are not covered by the warranty.

8 Warranty Terms

This warranty applies only to users and distributors who purchase THINKCAR TECH INC

www.thinkcar.com THINKCAR TK-IMT602 products through normal procedures. Provide free

warranty within three years. THINKCAR TECH warrants its electronic products for damages

caused by defects in materials or workmanship. Damages to the equipment or components

caused by abusing, unauthorized modification, using for non-designed purposes, operation in

a manner not specified in the instructions, etc.are not covered by this warranty. The

compensation for dashboard damage caused by the defect of this equipment is limited to

repair or replacement. THINKCAR TECH does not bear any indirect and incidental losses.

THINKCAR TECH will judge the nature of the equipment damage according to its prescribed

inspection methods. No agents, employees or business representatives of THINKCAR TECH

are authorized to make any confirmation, notice or promise related to THINKCAR TECH

products.

Service Line: 0086-755-29838879

Official Website: www.thinkcar.com

Products tutorial, videos, FAQ and coverage list are available on Thinkcar official website.

Follow us on

@thinkcar.official @ObdThinkcar

13 14

THINKCAR www.thinkcar.com

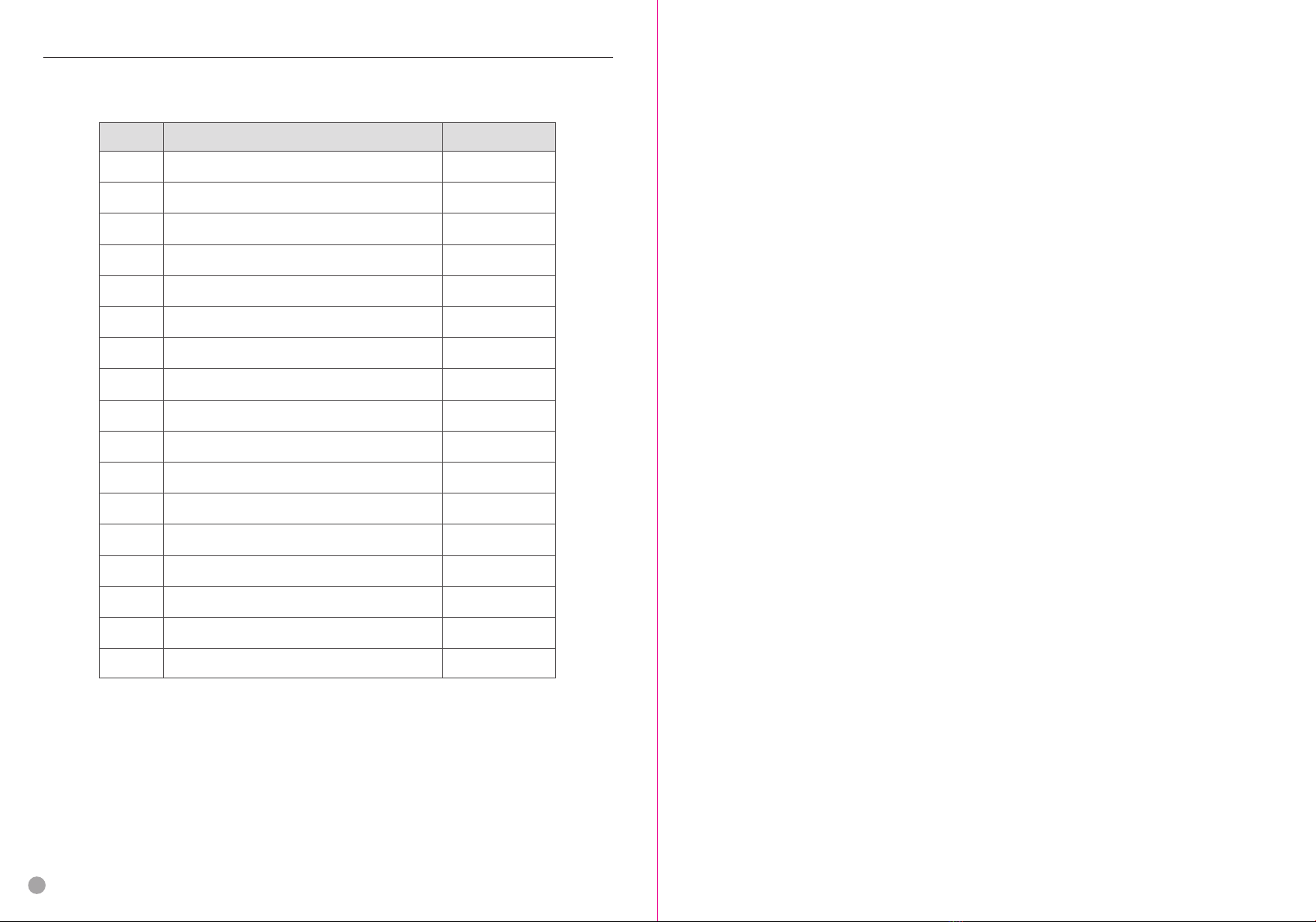

9 Packing list of TK-IMT602 Injector Cleaner & Tester

Name

Host machine

13.6 mm diameter conical adaptor

11 mm diameter connector

Special nozzle pads

Oil board plug

Ultrasonic tank cover

16 mm diameter reverse cleaning adapter

Nozzle gasket

Fuel rails

Adapter cable

Power cable

Fuel rail fixing screw

Fuel rail fixing nut

Ultrasonic cleaning stand

Refueling funnel

Cleaning fluid drain valve

User manual

Quantity (Pcs)

1

6

6

1

5

1

6

6

1

6

1

2

2

1

1

1

1

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

15

Table of contents

Other Thinkcar Diagnostic Equipment manuals

Thinkcar

Thinkcar THINKTPMS G1 User manual

Thinkcar

Thinkcar ADAS User manual

Thinkcar

Thinkcar X10 User manual

Thinkcar

Thinkcar THINKOBD 100 User manual

Thinkcar

Thinkcar ThinkTool PD8 User manual

Thinkcar

Thinkcar TKTT3 Instruction manual

Thinkcar

Thinkcar THINKOBD 500 User manual

Thinkcar

Thinkcar THINKSCAN Max User manual

Popular Diagnostic Equipment manuals by other brands

Interlogix

Interlogix RF Sniffer installation instructions

Dionex

Dionex ICS-6000 installation instructions

ShowPro

ShowPro RDM Xpress Kit user manual

DIGITAL YACHT

DIGITAL YACHT NAVDOCTOR NMEA 2000 Installation and instruction manual

Cando

Cando C-Pro manual

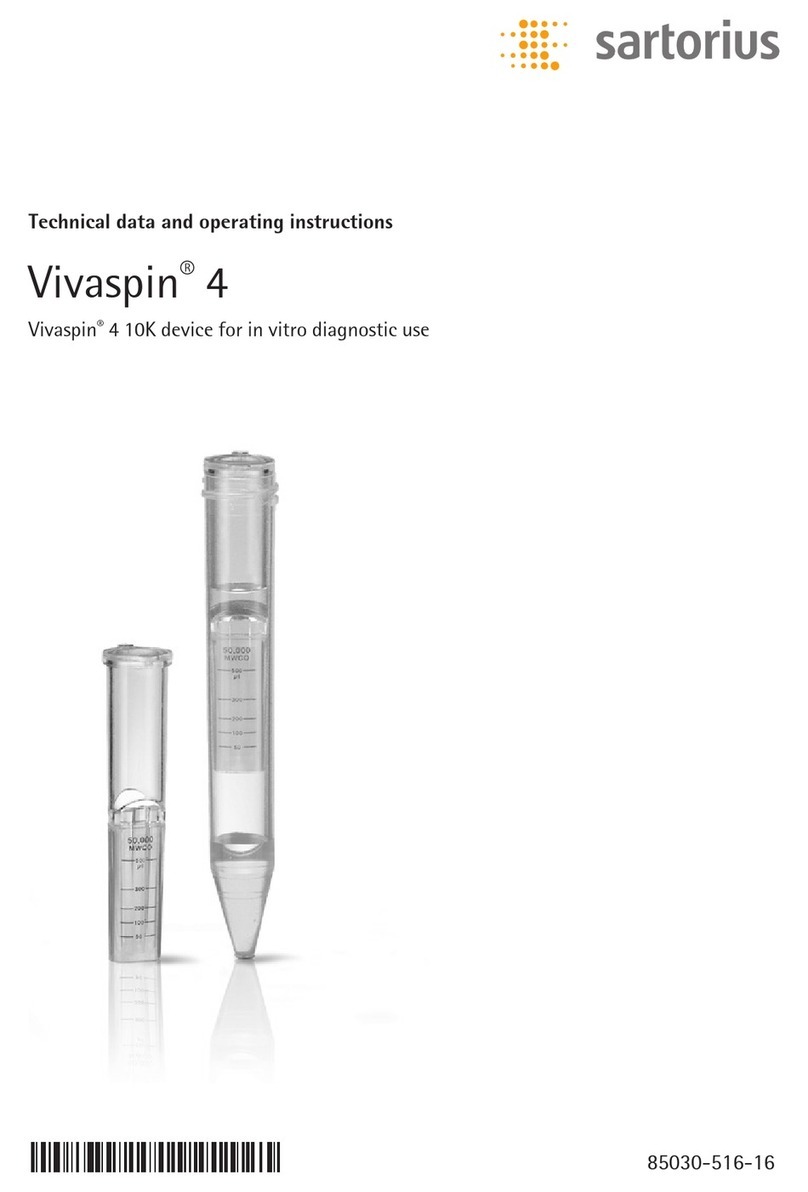

Sartorius

Sartorius Vivaspin 4 Technical data and operating instructions