Toro 02900 User manual

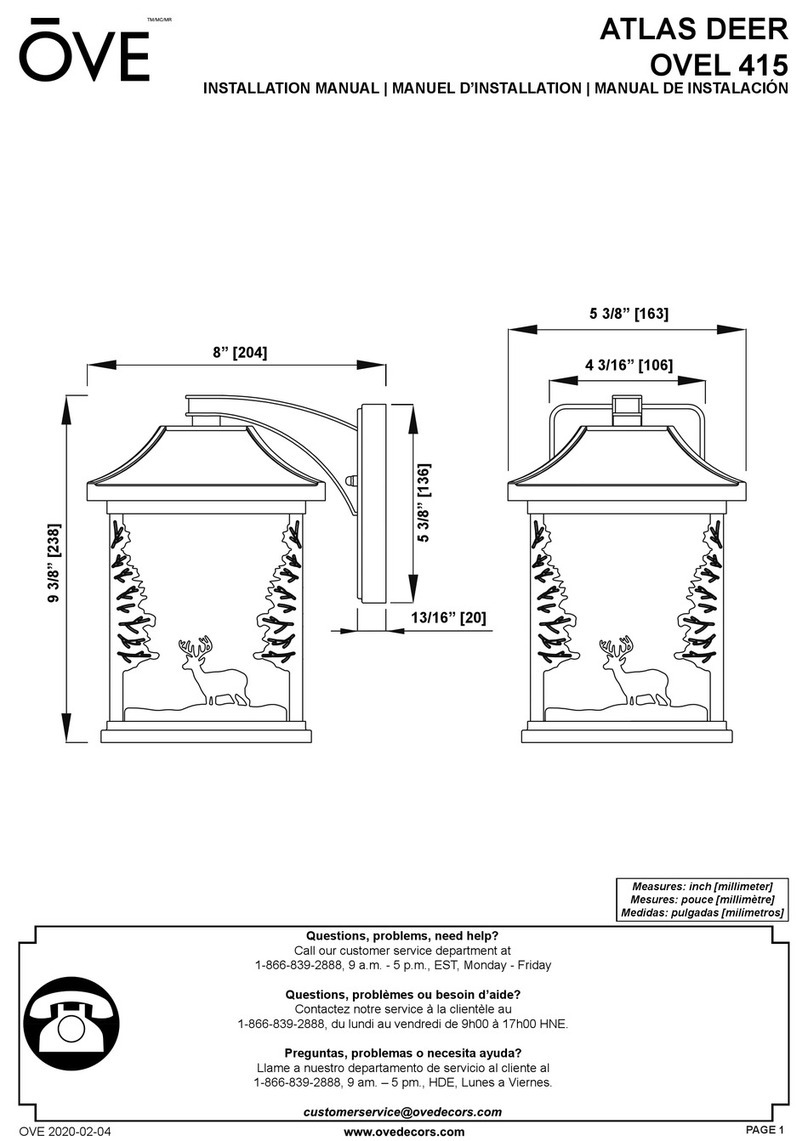

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 1of 12 Part No. 111-5100 (A)

Spellbrook, Bishop’s Stortford, Herts. CM23 4BU, England.

Telephone: 01279 723444 Fax: 01279 723821 E-mail: sales@hayter.co.uk

Service@hayter.co.uk Web: www.toro.com / www.hayter.co.uk

FITTING AND OPERATION INSTRUCTION SHEET

ROAD LIGHT KIT INCLUDING BRAKE LIGHTS

Model 02900

For CT2120 and CT2140

Models 30655 and 30656

ORIGINAL VERSION (EN)

Serial No. From 311000001

This kit is designed to provide a full set of road lights with mounting brackets and operating switches.

This is suitable for the CT2120/2140 with front ROPS bar only.

These instructions include safety, specications, delivery check list, maintenance, tting and operating instructions.

These instructions should be considered as part of the machine.

For all other information refer to your Operator’s Manual and Parts List.

In pursuit of continuous product development, TORO reserve the right to alter specications without notice.

Left and Right: Throughout this manual refers to the mower when looking in the direction of forward travel.

NOTE: This instruction sheet must be printed in colour.

INTRODUCTION

CONTENTS

Contents Page No.

Introduction 1

Safety precautions 2

Specications 2

Delivery Check List 3

Delivery Check List Exploaded View 4

Fitting Instructions 5 - 9

Operating Instructions 10

Maintenance 10

Spare Parts 11

Notes 11

Warranty 12

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 2of 12 Part No. 111-5100 (A)

SPECIFICATIONS

Weight: 14Kg

Voltage: 12 volts

Type of Bulb: LED/H4 Halogen

SAFETY PRECAUTIONS

Before working on the machine it is essential that you read and understand the Safety Precautions as shown in

the Operator’s Manual.

Before working on the machine it is essential that :

- The engine is switched off.

- The parking brake is applied.

- There is no pressure in the hydraulic system.

- The cutterheads are fully down on the ground.

WARNING: PREVENT ACCIDENTS - When drilling or carrying out other operations always wear eye

protection.

WARNING: PREVENT ACCIDENTS - Before working on the machines electrical systems ALWAYS disconnect

the battery terminals and ensure no contact is made between the terminals and the machines metalwork.

WARNING: ALWAYS SEEK PROFESSIONAL ADVICE FROM YOUR LOCAL AUTHORISED DEALER IF,

AFTER STUDYING THIS, YOU ARE UNSURE HOW TO FIT THIS KIT.

THIS SYMBOL MEANS BE ALERT! YOUR SAFETY IS INVOLVED.

EXERCISE GREAT CARE AND FOLLOW THE ADVICE GIVEN TO AVOID POTENTIAL

HAZARDOUS SITUATIONS

SYMBOLS

Item 3

Hazard Warning

Item 4

Direction Indicators

Item 5

Headlamp

High Beam

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 3of 12 Part No. 111-5100 (A)

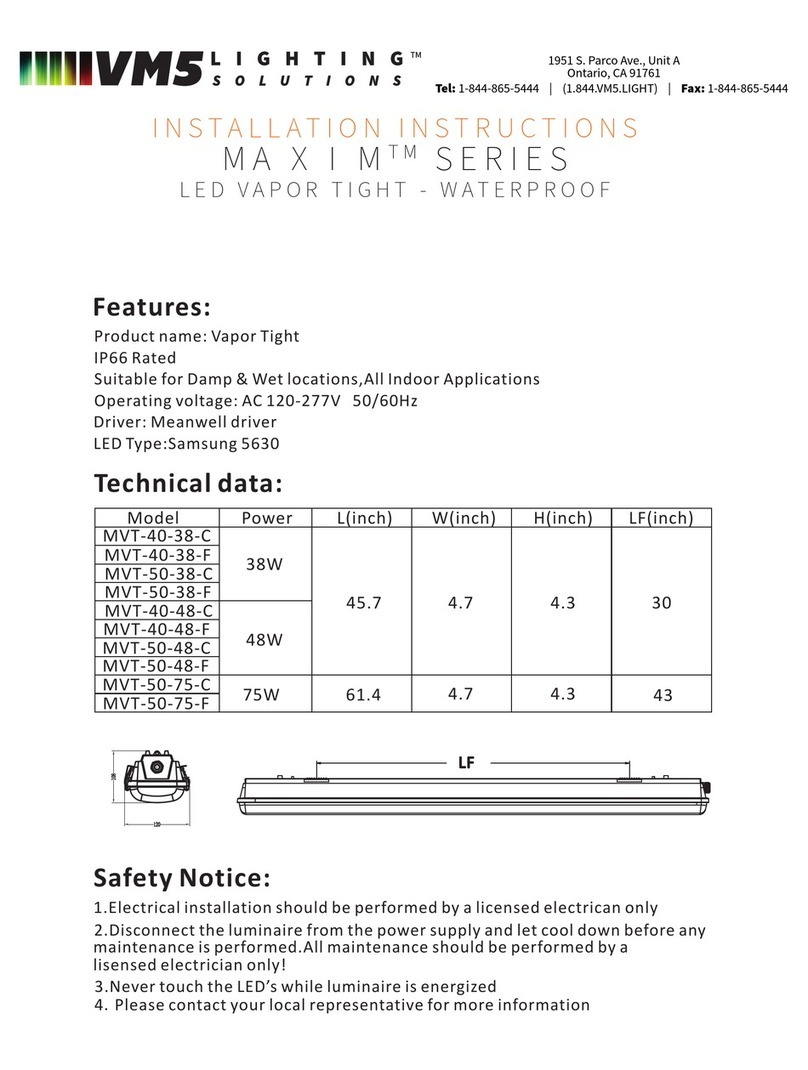

ITEM NO. DESCRIPTION PART NO. QTY. NOTE

DELIVERY CHECK LIST

1 FUSE - 10 AMP 70-09-026 1

2 FUSE - 15 AMP 70-09-151 1

3 SWITCH - HAZARD WARNING - CARLING 111-2223 1

4 CARLING SWITCH - INDICATOR 111-2244 1

5 CARLING SWITCH - LIGHTS 111-2252 1

6 LIGHT BRACKET - RIGHT BLACK 111-3119-03 1

7 LIGHT BRACKET - LEFT BLACK 111-4765-03 1

8 LIGHT GUARD BLACK 111-3710-03 2

9 PRESSURE SWITCH 111-3759 1

10 RED REFLECTOR 111-3760 2

11 SETSCREW M3*16 HEX SKT CAP 111-3764 2

12 ADAPTOR PRESSURE SWITCH 111-3765 1

13 FLASHER RELAY 111-3766 1

14 LIGHT - LED STOP / TAIL - TERMINATED 111-3851 2

15 LIGHT - LED INDICATOR REAR - TERMINATED 111-3852 2

16 LIGHT - LED FRONT MARKER - TERMINATED 111-3853 2

17 LIGHT - LED INDICATOR FRONT - TERMINATED 111-3854 2

18 LIGHT NUMBER PLATE - TERMINATED 111-3855 1

19 CONNECTOR LEAD REAR LIGHTS 111-3890 2

20 CONNECTOR FRONT LIGHTS 111-3892 2

21 BRACKET - FRONT LIGHT BLACK 111-4712-03 1

22 CONNECTOR LEAD INSTRUMENT PANEL 111-3893 1

23 NUT - NYLOC M5 09430 24

24 WASHER M5*10*1 09470 48

25 NUT-NYLOC M6 09438 4

26 NUT M16*2 NYL INS P TYPE 09456 2

27 SCREW HH M5*20 ZDH1E020U 24

28 WASHER - PLAIN M6*12, 1.6 09472 4

29 HEADLAMP ASSY DIP/MAIN 924633 2

30 WASHER M3 PLAIN HY09697 2

31 NUT M3 NYLOC HY09698 2

32 BRACKET - NUMBER PLATE BLACK 111-4710-03 1

33 BOLT M16*110, 8.8 ZBH1P110U 2

34 SCREW SOC HD CAP M6*25 ZCS1F025U 2

35 CONNECTOR PRESSURE SWITCH 111-3921 1

36 SEAL - DOWTY 1/4 INCH 10-06-030 1

37 PM2 CONNECTOR GOTHIC 924620 3

38 WASHER - PLAIN M8 ZWP1H000U 4

39 WASHER 5/16*7/8*15G GALV 09267 4

40 NUT - NYLOC M8, INSERT 09441 4

41 SCREW - HH M8*25 03162 4

42 WIRING HARNESS - FRONT LIGHTS 111-4790 2

44 WASHER 1/4*3/4 GALV ROOFING 09262 4

45 SETSCREW M6*30 ZDH1F030U 2

46 WASHER-SPRING M6 SC 09474 2

47 RED REFLECTOR ADHESIVE 111-5020 2

99 CABLE TIE 368*4,8 74-07-020 10 NOT SHOWN

99 CABLE TIE HY3966 10 NOT SHOWN

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 4of 12 Part No. 111-5100 (A)

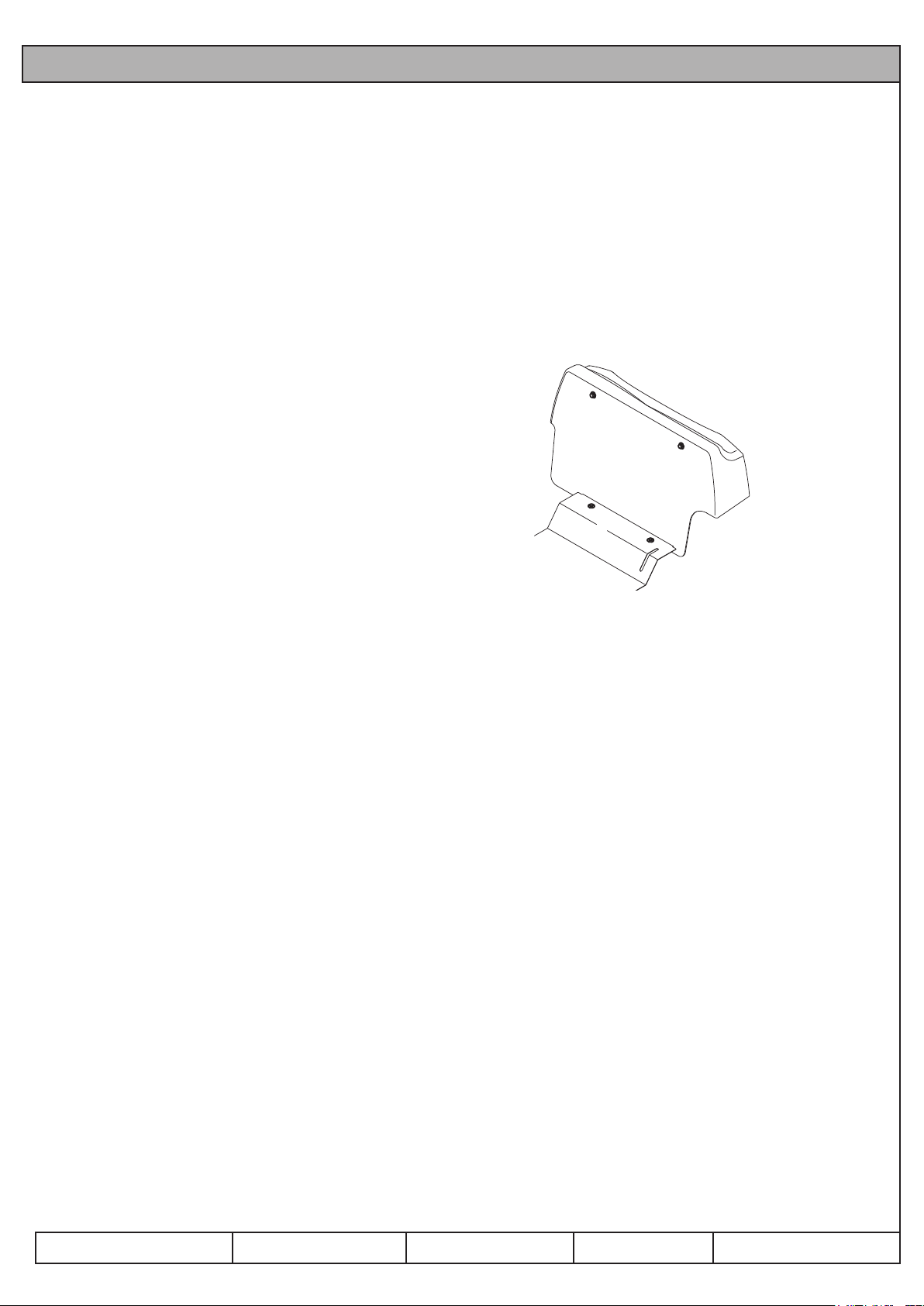

DELIVERY CHECKLIST EXPLOADED VIEW

Fig 1

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 5of 12 Part No. 111-5100 (A)

The LED rear indicators and rear red tail lights / stop lights attach to

the outside of the ROPS post on the left and right side and use exist-

ing bolt holes in the ROPS.

The headlights, front indicators and front white marker lights attach to

the front ROPS hoop.

The number plate with light attach to the bulkhead.

1. Open the engine cover.

2. Lift the platform.

3. Remove the bulkhead by unscrewing the 4 bolts. This is to

enable access to the main wiring loom. Refer to Fig 2.

4. Disconnect the positive cable from the battery.

5. Ensure that ROPS pivot bolts and clamp bolts are in place and

are tight.

6. Remove the ROPS pivot bolt on the left side of the mower.

7. Align the hole in the bracket (item 7) with this hole and insert the

new bolt (item 33).

8. Fit the new nut (item 26) and tighten to a torque of 15Nm.

Do not overtighten as this will make the ROPS difcult to fold.

9. Remove the ROPS pivot bolt on the right side of the mower.

10. Align the hole in the light bracket (item 6) with this hole and

insert new bolt (item 33).

11. Fit the new nut (item 26) and tighten to a torque of 15Nm.

Do not overtighten as this will make the ROPS difcult to fold.

12. NOTE: If there is already a beacon kit tted to the right side or a

waste bin kit tted to left side, it is allowable to use the same bolt

xing. It is advisable to use the new M16 nyloc nuts (item 26)

provided with this kit.

13. The light units (items 14 & 15) and the light guards (item 8) must

now be assembled onto these brackets. It is important that ALL

parts are assembled and in the correct order. The next steps refer

to the left side lights.

14. Attach the light guard (item 8) to the light bracket (item 7), on

the rear face. Attach the reector (item 10) onto the rear face

of the guard using a ZCS1F025U socket screw (item 34), plain

washer (item 28) and an M6 nyloc nut (item 25). Ensure the

reector is the correct way up. The top side is marked on the

reector. Do not overtighten at this stage until the light xing

bolts are in place.

15. Take three M5*20 setscrews (item 27) and place an M5 washer

(item 24) on each.

16. Take the red stop/tail light (item 14) and pass the screws

through the three lugs on its base.

FITTING INSTRUCTIONS

Fig 2

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 6of 12 Part No. 111-5100 (A)

Black

Red

Black

Red

Black

Green

Black

Green

Black

Red

Orange

Black

Red

White

Green

White

Red

Brown

Num. Plate

BLANK

BLANK

Indicator

Stop/Tail

17. Put these three screws through the three holes in the upper light

mounting position so that the red stop/tail lamp is mounted on

the rear face with the screws pointing through on the front face.

18. Place the M5 plain washer (item 24) and an M5 nyloc nut (item

23) on these three screws.

19. Repeat this procedure for the amber rear direction indicator

(without heat sink) (item 15).

20. Now tighten all xings including the centre one holding the

rear reector.

21. Feed all electrical cables down the front of the ROPS frame and

onto the electrical mount panel.

22. The cables must now be connected to the main wiring loom of

the machine and this is done with a connector lead (item 19). It

is important that the following connections are correctly made.

Refer to Fig 3.

23. Fit the 10 and 15 amp fuses as shown. Refer to Fig 4.

24. Drill a 8mm diameter hole on the centre line of the bulkhead,

15mm from the top.

25. Bolt the number plate bracket to the bulk head using items 25,

44, 45 and 46. Tighten the nut enough to allow the bolt to rotate

but not have play.

26. Replace bulk and secure with the two new number plate bolts

and two of the existing bolts.

27. Replace the bulkhead and secure with the 4 bolts. Refer to Fig 2.

28. Fit number plate bracket (item 32) with the mounting bolts for

the bulkhead.

29. Fix the number plate light (item 18) to the mounting

adjacent to the number plate (using items 11, 30 and 31).

30. Feed the cable through the 8mm hole in the bulk head. Push the

connector on the plugs. Refer to Fig 5.

31. As there isn’t a number plate light on the right side there won’t

be a connector to plug into one of the red/black connectors.

Leave this connector vacant. (Use the blanking plug to cover the

connector. Refer to Fig 3.

FITTING INSTRUCTIONS Continued

Fig 3

10A 15A 10A 10A 10A

Fig 4

Red

Black

Fig 5

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 7of 12 Part No. 111-5100 (A)

32. Connect the other end of the connector lead (item 19) to the main

loom connector located on the electrical mount panel.

33. Repeat this assembly procedure for the lights and connections on

the right hand side of the machine.

34. Plug the asher relay (item 13) into the vacant relay socket

located on the right side of the electrical mount panel (with the

writing in the forward position).

35. The front main lights attach to the front ROPS hoop using the

front lights mounting bracket (item 21).

36. Fix this bracket to the front ROPS hoop using two M8*25 set

screws (item 41) each side with the washer (item 38) under each

head and a washer (item 39) M8 nyloc nut (item 40) on the back.

37. Fit the lights (item 29) to the holes in the top surface of this

bracket.

38. The light units (items 16 & 17) must now be assembled onto this

bracket. The next steps refer to the left side lights.

39. Take three M5*20 setscrews (item 27) and place an M5 washer

(item 24) on each.

40. Take the front marker light (item 16) and pass the screws through

the three lugs on its base.

41. Put these screws through the three holes in the inner light

mounting position.

42. Place the M5 plain washer (item 24) and an M5 nyloc nut (item

23) on these three screws.

43. Repeat this procedure for the amber front direction indicator

(with heat sink) (item 15).

44. Connect a connector lead (item 20) to each lamp by passing the

end with just the pins, through the hole in the lamp body from

the inside so that the connector is inside the lamp.

45. Connect the connector to the lamp.

46. Now t the loose connector (item 37) to the pins on the other end

of this connector. Push the connectors into the plug as shown.

Refer to Fig 5.

FITTING INSTRUCTIONS Continued

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 8of 12 Part No. 111-5100 (A)

FITTING INSTRUCTIONS Continued

Limited

Lift Beacon

Hazard

Lights

Fig 7

Black

8

8

7

8

7

7

Red / White

Black

Green

Black

Blue

Front Marker

Front Indicator

Headlamp

Black 3

2

2

2

White

Green

Blue

1

6

4

8

8

8

Fig 6

47. The cables must now be connected to the main wiring loom of

the machine and this is done with a connector lead (item 42).

It is important that the following connections are correctly

carried out. Refer to Fig 6.

48. Pass the connector lead through the hole in front of the chassis

towards the cutter manifold and locate the two connectors on the

main wiring loom.

49. Plug the cables into these connectors.

50. Now the switches must be put into the control panel and

connected to the main wiring loom.

51. Remove the six screws xing the control panel to the control

pod.

52. Carefully lift off the panel ensuring that the connectors to the

existing switches are not disturbed.

53. In the rear face of the control pod, just above the key switch,

are switch blank panels beside the auto limited lift and beacon

switches. Refer to Fig 7.

54. Remove these and push the connectors and wires through the

switch hole. Connect the light and hazard switch before tting

the switch in the hole.

55. In the control panel, to the right of the horn button there is

another blanking plate. Push this out and insert the direction

indicator switch.

56. Feed the connector lead instrument panel so that the end with the

three connectors are inside the control pod.

57. Connect each connector to the correct switch using the labels as

indicators.

58. Feed the other end of this cable down the control arm and

connect to the multi pin connector on the main loom. This is

located to the right of the transmission pump.

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 9of 12 Part No. 111-5100 (A)

59. The final part to be fitted is the pressure switch that controls the

brake lights. This is screwed into the main transmission line.

60. Locate the three hose connections on the right side of the

transmission pump.

61. The lower front connection to the pump has a tee fitting with a

blanking cap.

62. Remove this blanking cap and screw on the pressure switch

adapter (item 12) using a ¼"dowty seal (item 36).

63. Screw the pressure switch (item 9) into this adapter.

Recommended tightening torque for these connections is 34Nm.

64. The electrical connector (item 35) must now be attached to the

cable on the main wiring loom.

65. Locate this cable (it will be coiled up and tied to the main loom

adjacent to the pressure switch). Connect wires to the plug. Refer

to Fig 8.

66. Plug the connector onto the pressure switch.

67. Cable tie all cables for the front lights, rear lights and the

pressure switch so that they are secure and to prevent them from

becoming trapped or chaffed.

68. Reconnect the battery positive cable.

69. Test the switches on the control panel to ensure that they are

handed correctly.

70. Refit the control panel ensuring that no connectors have become

detached and that no cables are nipped.

71. Lower and latch the engine cover.

72. Apply the reflectors to the engine cover. Ensure that the outside

edge of the reflector is adhered between 100-150mm from the

edge of the engine cover. Refer to Fig 9.

73. Lower and latch the operator platform.

74. Fix the serial label adjacent to the machine serial label.

FITTING INSTRUCTIONS Continued

14

23

G/Y

+BR

sig

-BU

Fig 8

Fig 9

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 10 of 12 Part No. 111-5100 (A)

OPERATING INSTRUCTIONS

Adjusting the headlights:

1. Loosen the nut that secures the head lights to the bracket.

2. Adjust the headlights into position by hand.

3. Tighten the nut to hold the light in the correct position.

Brake lights:

The light assembly is operated when the operator lifts their foot

off of the forward pedal or when reversing the machine.

Replace all worn or damaged parts with genuine Toro parts.

Check that all lights are working on a regular basis.

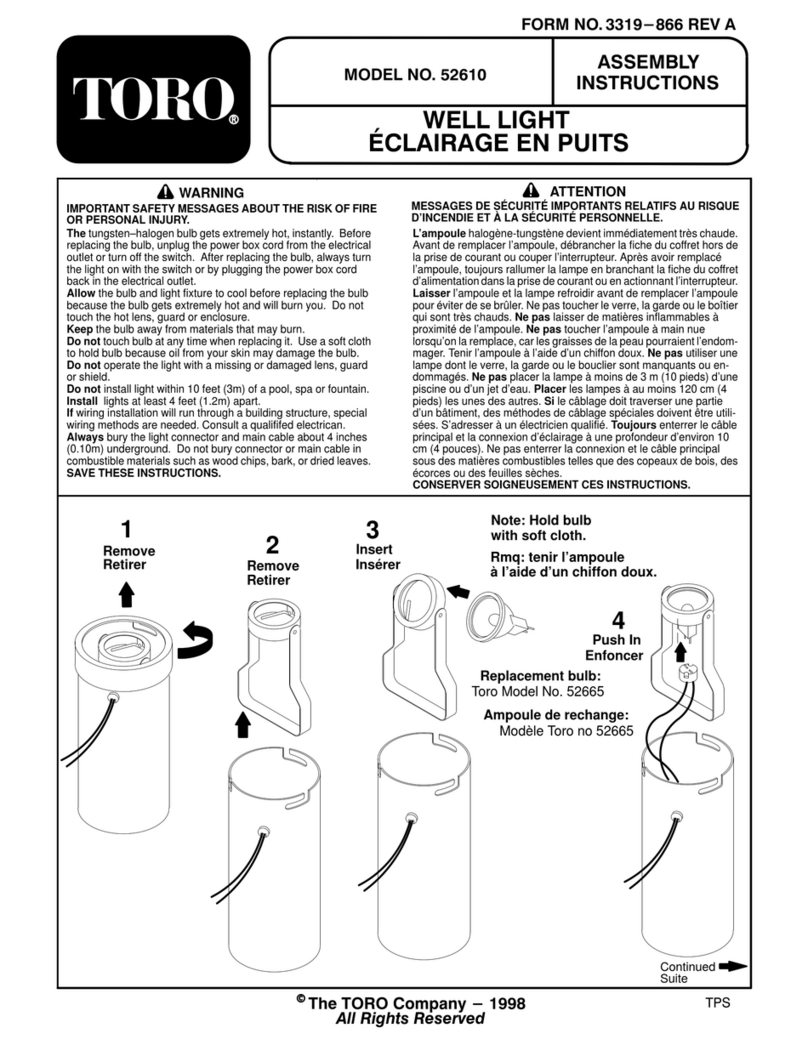

Head lights - replacing a bulb:

1. Remove the lense cover.

2. Replace the bulb.

3. Replace the lense cover.

4. Adjust lights to ensure that they comply with local road

legislation.

MAINTENANCE

SPARE PARTS

Bulb headlamp H4 Part No. 924632.

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 11 of 12 Part No. 111-5100 (A)

NOTES

Issued: 24.03.11 Approved: Mod. No. 5062856.A Sheet 12 of 12 Part No. 111-5100 (A)

WARRANTY

The Toro Total Coverage Guarantee

A Limited Warranty

Conditions and Products Covered

The Toro®Company and its afliate, Toro Warranty Company, pursuant

to an agreement between them, jointly warrant your Toro Commercial

product (“Product”) to be free from defects in materials or workmanship

for two years or 1500 operational hours*, whichever occurs rst. This

warranty is applicable to all products with the exception of Aerators

(refer to separate warranty statements for these products). Where a

warrantable condition exists, we will repair the Product at no cost to you

including diagnostics, labor, parts, and transportation. This warranty

begins on the date the Product is delivered to the original retail purchaser.

* Product equipped with an hour meter.

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products Distributor or

Authorized Commercial Products Dealer from whom you purchased the

Product as soon as you believe a warrantable condition exists. If you need

help locating a Commercial Products Distributor or Authorized Dealer, or

if you have questions regarding your warranty rights or responsibilities,

you may contact us at:

Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

E-mail: [email protected]

Owner Responsibilities

As the Product owner, you are responsible for required maintenance

and adjustments stated in your Operator’s Manual. Failure to perform

required maintenance and adjustments can be grounds for disallowing a

warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the warranty

period are defects in materials or workmanship. This warranty does not

cover the following:

•Product failures which result from the use of non-Toro replacement

parts, or from installation and use of add-on, or modied non-Toro

branded accessories and products. A separate warranty may be

provided by the manufacturer of these items.

•Product failures which result from failure to perform recommended

maintenance and/or adjustments. Failure to properly maintain your

Toro product per the Recommended Maintenance listed in the

Operator’s Manual can result in claims for warranty being denied.

•Product failures which result from operating the Product in an

abusive, negligent or reckless manner.

•Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up, during

normal Product operation include, but are not limited to, brakes

pads and linings, clutch linings, blades, reels, bed knives, tines,

spark plugs, castor wheels, tires, lters, belts, and certain sprayer

components such as diaphragms, nozzles, and check valves, etc.

•Failures caused by outside inuence. Items considered to be outside

inuence include, but are not limited to, weather, storage practices,

contamination, use of unapproved coolants, lubricants, additives,

fertilizers, water, or chemicals, etc.

•Normal noise, vibration, wear and tear, and deterioration.

•Normal “wear and tear” includes, but is not limited to, damage to

seats due to wear or abrasion, worn painted surfaces, scratched

decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are warranted

for the period of time up to the scheduled replacement time for that part.

Parts replaced under this warranty are covered for the duration of the

original product warranty and become the property of Toro. Toro will

make the nal decision whether to repair any existing part or assembly or

replace it. Toro may use remanufactured parts for warranty repairs.

Note Regarding Deep Cycle Battery Warranty:

Deep cycle batteries have a specied total number of kilowatt-hours they

can deliver during their lifetime. Operating, recharging, and maintenance

techniques can extend or reduce total battery life. As the batteries in this

product are consumed, the amount of useful work between charging

intervals will slowly decrease until the battery is completely worn out.

Replacement of worn out batteries, due to normal consumption, is the

responsibility of the product owner. Battery replacement may be required

during the normal product warranty period at owner’s expense.

Maintenance is at Owner’s Expense

Engine tune-up, lubrication cleaning and polishing, replacement of

Items and Conditions Not Covered lters, coolant, and completing

Recommended Maintenance are some of the normal services Toro

products require that are at the owner’s expense.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole remedy

under this warranty.

Neither The Toro Company nor Toro Warranty Company is liable for

indirect, incidental or consequential damages in connection with the

use of the Toro Products covered by this warranty, including any

cost or expense of providing substitute equipment or service during

reasonable periods of malfunction or non-use pending completion

of repairs under this warranty. Except for the Emissions warranty

referenced below, if applicable, there is no other express warranty.

All implied warranties of merchantability and tness for use are limited to

the duration of this express warranty. Some states do not allow exclusions

of incidental or consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and limitations may not

apply to you.

This warranty gives you specic legal rights, and you may also have other

rights which vary from state to state.

Countries Other than the United States or Canada

Customers should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are

dissatised with your Distributor’s service or have difculty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you

may contact us at Toro Warranty Company.

374-0277 Rev A

Table of contents

Other Toro Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

ADJ

ADJ 3D VISION PLUS User instructions

HD AUDIO SYSTEM

HD AUDIO SYSTEM M-YL812 instruction manual

Larson Electronics

Larson Electronics EPLRL-50-16.4-HR-SWB quick start guide

HOMBLI

HOMBLI Smart Pathway Light manual

Milwaukee

Milwaukee HEAVY DUTY L4 NL400 user manual

Adaptive Micro Systems

Adaptive Micro Systems Beta Brite Programming manual