© 2011 Thorlabs

Table of Contents

Foreword 4

Part I General Information 5

................................................................................................................................... 51 Safety

Part II Getting Started 6

................................................................................................................................... 61 Ordering Codes and Accessories

................................................................................................................................... 62 Unpacking

................................................................................................................................... 63 Preparation

................................................................................................................................... 84 Operating Elements

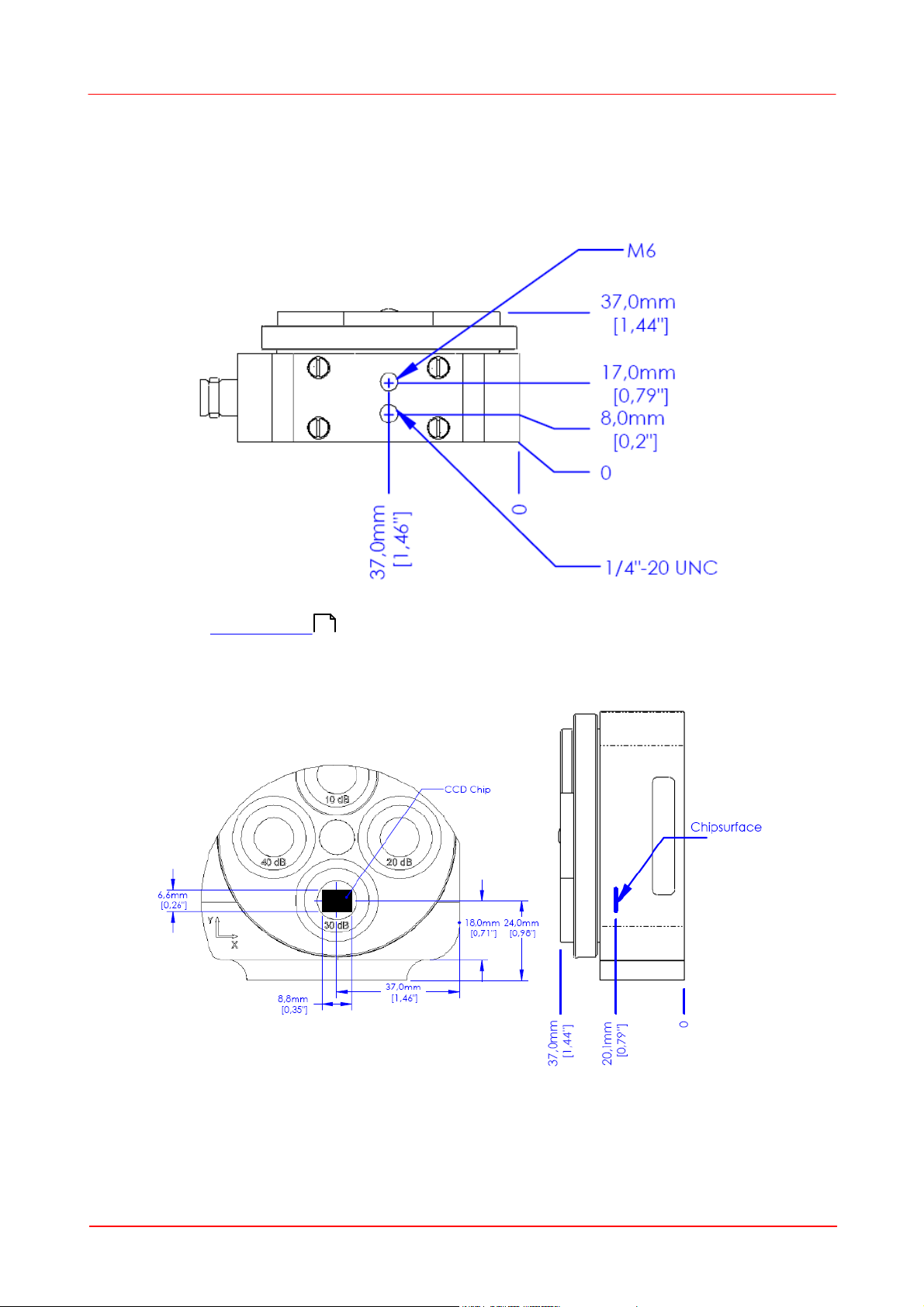

......................................................................................................................................................... 8Mounting and Sensor Position

......................................................................................................................................................... 9Filter Wheel

......................................................................................................................................................... 11Connectors

......................................................................................................................................................... 12Trigger Input

Part III Operating the Beam Profiler 13

................................................................................................................................... 131 Requirements

................................................................................................................................... 132 Installation

......................................................................................................................................................... 13Softw are Installation

......................................................................................................................................................... 23Connection to the PC

......................................................................................................................................................... 24Start the Application

................................................................................................................................... 263 The Graphics User Interface (GUI)

......................................................................................................................................................... 26GUI Overview

......................................................................................................................................................... 31Child Window s

.................................................................................................................................................. 332D Projection

.................................................................................................................................................. 363D Profile

.................................................................................................................................................. 37X,Y Profiles

.................................................................................................................................................. 39Calculation Results

........................................................................................................................................... 40Pass/Fail Test

.................................................................................................................................................. 41Plots

........................................................................................................................................... 42Plot Positions

........................................................................................................................................... 43Plot Pow er

........................................................................................................................................... 44Plot Gaussian Fit

........................................................................................................................................... 45Plot Orientation

........................................................................................................................................... 46Beam Stability

......................................................................................................................................................... 47Save Settings

................................................................................................................................... 484 Measurement with the Beam Profiler

......................................................................................................................................................... 49Operating the Instrument

......................................................................................................................................................... 50Device Settings

......................................................................................................................................................... 59Application Settings

......................................................................................................................................................... 65Pow er Correction

......................................................................................................................................................... 66Ambient Light Correction

......................................................................................................................................................... 67Hot Pixel Correction

......................................................................................................................................................... 69Measurement Results

......................................................................................................................................................... 70Save Measurement Results

......................................................................................................................................................... 75Pow er Ranges

......................................................................................................................................................... 76Pulsed Laser Sources

.................................................................................................................................................. 76No Trigger

.................................................................................................................................................. 76Softw are Trigger