TLV VA1 User manual

172-65167M-01 (VA Series) 8 January 2003

Rapid Initial Air Vent

VA1 x

xx

x

VA2

VA3 x

xx

x

VA4 x

xx

x

VA5

Copyright © 2003 by TLV CO., LTD.

All rights reserved

ISO 9001/ ISO 14001

Manufacturer

Kakogawa, Japan

is approved by LRQA LTD. to ISO 9001/14001

172-65167M-01 (VA Series) 8 Jan 2003

1

Contents

Introduction........................................................................ 1

Safety Considerations ....................................................... 2

Features of the VA Air Vent............................................... 4

Operation........................................................................... 4

Specifications .................................................................... 5

Configuration ..................................................................... 5

Installation ......................................................................... 6

Maintenance...................................................................... 7

Disassembly / Reassembly ............................................... 7

Troubleshooting................................................................. 8

Product Warranty............................................................... 9

Introduction

Thank you for purchasing the Rapid Initial Air Vent.

This product has been thoroughly inspected before being shipped from the factory.

When the product is delivered, before doing anything else, check the specifications

and external appearance to make sure nothing is out of the ordinary. Also be sure to

read this manual carefully before use and follow the instructions to be sure of using

the product properly.

This rapid initial air vent features a precision-polished float and rubber valve seat

combination that assures a tight seal. Simple, compact construction with no hinges

or levers and only one moving part, the float, provides trouble-free operation and

long service life. The rapid initial air vent is ideal for use where transport of hot or

cold water must take place quickly, such as water supply piping, hot and cold water

tanks and water pumps.

If detailed instructions for special order specifications or options not contained in this

manual are required, please contact for full details.

This instruction manual is intended for use with the model(s) listed on the front cover.

It is necessary not only for installation but for subsequent, maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for

future reference.

172-65167M-01 (VA Series) 8 Jan 2003

2

Safety Considerations

x Read this section carefully before use and be sure to follow the instructions.

x Installation, inspection, maintenance, repairs, disassembly, adjustment, and

valve opening/closing should be carried out only by trained maintenance

personnel.

x The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

x The three types of cautionary items above are very important for safety: be sure

to observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

WARNING NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

CAUTION

DO NOT use this product outside the recommended operating

pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

Use hoisting equipment for heavy objects (weighing

approximately 20 kg or more).

Failure to do so may result in back strain or other injury if the object

should fall.

Take measures to prevent people from coming into direct contact

with product outlets.

Failure to do so may result in burns or other injury from the discharge

of fluids.

Do not use excessive force when connecting threaded pipes to the

product.

Over-tightening may cause breakage leading to fluid discharge, which may

cause burns or other injury.

Safety cautions continued on next page.

172-65167M-01 (VA Series) 8 Jan 2003

3

CAUTION

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the surface of

the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other injuries

or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the product

in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the discharge

of fluids.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

172-65167M-01 (VA Series) 8 Jan 2003

4

Features of the VA Air Vent

1. The vents have no hinges or levers: the only moving part is the self-leveling free

float, which eliminates concentrated wear and provides long service life.

2. The vents are made up of few parts and the construction has been kept simple,

so maintenance checks are also simple.

Operation

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Principles of air and condensate discharge:

1. Rapid Venting of Initial Air at Startup

Gas from inside the piping is very quickly pushed out around

the float guide by liquid pressure.

2. Air Vent Closes

After venting, the float rises with the rising liquid level, closing

the valve. Once closed, the valve will not reopen, even if gas

accumulates inside the product and the liquid level drops.

3. Closed Position

When the pressure inside the piping drops to near or less

than atmospheric pressure, the float drops opening the vent.

Air is allowed to enter to facilitate the drainage of liquid from

the piping.

Air

Condensate

172-65167M-01 (VA Series) 8 Jan 2003

5

Specifications

DO NOT use this product outside the recommended operating pressure,

temperature and other specification ranges. Improper use may result in

such hazards as damage to the product or malfunctions which may

lead to serious accidents. Local regulations may restrict the use of this

product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Model

Size

Inlet / Outlet

mm

Max. Oper.

Press. (PMO)

MPaG

Max. Oper.

Temp. (TMO)

°C

Max. Allowable

Press.* (PMA)

MPaG

Max. Allowable

Temp.* (TMA )

°C

Weight

kg

VA1 50 / 20 4.4 – 5.5

VA2 65 / 25 5.0 – 6.7

VA3 80 / 32 8.4 – 10

VA4 100 / 65 29 – 34

VA5 150 / 100

1.0 100 1.0 150

65 – 72

(1 MPa = 10.197 kg/cm2)

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are PRESSURE

SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

NOTE: Products with special order specifications may differ from the information in the table above. For

full details, please refer to the product drawings.

Configuration

VA1 · VA2 · VA3 VA4 · VA5

No. Name No. Name No. Name

1 Body 5 Cover Bolt 8 Set Screw

2 Cover 6 Valve Seat 9 Float Guide

3 Float 7 Valve Seat Holder 10 Snap Ring

4 Cover Gasket

172-65167M-01 (VA Series) 8 Jan 2003

6

Installation

DO NOT use this product outside the recommended operating pressure,

temperature and other specification ranges. Improper use may result in

such hazards as damage to the product or malfunctions which may

lead to serious accidents. Local regulations may restrict the use of this

product to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg or more). Failure to do so may result in back strain or other injury if

the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, and adjustment should

be done only by trained maintenance personnel.

Note: This product is designed for rapidly venting initial gasses. If gas is expected to

accumulate in the piping during operation, use together with an automatic air vent.

1. Before installation, be sure to remove all protective seals.

2. Before installing the product, blow out the inlet piping to remove any piping

scraps, dirt and oil. Close the inlet valve after blowdown.

3. This product must be installed vertically and with the inlet at the bottom and

the outlet at the top.

4. The product should be inclined no more than 5° horizontally and front-to-back.

5. As this air vent is for the discharge of air and gas from liquid-carrying pipes, it

must not be used for the discharge of air or gas from steam spaces.

6. Install the product at a point where air and gas are likely to collect such as a

bend in the piping.

7. Install piping leading to a drainage vessel or ditch.

8. Be sure to install a valve and strainer (40 mesh or greater) at the product inlet.

Allowable angles of inclination for installation

VA1 · VA2 · VA3 VA4 · VA5

172-65167M-01 (VA Series) 8 Jan 2003

7

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Parts Inspection

When parts have been removed, or during periodic inspections, use the following

table to inspect the parts and replace any that are found to be defective.

Procedure

Gasket(s): check for warping and damage

Valve Seat: check for scratches or wear

Float: check for scratches or dents

Float Guide: check for damage

Disassembly / Reassembly

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

Use hoisting equipment for heavy objects (weighing approximately

20 kg or more). Failure to do so may result in back strain or other injury if

the object should fall.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble. (Installation, inspection, maintenance, repairs, disassembly

and adjustment should be done only by trained maintenance personnel.)

Dissassembly / Reassembly Procedure

Part During Disassembly During Reassembly

Cover Bolt Remove with a socket wrench Consult the table of tightening torques

and tighten to the proper torque

Cover Lift off to remove Make sure there are no pieces of the old

gasket left on the sealing surfaces and

reattach

Cover Gasket Remove, clean sealing surfaces Replace with a new gasket

Set Screw Remove with a Philips

screwdriver

Consult the table of tightening torques

and tighten to the proper torque

Valve Seat Holder Remove; take care as it may

come with the valve seat

Attach making certain that the valve seat

in the proper position

172-65167M-01 (VA Series) 8 Jan 2003

8

Dissassembly / Reassembly Procedure (Continued)

Part During Disassembly During Reassembly

Valve Seat Remove being careful not to

scratch the sealing surface

Clean or replace with new if sealing

surface is warped or damaged

Float Remove, being careful not to

scratch the polished surface

Insert, being careful not to scratch or

misshape

Snap Ring Remove with appropriate pliers Insert securely into groove

Float Guide Remove without misshaping Insert, being careful not to misshape

Torque Tightening Table

Cover Bolt Set Screw

Model Torque

N·m

Distance Across Flats

mm

Torque

N·m

Screw Head

VA1 50 17 0.2 +

VA2 50 17 0.2 +

VA3 50 17 0.2 +

VA4 80 24 0.2 +

VA5 200 36 0.2 +

1 Nm |10 kgcm

Troubleshooting

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

When the product fails to operate properly, use the following table to locate the

cause and remedy.

Problem Cause Remedy

The trapped air cannot displace the water

in the piping

Correct the inlet piping

The valve seat is clogged with dirt or

foreign matter

Clean the valve seat

No air is

discharged

or discharge is

poor*

The inlet or outlet piping is clogged Clean the piping

There is a build-up of rust or scale on the

valve seat or the valve seat is damaged

Clean the valve seat or

replace with a new valve seat

The float is misshapen, dirty or has a film

build-up

Clean the float or replace with

a new float

Liquid leaks

when the vent

is closed

The installation angle of inclination is

incorrect

Correct the installation

The float is damaged or filled with liquid Replace with a new floatThe vent does

not close and

liquid is blowing The specific gravity of the liquid is outside

the specifications for this product

Select a product with suitable

specifications for the

operating conditions

* Note: Once the air vent closes, it will remain closed until internal pressure drops to near or

below atmospheric pressure. This condition may be confused with a malfunction

(blocked). If gas is expected to accumulate in the piping during operation, use together

with an automatic air vent.

172-65167M-01 (VA Series) 8 Jan 2003

9

Product Warranty

1. Warranty Period

One year following product delivery.

2. Warranty Coverage

TLV CO., LTD. warrants this product to the original purchaser to be free

from defective materials and workmanship. Under this warranty, the

product will be repaired or replaced at our option, without charge for parts

or labor.

3. This product warranty will not apply to cosmetic defects, nor to any

product whose exterior has been damaged or defaced; nor does it apply in

the following cases:

x Malfunctions due to improper installation, use, handling, etc., by

other than TLV CO., LTD. authorized service representatives.

x Malfunctions due to dirt, scale, rust, etc.

x Malfunctions due to improper disassembly and reassembly, or

inadequate inspection and maintenance by other than TLV CO., LTD.

authorized service representatives.

x Malfunctions due to disasters or forces of nature.

x Accidents or malfunctions due to any other cause beyond the

control of TLV CO., LTD.

Under no circumstances will TLV CO., LTD. be liable for consequential

economic loss damage or consequential damage to property.

* * * * * * *

For Service or Technical Assistance:

Contact your representative or your regional office.

Manufacturer

CO., LTD.

881 Nagasuna, Noguchi

Kakogawa, Hyogo 675-8511 JAPAN

Tel: 81-(0)794 - 27 - 1800

Other manuals for VA1

1

This manual suits for next models

4

Table of contents

Other TLV Industrial Equipment manuals

TLV

TLV PowerTrap GP5C User manual

TLV

TLV PowerDyne P46SRN User manual

TLV

TLV DC3A-H User manual

TLV

TLV QuickTrap FS Series User manual

TLV

TLV QuickTrap FL Series User manual

TLV

TLV UFO3-BN User manual

TLV

TLV J3S-X-RV User manual

TLV

TLV QuickTrap FJ32-B User manual

TLV

TLV JA Series User manual

TLV

TLV JH3LH-X User manual

Popular Industrial Equipment manuals by other brands

Extreme Networks

Extreme Networks XEM XTR Operation manual

Napa

Napa Carlyle Tools 791-7125A operating manual

SCHUNK

SCHUNK PZN Assembly and operating manual

Montabert

Montabert Z92 instruction manual

Mayr

Mayr ROBATIC 500.1 Series Installation and operational instructions

Siemens

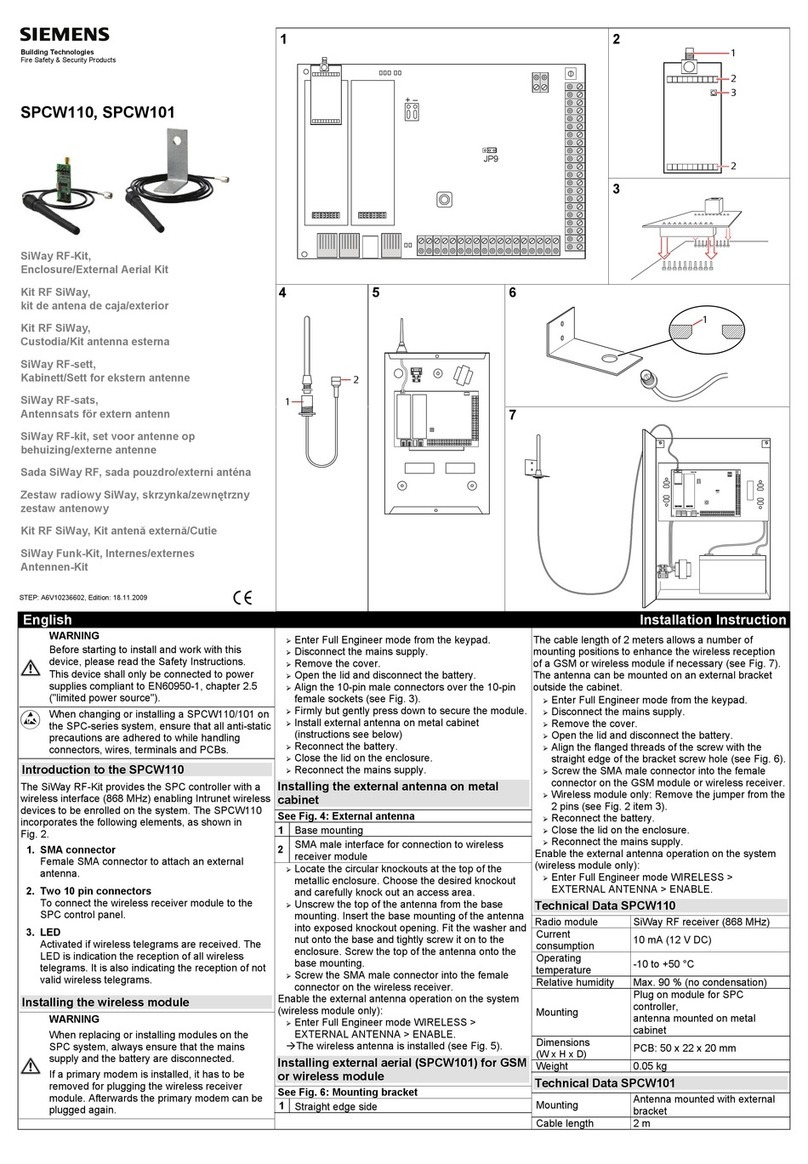

Siemens SPCW110 quick start guide