Tinker & Rasor APS Instruction sheet

Table of contents

Other Tinker & Rasor Security Sensor manuals

Tinker & Rasor

Tinker & Rasor M1/AC Instruction sheet

Tinker & Rasor

Tinker & Rasor M/2 Instruction sheet

Tinker & Rasor

Tinker & Rasor AP/W User manual

Tinker & Rasor

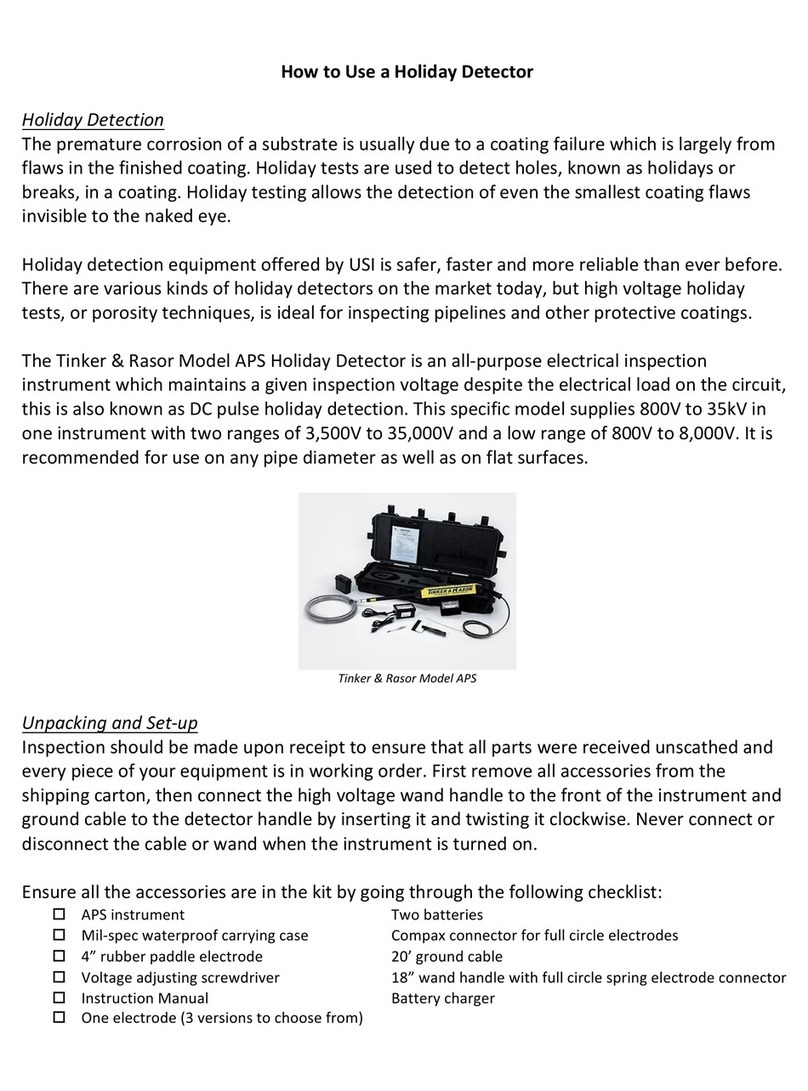

Tinker & Rasor APS User manual

Tinker & Rasor

Tinker & Rasor AP/AC Instruction sheet

Tinker & Rasor

Tinker & Rasor 7-T Instruction sheet

Tinker & Rasor

Tinker & Rasor AP/W User manual

Tinker & Rasor

Tinker & Rasor PD Instruction sheet

Tinker & Rasor

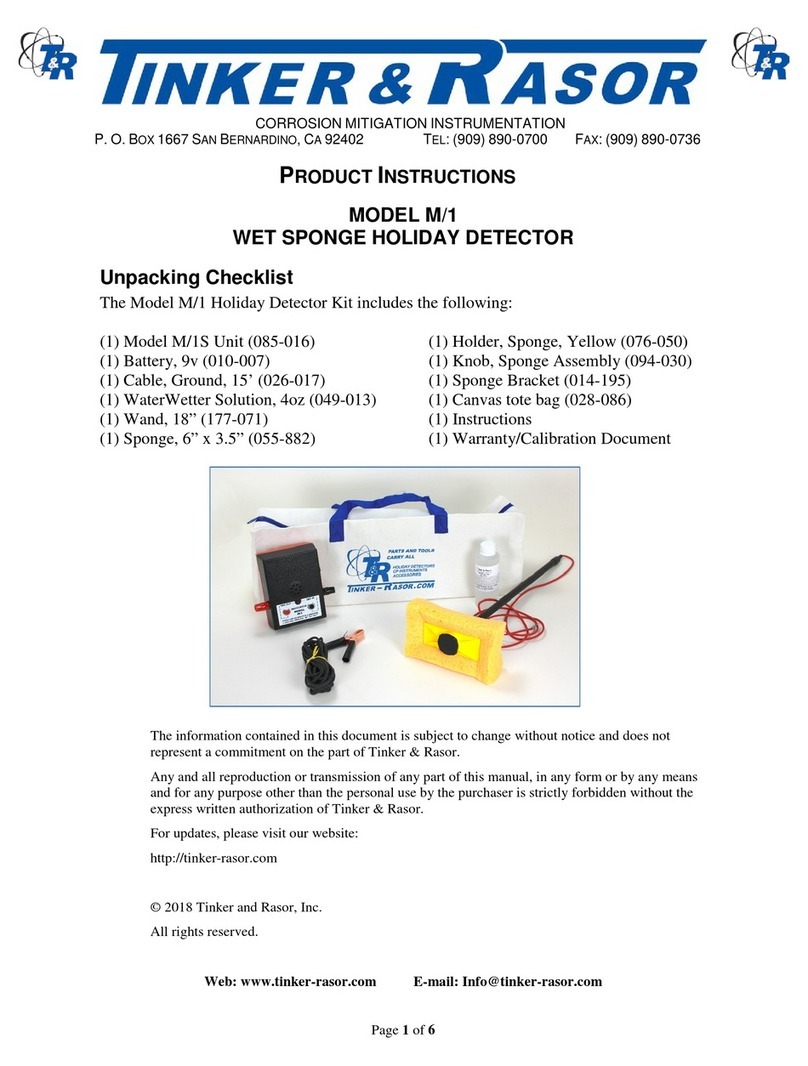

Tinker & Rasor M/1 Instruction sheet

Tinker & Rasor

Tinker & Rasor AP User manual

Popular Security Sensor manuals by other brands

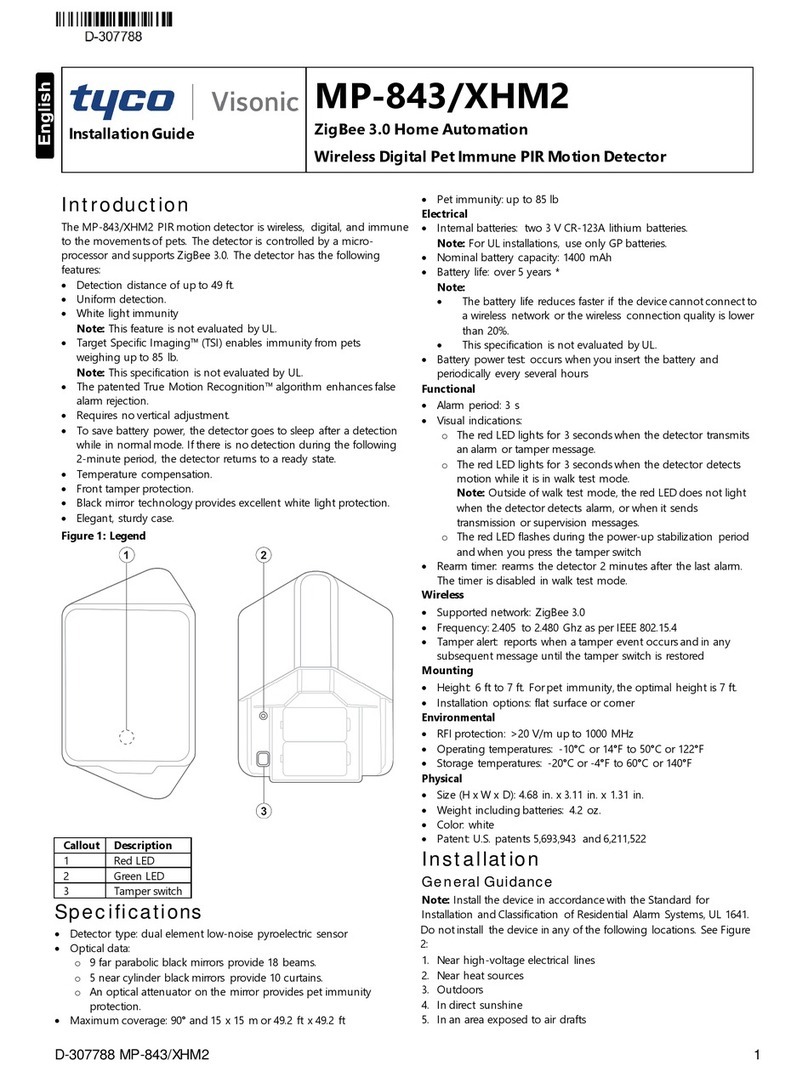

Risco

Risco WatchOUT installation instructions

ATP Electronics

ATP Electronics Heated Pentode ZX-1A owner's manual

TEUFELBERGER

TEUFELBERGER antiSHOCK Manufacturer's information and instructions for use

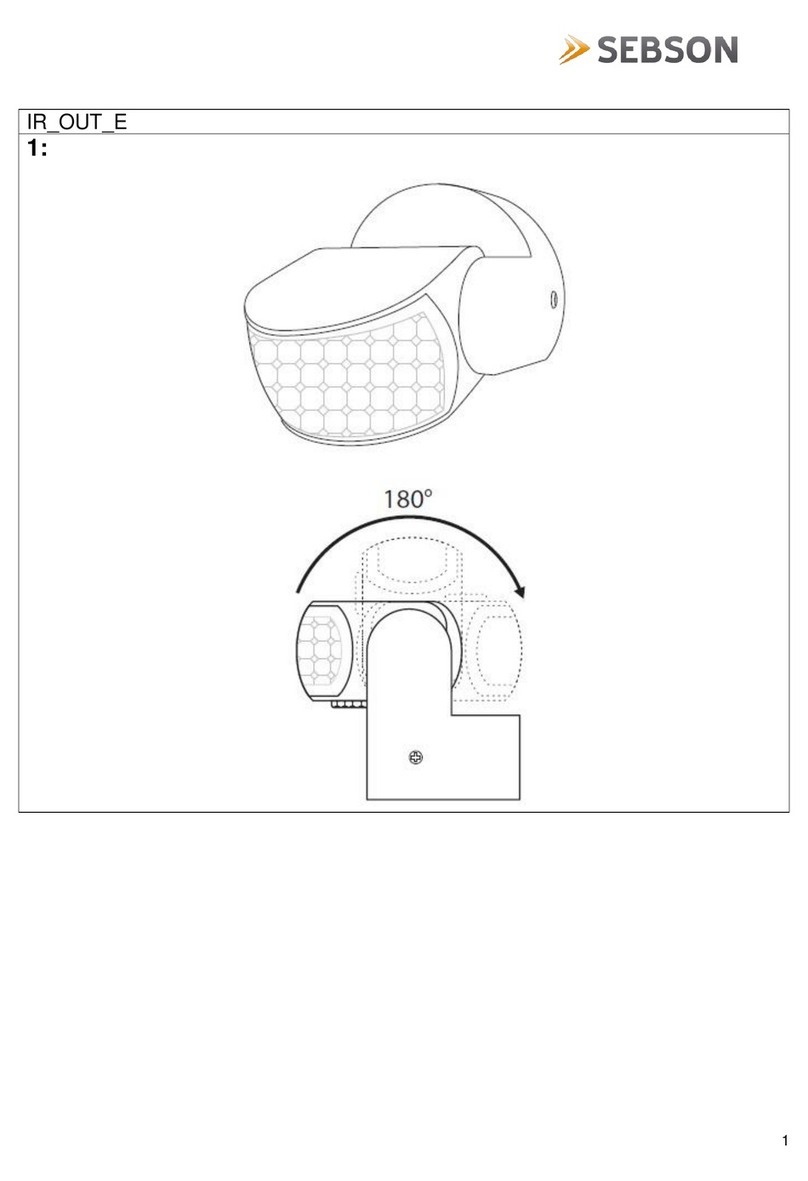

Malmbergs

Malmbergs OS-360PA instruction manual

FORTEZA

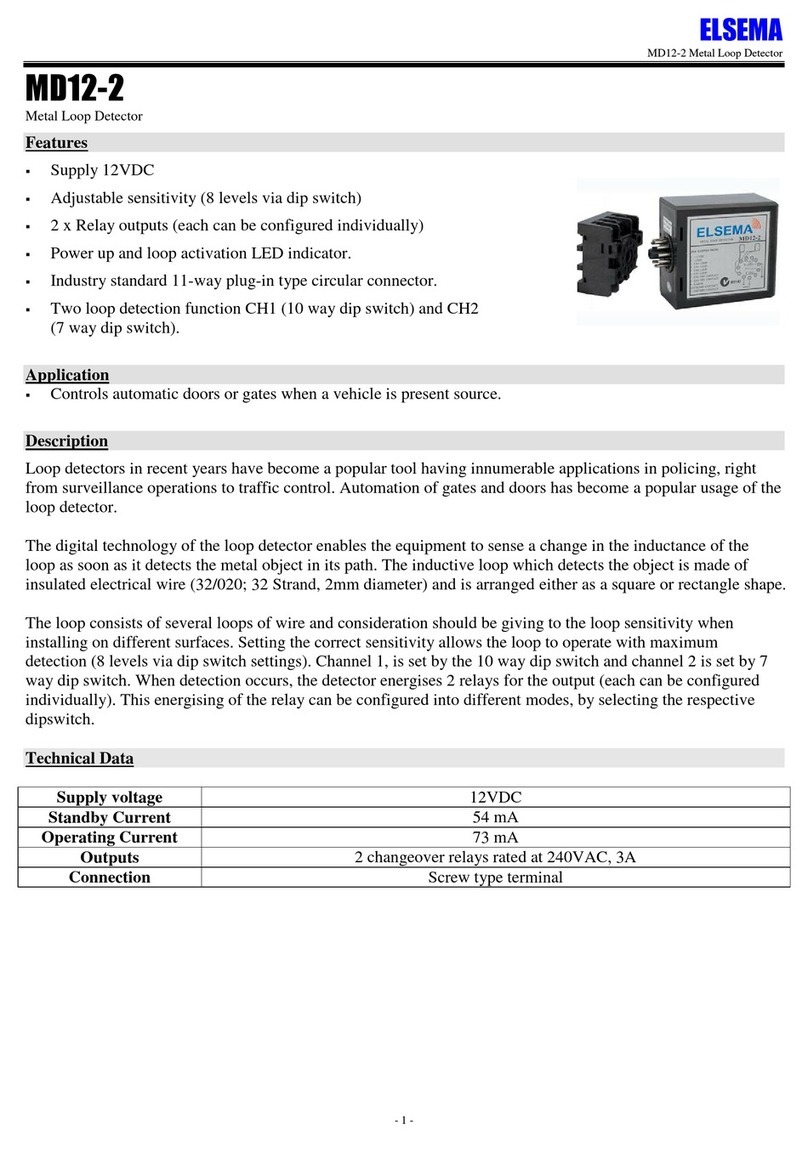

FORTEZA FMC 24 Pro General description manual

Powerfix Profi

Powerfix Profi 285131 Operation and safety notes

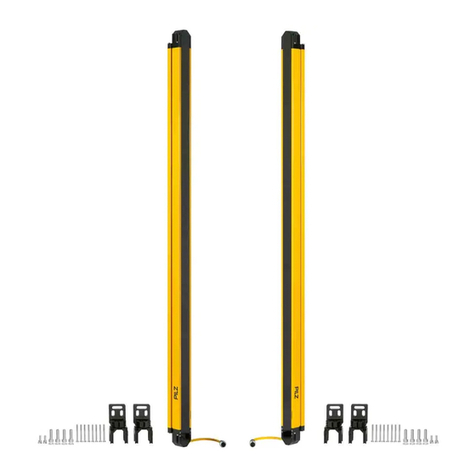

Pilz

Pilz PSEN opII4H Series operating manual

AJAX

AJAX FireProtect 2 (CO) Jeweller user manual

Becker

Becker Centronic SensorControl SC711A Assembly and operating instructions

Transistor

Transistor Lynx manual

Global Fire

Global Fire ZEOS-AD-S quick start guide

Vision

Vision ZD2105IN-5 Installation & operation manual