ENGLISH

3

III. OPERATION

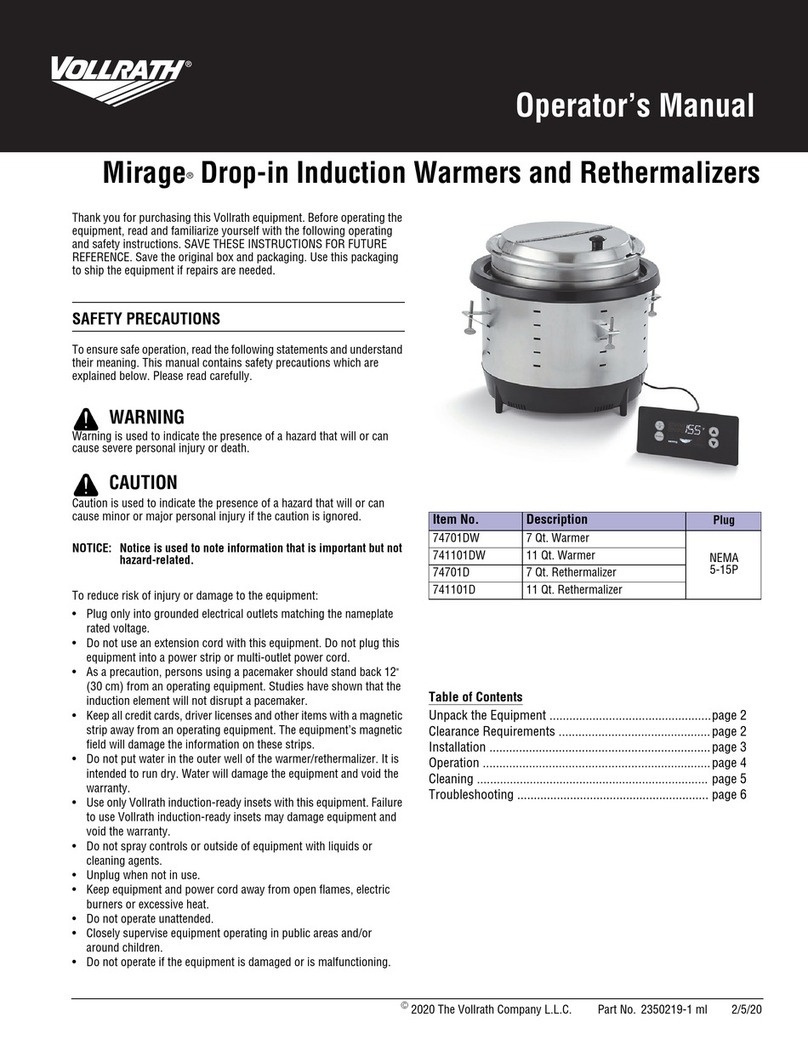

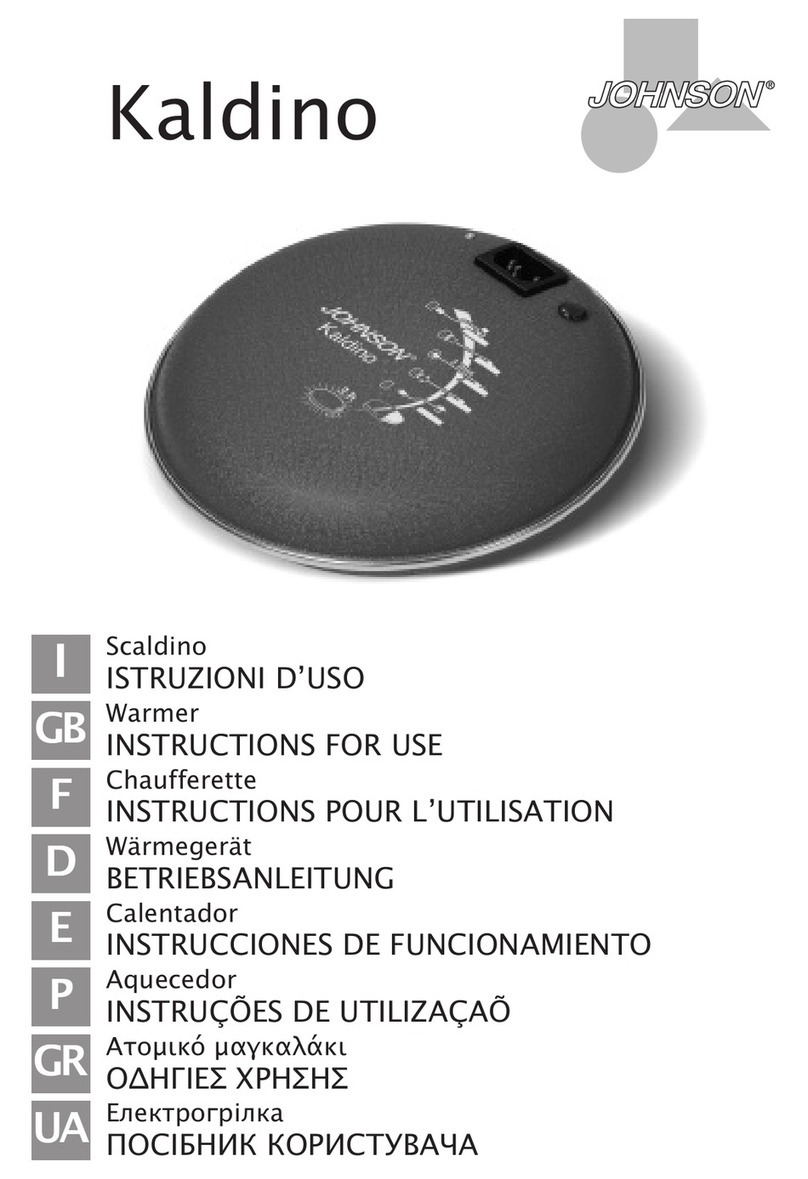

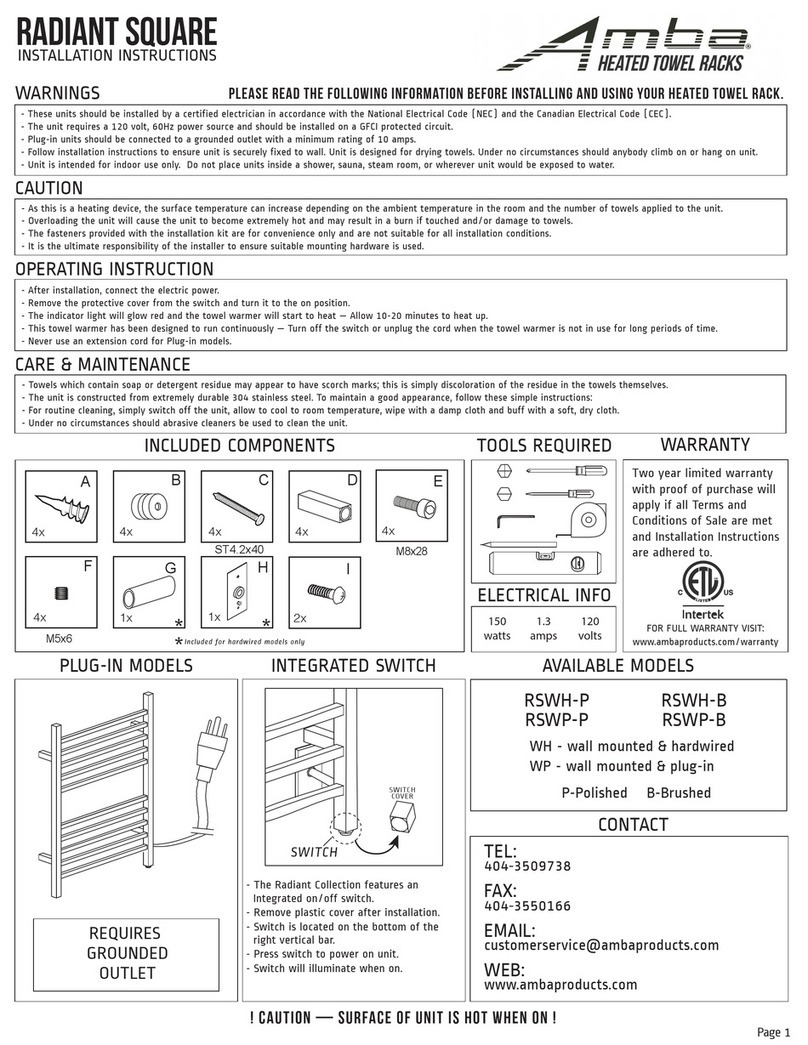

A. Location and Function of Contro s

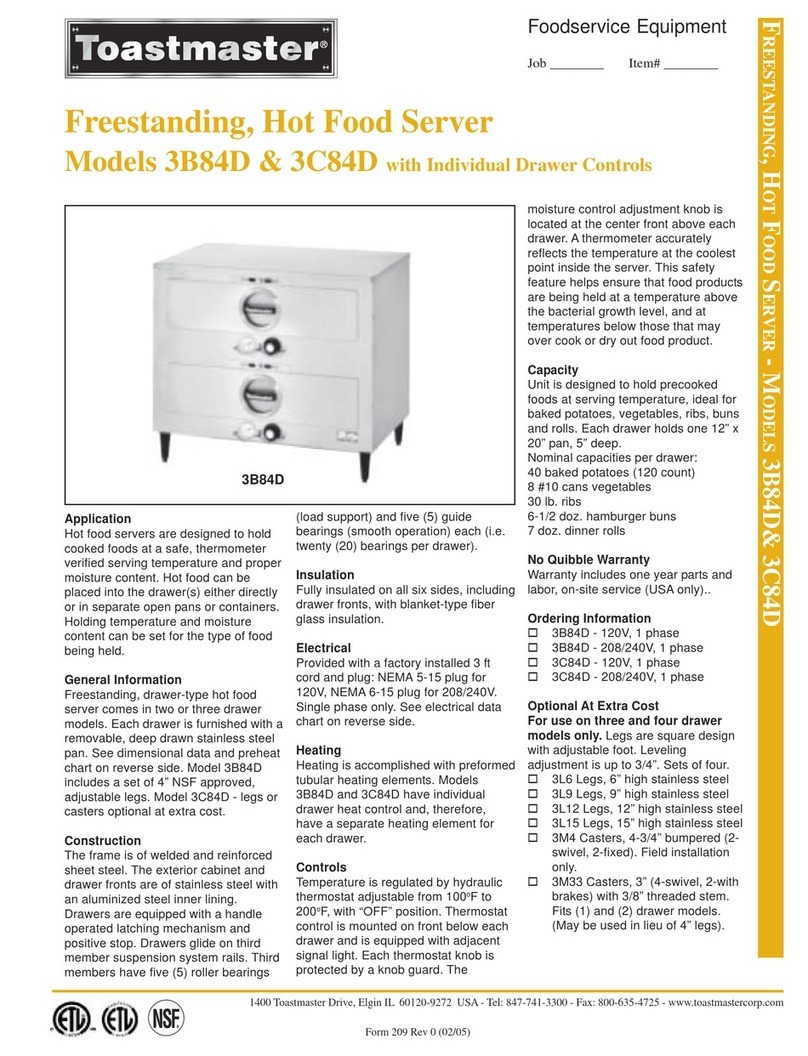

This section provides a basic description of the hot food server controls,

their location, and the functions they perform. The operator MUST be

familiar with the controls. See Figure 5.

1. Power On/Off (I/O) Swi ch

Switches the heating element ON ( ) and OFF (O).

2. Tempera ure adjus men knob

Adjusts the temperature setting of the heating element. This

controls the temperature of the cabinet and pan.

1 is the minimum setting (100°F/38°C after preheating).

9 is the maximum setting (200°F/93°C after preheating).

3. Thermome er

Displays the temperature of the cabinet and pan. A green zone

of 150-175°F (66-79°C) shows the optimum temperature range

for most food products.

4. Mois ure con rol slider

Opens and closes the moisture vents in the front panel of the

drawer.

Moving the slider to the CR SP (left) position opens the

vents, allowing moisture to escape and causing a crisper

food product.

Moving the slider to the MO ST (right) position closes the

vents, trapping moisture inside the cabinet and food product.

B. Operation Procedure

1. Restore electrical power to the hot food server at the circuit

breaker/fused disconnect. Switch the Power On/Off ( /O) switch

to the ON ( ) position.

2. Turn the temperature adjustment knob (if necessary) to the

desired setting for the food product.

3. Allow the hot food server to preheat for 20 minutes.

CAUTION - HOT SURFACE

USE CAUTION WHEN LOADING FOOD INTO, AND

REMOVING FOOD FROM, THE PAN. THE SURFACES OF

THE PAN ARE HOT.

4. Open the drawer. Load the food product into the pan, and close

the drawer. Check that the drawer is fully closed to prevent heat

loss into the environment.

5. Move the moisture control slider (if necessary) to open or close

the moisture vents, as required by the food product.

6. The food product will be kept at the temperature shown on the

thermometer. When unloading the product, use caution to avoid

touching the hot surfaces of the pan.

IMPORTANT

I may be necessary o clean he pan af er removing some food

produc s. Refer o Sec ion IV, Daily Cleaning, in his Manual.

C. Shutdown Procedure

1. Switch the Power On/Off ( /O) switch to the OFF (O) position.

Disconnect electrical power to the hot food server at the circuit

breaker/fused disconnect.

2.

Temperature

adjustment

knob

1. Power

On/Off (I/O)

Switch

. Thermometer

4. Moisture

control slider

Figure 5

IV. DAILY CLEANING

WARNING

WHEN CLEANING THE HOT FOOD SERVER, NEVER

APPLY ENOUGH LIQUID TO STAND IN PLACE ON THE

UNIT. DO NOT SPRAY, RINSE, OR SUBMERGE THE HOT

FOOD SERVER. EXCESSIVE MOISTURE IN THE UNIT

WILL CAUSE A SEVERE ELECTRICAL HAZARD AND MAY

OTHERWISE DAMAGE THE HOT FOOD SERVER.

CAUTION

DO NOT clean your ho food server using abrasive cleaners or pads.

Bo h will scra ch and dull he finish.

1. Switch the Power On/Off ( /O) Switch to the OFF (O) position.

2. Disconnect electrical power to the hot food server at the circuit

breaker/fused disconnect.

3. Allow the hot food server to cool.

CAUTION - HOT SURFACE

DO NOT TOUCH HOT SURFACES ON THE HOT FOOD

SERVER, OR ATTEMPT TO REMOVE THE PAN, UNTIL THE

UNIT HAS COOLED THOROUGHLY.

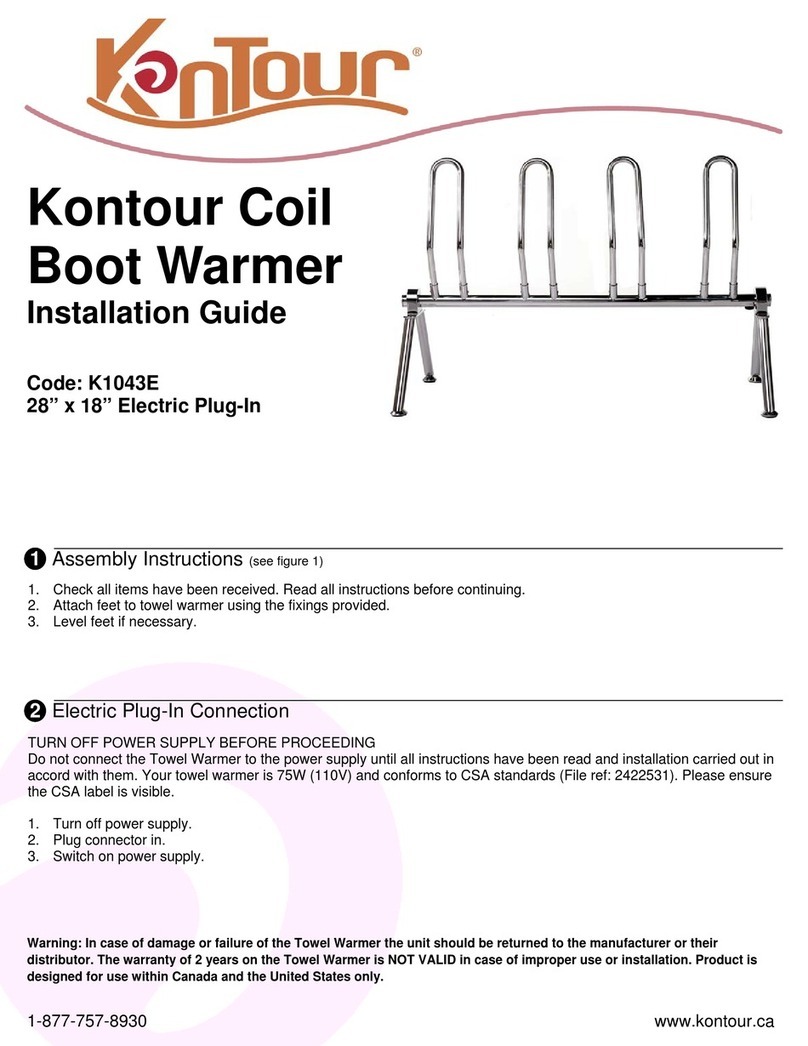

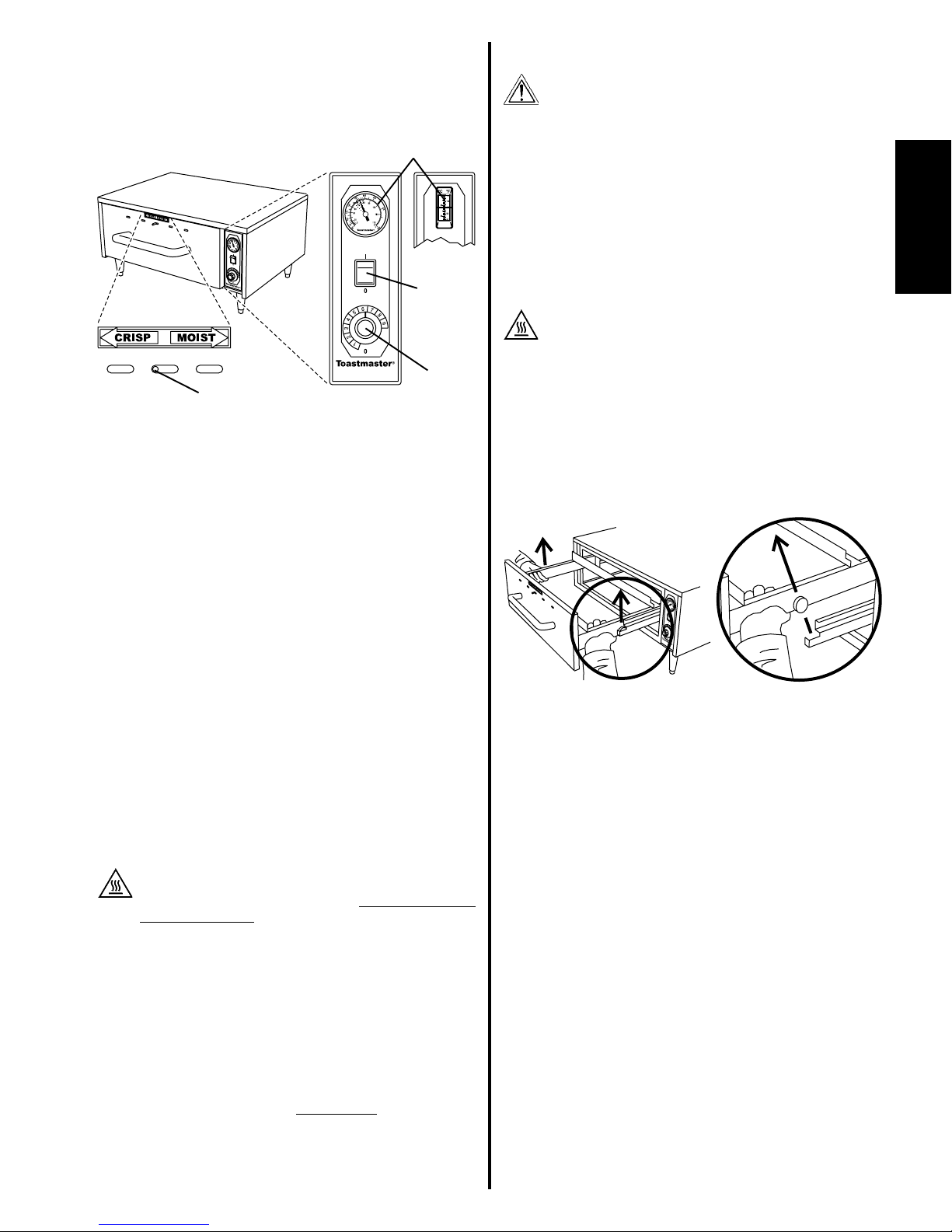

5. Cleaning he Cabine In erior and Drawer

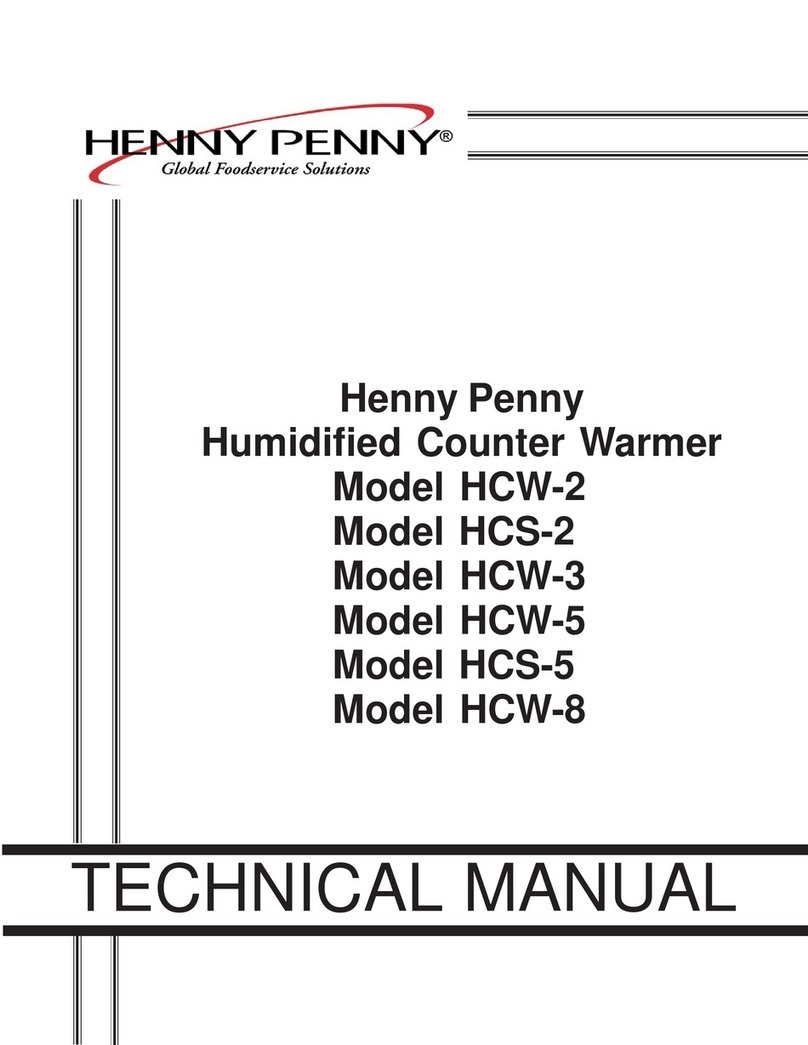

a. Remove the drawer from the cabinet as follows:

Open the drawer AND REMOVE THE PAN.

Lift both side rails of the drawer until the rollers are

free, as shown in Figure 6.

Pull the drawer forward, up, and out of the hot food

server.

b. Use a stiff nylon brush to loosen food particles and crumbs

from the following areas:

drawer rails

drawer rollers

cabinet interior

c. Wipe or vacuum the food residue from the interior of the

cabinet.

d. Rinse the drawer rails, drawer rollers, and cabinet interior

with a sponge or cloth soaked in warm detergent water.

e. Wipe the components with a clean, damp cloth, and allow

them to air dry.

5. Cleaning he Pan

a. Empty the contents of the pan.

b. Wash the pan in hot soapy water, and rinse it. Allow the

pan to air dry.

NOTE: If desired, he pan can be pre-rinsed, run hrough a

dishwa er, and hen air-dried.

6. Cleaning he Ex erior of he Ho Food Server

a. Wipe the exterior of the cabinet with a sponge or cloth

soaked in warm detergent water.

b. Wipe with a clean, damp cloth to remove the excess

detergent, and then wipe again to dry the hot food server.

NOTE: If desired, he ex erior surfaces of he cabine can be

cleaned using a s ainless s eel cleaner/polish. Be sure o wipe

he polish in he direc ion of he grain o avoid scra ching he

finish.

7. Replace all components into the hot food server.

Figure 6