MTUT007MOEN

MONOFLANGE

USER’S AND MAINTENANCE MANUAL

REV. B

PAG. 4/13

Before installing a new valve in a line, make sure that materials used for construction, surface treatments,

seats and seals are suited for the intended service. All information are indicated on the tag placed on the

valve (or fastened). Pay attention especially to maximum admissible pressure (PS), project temperature

and rating of input and output connections. In case of missing information, please contact WIKA Instruments

Italia

Remove any protective covers used to protect the terminals during transport and strongly clean the contact

surfaces from protective film if they are applied.

Be sure that the position of the valve is completely open before installing it on the line.

Be sure that pipeline is completely clean and without foreign forms before proceeding with mounting and

running of the valve.

To increase the probability of trouble free service, ensure that proper care and attention is taken during

the installation process.

Unpack the monoflange and check the tag, nameplate or body stamping for correct part / identification

number.

Check the monoflange tag nameplate for flow direction to ensure correct installation. If the valve

schematic is not shown on the valve body, refer back to the relevant general assembly drawing or

contact WIKA Instruments Italia.

Immediately prior to valve installation check the piping to which the valve is to be connected, for

cleanliness and freedom from foreign materials.

3.1. Threaded Valve Installation

Pipe or fitting connections must be tight. Threaded pipe joints depend on a good fit between the male

and female pipe threads usually with the use of a thread tape or sealant.

Check the threads on both the valve and the mating pipe for both form and cleanliness.

Do not use substantial wrenching force on a tapered pipe joint until it is apparent that threads are

properly engaged. Taper pipe threads are inherently loose fit at entry.

3.2. Welding Joint Valve Installation

Welding joints properly made provide a structure and metallurgical continuity between the pipe and the

valve. All welding should be in accordance with the appropriate installation code.

3.3. Flanged Joint Valve Installation.

Prior to assembly, mating flanges should be checked to ensure correct size and rating. Flanges should be

assembled using correct gasket or seal ring and bolting as specified in ANSI B16-5

4. OPERATION

Monoflanges which have been matched to a typical service application and properly installed in its piping

system can be expected to have a long service life with a minimum of attention. However, valves have

moving and wearing parts and depend on long term preservation of highly finished surfaces on certain

working parts for satisfactory performance.

The handle of the valve has been designed to provide an adequate force to operate the valve with the

maximum pressure differential across it. The use of an additional mechanical device to operate the valve

is not recommended as this may result in damage to the valve

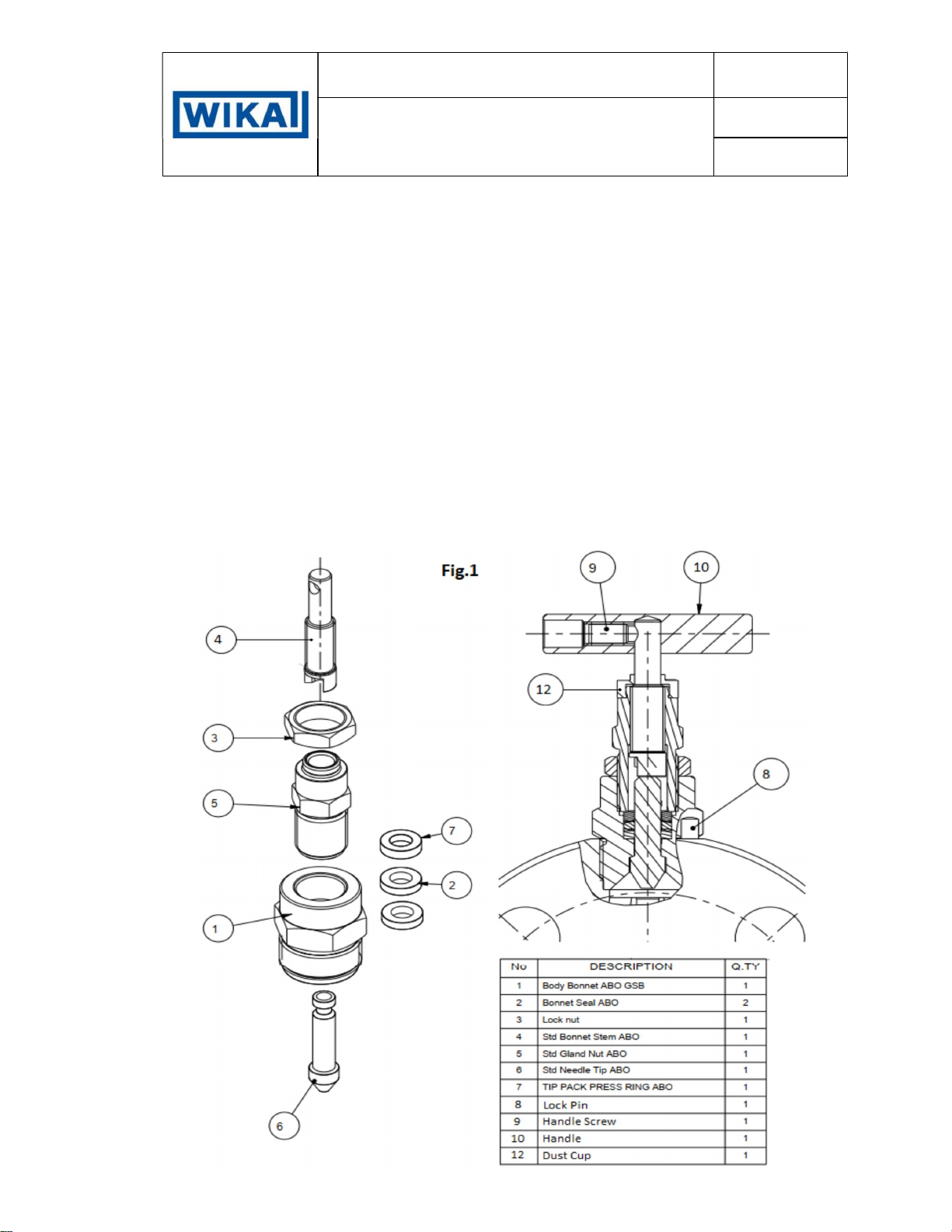

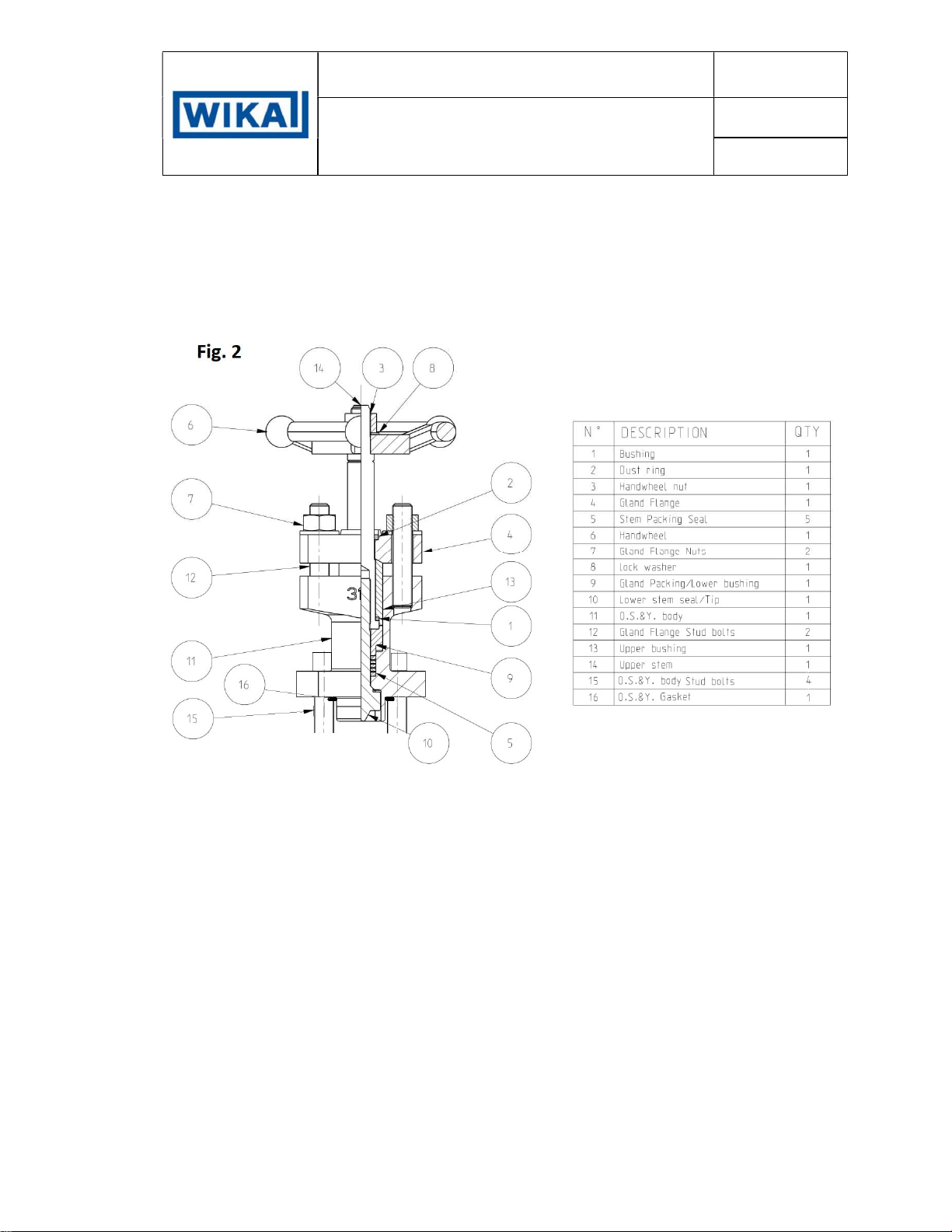

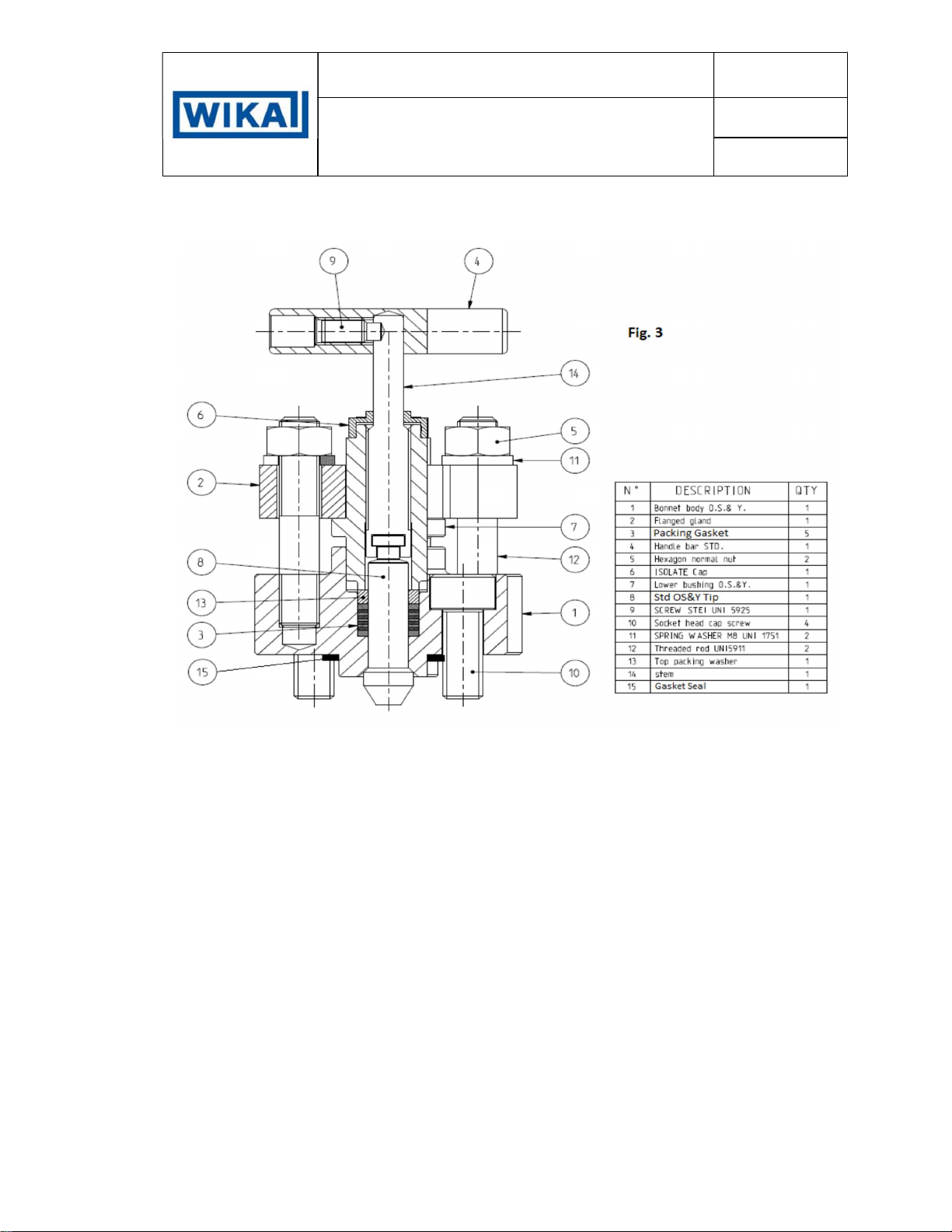

OS&Y Bonnet Approximately 8 turns from open to close, clockwise to close

Needle Screwed bonnet Approximately 4 turns from open to close, clockwise to close