75 W Xenon Light Source

Table of Contents

Chapter 1 Warning Symbol Definitions ...........................................1

Chapter 2 Safety.................................................................................2

Chapter 3 Product Overview.............................................................4

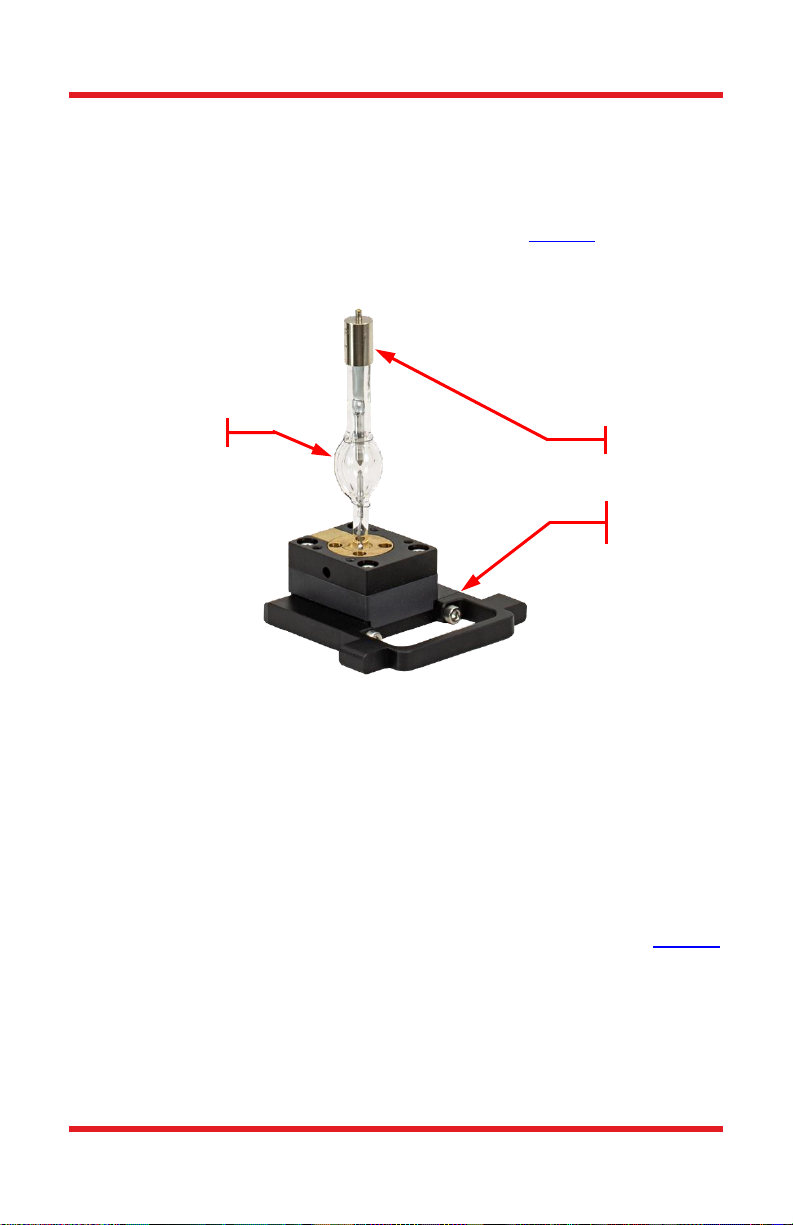

3.1. Xenon Light Source ........................................................ 4

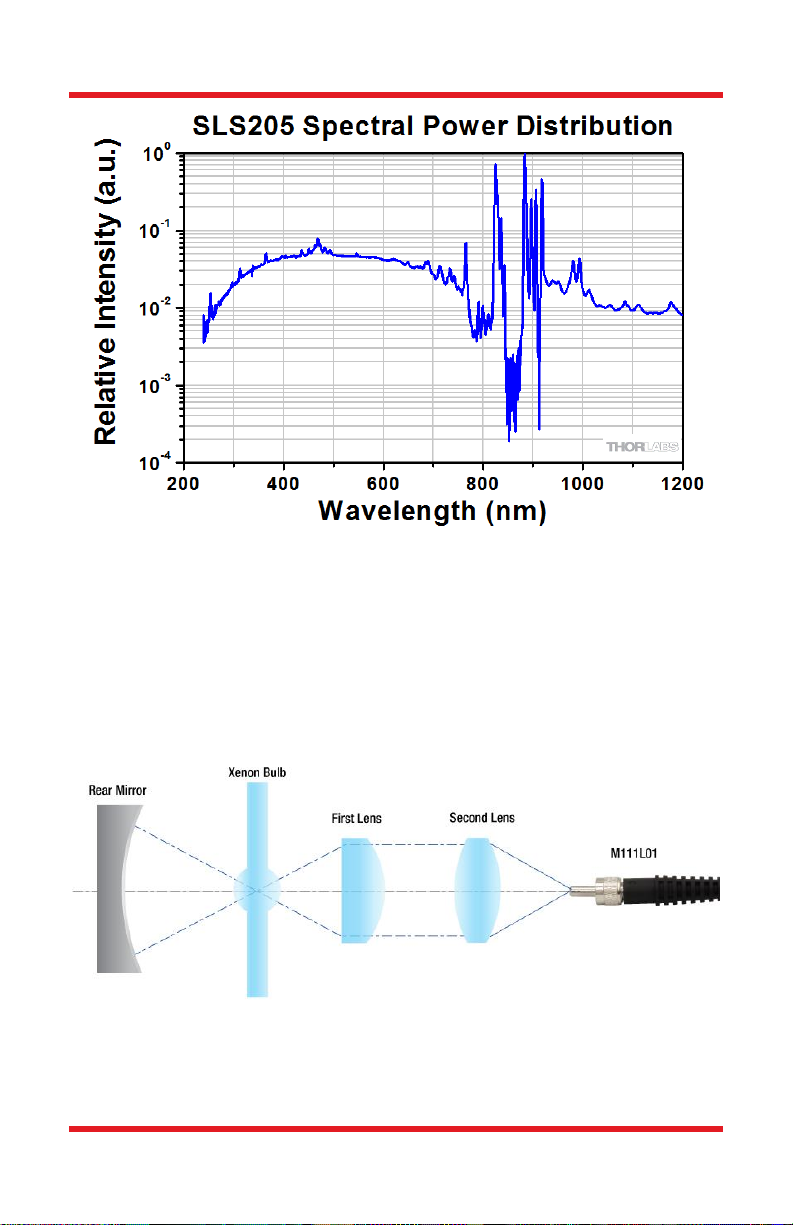

3.2. Spectrum ....................................................................... 4

3.3. Optical Configuration .................................................... 5

Chapter 4 Operation...........................................................................6

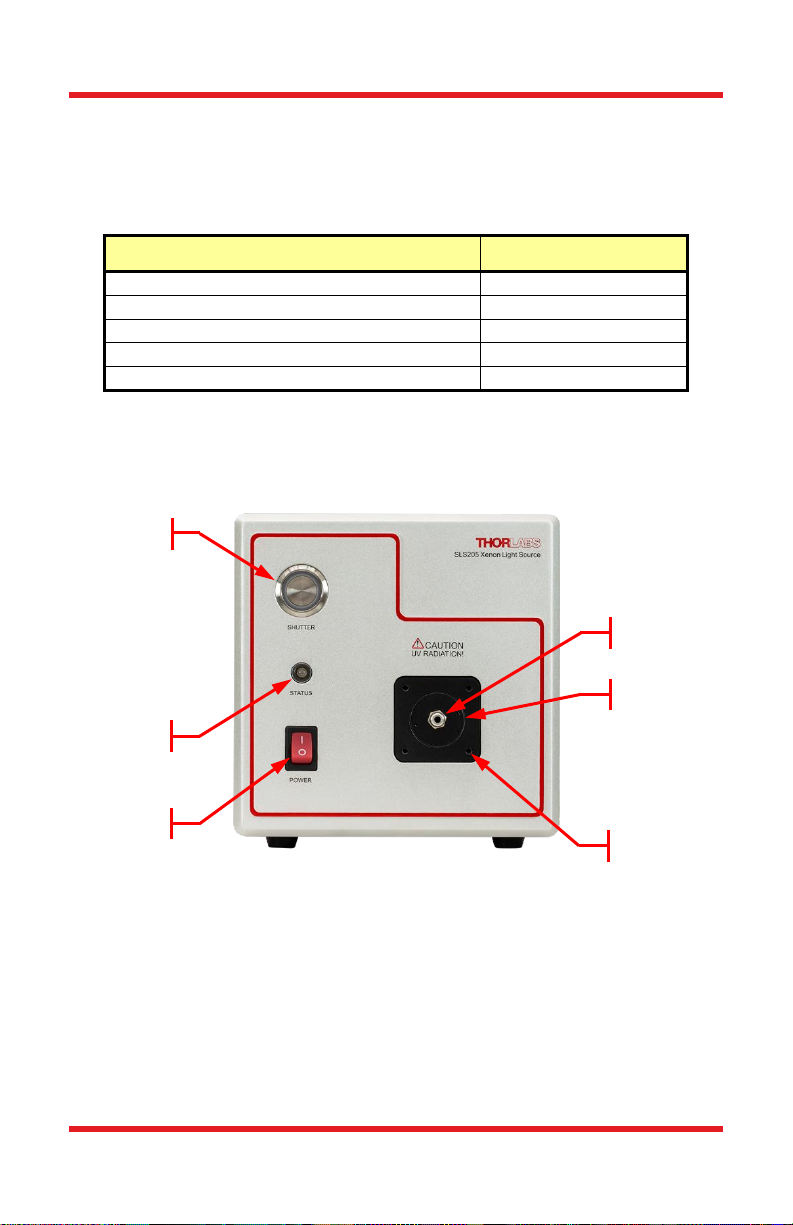

4.1. Parts List........................................................................ 6

4.2. Operating Elements ....................................................... 6

4.3. Bulb Installation ............................................................ 7

4.4. Switching on the Light Source ...................................... 11

4.5. Status Indicator ........................................................... 13

4.6. Application Ideas ......................................................... 13

Chapter 5 Maintenance....................................................................14

5.1. Fuse Replacement........................................................ 14

5.2. Bulb Replacement........................................................ 15

Chapter 6 Specifications.................................................................18

Chapter 7 Mechanical Drawing.......................................................19

Chapter 8 Certifications and Compliances ...................................20

Chapter 9 Regulatory.......................................................................22

Chapter 10 Thorlabs Worldwide Contacts.......................................23