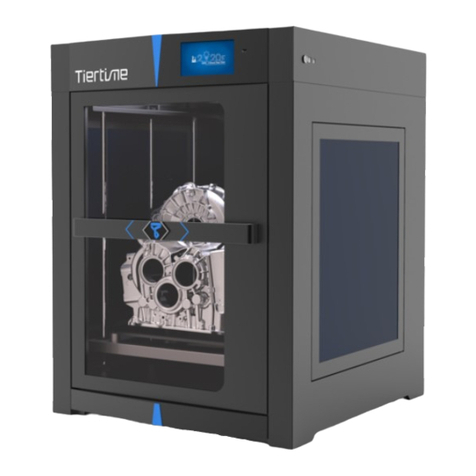

TierTime UP BOX+ User manual

1

1

USER MANUAL

FOR UP BOX+

1

2

Precautions

Printer Body

Accessories

Unpacking

Installing Print Board

Installing Filament

Installing UP Studio Software

Initializing Printer

Automatic Platform Calibration

Automatic Nozzle Height Detection

Manual Platform Leveling

Preparing for Printing

Printer Control Buttons

LED Light Bar

Software Interface

Setup Wi-Fi

Product Activation

Loading a Model

Printing a Model

Pausing a Print Job

Rotating a Model

Scaling a Model

4

5

7

8

8

9

9

10

11

12

13

14

15

16

17

18

22

23

24

25

26

27

Table of Contents

1

3

Moving a Model

Making Copies

Merging and Saving Models

Printing Preference

Printing Parameters

Converting a 2D Picture into a 3D Model

Machine and Software Settings

Controlling Multiple Printers with USB

Printer Info and Naming a Printer

Printing Techniques

Fine Manual Calibration

Setting Compensation Values

Maintenance

Filament Check and Blackout Recovery

Troubleshooting

UP BOX+ Specications

28

29

30

31

33

34

36

37

38

39

40

42

43

44

45

46

Table of Contents

1

4

UP BOX+ 3D printer only works with the power adapter provided by the original manufacturer, otherwise the

machine could become damaged or even cause a re hazard. Keep the power adapter away from water and high

temperature environments.

During printing, the temperature of the nozzle of UP

BOX+ could reach 260°C and the print platform could

reach 100°C. Do not touch these parts with your bare

hands while they are hot—not even with the heat

resistant gloves included with the machine—as the

temperature could damage the gloves and injure

your hands.

Wear goggles when removing the supporting material from models, or detaching models from the print board.

During printing, the nozzle and the print platform

could be moving at high speeds. Do not touch these

parts while they are moving.

When printing with ABS or PLA, the plastics will generate a slight odor. Run the printer in a well-ventilated

environment. We also suggest you put the printer in an environment with a stable temperature as unwanted

cooling could cause adverse eects to the print quality.

When the UP software is sending data to the printer—indicated on the status bar on the left bottom corner of the

software interface with the text "sending layers"—do not unplug the USB cable as this will disrupt the data transfer

and result in a printing failure. The USB cable can be unplugged after the data transfer is nished.

The UP BOX+'s ideal working temperature is between 15°C and 30°C with relative humidity between 20–50%.

Users are recommneded to discharge any static charge from the body before touching the machine to prevent

interruption of printing and any potential damage to the printer.

Precautions

Warning label on printer:

High Temperature,

do not touch!

Warning label on printer:

Moving Parts, do not touch!

1

2

3

4

5

6

7

1

5

Spool Holder

Magnetic Cover

Filament Spool

Top Lid

Front Door

Initialization Button

Extrude/Withdraw Button

Pause/Stop Button

Power Interface

USB Interface

Power Switch

Printer Body

1

6

X-Axis

Y-Axis

Z-Axis

Print Platform

LED Bar

Air Filter

Print Head Mount

Automatic Leveling Probe Print Head Locking Srew

Magnets

Print Head

Nozzle

Fan

Duct

Wind

Lever

Fans

Nozzle Height Detector

1

7

Accessories

ABS Filament Nozzle WrenchPlierHex Keys

2.0mm, 2.5mm

Power Adapter USB CableScraperPower Cable

Perforated Print Board

(Perf Board)

Perforated Print Board

(Perf Board) and UP Flex

Print Board

1kg Spool Cover

Print Head Nozzle

All accessories may subject to change without prior notice. If anything is missing, please contact

Gloves

Micro SD card and

Reader

1kg Spool Rack Add-on Calibration Card

1

8

Unpacking: Remove Foams and Nylon Ties

Lay down the foam at the bottom, turn it 90 degrees to

remove, and no need to lift the platform.

Remove the nylon ties (labelled with "Remove me") from the

smooth rods.

Keep the packaging material handy. You may need it when

shipping the product in the future.

Installing Print Board

1. Position the print board on the build platform so

that all the at head screws on the heating plate

are inside the holes on the print board.

2. Press the print board and the heating plate

together at the lower left and lower right corners.

Then slide the print board forward to lock it onto

the heating plate.

3. Make sure all holes are locked properly so that

the print board is at.

4. Install or remove the print board when the

platform and print board are cool.

Unlocked Locked

Install Print Board

90°

1

9

Installing Filament

1. To install the lament spool, open the magnetic

cover and insert the lament into the guiding tube

at the spool holder.

2. Push the lament into the guiding tube until it

comes out from the other end. Put the spool

onto the spool holder and cover the spool with

the magnetic cover.

Installing UP Studio Software

1. Go to the Support Section of www.up3d.com to download the latest version of the UP Studio. The Mac

version of the UP Studio can only be obtained through Apple App Store.

2. Double-click the setup.exe le to install the software. (The default installation path is C:\Program Files\UP

Studio\). A pop-up window will appear. Select "Install" and follow the instructions to nish. The printer’s driver

will be installed in the system.

1KG Spool

Rack Add-on

To use 1KG spool, put the

Spool Rack Add-on onto

the orignal spool rack. A

protruding magnetic cover

is also provided with the

machine to accommadate

thicker spools.

1

10

Initializing Printer

Initialization is required every time the

machine is switched on. During initialization,

the print head and the print platform move

slowly and hit the endstops of the XYZ

axes. This is essential as the printer needs

to nd the endpoints to each axis. Other

software options will light up and become

available for use only after initialization.

Initialization Button

There are two ways to initialize your printer:

1. The UP BOX+ can be initialized by clicking the

"Initialize" option in the software menu (shown

above).

2. When the printer is idle, press and hold the

initialization button on the printer.

Other functions of Initialization Button:

1. Stop the current print job: During an on-going

print job, press and hold the button.

2. Reprint the last job: Double-press the button.

1

11

Platform calibration is the most important step for successful printing as it ensures part adhesion

on the rst layer. Ideally, the distance between the nozzle and the platform is constant, but in

reality the distance varies at different positions due to many reasons (e.g. a slightly tilted platform),

which could cause warping on prints or even a complete print failure. Fortunately, UP BOX+

introduces the features like automatic platform leveling and automatic nozzle height detection,

which can make the calibration process nish quickly and easily.

In the Calibration section, click Auto Level to initiate auto

leveling. The leveling probe will be lowered and start to probe

nine positions on the platform. After probing the platform, the

leveling data will be updated and stored in the machine. The

leveling probe retracts automatically.

Nozzle height detection will be started automatically after auto

leveling process. The print head will move toward the nozzle

height detector. Eventually, the nozzle will touch and press the

thin metal sheet on the device to make the measurement.

Calibration Tips:

1. Perform calibration when the nozzle is not heated.

2. Remove residual plastic on the tip of the nozzle before calibration.

3. A print board should be in place on the platform before calibration.

4. Autoleveling and nozzle height detection can only be initiated when nozzle temperature is under 80 °C.

Automatic Platform Calibration

Auto leveling probe

retracted.

Auto leveling probe

lowered.

Nozzle Height

Dectector.

1

12

Automatic Nozzle Height Detection

You may initiate the Automatic Nozzle Height Detection

without the Autoleveling.

In the Calibration section, click " Detect Nozzle".

If consistent warping still occurs after auto-leveling, it may be due to a severe unleveling of

the platform which exceeds the capability of the auto-leveling function. In which case, you

should perform a manual leveling before auto-leveling (see the next page).

You may also level the platform without using the auto-leveling and nozzle detection

functions. Please refer to Page 40 for details.

During nozzle height

detection, the print head

nozzle will touch the thin

metal sheet on the detector

to make measurement.

After nozzle height detection,

the software will ask which type

of print board is used on the

machine, choose the currently

used type of board to nish the

measurement.

1

13

Manual Platform Leveling

Usually users do not need to adjust the

platform manually. This is only necessary if

the automatic leveling function was unable

to effectively level the platform.

There are four screws under the platform

of UP BOX+: two knobs in the front and

two knobs under the platform at the back.

These knobs can be fastened or loosened

to adjust the leveling of the platform.

In the calibration section use the reset button to

set all the compsenation values to zero. Then use

the nine numbered buttons to move the platform to

different locations.

You can also use the "Move" button to move the

print platform to a particular height.

First move the print head to the center of the

platform and move the platform to almost touching

the nozzle (e.g. nozzle height). Use the Calibration

Card to determine the correct platform height.

Try to move the Calibration Card and feel the drag

between the platform and the nozzle. Make sure

you can feel the similar drag resistance at all 9

positions by moving the print head and adjusting

the screws while the platform height is xed.

The platform is too high.

The nozzle is pinning the

Calibration Card onto the

platform. Lower the platform

slightly.

The height is just right.

Can feel some resistance

when moving paper.

The platform is too low.

No resistance is felt at all

when moving the paper.

Raise the platform slightly.

1

14

Preparing for Printing

Make sure the printer switched on

and connected to a computer. Click

the "Maintenance" button in the

software.

Choose ABS or the material you

choose from the dropdown material

list, and input the lament weight.

Click "Extrude". The print head will

start to heat up. About ve minutes,

the temperature of the print head

will reach the melting temperature,

e.g. for ABS, it is 260°C. The printer

will buzz and the print head will

start to extrude.

Gently insert the lament into the

small hole on the print head. The

lament will be fed into the print

head automatically when it reaches

the extruder gear inside the print

head.

Check the nozzle for plastic

extrusion. If plastic is coming out

from the nozzle, it means the

lament is loaded correctly and the

printer is ready for printing. (The

extrusion will stop automatically

after a while.)

1

2

3

4

5

1

15

Printer Control Buttons

Printer Control Buttons

Long Press

Double Press

Single Press

INITIALIZE

LIGHTS

ON/OFF

EXTRUDE

FILAMENT

RE-PRINT

LAST JOB

LIGHTS ON

(2 mins)

WITHDRAW

FILAMENT

PLATFORM PREHEAT

15 MIN

PAUSE/

RESUME

STOP

LED Light Bar and Front Door Check

When a print job is nished,

the LED light bar will be in RED

color. Under such condition, the

machine will not respond to any

command and print jobs. This is

to prevent unwanted actions that

may crash the print head into the

printed object.

To resume to normal, the front

door must be opened once after

a print job is nished.

1

16

Printing and Pre-heating

Progress bar.

Sleeping Mode

Alternated lighting of progress

bar

Sleeping mode: Machine will enter the sleeping mode after

it has been idling for 2 minutes when it is not initialized.

Single press the initialization button can exit the sleeping

mode.

The sleeping mode is only available in certain countries. If

the machine does not enter the sleeping mode, it does not

mean it is malfunctioning.

LED Light Bar

1

17

Software Interface

Account

UP (Print)

Library

Help

Printer name

Nozzle & Platform

Temperature

Current

Material

Printer Status

Account

Settings

Share

Skin

Model

Adjustment

wheel

Back to home

Add a Model/

Picture

Print

Initialize

Calibration

Maintenance

Connection

type

Build

Space

Mirror

Save

Delete

Restore to

default

Undo

Fix

Model

Perspectives

To 2nd Level

Menu

Undo

Scale

Move

Rotate

Auto Place

To 1st level

Menu

1

18

or

Connecting to UP BOX+ through Wi-Fi requires a Wireless Local Area Network (WLAN). The

computer and the printers must connect to the same WLAN (same SSID) before they can

communicate.

In order to achieve stable Wi-Fi connection, It is highly recommended to use the printer under

a capacious Wi-Fi environment. A crowded network or an area with many Wi-Fi networks are

known to cause interruption during data transfer.

Machine Settings - Wi-Fi Connection

1

19

At the top right corner click the

printer tab

Click the “Printer Detail” button.

Wi-Fi Setup

Connect UP BOX+ to a computer through USB.

2

1

1

20

Click the dropdown menu to choose an available network.

3

Choose your network from the drop down list.

Table of contents

Other TierTime 3D Printer manuals

TierTime

TierTime UP mini 3 User manual

TierTime

TierTime Filament Dryer PRO User manual

TierTime

TierTime UP mini 2 Configuration guide

TierTime

TierTime UP Mini 2 ES User manual

TierTime

TierTime UP BOX User manual

TierTime

TierTime UP Plus 2 User manual

TierTime

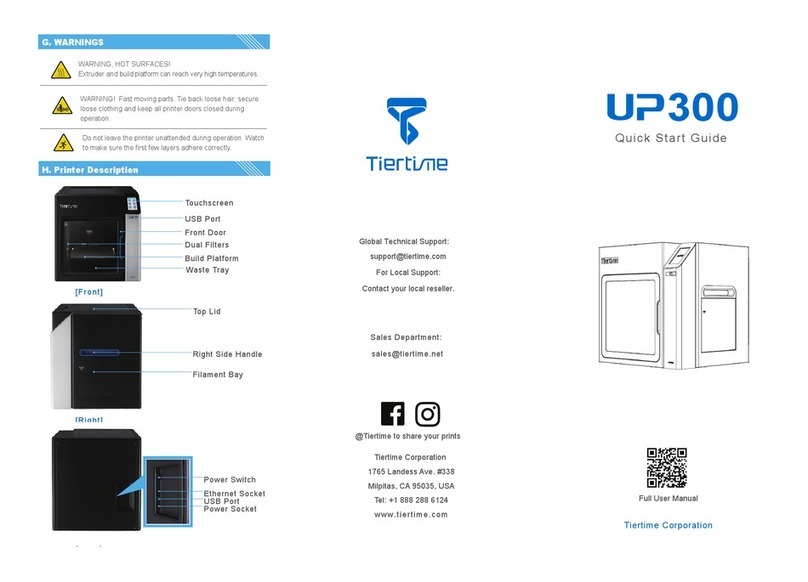

TierTime UP300 User manual

TierTime

TierTime UP BOX User manual

TierTime

TierTime UP600 User manual

TierTime

TierTime UP300D User manual