ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

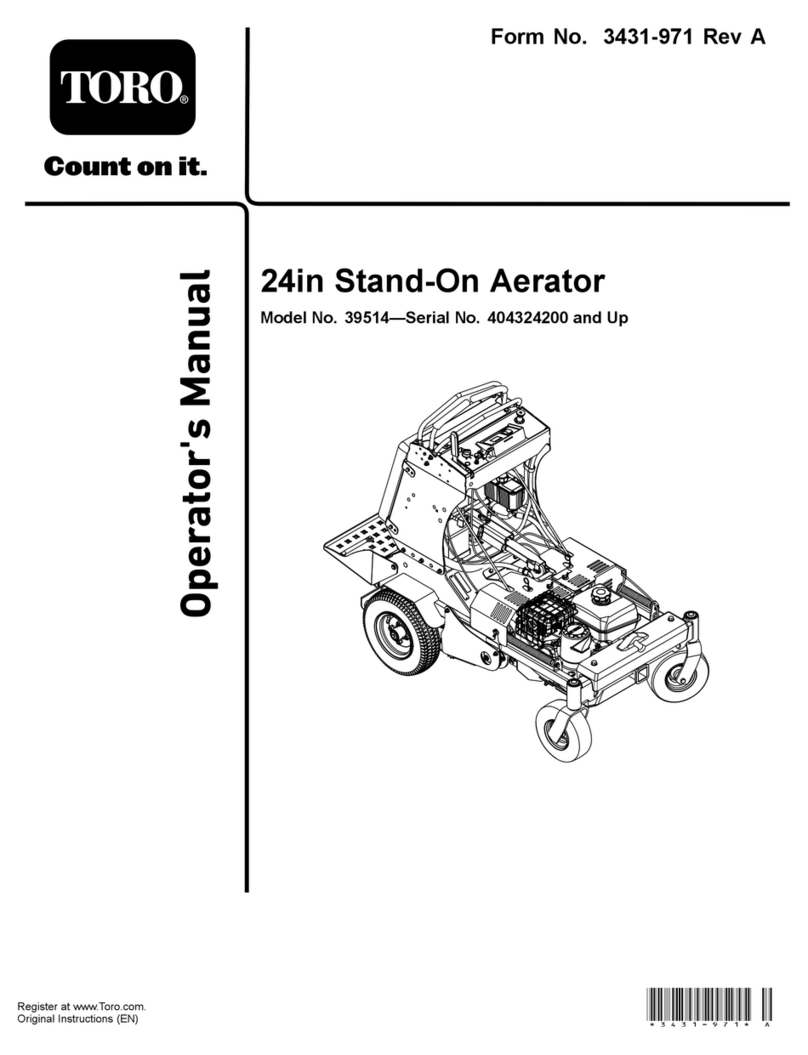

Introduction

Thisrotary-bladelawncuttingdeckismounted

toaride-onmachineandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,

andoncommercialgrounds.Usingthisproductfor

purposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersarestampedonaplateonthe

rearofthecuttingunit,underthecover.Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

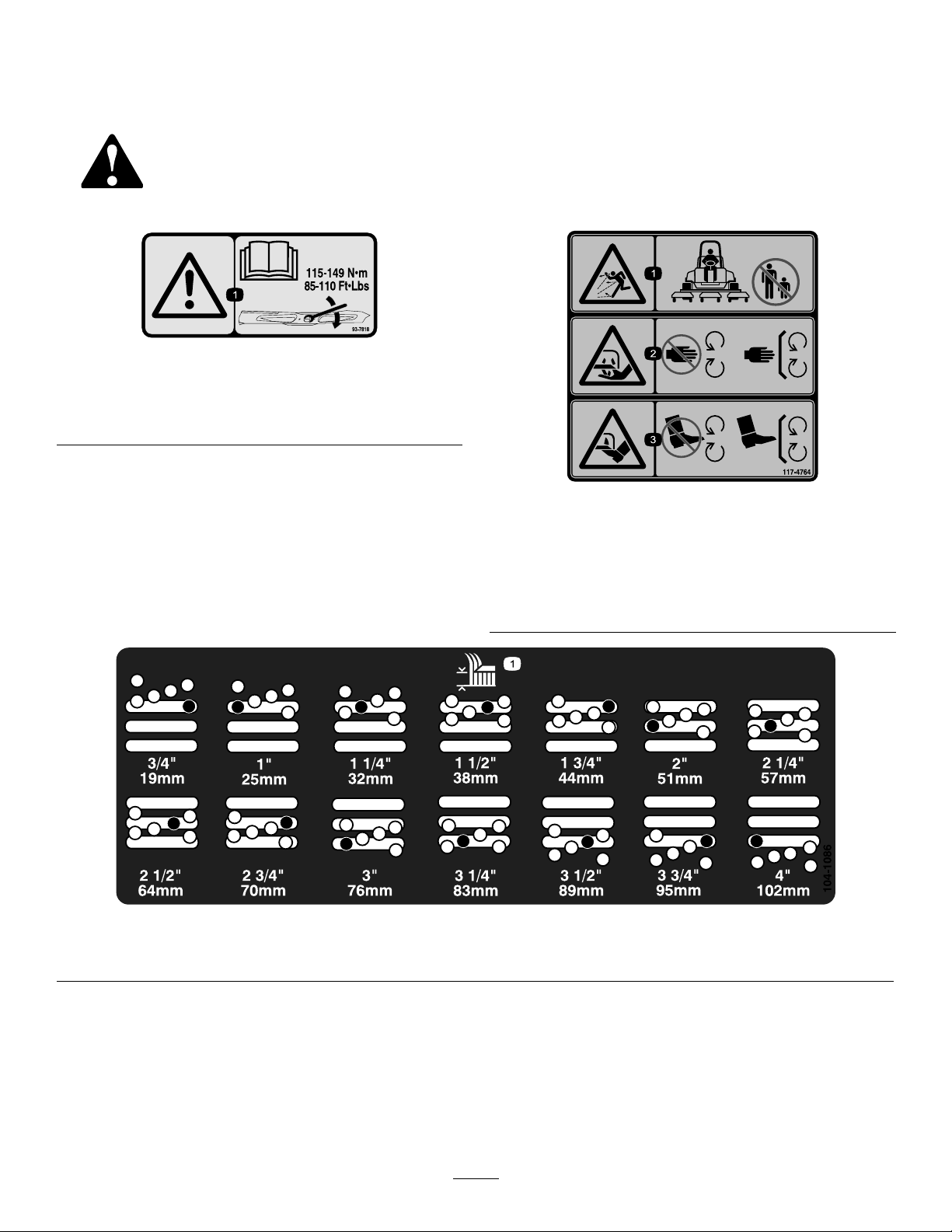

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

GeneralSafety...................................................3

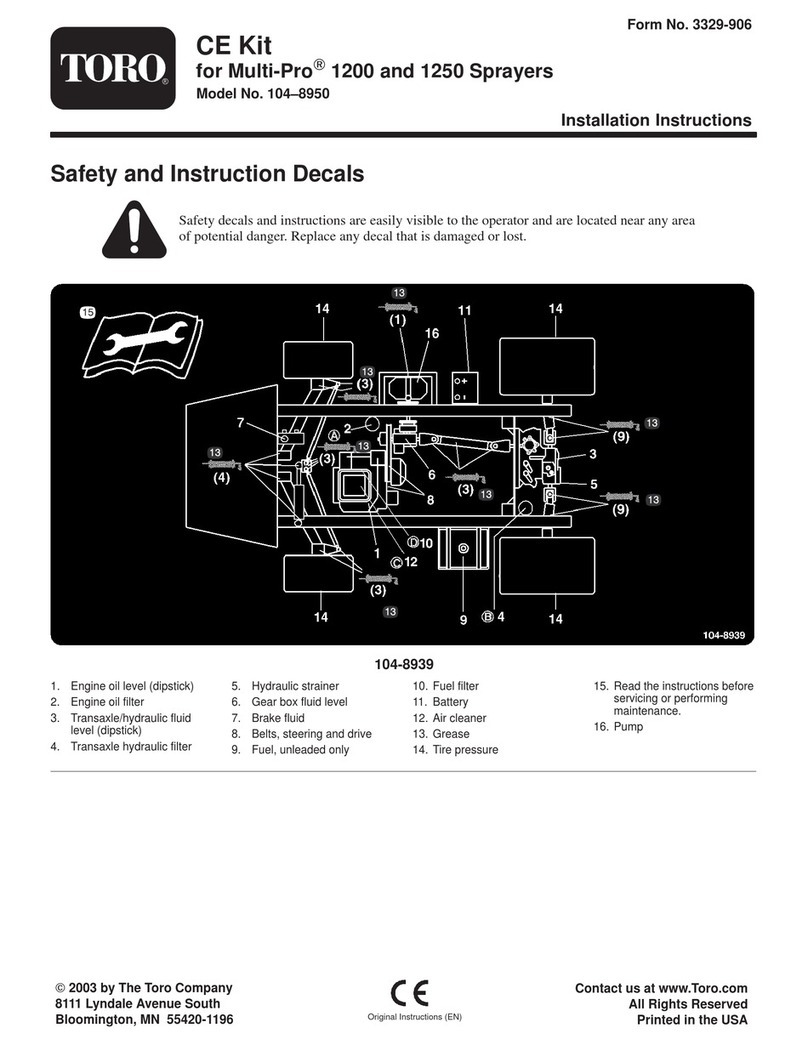

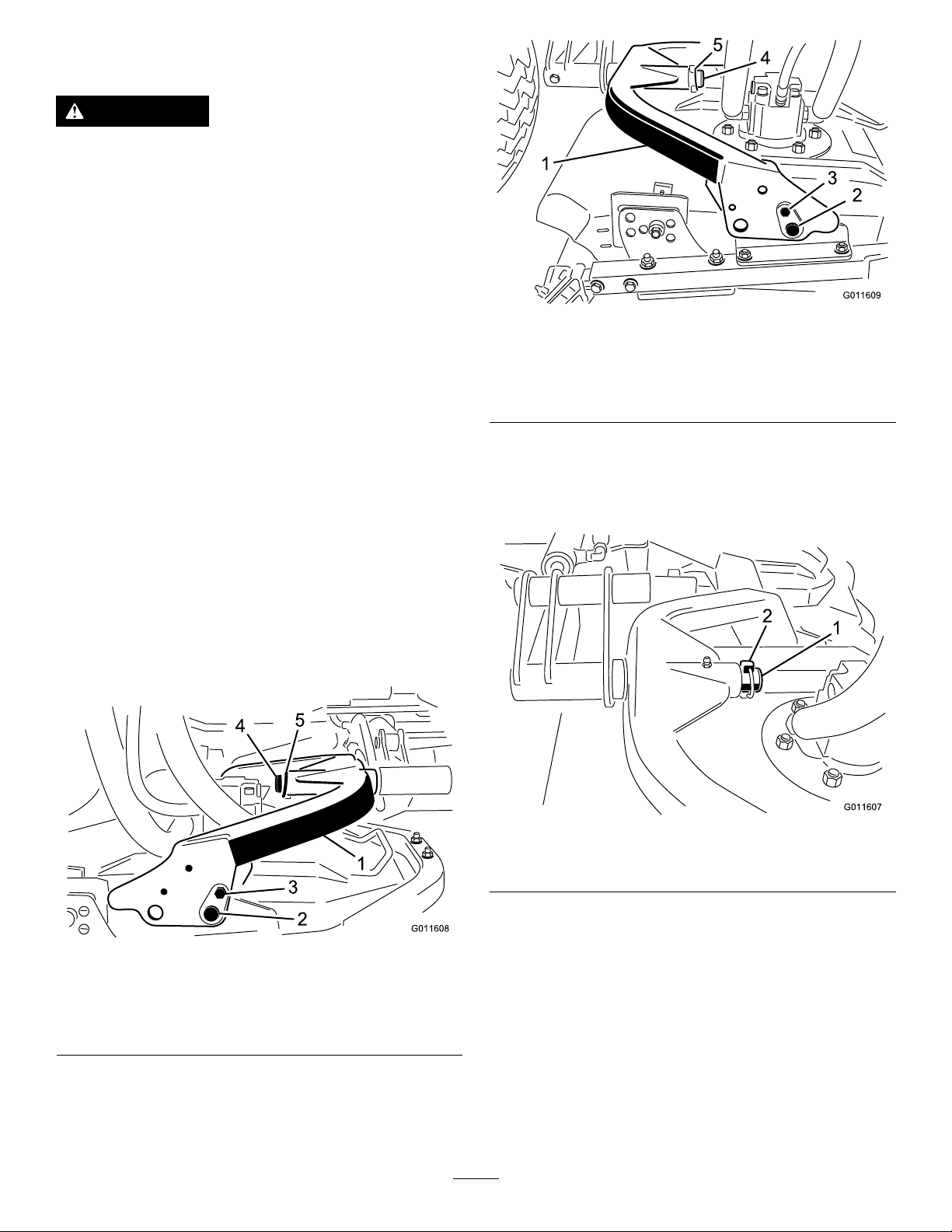

SafetyandInstructionalDecals..........................4

Setup........................................................................5

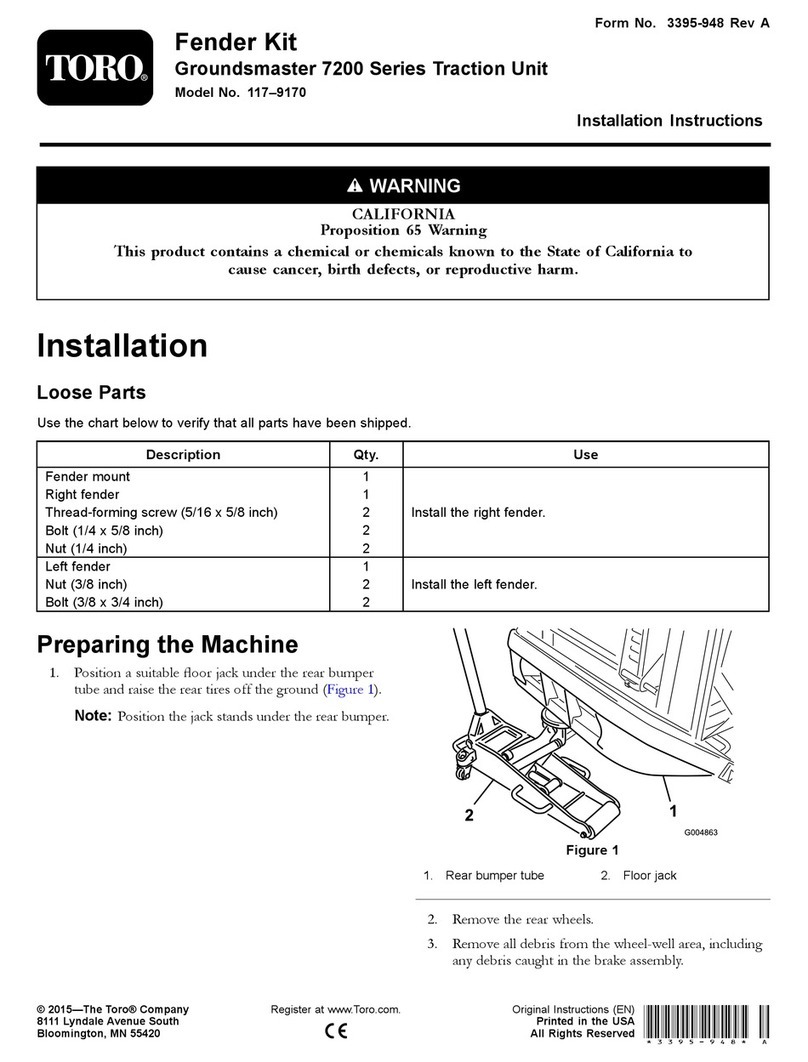

PreparingtheMachine........................................5

MountingtheCuttingUnittotheTraction

Unit.................................................................5

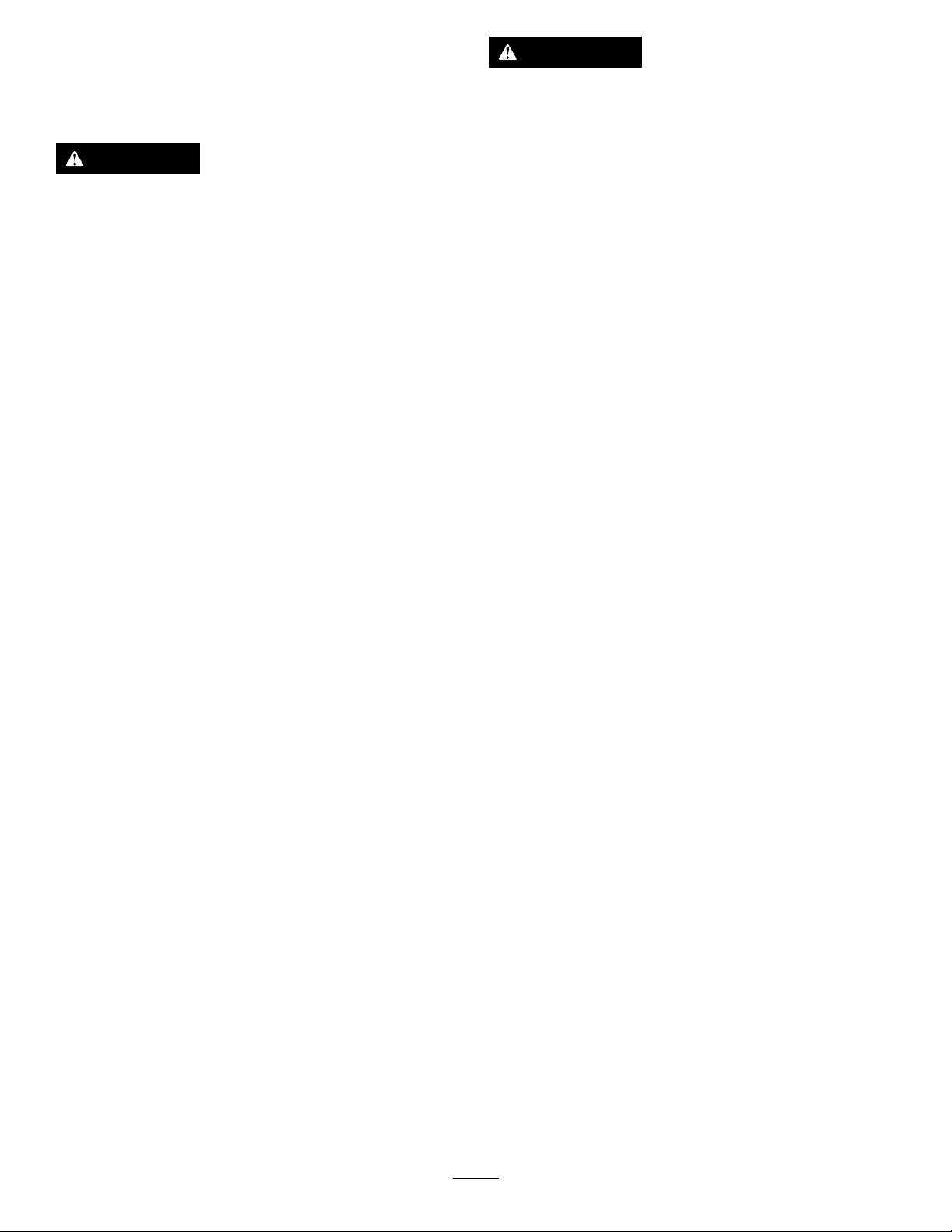

AdjustingtheHeight-of-Cut.................................6

AdjustingtheRollerScraper...............................6

InstallingtheMulchingBafe..............................7

ProductOverview.....................................................7

Specications....................................................7

Attachments/Accessories...................................7

Operation..................................................................8

SelectingaBlade................................................8

OperatingTips...................................................9

Maintenance...........................................................10

RecommendedMaintenanceSchedule(s)...........10

GreasingtheBearings......................................10

SeparatingtheCuttingUnitfromtheTraction

Unit...............................................................10

MountingtheCuttingUnittotheTraction

Unit................................................................11

ServicingtheCuttingBlades..............................11

ServicingtheFrontRoller.................................14

Storage...................................................................15

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved