5.6mm/9mmLaserDiodeMount Chapter3:Setup

Page4 TTN013394‐D02

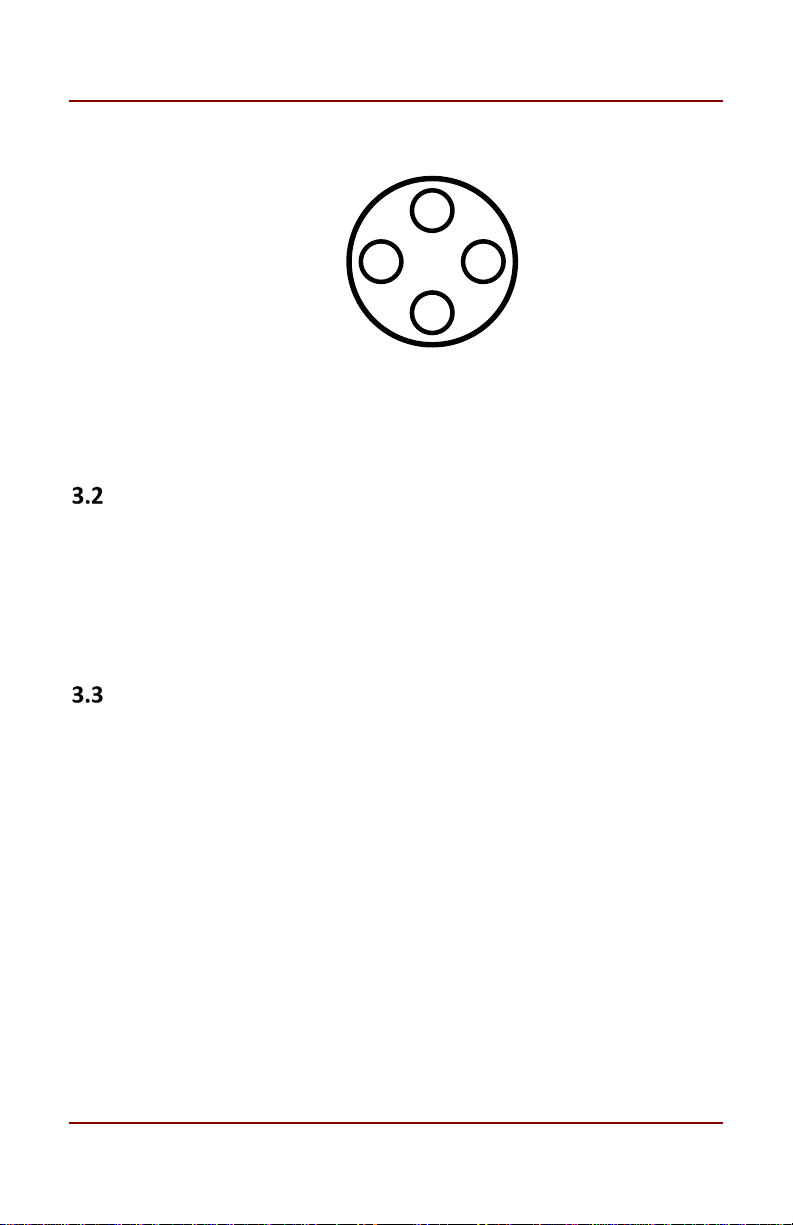

The four sockets comprising the laser diode connector are

through‐hole type sockets with a blind clearance of 0.48”

(1.22cm)measuredfromthefrontfaceofthecoppercoldplate.

Itisnotnecessarytotrimthelaserdiodeleadspriortomounting

intothisconnectorunlesstheyarelongerthan0.48”(1.22cm).

Thelaserconnectorislocatedcloseenoughtothefrontfaceof

thecoppercoldplatetoalloweasyinstallationofshort‐leaded

lasers. The clearance area around the LD and PD sockets is

sufficienttopreventthepinsfromcontactingthecoldplate.

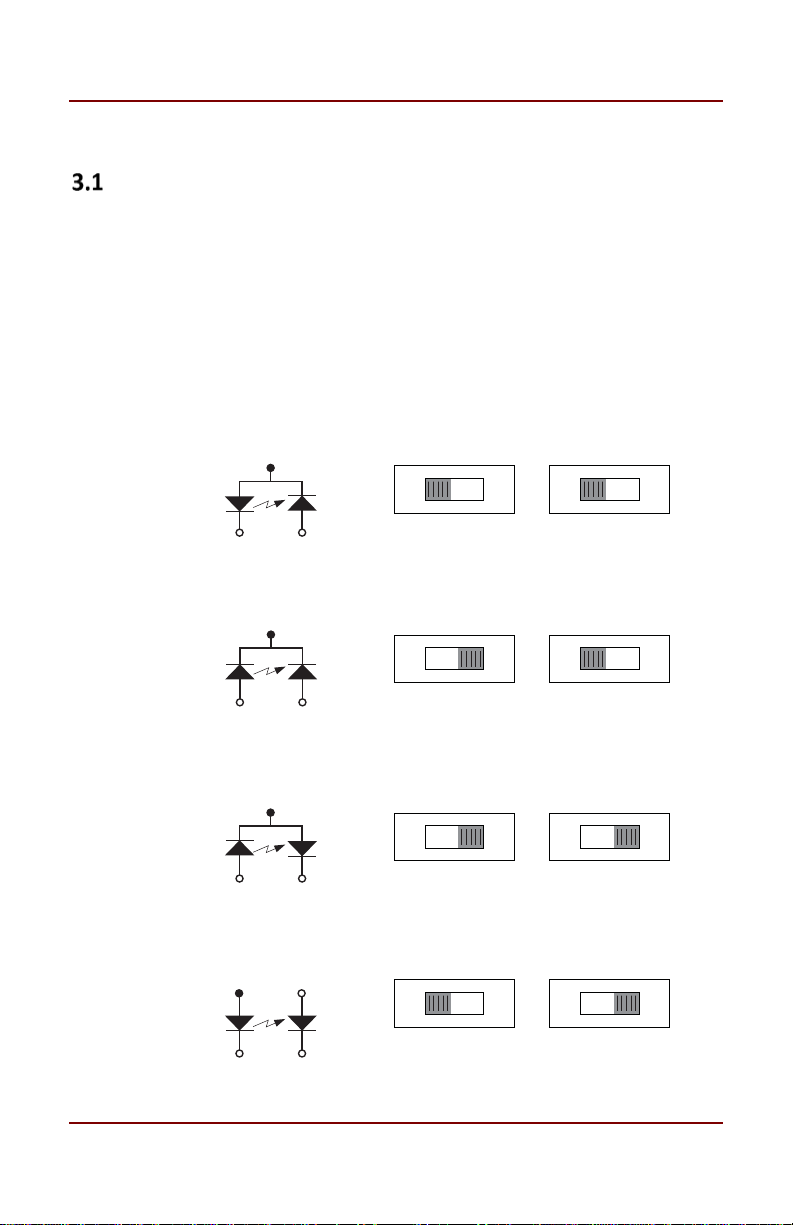

Mostlaserdiodesarethreepinswiththecasetiedtooneofthe

laserpinsandalsotooneofthephotodiodepins.Theotherlaser

and photodiode pins will be isolated from the case. The

LDM21(/M) was designed to operate the laser case at ground

potential,thereforethiscommonpinwillbeinsertedintoeither

the12o’clockorthe6o’clockpositionofthelaserconnector.

Locatetheisolatedlaserpinandinsertitinthe3o’clockposition.

Theisolatedphotodiodeshouldnowbeinthe9o’clockposition.

Refer to Fig. 3. (Orient the mount with the PD polarity switch

abovetheLDsocket).

TheLDM21(/M)MountisalsocompatiblewithstyleEandstyle

Hlaserdiodes,whichdonothaveaphotodiode;theyhaveonly

alaserdiodeandagroundpin.Theycanthereforebesetupthe

same as style A (LD Anode Ground) or style B (LD Cathode

Ground)respectively.

Replace the laser mounting flange and the cover. Install both

screwsthroughthemountingflangeandlooselyintothemount.

Carefullytighteneachscrewalittlebitatatimeuntiltheflange

isjustsnug.Donotover‐tighteneitherscrew‐theflangeshould

sitslightlyabovethecoldplate.Reinstallthecoverusingthefour

2‐56capheadscrewsprovided.