TierTime UP mini User manual

version:4.6.23

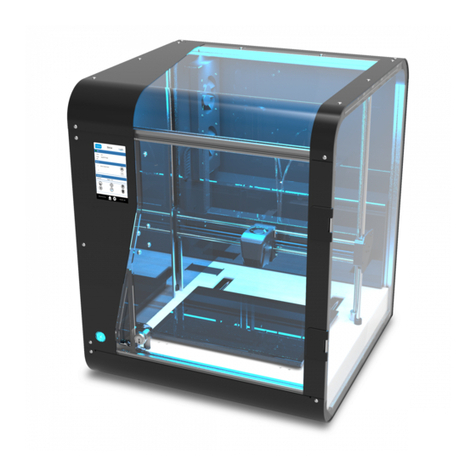

UP mini

user manual

Table of Content

Precautions .......................................................................................................................... 01

Printer Body illustration .................................................................................................. 03

Accessories .......................................................................................................................... 05

Installing the Print Head ................................................................................................ 06

Install the Perf Board ....................................................................................................... 07

Install UP Software ........................................................................................................... 08

Initialization of Printer ..................................................................................................... 09

Platform Calibrate

1.Setting Nozzle Height ...................................................................................... 11

2.Setting Compensation Values......................................................................13

Prepare for Printing ..........................................................................................................14

Loading a Model ................................................................................................................. 15

Software Interface .............................................................................................................17

Moving Model ...................................................................................................................... 18

Rotate Model ....................................................................................................................... 19

Scale Model .......................................................................................................................... 19

Duplicate Model ..................................................................................................................

20

Printing Parameters .........................................................................................................

20

Annotation for Printing Parameters ..........................................................................

21

Repair Model ........................................................................................................................22

Calibration for the Correct Dimension .....................................................................23

Printing Techniques ................................................................................................. 24

Troubleshooting .................................................................................................................. 25

01

1. UP mini 3D printer requires power adapter provided by original manufacturer. Otherwise it

could casue damage to machine or even fire hardzard. Please also keep the power adapter

away from water and high temperature.

2. During printing, the nozzle of the printer will reach 260oC and the print platform could reach

60oC. Please do not touch these parts with bare hand while they are hot, not even with the heat

resistant gloves included with machine as the temperature could damage the glove and your

hand.

4. During Printing, the nozzle and print platform will move at high speed, do not touch these parts

while they are moving.

5. Please wear goggles when removing the supporting material from model and detaching model

from perf board.

6. When printing ABS and PLA, slight smell will be produced, please run the printer in a well

ventilated environment. We also suggest you to put the printer in an enviroment with stable

temperature, as unwanted cooling could has adverse eect on print quality.

7. When UP softwre is sending data to printer, where the status bar on the left bottom corner

is showing "sending layers", do not unplug USB cable, as this will interrup data transfer and

results in printing failure. USB cable can be unpluged after data printing started.

8. UP mini's working temperature is between15oC and 30oC relative humidity 20%-50%. It is

recommended to discharge static charge from user's body before touching the machine to

prevent interruption of printing and damaging the printer.

Warning label on printer:

High Temperature, do not touch!

Warning label on printer:

Moving parts, do not touch!

Precautions

02

UP mini Specication

Technology MEM (Melted Extrusion Manufacturing)

Build Volume 120x120x120mm

Print Head Single, Modular for easy replacement.

Z-resoution 0.2/0.25/0.3/0.35mm

Supporting Structure Automactically generated, easy to remove,

adjustable

Platform Leveling Manual

Print Surface Heated bed with perf board

Unterthered Printing Yes

Bundled Software UP Software

Compatible File Formats STL, UP3, UPP

Connectivity USB

Operating System WinXP/Vista/7/8, Mac OS

Poweradapter 110-240VAC, 50-60Hz, 220W

Printer Body Metal Chassis, enlosed.

Printer Weight 6KG / 13 LB

Printer Demiension 240(W) x 355 (H) x 240 (D)mm

Weight with Packaging 11.2KG / 25LB

Printing

Software

Power Supply

Mechanical

03

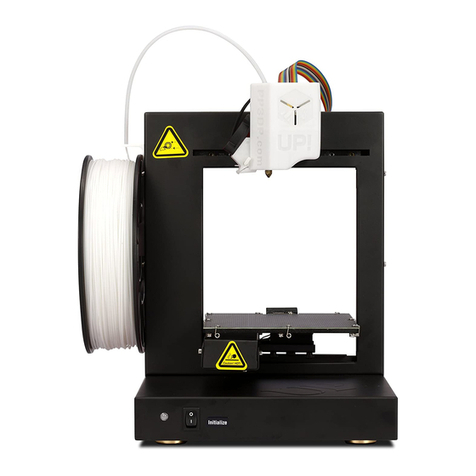

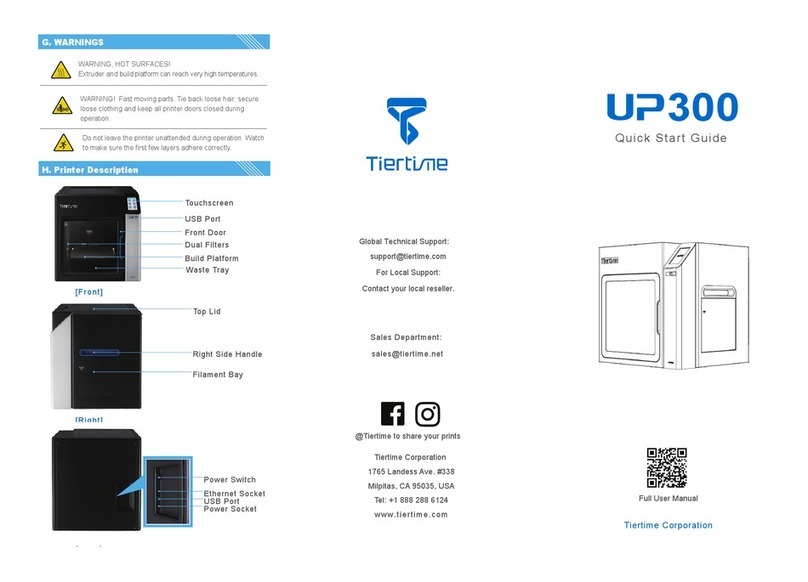

USB Port

Power Connector

Top Lid

Front Door

Initialization Button

Power Switch

Spool Holder

USB Port

Power Connector

Printer Body illustration

04

Print Head

Print Platform

Initialization Button

Print Head

Nozzle

X-Axis

Y-Axis

Z-Aixs

05

Accessories

Print HeadSpool Holder ABS Filament

Plier

Perf BoardUSB Cable Power Adapter

Filament guiding tube

Hex Key

Gloves

Nozzle Wrench

Blots and Nuts

Shovel

06

Installing the Print Head

Correct installation.

Incorrect installation, note the magnet

under the print head is not in contact

with the motor.

There are 3

magnets for holding

the print head in

place.

1

During installation

make sure the

magnets are aligned

to the metal plates

on the print head's

stepper motor.

2

After tting the print

head, plug in the

cable to connector

residing on the print

head.

3

07

Slide the perf

board into the

slots on the

2 sides of the

platform.

Finsihed.

Install the Perf Board

Install the Spool Holder

Hook the spool holder on the back of the printer.

Install Filament Spool

As shown in the diagram, put the

lament spool on the spool holder

and put the lament through the

filament guide tube, then insert

the tube into the printer through

the hole under the lid.

1 2

08

Install UP software

1. Go to www.pp3dp.com to download

the latest version of UP Software.

2.Double click UP! Setup.exe

to install the software(default

installation directory C:\Program

files\UP a pop up window will

appear, select"install" and

following the instruction to

finish. The printer's driver is now

installed into the system.

After installation,in the UP folder:

Driver folder contains the printer drivers.

Example the example folder contains STL les for the printed

parts of UP printers and example les.

Testing of printer driver installation

UP

UP

First make sure computer and printer

is connected to computer via USB

cable and the printer is switched on.

The initialization button should be light

up in red color.

09

After driver installation,

double click the desktop

icon of UP software to

open it.

UP

Click"3D Print".

"Initialize" and "Maintenance"

options will light up and

avaliable for selection.This

indicate the successful

installation of printer driver.

Initialization of printer

Initialization is required for everytime the machine is switched on. During initialization the

XYZ aixs will move slowly and hit the endstops. This is essential as the printer need to nd

the endpoints of each axis.

Initialization Button

Two ways of initialization:

1. UP mini can be initialized by clicking initialization option in

the menu which is shown above.

2. The printer has initialization button on front of the

machine shown in the picture below. When the printer is

idle, press this button will trigger initialization

After initialization, the other software options will light up

and become available for use. These options can only be

chosen after initialization.

10

The other functions of Initialization Button:

1. Stop current print job:During printing press and hold the button.

2. Switch On/Off print head LED:Quick double hit of the button.

Platform Calibration

Plarform calibrate is the most important step for successfull printing, as it ensures the first

layer adhesion.The actaual calibration is done by measuring the distance between the nozzle

and platform.Ideally, the distance between nozzle and platform is constant, but in reality the

distance varies at dierent position due to many reasons (eg. slightly tilted platform.) To calibrate

the platform, we just need to tell the machine, on 9 calibration points, the height of plaform

that is touching the nozzle.The printer will able to compensate for distal errors base on our

measurements.The calibration procedure contains 2 parts:

1. Setting nozzle height.

2. Setting compensation values.

D.9 calibration point buttons,

represent 9 positions on platform,

after clicking the nozzle will move

to the corresponding positions.

The drop down menu beside

the button is for setting leveling

compensation values.

Platform calibration interface:

Open: Menu - 3D Print - Platform calibrate

Interface annotation: A.Moving Platform UP/DOWN:

click/hold the button, platform

will move accordingly.

B.Display the current platform

height.

C.Setting nozzle height: click this

will set the current platform

height as the nozzle height.

11

Platform Calibrate: 1.Setting Nozzle Height

Setting nozzle height, actually, is not setting the nozzle itself as UP mini's print head

does not move in the Z-axis. Here the nozzle height we are refering to is a platform height

value, at this height, the platform will be just touching the nozzle (thus "nozzle height").

After setting the value, the platform will be restricted to move over "nozzle height" as the

it will start crashing onto the nozzle if going beyond it. The nozzle height value is important

for protecting the printer from damages as well as being the basis for calculating leveling

compensations.

During the calibration we are measuring distance shorter than 1mm, so we recommend

using a print paper as a guide for measurement.

Protocol for setting nozzle height:

1

2

3

4

5

Initialize printer

Open the calibration interface

and press the UP key, note

the current height value, stop

the platform at about 115.

Put print paper on platform.

Hit the "5" button.Nozzle will go

to the center of the platform.

Raise the platform until it is

just touching the nozzle. We

can move the paper between

the nozzle and platform and

see if there is any resistance.

Like to diagram below.

12

Platform Too high, nozzle

is pinning paper onto

the platform, Lower the

platfrom slightly.

Just right,could feel some

resistance when moving

the paper.

Platform too low, no

resistance at all when

moving paper, raise the

platform slightly.

When obtained the right platform

height, write down the value of "current

height".

We will refer this as the "platform

height".

Repeat step 1- 6 for all other 8

positions and obtain their platform height

value when touching the nozzle.

6

7

8

When obtained the platform value of

all 9 positions.Find out the smallest value

among the 9 calibration points.

As you can see in this case, the

calibration point 1 has the smallest

platform height value, it is actully the

highest point on the platform. (therefore

the platform does not need to rise as

high as the other points to reach the

nozzle

Platform Values at 9 calibration points

(hypothetical):

1: 119 2:119.5 3: 120

4: 119.5 5: 119.9 6: 119.1

7: 119.2 8: 119.4 9: 119.8

We set this height as "Nozzle Height"

since it is where the nozzle first start to

touch the platform. Now go to calibration

point 1 and rise platform to 119.

Click the button" Set Nozzle Height" to

nish.

13

Platform Calibration: 2.Setting Compensation Values

As shown in the left, when platform

is at the "nozzle height", only part of

the platform is touching the nozzle.

Therefore we need to set compensation

values for all other calibration points to

inform the printer about the distance

between nozzle and print surface

thorughout the XY plane.

For example, setting the

compensation value for calibration

point No.3. Assume the "platform

height" is 120 and the "nozzle height"

is 119, the compensation value

should be set to 1.0.

After setting 1.0 in the drop down

menu, the nozzle will move to point

No.3 and the platform will rise 1 mm.

Now we can use the paper again to

verify the compensation value.

After setting all calibration points click

“Appy/Save Current Values ” to finish

the calibration.

Afte setting the nozzle height, the drop down menu next to the

buttons will be available. A compensation value between 0.1 - 1.0 mm

will be available for setting.

To calculate compensation value:

Platform height - nozzle height = compensation value

14

Prepare for Printing

Make sure printer switched on and

connected to computer. Select Main

Menu - 3D Print - Maintainance.

Hit "Extrude" button,the print

head will start to heat up, within 5

minutes its temperature will reach

260oC,then printer will buzz and the

print head startts to extrude.

Gently insert the iament into the

small hole on the print head. The

filament will be feed into the print

head automatically when it reach the

extruder gear inside the print head.

Check the nozzle for plastic

extrusion. If plastic is coming out

from the nozzle that means the print

head is ready. The extrusion will stop

automatically.

1

2

3

4

15

Click Load

Choose your model.

Loaded model on

the print plate.

Loading a model

1

2

3

4

Click print to open

the print preview

window.

16

Click "OK" to start printing.

The program will rst slice

the model into Gcode and

then transfer the data to

the printer.

Annotation of Print Preview Interface:

After sending the data, the

program will suggest the amount

of material and time needed for

the model in a pop up window.

At the same time, the nozzle

will start to heat up. The print

job will start automatically after

clicking"OK"

When printier nished receiving the print data, user could disconnect

it from computer for untethered printing.

a

b

d

e

f

h

g

c

5

6

a. Display the printer model.

b. Dispaly the noozle height.

c. Click to enter printer preference to set printing parameters.

d. If you model is not solid (defective), turn on this option.

e. No raft will be printed if this is turned on, print bed leveling will be disabled

as well.

f. Print Quality: the better the print quality the slower the print speed.

g.Set the pause height, the printer will pause at indicated heightness for

changing laments.

h.Continuous heating of platform after printing, save heating time for

consective printing and preventing breakage due to rapid cooling in cold

weather.

17

Quick functional Buttons

Main Menu

Status Bar

Display the statsu

of printer and

software.

Software Interface

1. Load:Load a model.

2. Save:Save the model into .UP3, a propritory 3D model le for UP printers.

3. Unload:Unload the selected model.

4. Print:Print the current print plate.

5. About:Display software version, printer model, rmware version and etc.

6. View Perspective: A variety of pre-set of perspective.

7. Adjustments:Move, Rotate, Scale.

8. Set the value of adjustments.

9. Set the orientation of ajustments.

10. Place:

Place the model to the center of the print plate. If more than one model

exist software will optimize their positions and distance to each other.

11. Stop: If connected to printer, click this will stop the print.(cannot be resumed)

1

2

3

4

5

6

7

8

9

10

11

Print Plate

-left mouse click and hold, moving

mouse to adjust camera angle.

-Right mouse click and hold, moving

mouse to move print plate.

-Mouse wheel could scale the print

plate view.

-The print plate size depend on

the printer model connected to

computer.

18

1

Click Move

button.

Moving Model

Click to select

model.

2

3

4

Select distance

value to in the drop

dwon menu.

Choose an axial

direction to move

the model.

Drag model with mouse on XY-plane: Press and hold Ctrl Key, mouse left

click and hold the target model, now the model could be dragged around

on XY-plane.

Drag model with mouse on Z-axis: Press and hold Shift Key mouse left

click and hold the target model, now the model could be dragged along

the Z-axis.

Multiple models could be stacked by moving. They can also be fused into

single model by "Merge" function in the "Edit" Menu.

Table of contents

Other TierTime 3D Printer manuals

TierTime

TierTime UP300D User manual

TierTime

TierTime UP300 User manual

TierTime

TierTime UP mini 3 User manual

TierTime

TierTime UP Plus 2 User manual

TierTime

TierTime Filament Dryer PRO User manual

TierTime

TierTime UP mini 2 Configuration guide

TierTime

TierTime UP BOX User manual

TierTime

TierTime UP300 User manual

TierTime

TierTime UP300D User manual

TierTime

TierTime UP BOX User manual