the

TIMEX

Model

40

Movement

The

Timex

Model

40

is

an

9%

x

12%

ligne

electric

watch

movement

.

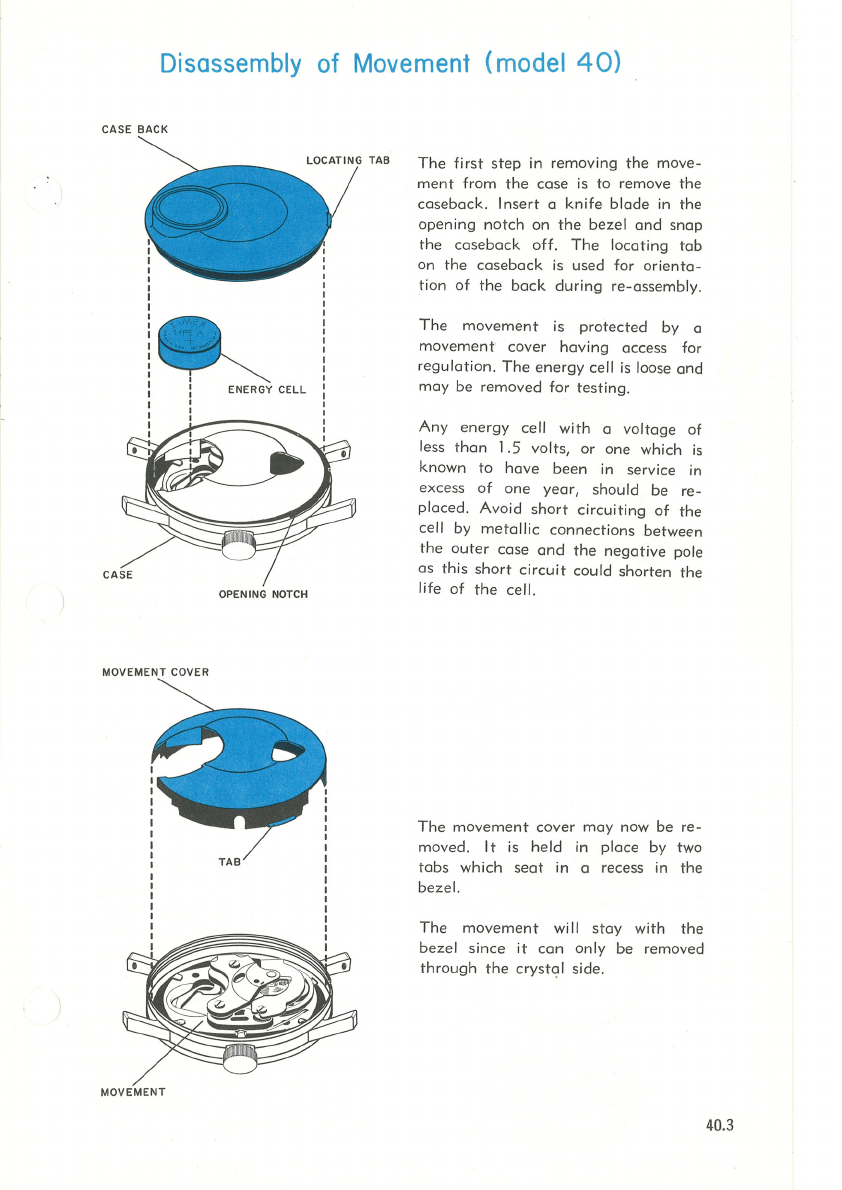

The

power

to

drive

the

movement

is

supplied

by

a

miniature

energy

cell. Power

from

the

energy

cell drives

the

balance.

The

balance

drives

the

time

train

which,

in

turn,

rotates

the

hands.

The

energy

cell

is

guaranteed

for

12

months

and

replacement

cells

are

avail-

able

from your local

Timex

dealer,

repair

station

or

the

Timex

Material

Sales

Division.

It

is

important

to

use

only

genuine

Timex

Energy Cells,

Type

A.

Other

types,

although

they

look

the

same,

may

not

deliver

the

necessary

voltage

or

life

and,

in

addition,

may

leak

,

ser

i

ously

damaging

the

movement

.

The

hands

are

set

in

the

normal

method-tha

t is, pulling

out

and

rot

ating

the

crown.

The

Model

40

incorporates

a

device

which

stops

the

movement

when

the

crown

is

in

the

set

position

. In

this

position,

the

flow of

current

from

the

energy

cell

is

interrupted

and

the

energy

cell is

not

being

discharged

.

The

Timex

electric

has

an

hourly

beat

of

21,600

.

The

large

balance

has

a

temperature

compensated

hairspring

and

the

rate

can

be

adjusted

in

the

usual

way by moving

the

regulator.

The

Timex

electric

can

be

checked

in all positions

on

a

normal

watch

rate

recorder.

The

Timex

electric

can

be

dismantled

and

repaired

with

conventional

tools.

There

is no

need

for special

knowledge

of

electricity

or

electronics,

or

any

need

for

complicated

electrical

measuring

or

inspection

devices, new tools or microscopes.

For

checking

the

battery

voltage,

a

high

ohm

volt

meter

(about

20,000

ohms

per

volt),

which

is

now in

use

in

most

repair

stations,

is

sufficient

.

Since

watch

contains

permanent

magnets,

no

attempt

should

be

made

to

demagnetize

the

watch.

40.1