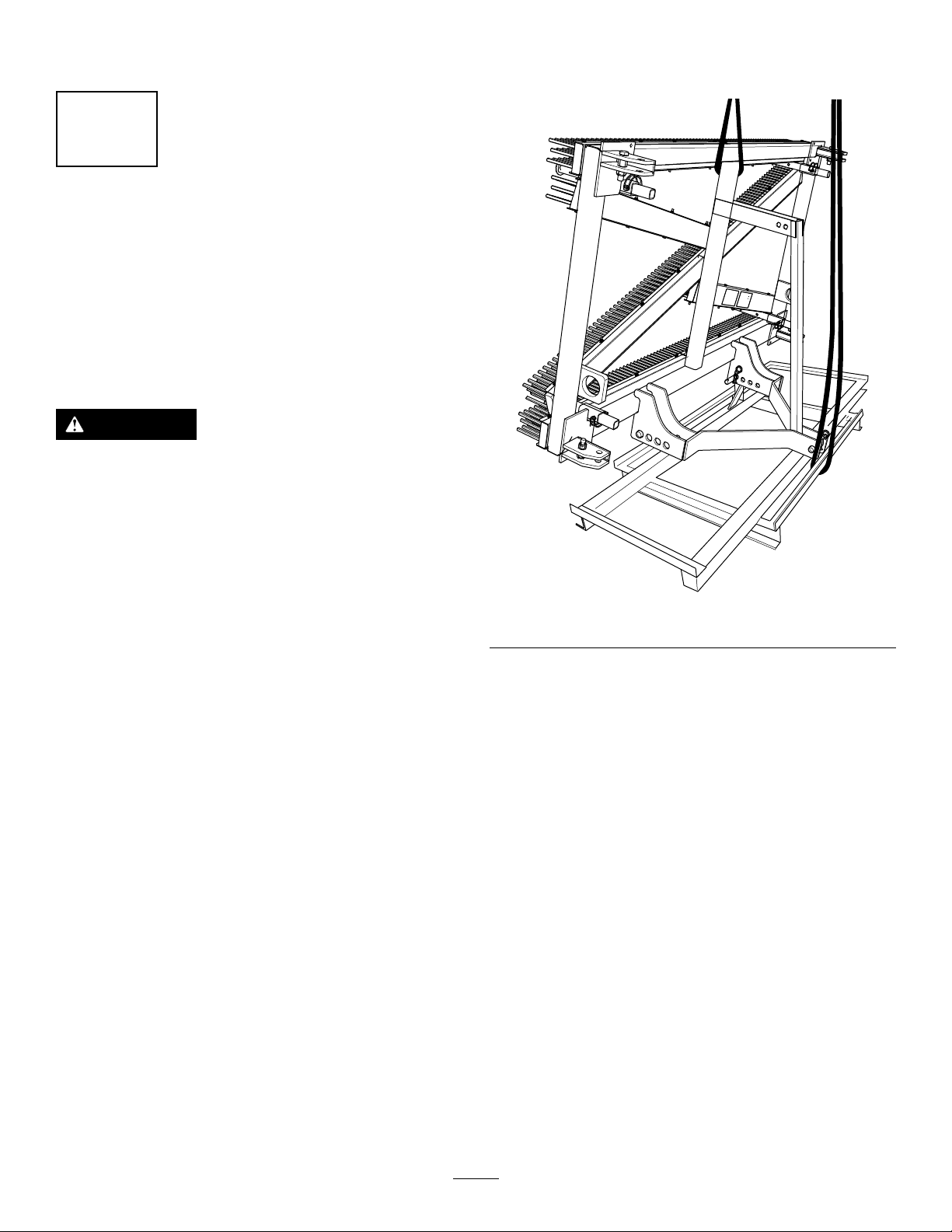

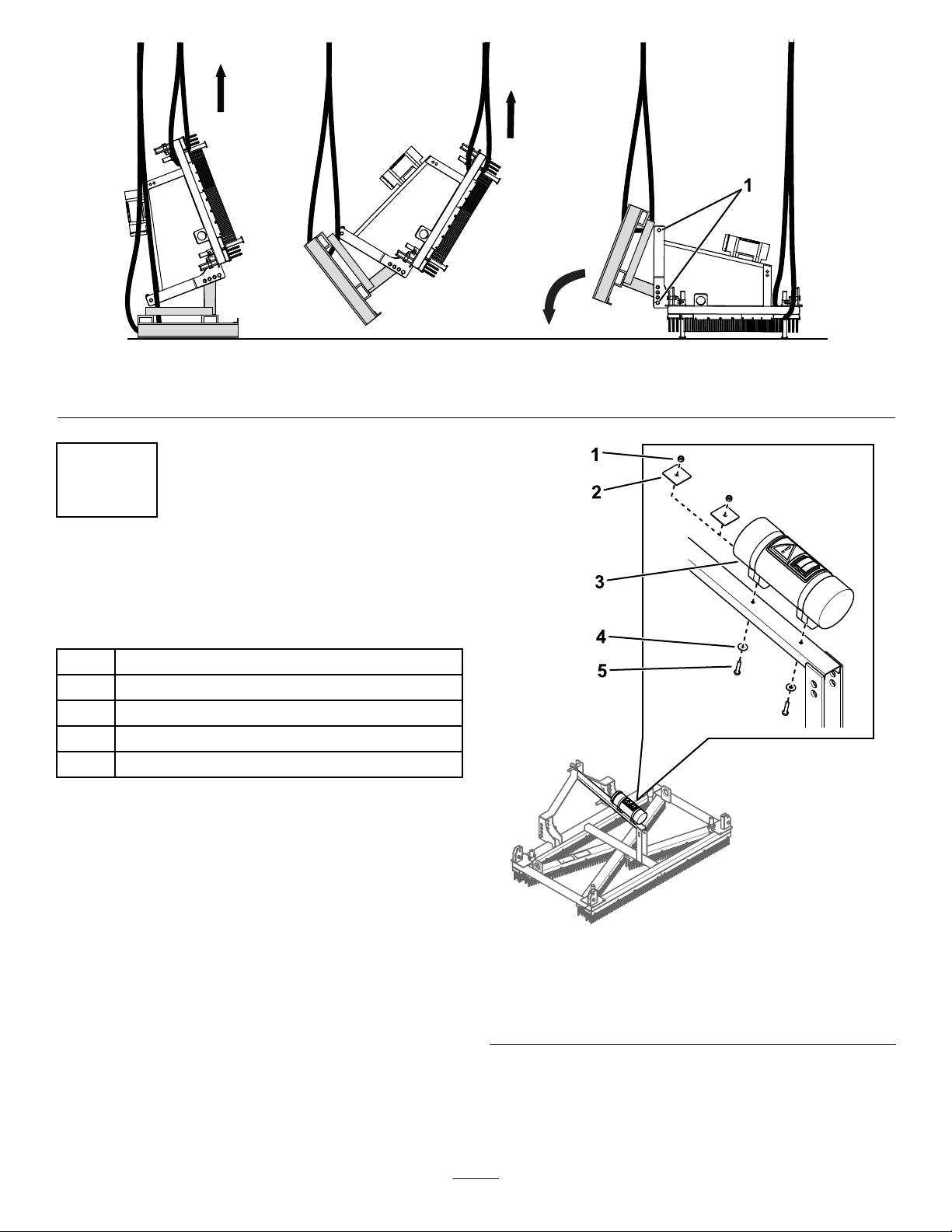

Transportingthe

Attachment

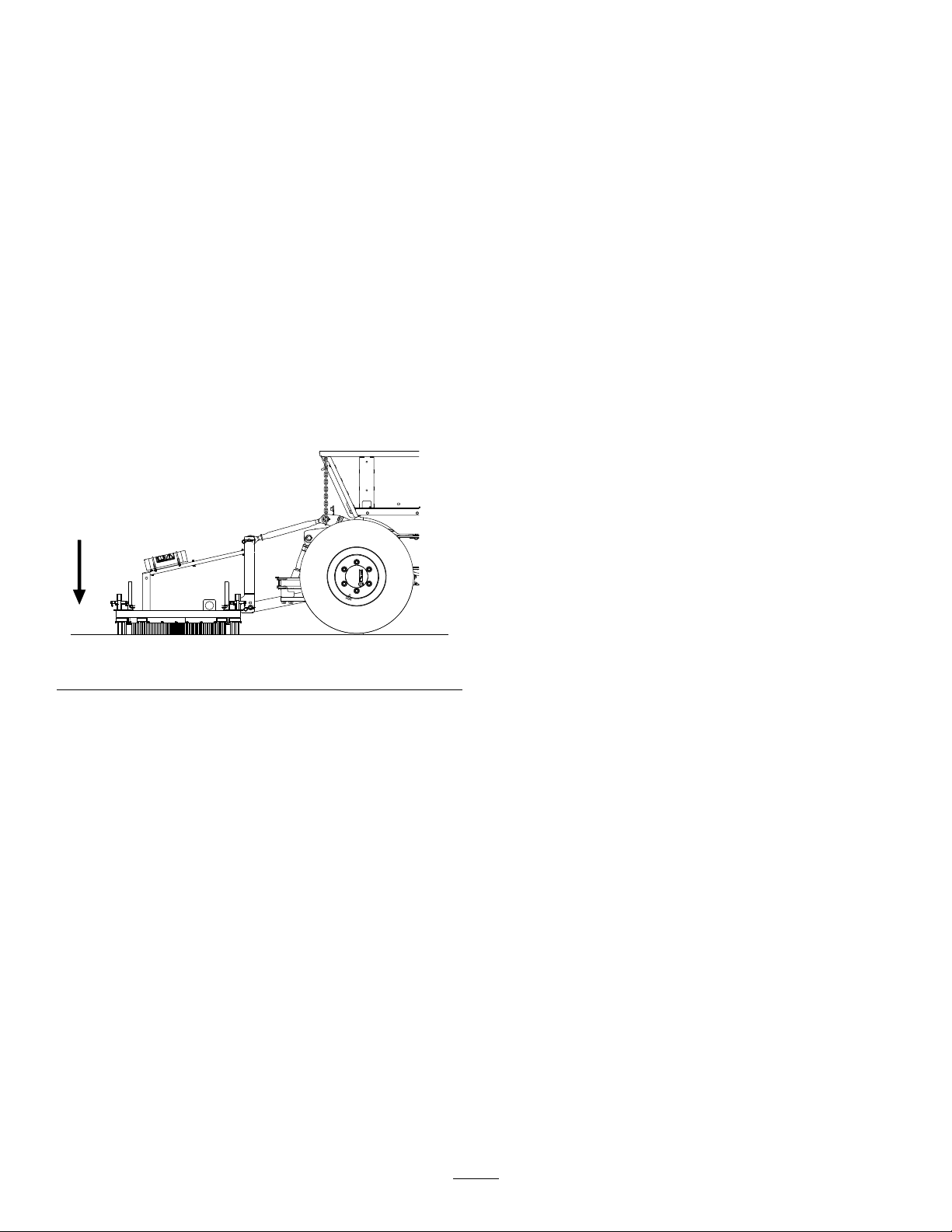

Tobegintransportoperation,raisethemachine.T o

avoidlossofcontrol,traversesteepinclinesslowly,

approachroughareasatreducedspeedandcross

severeundulationscarefully.

Important:Donotexceedtransportspeedsof

12km/h(7.5mph).

DuringOperation

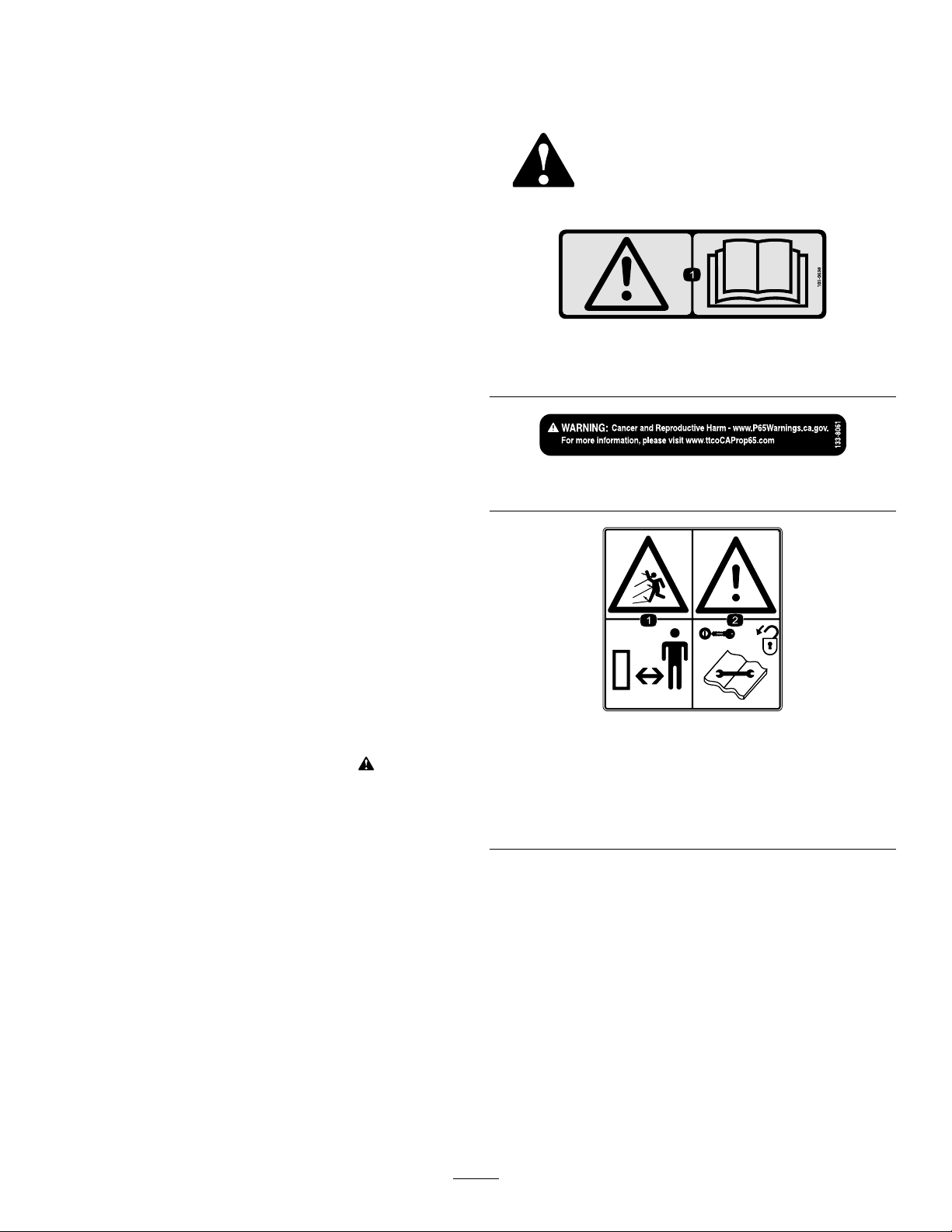

DuringOperationSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhentired,ill,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Keepyourhandsandfeetawayfrommovingparts.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stoptheattachmentwheneveryouarenotusingit.

•Stopthemachine,shutofftheengine,removethe

key,waitforallmovingpartstostop,andinspect

themachineafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Reducespeedonroughroadsandsurfaces.

•Whentheattachmentisconnectedtoatraction

unitandintheraisedposition,theweightofit

affectsstability,braking,andsteering.Exercise

cautionwhentransportingbetweenworkingareas.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–Engagetheparkingbrake.

–Lowertheattachment.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostopbeforeleaving

themachine.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•UseBullseyeaccessories,attachments,and

replacementpartsonly.

SlopeSafety

•Reviewthetractionunitspecicationstoensure

thatyoudonotexceeditsslopecapabilities.

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Youareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Reviewandunderstandtheslopeinstructionsin

themanualandonthetractionunit.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey.

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandtodetermine

whetheryoucanoperatethemachineinthe

conditionsonthatdayandatthatsite.Changes

intheterraincanresultinachangeinslope

operationforthemachine.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction.Maketurnsslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityareinquestion.

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.

•Useextremecautionwhenoperatingthemachine

neardrop-offs,ditches,embankments,water

hazards,orotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

9