Plasma Light Sources with Liquid Light Guide

Table of Contents

Chapter 1 Warning Symbol Definitions.............................................................................................. 1

Chapter 2 Safety .................................................................................................................................... 2

Chapter 3 Description........................................................................................................................... 3

3.1. Overview ..........................................................................................................................3

3.2. Light Emitting Plasma.....................................................................................................3

3.3. Liquid Light Guide...........................................................................................................4

3.4. Spectrum..........................................................................................................................4

Chapter 4 Setup ..................................................................................................................................... 5

4.1. Part List............................................................................................................................5

4.2. Operation Elements ........................................................................................................5

4.3. Initial Setup......................................................................................................................6

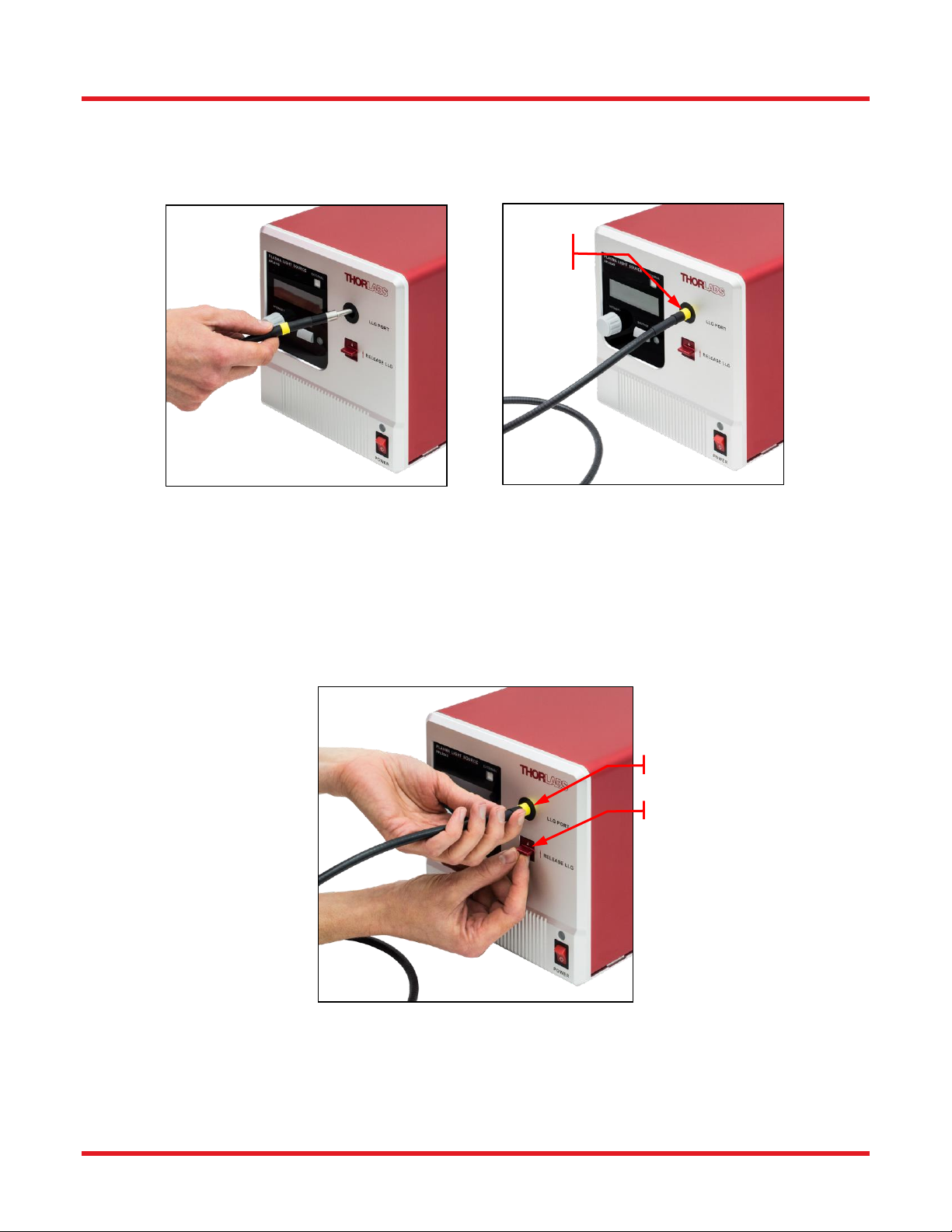

4.4. Connected Liquid Light Guide.......................................................................................6

4.5. Microscope Collimation Adapters .................................................................................8

Chapter 5 Operation.............................................................................................................................. 9

5.1. Starting the Light Source ...............................................................................................9

5.2. LCD Screen....................................................................................................................10

5.3. Shutter Operation..........................................................................................................10

5.4. Intensity Tuning.............................................................................................................10

5.5. External Control ............................................................................................................10

5.5.1. External Shutter Operation .................................................................................................. 11

5.5.2. ANALOG IN and TRIGGER IN ............................................................................................ 11

5.5.3. ANALOG OUT and TRIGGER OUT ................................................................................... 11

5.5.4. Signal Train ......................................................................................................................... 12

5.6. Operation Modes...........................................................................................................13

5.6.1. Open Loop Mode ................................................................................................................ 13

5.6.2. Closed Loop Mode .............................................................................................................. 13

5.6.3. Eco Mode ............................................................................................................................ 13

5.7. Stability and Noise ........................................................................................................14

5.8. Warning and Errors.......................................................................................................15

Chapter 6 Maintenance........................................................................................................................16

6.1. Fuse Replacement.........................................................................................................16

6.2. Bulb Module Replacement ...........................................................................................16

6.3. Firmware Update...........................................................................................................20

Chapter 7 Software GUI.......................................................................................................................21

Chapter 8 Command Line Operation.................................................................................................22

8.1. Command-Line Interface Overview .............................................................................22