TLV PowerDyne QuickTrap P46UC-Y User manual

172-65591A-01 (P46UC-Y) 19 January 2021

Manufacturer

881 Nagasuna, Noguchi, Kakogawa, Hyogo, 675-8511, Japan

Tel: [81]-(0)79-422-1122 Fax: [81]-(0)79-422-0112

Copyright © 2021 by TLV Co., Ltd. All rights reserved

Thermodynamic Steam Trap

QuickTrap®

Trap Unit

P46UC-Y

172-65591A-01 (P46UC-Y) 19 Jan 2021

1

Contents

Introduction ........................................................................ 1

Checking the Piping........................................................... 3

Specifications..................................................................... 4

Configuration...................................................................... 4

Installation.......................................................................... 5

Maintenance....................................................................... 6

Disassembly/Reassembly.................................................. 7

Instructions for Plug/Holder Disassembly and Reassembly... 10

Troubleshooting ............................................................... 11

TLV EXPRESS LIMITED WARRANTY............................ 12

Options............................................................................. 14

Introduction

Thank you for purchasing the TLV PowerDyne thermodynamic steam trap.

This product has been thoroughly inspected before being shipped from the factory.

When the product is delivered, before doing anything else, check the specifications and

external appearance to make sure nothing is out of the ordinary. Also be sure to read

this manual carefully before use and follow the instructions to be sure of using the

product properly.

This trap unit is of a revolutionary design that uses a high-performance universal flange

and features a built-in automatic blow-off function and will function as a trap when

installed onto a two bolt connector in the existing pipeline. As it includes a built-in

screen with a large surface area this trap unit is intended for use with connector units

that do not have a built-in screen (Spirax Sarco: PC10, Armstrong: Standard

Connector). The universal flange allows the trap to be installed in either horizontal or

vertical piping. This flexibility greatly reduces the time required for installation and

removal, as compared to conventional steam traps, and also facilitates repair and

maintenance operations. This PowerDyne thermodynamic steam trap features a

bimetal ring for thermostatic air venting, which allows the quick, automatic discharge of

large quantities of initial air and cold condensate immediately after operation start-up,

thereby greatly reducing start-up time. This PowerDyne thermodynamic steam trap,

with its superior features listed above, in combination with the proven performance

record of the bimetal thermostatic air vent, increases heating efficiency and reduces

manpower requirements for maintenance and bypass blowdown.

If detailed instructions for special order specifications or options not contained in this

manual are required, please contact TLV for full details.

This instruction manual is intended for use with the model(s) listed on the front cover. It

is necessary not only for installation, but for subsequent maintenance, disassembly/

reassembly and troubleshooting. Please keep it in a safe place for future reference.

172-65591A-01 (P46UC-Y) 19 Jan 2021

2

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may

occur as a result of erroneous handling, three different types of cautionary

items are used to indicate the degree of urgency and the scale of potential

damage and danger: DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be

sure to observe all of them as they relate to installation, use, maintenance

and repair. Furthermore, TLV accepts no responsibility for any accidents or

damage occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or serious

injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the discharge

of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the surface

of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other injuries

or damage.

Be sure to use onlythe recommended components when repairing

the product, and NEVER attempt to modify the product in any way.

Failure to observe these precautions may result in damage to the product

and burns or other injurydue to malfunction or the discharge of fluids.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

172-65591A-01 (P46UC-Y) 19 Jan 2021

3

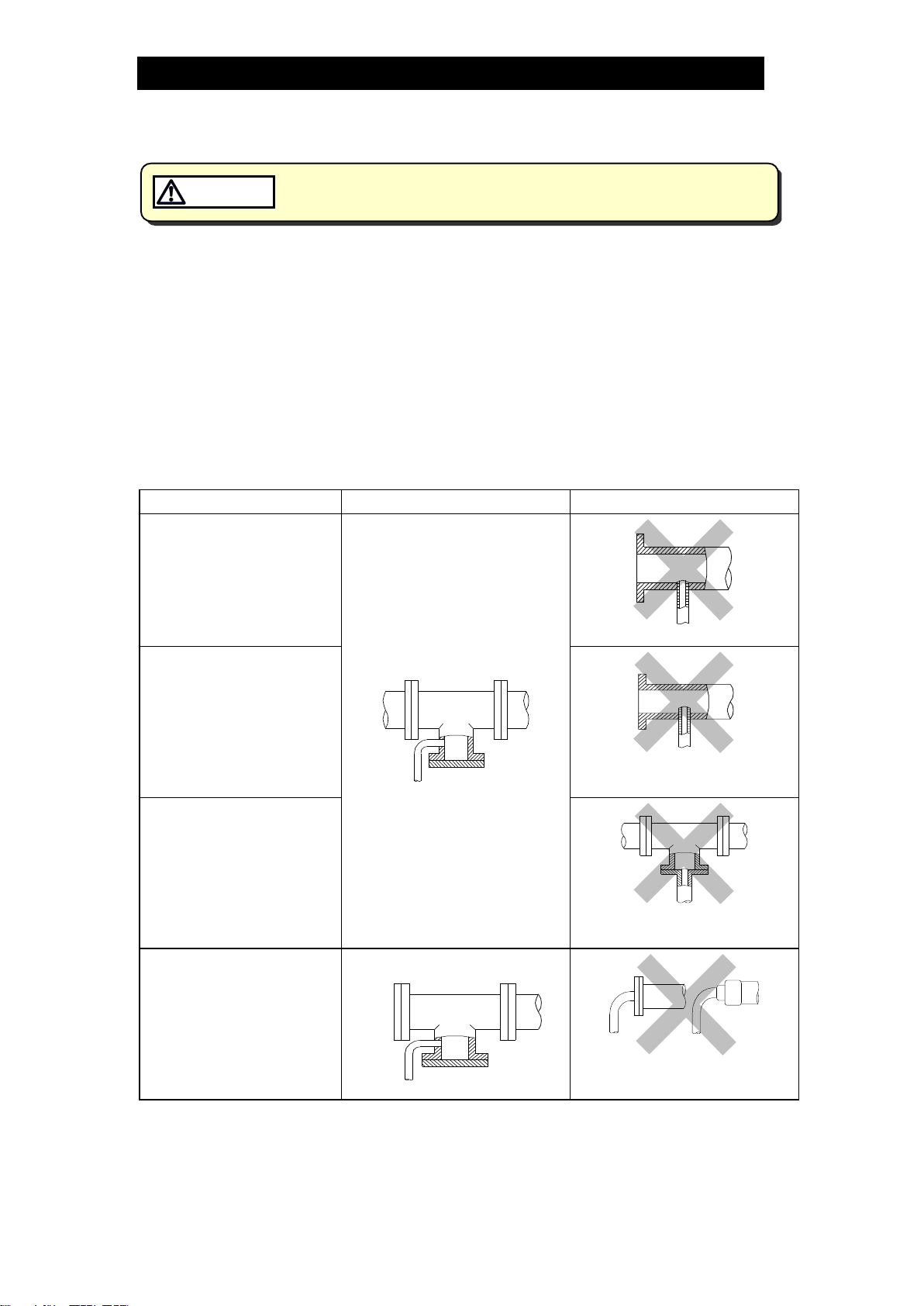

Checking the Piping

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Check to make sure that the pipes to be connected to the trap have been installed

properly.

1. Is the pipe diameter suitable?

2. Has sufficient space been secured for maintenance?

3. Have isolation valves been installed at the inlet and outlet? If the outlet is subject to

back pressure, has a check valve (TLV-CK) been installed?

4. Is the inlet pipe as short as possible, with as few bends as possible, and installed

so the liquid will flow naturally down into the trap?

5. Has the piping work been done correctly, as shown in the figures below?

Requirement

Correct

Incorrect

Install catchpot with the

proper diameter.

Diameter is too small.

Make sure the flow of

condensate is not

obstructed.

Diameter is too small and inlet

protrudes into pipe interior.

To prevent rust and scale

from flowing into the trap,

the inlet pipe should be

connected 25 –50 mm (1

–2 in) above the base of

the T-pipe.

Rust and scale flow into the

trap with the condensate.

When installing on the

blind end, make sure the

flow of condensate is not

obstructed.

Condensate collects in the

pipe.

172-65591A-01 (P46UC-Y) 19 Jan 2021

4

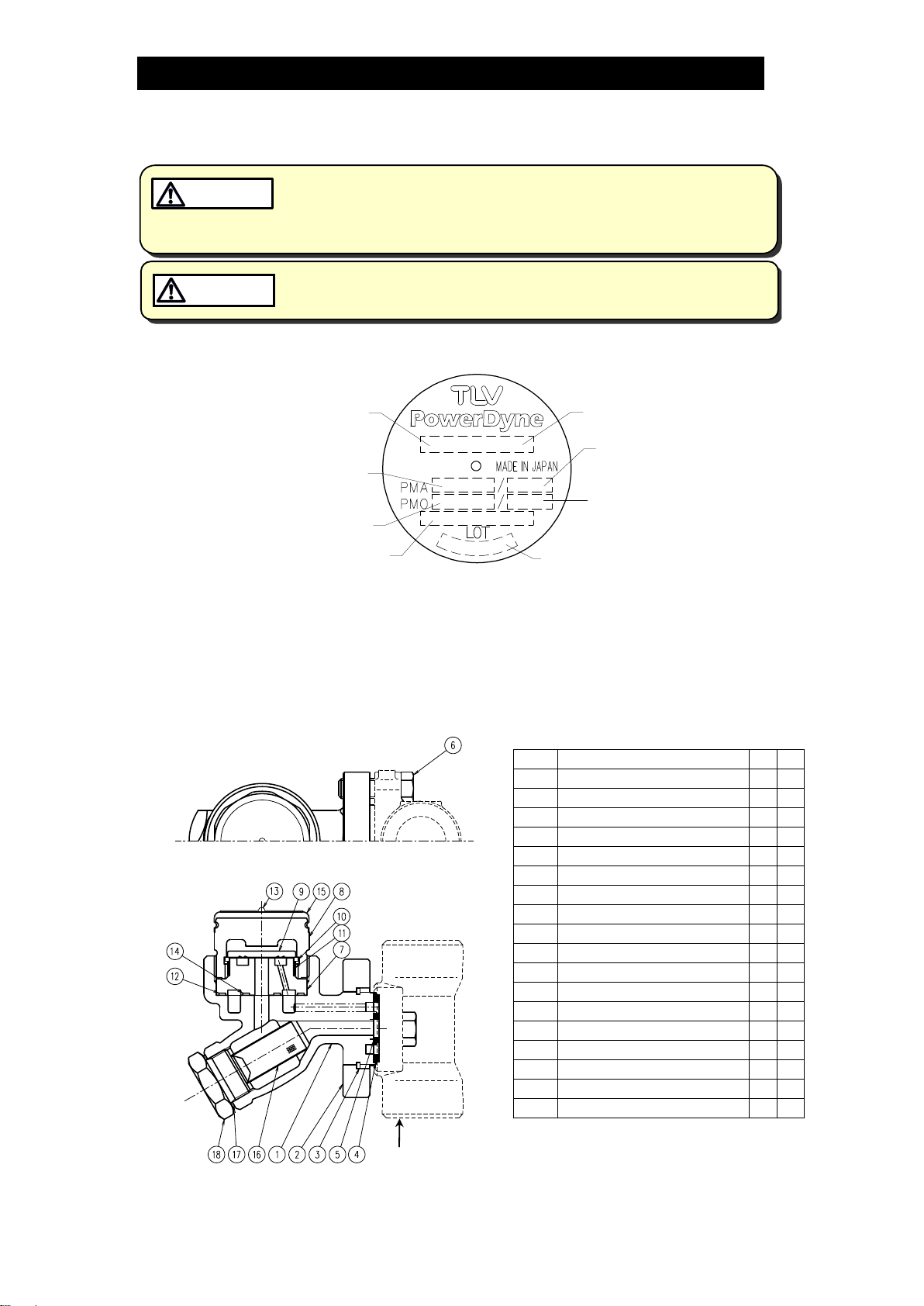

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Refer to the product nameplate for detailed specifications.

Model

Production Lot No.

Maximum Allowable

Temperature (TMA)*

Maximum Operating

Temperature (TMO)

Nominal Diameter

Maximum Allowable

Pressure*

Maximum Operating

Pressure

Valve No.**

Minimum Operating Pressure: 0.03 MPaG (5 psig)

Maximum Allowable Back Pressure: 80% of the inlet pressure

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

Configuration

Connector body

without screen

No.

Name

M

R

1

Trap Body

2

Connector Flange

3

Snap Ring

4

Outer Connector Gasket

5

Inner Connector Gasket

6

Connector Bolt

7

Module Valve Seat

8

Cover

9

Disc

10

Disc Holder Ring

11

Air Vent Ring

12

Outer Module Gasket

13

Nameplate

14

Inner Module Gasket

15

Cap

16

Screen

17

Screen Holder Gasket

18

Screen Holder

*Replacement parts are available only in

the following kits:

M: Maintenance Kit

R: Repair Kit

172-65591A-01 (P46UC-Y) 19 Jan 2021

5

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

The installation procedures shown below are only for the P46UC-Y (trap unit). Please

follow the instruction manual provided by the manufacturer when installing the

connector unit itself.

Applicable connector units: Spirax Sarco PC10, Armstrong standard connector

(neither includes a screen)

(Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.)

1. Install the product, onto the connector unit only if the connector unit is at ambient

temperature and there are no scratches or dirt on the seating surface of the gasket.

2. Before installation, be sure to remove all protective seals.

3. When installing the product onto the connector unit, the universal flange face (for

connecting to the trap unit) must be in the vertical plane, and the trap unit must be

installed with the nameplate facing upwards.

Refer to the “Detaching / Reattaching the Trap Unit”in the “Disassembly /

Reassembly”section described later in this manual.

4. Open the inlet and outlet valves and check to make sure that the product functions

properly.

If there is a problem, determine the cause using the “Troubleshooting” section in this

manual.

Installation Examples: Horizontal Piping

Correct

Incorrect

Nameplate is not facing

upwards

UniversalConnectorFlangeis not

inthe vertical plane

GroundGround

Nameplate

Connector

Flange

GroundGround

GroundGround

GroundGround

GroundGround

Installation Examples: Vertical Piping

Correct

Incorrect

Nameplate is not facing upwards

GroundGround

Nameplate

Connector

Flange

GroundGround

GroundGround

172-65591A-01 (P46UC-Y) 19 Jan 2021

6

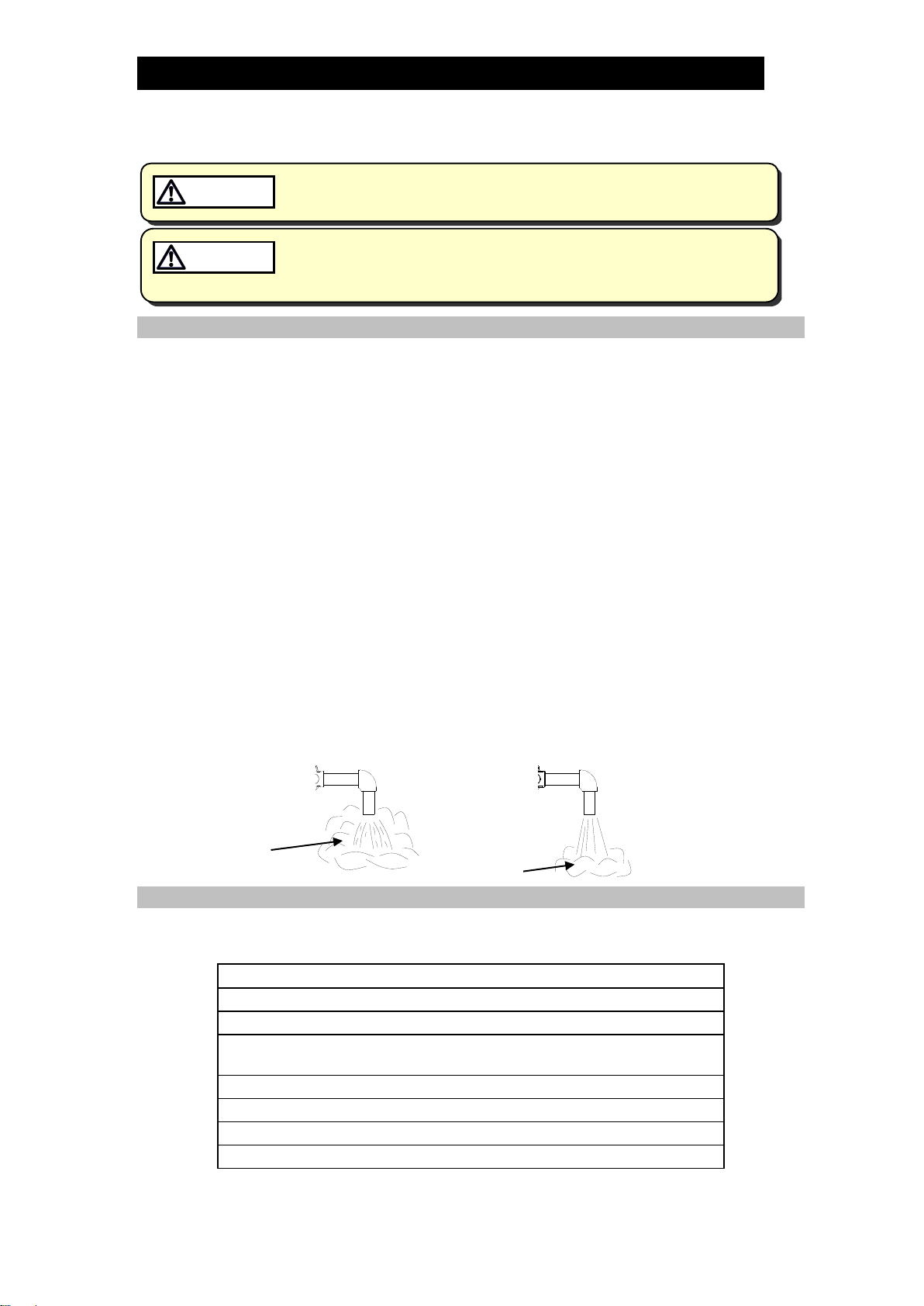

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Inspection

A visual inspection of the following items should be done on a daily basis to determine

whether the product is operating properly or has failed. Periodically (at least biannually)

the operation should also be checked by using diagnostic equipment such as a

stethoscope, thermometer, TLV Pocket TrapMan or TLV TrapMan.

If the product should fail, it may cause damage to piping and equipment, resulting in

faulty or low quality products or losses due to steam leakage.

Normal

:

Condensate is discharged continuously, together with flash steam,

and the sound of flow can be heard. If there is very little

condensate, there is almost no sound of flow.

Blocked

(Discharge Impossible)

:

No condensate is discharged. The product is quiet and makes no

noise, and the surface temperature of the product is low.

Blowing

:

Live steam continually flows from the outlet and there is a

continuous metallic sound.

Steam Leakage

:

Live steam is discharged through the trap outlet together with

condensate, accompanied by a high-pitched sound.

(When conducting a visual inspection, flash steam is sometimes mistaken for steam leakage. For this

reason, the use of a steam trap diagnostic instrument [such as TLV TrapMan if appropriate] in

conjunction with the visual inspection is highly recommended.)

Parts Inspection

When parts have been removed, or during periodic inspections, use the following table

to inspect the parts and replace any that are found to be defective.

Procedure

Gaskets:

Check for warping or scratches

Screens:

Check for clogging or corrosion

Disc:

Check for scratches or wear

Check dirt, oil film, wear and damage

Disc Holder Ring:

Check for scratches or wear

Air Vent Ring:

Check for scratches or wear

Module Valve Seat

Check for scratches or wear

Body Interior:

Check for build-up of scale

Flash Steam

Live Steam Leakage

Clear, slightly

bluish jet

White jet

containing

water droplets

172-65591A-01 (P46UC-Y) 19 Jan 2021

7

Disassembly/Reassembly

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

The Disassembly/Reassembly procedures shown below are only for the P46UC-Y (trap

unit). Please follow the instruction manual provided by the manufacturer when

disassembling / assembling the connector unit itself.

Use the following procedures to remove the product and components. Use the same

procedures in reverse to reassemble.

(Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.)

Detaching / Reattaching the Trap Unit

Part

During Disassembly

During Reassembly

Connector Bolts

Remove with a socket wrench

Consult the table of tightening torques

and tighten to the proper torque

Trap Unit

Remove the trap unit

Follow the special instructions below

(Fig. A)

Inner/Outer

Connector

Gaskets

Remove with a scraper and

clean the connector flange with a

soft tool

Replace with new gaskets; to facilitate

assembly and prevent loosening of the

gaskets, apply a small amount of

adhesive at 120º intervals around the

outer edge of the gaskets

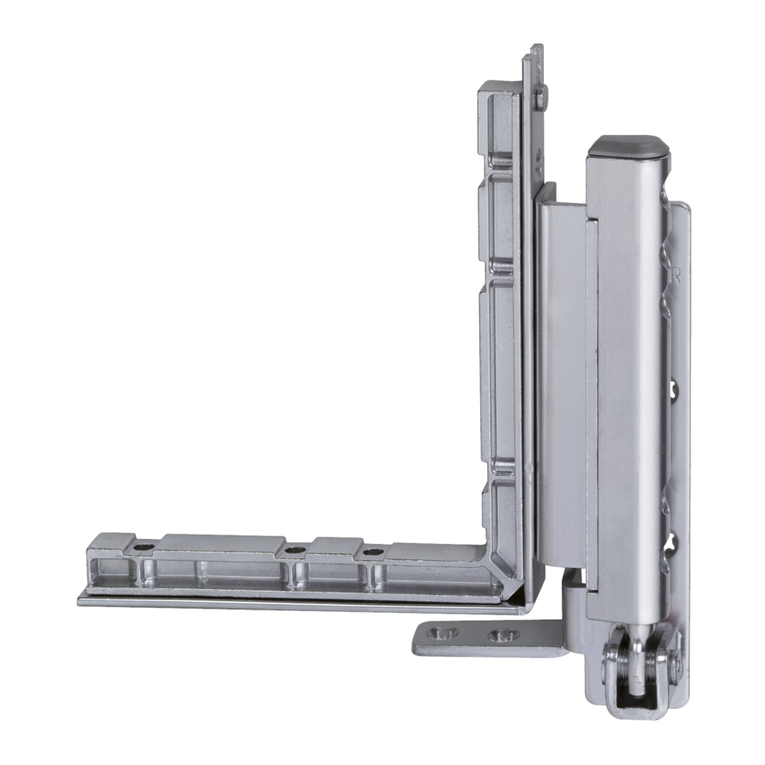

Attaching the Trap Unit to the Connector Unit (Fig. A)

1. If attaching a new trap unit, be sure to remove the protective

cap from the connector flange. Be careful not to drop the

gaskets when removing the cap.

2. Grasp the end of the trap unit and align its gasket housing with

the indentation on the connector unit. Be sure to have the

nameplate facing upwards.

3. Once aligned, insert and finger tighten the connector bolts.

Verify that the trap unit is within the allowable inclination.

Figure A

Disassembly / Reassembly of Components (Screen) Inside the Trap Body

Part

During Disassembly

During Reassembly

Screen Holder

Remove with a socket wrench

Consult the table of tightening torques

and tighten to the proper torque

Screen Holder

Gasket

Remove the gasket

Replace with a new gasket only if warped

or damaged

Screen

Remove with needle-nose pliers

Insert securely into the trap body

172-65591A-01 (P46UC-Y) 19 Jan 2021

8

Removing / Reattaching of Components (Valve Seat Unit) Inside the Trap Body

Part

During Disassembly

During Reassembly

Figure B

Sealing

surface

Cover

Remove with a socket

wrench.

If the cover is seized do not

try to force it loose as this

could result in damage to

the piping. If the cover

appears to be seized,

loosen and remove the

connector bolts and

remove the entire trap unit

from the connector unit.

Then secure the trap unit in

a vice before attempting to

remove the cover.

Consult the table of

tightening torques and

tighten to the proper torque

Disc

Remove, being careful not

to scratch the lapped

surface

Make sure that the seat

surface (lapped side with

groove) is facing down,

toward the valve seat (Fig. B)

Disc Holder

Ring

Remove without bending

Set on the air vent ring and

make sure that it does not

sit on the valve seat surface

Air Vent Ring

Remove without bending,

as it will not return to its

proper shape

Reinsert without bending

Module Valve

Seat

Remove, being careful not

to scratch the lapped

surface

Insert into the body levelly,

being careful not to tilt it or

to scratch the seat surface

Outer Module

Gasket

Remove with a scraper and

clean the gasket housing

Replace with a new gasket

if misshapen or damaged

Inner Module

Gasket

172-65591A-01 (P46UC-Y) 19 Jan 2021

9

Table of Tightening Torques

Part Name

Torque

Distance Across Flats

Nm

(lbfft)

mm

(in)

Cover

250

(185)

46

(113/16)

Connector Bolt

39

(28)

14

(9/16)

Screen Holder

100

(73)

30

(13/16)

(1 Nm 10 kgcm)

NOTE:

- Coat all threaded portions with anti-seize.

- If drawings or other special documentation were supplied for the product, any torque

given there takes precedence over values shown here.

Exploded View

Nameplate

Cover

Disc

Disc Holder Ring

Air Vent Ring

Module Valve Seat

Inner Module Gasket

Outer Module Gasket

Trap Body

Screen Holder

Screen Holder Gasket

Screen

Connector Flange

Inner Connector Gasket

Outer Connector Gasket

(Connector Body)

Connector Bolt

Valve Seat Unit

Cap

172-65591A-01 (P46UC-Y) 19 Jan 2021

10

Instructions for Plug/Holder Disassembly and Reassembly

The seal on the threaded plugs/holders found on TLV products is formed by a flat metal

gasket. There are various installation orientations for the gaskets, such as horizontal,

diagonal and downward, and the gasket may be pinched in the thread recesses during

assembly.

Instructions for Disassembly and Reassembly

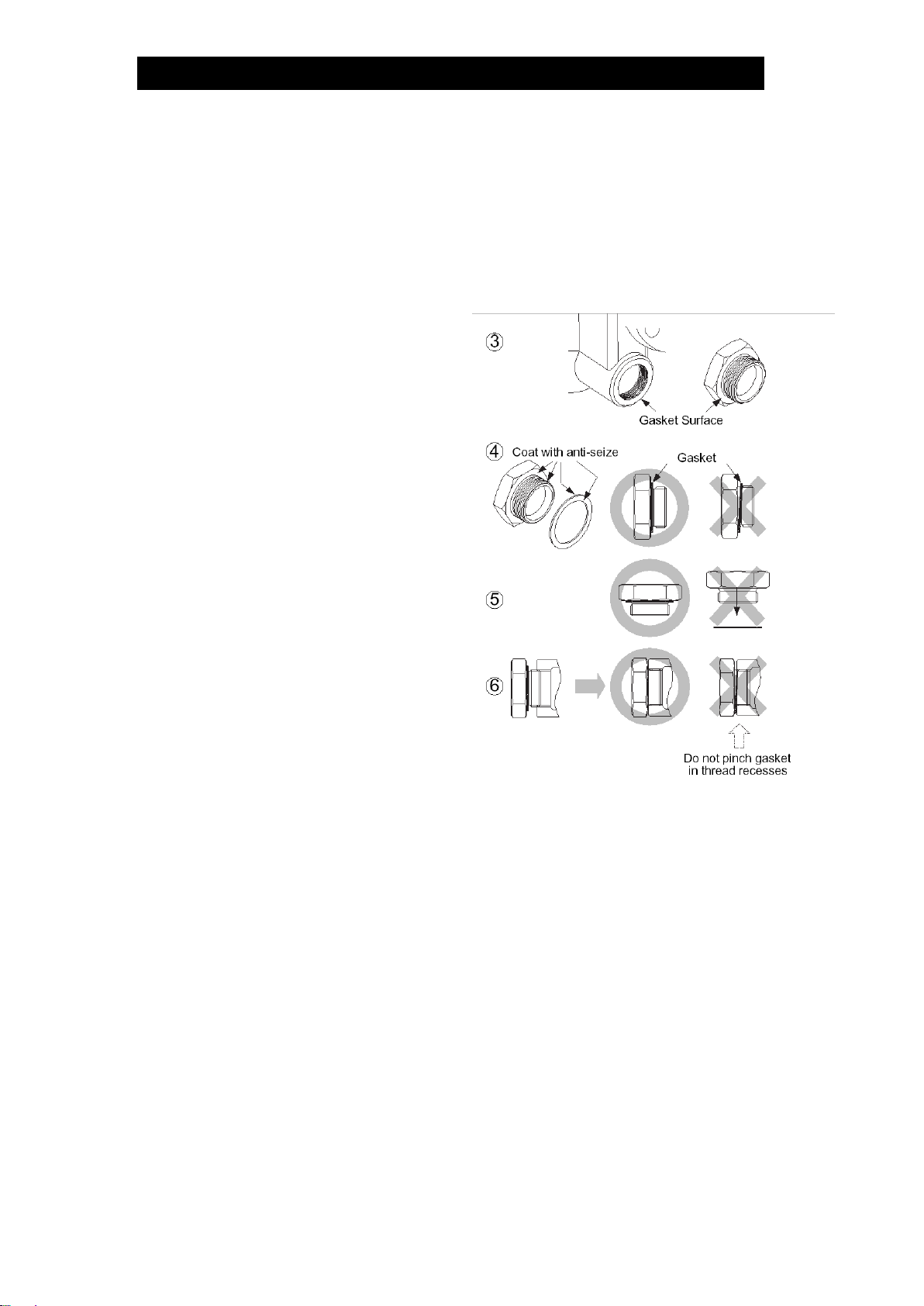

①Remove the plug/holder using a tool

of the specified size (distance across

flats).

②The gasket should not be reused. Be

sure to replace it with a new gasket.

③Clean the gasket surfaces of the

plug/holder and the product body

using a rag and/or cleaning agents,

then check to make sure the

surfaces are not scratched or

deformed.

④Coat both the gasket surface of the

plug/holder and the threads of the

plug/holder with anti-seize, then

press the gasket onto the center of

the gasket surface of the plug/holder,

making sure the anti-seize affixes

the gasket tightly to the plug/holder.

Check to make sure the gasket is

not caught in the recesses of the

threads.

⑤Hold the plug/holder upside down to

make sure that the anti-seize makes

the gasket stick to the plug/holder even when the plug/holder is held upside down.

⑥Screw the plug/holder by hand into the product body while making sure that the

gasket remains tightly affixed to the center of the gasket surface of the plug/holder.

Make sure the entire gasket is making contact with the gasket surface of the

product body. It is important at this point to make sure the gasket is not pinched in

the thread recesses of the plug/holder.

⑦Tighten the plug/holder to the proper torque.

⑧Next, begin the supply of steam and check to make sure there is no leakage from

the part just tightened. If there is leakage, immediately close the inlet valve and, if

there is a bypass valve, take the necessary steps to release any residual pressure.

After the surface of the product cools to room temperature, repeat the procedure

beginning from step 1.

172-65591A-01 (P46UC-Y) 19 Jan 2021

11

Troubleshooting

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

If the trap fails to operate properly, use the following table to locate the cause and

remedy.

Problem

Cause

Remedy

No condensate is

discharged (blocked)

or discharge is poor

The module valve seat, screen or piping

are clogged with rust or scale

Clean parts

The disc is stuck to the module valve

seat surface

Clean parts

Air binding has occurred

Perform a bypass blowdown, or

close the trap inlet valve and

allow the trap to cool

Air binding due to the disc holder ring or

air vent ring wear

Replace with a new disc holder

ring or air vent ring

Steam-locking has occurred

Perform a bypass blowdown or

close the trap inlet valve and

allow the trap to cool. Piping

correction may also be required.

Trap operating pressure is below the

minimum specified pressure or there is

insufficient pressure differential between

the trap inlet and outlet

Compare specifications and

actual operating conditions

Steam is discharged

or leaks from the

outlet

(blowing)

(steam leakage)

Rust or scale on the disc or on the

module valve seat

Clean parts

Disc or module valve seat surface

damage or wear

Replace with a new disc

Replace with a new module

valve seat or trap unit

Improper installation orientation

Correct the installation

Trap vibration

Lengthen the inlet piping and

fasten it securely

Trap operating pressure is less than the

minimum specified pressure or the back

pressure exceeds the allowable back

pressure

Compare specifications and

actual operating conditions

The back pressure exceeds the

allowable back pressure (50% of inlet

pressure)

Compare specifications and

actual operating conditions

Steam is leaking from

a place other than the

outlet

Gasket deterioration or damage

Replace the gaskets

Improper tightening torque was used

Tighten to the proper torque

Note: If parts need replacement, refer to the parts list in this manual and select the appropriate

kit/unit for replacement parts. Parts are only available as a part of the kits/units shown.

172-65591A-01 (P46UC-Y) 19 Jan 2021

12

TLV EXPRESS LIMITED WARRANTY

Subject to the limitations set forth below, TLV Corporation, a North Carolina corporation

(“TLV”) warrants that products which are sold by it, TLV CO., LTD., a Japanese corporation

(“TLVJ”) or TLV International, Inc., a Japanese corporation (“TII”), (hereinafter the

“Products”) are designed and manufactured by TLVJ, conform to the specifications

published by TLV for the corresponding part numbers (the “Specifications”) and are free

from defective workmanship and materials. With regard to products or components

manufactured by unrelated third parties (the “Components”), TLV provides no warranty

other than the warranty from the third party manufacturer(s), if any.

Exceptions to Warranty

This warranty does not cover defects or failures caused by:

1. improper shipping, installation, use, handling, etc., by other than TLV or service

representatives authorized by TLV; or

2. dirt, scale or rust, etc.; or

3. improper disassembly and reassembly, or inadequate inspection and maintenance

by other than TLV or service representatives authorized by TLV; or

4. disasters or forces of nature or Acts of God; or

5. abuse, abnormal use, accidents or any other cause beyond the control of TLV; or

6. improper storage, maintenance or repair; or

7. operation of the Products not in accordance with instructions issued with the

Products or with accepted industry practices; or

8. use for a purpose or in a manner for which the Products were not intended; or

9. use of the Products in a manner inconsistent with the Specifications; or

10. use of the Products with Hazardous Fluids (fluids other than steam, air, water,

nitrogen, carbon dioxide and inert gases (helium, neon, argon, krypton, xenon and

radon)); or

11. failure to follow the instructions contained in the TLV Instruction Manual for the

Product.

Duration of Warranty

This warranty is effective for a period of the earlier of: (i) three (3) years after delivery of

Products to the first end user in the case of sealed SST-Series Products for use in steam

pressure service up to 650 psig; (ii) two (2) years after delivery of Products to the first end

user in the case of PowerTrap®units; or (iii) one (1) year after delivery of Products to the

first end user in the case of all other Products. Notwithstanding the foregoing, asserting a

claim under this warranty must be brought by the earlier of one of the foregoing periods,

as applicable, or within five (5) years after the date of delivery to the initial buyer if not

sold initially to the first end user.

ANY IMPLIED WARRANTIES NOT NEGATED HEREBY WHICH MAY ARISE BY OPERATION

OF LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE AND ANY EXPRESS WARRANTIES NOT NEGATED HEREBY,

ARE GIVEN SOLELY TO THE INITIAL BUYER AND ARE LIMITED IN DURATION TO ONE (1)

YEAR FROM THE DATE OF SHIPMENT BY TLV.

Exclusive Remedy

THE EXCLUSIVE REMEDY UNDER THIS WARRANTY, UNDER ANY EXPRESS WARRANTY

OR UNDER ANY IMPLIED WARRANTIES NOT NEGATED HEREBY (INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE), IS

REPLACEMENT; PROVIDED: (a) THE CLAIMED DEFECT IS REPORTED TO TLV IN WRITING

WITHIN THE APPLICABLE WARRANTY PERIOD, INCLUDING A DETAILED WRITTEN

DESCRIPTION OF THE CLAIMED DEFECT AND HOW AND WHEN THE CLAIMED DEFECTIVE

PRODUCT WAS USED; AND (b) THE CLAIMED DEFECTIVE PRODUCT AND A COPY OF THE

172-65591A-01 (P46UC-Y) 19 Jan 2021

13

PURCHASE INVOICE IS RETURNED TO TLV, FREIGHT AND TRANSPORTATION COSTS

PREPAID, UNDER A RETURN MATERIAL AUTHORIZATION AND TRACKING NUMBER

ISSUED BY TLV. ALL LABOR COSTS, SHIPPING COSTS, AND TRANSPORTATION COSTS

ASSOCIATED WITH THE RETURN OR REPLACEMENT OF THE CLAIMED DEFECTIVE

PRODUCT ARE SOLELY THE RESPONSIBILITY OF BUYER OR THE FIRST END USER. TLV

RESERVES THE RIGHT TO INSPECT ON THE FIRST END USER’S SITE ANY PRODUCTS

CLAIMED TO BE DEFECTIVE BEFORE ISSUING A RETURN MATERIAL AUTHORIZATION.

SHOULD SUCH INSPECTION REVEAL, IN TLV’S REASONABLE DISCRETION, THAT THE

CLAIMED DEFECT IS NOT COVERED BY THIS WARRANTY, THE PARTY ASSERTING THIS

WARRANTY SHALL PAY TLV FOR THE TIME AND EXPENSES RELATED TO SUCH ON-SITE

INSPECTION.

Exclusion of Consequential and Incidental Damages

IT IS SPECIFICALLY ACKNOWLEDGED THAT THIS WARRANTY, ANY OTHER EXPRESS

WARRANTY NOT NEGATED HEREBY, AND ANY IMPLIED WARRANTY NOT NEGATED

HEREBY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, DO NOT COVER, AND NEITHER TLV, TII NOR TLVJ WILL IN

ANY EVENT BE LIABLE FOR, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING,

BUT NOT LIMITED TO LOST PROFITS, THE COST OF DISASSEMBLY AND SHIPMENT OF

THE DEFECTIVE PRODUCT, INJURY TO OTHER PROPERTY, DAMAGE TO BUYER’S OR THE

FIRST END USER’S PRODUCT, DAMAGE TO BUYER’S OR THE FIRST END USER’S

PROCESSES, LOSS OF USE, OR OTHER COMMERCIAL LOSSES. WHERE, DUE TO

OPERATION OF LAW, CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER THIS

WARRANTY, UNDER ANY OTHER EXPRESS WARRANTY NOT NEGATED HEREBY OR

UNDER ANY IMPLIED WARRANTY NOT NEGATED HEREBY (INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE)

CANNOT BE EXCLUDED, SUCH DAMAGES ARE EXPRESSLY LIMITED IN AMOUNT TO THE

PURCHASE PRICE OF THE DEFECTIVE PRODUCT. THIS EXCLUSION OF CONSEQUENTIAL

AND INCIDENTAL DAMAGES, AND THE PROVISION OF THIS WARRANTY LIMITING

REMEDIES HEREUNDER TO REPLACEMENT, ARE INDEPENDENT PROVISIONS, AND ANY

DETERMINATION THAT THE LIMITATION OF REMEDIES FAILS OF ITS ESSENTIAL

PURPOSE OR ANY OTHER DETERMINATION THAT EITHER OF THE ABOVE REMEDIES IS

UNENFORCEABLE, SHALL NOT BE CONSTRUED TO MAKE THE OTHER PROVISIONS

UNENFORCEABLE.

Exclusion of Other Warranties

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, AND

ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY

DISCLAIMED.

Severability

Any provision of this warranty which is invalid, prohibited or unenforceable in any

jurisdiction shall, as to such jurisdiction, be ineffective to the extent of such invalidity,

prohibition or unenforceability without invalidating the remaining provisions hereof, and

any such invalidity, prohibition or unenforceability in any such jurisdiction shall not

invalidate or render unenforceable such provision in any other jurisdiction.

13901 South Lakes Drive, Charlotte, NC 28273-6790, U.S.A.

Tel: [1]-704-597-9070 Fax: [1]-704-583-1610

172-65591A-01 (P46UC-Y) 19 Jan 2021

14

Options

When operating the blowdown valve, stand to the side well clear of the

outlet to avoid contact with internal fluids that will be discharged. Failure

to do so may result in burns or other injury.

CAUTION

Do not use excessive force when opening the blowdown valve. Such

force may break the pin equipped as a valve stopper pin, causing a

blowout from internal pressure resulting in burns or other injury.

CAUTION

With Blowdown Valve (TLV BD2)

Configuration

Screen Holder Gasket

BD2 Valve Seat

(Screen Holder)

BD2 Valve

Discharge Hole

Screen

Stopper Pin

TLV Blowdown Valve: BD2

The BD2 Blowdown Valve, installed in the screen area of the trap body, uses the trap’s

internal pressure to blow any condensate, steam, dirt or scale accumulated around the

screen area out to atmosphere.

172-65591A-01 (P46UC-Y) 19 Jan 2021

15

BD2 Blowdown Valve Operation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

1. The BD2 valve is in the closed position when the BD2 is shipped from the factory.

Before attempting to operate the BD2, reconfirm that the BD2 valve is still in the

closed position. Locate the blow outlet and, during operation, stand to the side and

well clear of it, as the jet of condensate or steam could cause burns.

2. Remain in the area the entire time the BD2 valve is in the open position. Before

opening the BD2 valve, grip the BD2 valve seat with a wrench and hold firmly in

place so that it will not rotate when the BD2 valve is loosened. Grip the BD2 valve

with another wrench and slowly loosen. Condensate and steam will discharge from

the blow outlet in a jet stream. Be careful not to loosen the BD2 valve so far that it

becomes removed from the BD2 valve seat. (If the grooved pin becomes damaged,

large quantities of steam will be discharged in a jet stream.)

3. Close the BD2 valve until the flow of fluid completely stops. If the flow of fluid does

not stop, re-open the valve (as in step “2”) to blow out any scale or dirt that may be

caught in the valve. Re-tighten the valve until the flow of fluid stops completely.

Tightening Torques and Distance Across Flats

Part Name

Torque

Distance Across Flats

Nm

(lbfft)

mm

(in)

BD2 Valve

30

(22)

17

(21/32)

Screen Holder

100

(73)

30

(13/16)

(1 Nm 10 kgcm)

NOTE: Avoid the use of excessive tightening torques, as threaded parts may become damaged.

Table of contents

Other TLV Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

EASTMAN

EASTMAN C Series Instruction and Illustrated manual

Yale

Yale MWW Series operating instructions

Wow

Wow Coolius 4000 Bus instruction manual

PCB Piezotronics

PCB Piezotronics PCB Load & Torque 1102-03A Installation and operating manual

Indutherm

Indutherm VTC Series instruction manual

Speedball

Speedball 004230 manual