Toro 09930 User manual

FormNo.3368-805RevC

ProCoreSR48,SR54,SR54–S,

SR70,SR70–S,SR72andSR75

Aerators

ModelNo.09930—SerialNo.311000001andUp

ModelNo.09931—SerialNo.311000001andUp

ModelNo.09932—SerialNo.311000001andUp

ModelNo.09933—SerialNo.311000001andUp

ModelNo.09934—SerialNo.311000001andUp

ModelNo.09935—SerialNo.311000001andUp

ModelNo.09936—SerialNo.311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.Toro.com.OriginalInstructions(EN)

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SafetyandInstructionalDecals.............................6

Setup...........................................................................8

1RemovingtheAeratorfromtheCrating..............9

2ConnectingtheLowerLinkArms......................9

3ConnectingtheHydraulicTopLink

(ModelsSR48,SR54,SR70,SR72and

SR75).............................................................10

4ConnectingtheTractorUpperLink(Models

SR54–SandSR70–S)......................................12

5VerifyingtheHydraulicTopLinkSet

Up..................................................................12

6CheckingthePTOAngle.................................13

7FittingthePTOshaft.......................................14

8InstallingthePTOShield.................................15

9ConnectingthePTOShaft...............................16

10AdjustingtheSwayLinks................................17

11LevelingtheAeratorSide-to-Side...................18

12InstallingtheTines.........................................18

13SettingtheTineDepth(ModelsSR54–S

andSR70–S)...................................................18

14InstallingtheRearGuard................................19

15InstallingtheLatchLock................................20

16RemovingtheStorageStands(ModelsSR54

andSR70)......................................................20

17RemovingtheStorageStands(ModelsSR48

andSR72).......................................................21

ProductOverview......................................................22

Specications.....................................................22

Attachments/Accessories...................................22

Operation...................................................................23

TractorControls.................................................23

PrinciplesofOperation......................................23

TractorPTOSpeed............................................23

TrainingPeriod...................................................23

BeforeAerating..................................................23

AeratingProcedures...........................................24

OperatingTips...................................................24

SubsoilCultivation.............................................25

HardGround.....................................................25

Longer/LargerTines..........................................25

MultiRowAdapterHeads..................................25

RootZoneLifting..............................................25

UsingtheHoodPropRodsModelSR75

only................................................................25

AdjustingtheTineAngle....................................26

AdjustingtheTineDepth(ModelsSR54–S

andSR70–S)...................................................27

TransportOperation..........................................27

InspectionandCleanupafterUse........................28

Maintenance...............................................................29

RecommendedMaintenanceSchedule(s)................29

LiftingtheMachine............................................29

GreasingtheBearings.........................................30

CheckingtheGearboxOil..................................30

ChangingtheGearboxOil..................................31

Inspecting/AdjustingtheDriveChain................31

AdjustingthePTOClutch..................................32

FastenerTorqueSpecications............................32

CheckingtheSprings..........................................33

AdjustingtheHoleSpacing.................................33

RemovingtheAeratorfromtheTractor...............33

TroubleShooting...............................................34

Storage.......................................................................35

3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

BeforeOperating

•OwnersofthisAeratormustgiveoperatorsand

employeesfulloperationandsafetyinstructions

beforeallowingthemtooperatethismachineandat

leastannuallythereafter.Anoperatorwhohasnot

readandfullyunderstoodalloperatingandsafety

instructionsisnotqualiedtooperatethismachine.

Becomefamiliarwithallcontrolsandknowhowto

stopquickly.

•Donotallowchildrentooperatethemachine.Do

notallowadultstooperatethemachinewithout

properinstruction.

•Removealldebrisorotherobjectsthatmight

interferewithoperation.Keepallbystandersaway

fromtheworkarea.

•Locateandmarkallundergroundobstructionssuch

asirrigationcomponents,electricalortelephone

lines.

•Makesuretractorisinneutralandparkingbrake

appliedbeforestarting.RefertoTractorOperator's

Manualforsafestartingprocedures.

•Ensurethatyourtractorissuitableforusewithan

implementofthisweightbycheckingwithyour

tractorsupplierormanufacturer.

•Mountingtheaeratortotherearofthetractorwill

decreasetheweightonthetractorfrontaxle.To

assureadequatesteeringcontrolandstabilityitmay

benecessarytoaddballasttothefrontofthetractor.

RefertoTractorOperator'sManualforballast

requirements.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisdamaged,repairor

replaceitbeforeoperationiscommenced.Also

tightenanyloosenuts,boltsandscrewstoensure

machineisinsafeoperatingcondition.

•Donotoperatemachinewhilewearingsandals,

tennisshoes,sneakersorshorts.Also,donotwear

loosettingclothingwhichcouldgetcaughtin

movingparts.Alwayswearlongpantsandsubstantial

shoes.Wearingsafetyglasses,safetyshoes,hearing

protectionandahelmetisadvisableandmaybe

requiredbysomelocalordinancesandinsurance

regulations.

WhileOperating

•Neveroperatethetractorinreversewhentheaerator

islowered.

•Keepallbystandersandpetsawayfromthework

area.

•Usingthemachinedemandsattention,andto

preventlossofcontrol:

–Useonlyindaylightorwhenthereisadequate

articiallight.

–Watchforholesorotherhiddenhazards.

–Donotoperatethemachineclosetoasandtrap,

ditch,creekorotherhazard.

–Reducespeedonsidehillsandbeforemaking

sharpturnstopreventtippingorlossofcontrol.

–Lookbehindtheaeratorbeforebackingup.

•Ifthetinesstrikeasolidobjectorthemachine

vibratesabnormally,disengagethePTO,setthe

parkingbrakeandshuttheengineoff.Removekey

fromignitionswitch.Checkaeratorandtractionunit

fordamage.Repairanydamagebeforerestartingthe

engineandoperatingthetines.Besuretinesarein

goodconditionandallboltsaretight.

•Beforeleavingmachineunattended,disengagepower

toaerator,loweraeratorontostoragestandsandset

parkingbrake.Stopengine.

•Neverdismountwhiletractorisinmotion.Never

getonorofftractorwhileengineisrunningand

PTOdriveshaftisengaged.NeverstepoverPTO

shafttoreachothersideofaerator-walkaround

themachine.

•Whenliftingtheaerator,disengagethePTOwhen

therollerisapproximately5inchesfromtheground.

•Donotoperatethismachinewithouttherolleron

theground.Neveroperatewiththemachinein

theraisedposition.

•Parktheaeratoronahard,levelsurface,installthe

aeratorstoragestandsbeforedisconnectingfrom

tractor.

•Ifitisnecessarytoprobebelowthesoilsurface,use

anonconductivematerialtopreventelectricalshock

incaseelectricalwiresarepresent.

•Alwayslowertheaeratortothegroundbefore

leavingthetractorunattended.Neverleavethe

aeratorintheraisedpositionwhenitisunattended.

4

Transporting

•Theaeratorisheavy.Whenattachedtoatractor

andintheraisedposition,itsweightwillaffect

stability,brakingandsteering.Exercisecautionwhen

transportingbetweenworkingareas.

•Alwaysmaintainpropertractortirepressure.

•Besureyouareincompliancewithallregulations

beforetransportingequipmentonthepublicroads

andhighways.Makesureallrequiredreectors

andlightsareinplaceandarecleanandvisibleby

overtakingandoncomingtrafc.

•Neverallowpassengerstorideonthemachine

duringtransport.

•Reducespeedonroughroadsandsurfaces

•Independentwheelbrakesshouldalwaysbelocked

togetherwhentransporting.

PTOShaft

•ForallPTOshaftsteelparts(tubes,bearings,joints

etc.)disassemblyorrepairs,itishighlyadvisable

tocontactyourlocalTorodistributor.Removalof

componentsforrepairsandreassemblymaydamage

somepartsifnotperformedwithspecialtoolsby

trainedtechnicians.

•ThePTOshaftmustnotbeusedwithouttheguards

supplied,withpartialprotectionorwithdamaged

guards.OnCEmachines,operationisprohibited

withoutthespecialanti-rotationchainscorrectly

installed,soastopermitthemaximumangleofthe

PTOshaftwithoutbreakingthechains.

•Frictionclutchesmaybecomehotduringuse.Do

nottouch.Toavoidtheriskofre,keepthearea

aroundtheclutchfreeofammablematerialand

avoidprolongedslippingoftheclutch.

Maintenance

•Beforemakingadjustmentsorperforming

maintenanceontheaerator,switchofftheengine,

stopthePTOandapplytheparkingbrakebefore

dismountingfromthetractor.Besuretheaeratoris

onthegroundorloweredontothesafetystands.

•Supportthemachinewiththeblocks,jacksoron

storagestandswhenworkingbeneathit.Never

relyonthetractor'shydraulicstosupportthe

machine.

•Placeallcontrolsinneutral,stoptheengine,apply

parkingbrakeandwaitforallmovingpartsto

stopbeforeservicing,maintaining,adjustingor

unblockingtheaerator.

•Besurethemachineisinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.Checkthetine

mountingboltsdailytobesuretheyaretightened

tospecication.

•Donotcheckoradjustthechaintensionwhenthe

tractorengineisrunning.

•Besureallguardsarereplacedandthehoodis

securedshutaftermaintainingoradjustingthe

machine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.Toensureoptimum

performanceandsafety,alwayspurchasegenuine

Tororeplacementpartsandaccessoriestokeepthe

ToroallToro.Neveruse"will-t"replacementparts

andaccessoriesmadebyothermanufacturers.Look

fortheTorologotoensuregenuineness.Using

unapprovedreplacementpartsandaccessoriescould

voidthewarrantyofTheToroCompany.

StorageSafety

•Storetheaeratoronthestoragestandspositionedon

armlevelsurface.

•Storetheaeratorawayfromareasofhumanactivity.

•Donotallowchildrentoplayonoraroundthe

storedmachine.

•Makesuretheaeratorispositionedonrmandsolid

groundsoitdoesnotsinkortipover.

5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

117–7052

1.ReadtheOperator’sManual,donotoilthechaindrive.

100–3612

1.Entanglementhazard—stayawayfrommovingparts,keep

allguardsandshieldsinplace.

110-4668

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.PTOspeedandinputdirection.

3.Usecliptosecurelashcablewhennotinuse.Uselash

cabletosupportthepowertake-offwhenthemachineis

disconnectedfromtractor.

117–7051

1.Crushinghazardofhandorfoot—keepbystandersasafe

distancefromthemachine.

92–1581

92–1582

6

117–7050

1.Warning—readtheOperator'sManual.

2.Warning—removetheignitionkeyandreadtheinstructionsbeforeservicingorperformingmaintenance.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Entanglementhazard,belt—stayawayfrommovingparts,keepallguardsinplace.

5.Crushinghazardofhandorfoot—keepbystandersasafedistancefromthemachine.

6.Crushinghazardofhandandbody—supportmachineonstandwhennotinuse.

7.Fallinghazard—donotcarrypassengers.

120-0625

1.Pinchpoint,hand—keephandsaway.

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Nopartsrequired–Removetheaeratorfromthecrating

Hitchpin2

2Lynchpin2

Connectlowerlinkarms(Hitchpinsand

lynchpinsareshippedinstalledonthe

SR54andSR54-SAerators)

Hydraulictoplink1

Hydraulichose,3–1/2feet1

Hydraulichose,2–1/2feet1

Extensionbracket2

Rotationalbracket1

3

Hosequickcouplings2

ConnectHydraulicT opLink(Models

SR48,SR54,SR70,SR72andSR75)

Springloadedtoplink1

Linkpin3

4Lynchpin3

ConnectUpperLink(ModelsSR54–S

andSR70–S)

5Nopartsrequired–Verifythetoplinksetup

6Nopartsrequired–CheckingthePTOangle

7PTOshaft1FittingthePTOshaft

8PTOShield1InstallthePTOShield

Pin(suppliedwithPTOshaft)1

9Nut(suppliedwithPTOshaft)1ConnectPTOShaft

10Nopartsrequired–AdjustingSwayLinks

11Level(notsupplied)1LevelAeratorSide-to-Side

12TinesA/RInstalltheTines

13Nopartsrequired–Setthetinedepth

Rearguard1

Screw,3/8x3–1/4inch4

Flatwasher,.438x1.00inch12

Locknut4

14

Endcap2

Installtherearguard

Lockplate2

Tapbolt2

15Retainingring2

Installthelatchlock

16Nopartsrequired–RemoveStorageStands

17Nopartsrequired–RemoveStorageStands

8

MediaandAdditionalParts

DescriptionQty.Use

Operator'sManual1Readbeforeoperatingtheaerator

PartsCatalog1Usetoreferencepartnumbers

SpringWires-SR484Replacementspringwires

SpringWires-SR482Replacementspringwires

SpringWires-SR54&SR54-S6Replacementspringwires

SpringWires-SR70&SR70-S8Replacementspringwires

SpringWires-SR724Replacementspringwires

SpringWires-SR722Replacementspringwires

SpringWires-SR754Replacementspringwires

SpringWires-SR752Replacementspringwires

Operatortrainingmaterials1Viewbeforeoperatingtheaerator

PTOOperatorsManual1Readbeforeoperatingtheaerator

1

RemovingtheAeratorfrom

theCrating

NoPartsRequired

Procedure

1.Removetheaeratorfromthecrating.

2.Removetheboltssecuringtheaeratorstoragestands

totheshippingpalletandremovetheaeratorfrom

thepallet.

3.Removethestoragestandsfromtheaerator.Retain

themforstorageuse.

Note:TheSR54-SandtheSR70-Sdonothave

shippingstands.

4.Placetheaeratoronaat,levelsurfacewiththe

frontrolleronthegroundanda2x4positioned

undertheheads.

2

ConnectingtheLowerLink

Arms

Partsneededforthisprocedure:

2Hitchpin

2Lynchpin

Procedure

1.Backthetractorsquarelyuptotheaeratoruntil

thelowerlinkarmsarealignedwiththemounting

brackets.

Note:Theaeratorgearboxshaftshouldbeinline

withthetractorPTOshaft(centeredonthetractor).

Iftheyarenotinline,adjustthelowerlinkarms,

fromsidetosideuntiltheshaftsarealigned.

2.MakesurethePTOisdisengaged.

3.Engagetheparkingbrake,STOPtheengineand

removethekeyfromtheignition.Waitforthe

engineandallmovingpartstoSTOPbeforeleaving

theOperator'sseatonthetractor.

Note:Formaximumgroundclearance,thehitch

pinsshouldbesecuredintheaeratorlowermounting

bracketholes,whensoequipped.Todetermine

9

whentousetheuppermountingholes,referto

ConnectingthePTOShaft.

SR54andSR54-SAeratorsonly

Note:Thehitchpinsandlynchpinsareshipped

installedontheSR54andSR54-SAerators.

4.Securethelowerlinkarmstotheaeratormounting

pinswithlynchpins(Figure3).

Figure3

1.Aeratormountingpin3.Lynchpin

2.Lowerlink

SR48,SR70,SR70-S,SR72andSR75Aerators

only

5.Securethelowerlinkarmstotheaeratormounting

bracketswithhitchpinsandlynchpins(Figure4).

Figure4

1.Hitchpin3.Lowerlink

2.Aeratormountingbracket4.Lynchpin

3

Connectingthe

HydraulicTopLink

(ModelsSR48,SR54,SR70,

SR72andSR75)

Partsneededforthisprocedure:

1Hydraulictoplink

1Hydraulichose,3–1/2feet

1Hydraulichose,2–1/2feet

2Extensionbracket

1Rotationalbracket

2Hosequickcouplings

Procedure

Note:Makesurethesuppliedcouplingsarecorrectfor

thetractor.Ifnot,itwillbenecessarytocontactthe

tractormanufacturertoobtainthecorrectcouplings.

Thetractormustbeequippedwithadoubleactingspool

valvewithanoperatorcontrolleverandtwo1/2inch

(12.7mm)quick-releasecouplingsattherearofthe

tractor.Twoquickcouplingshavebeenprovidedtot

tothehydraulictoplinkhoses(1/2–14NPTFhoseend

threadsize).

Thissectionwillbeusedtoinstallthehosesand

determinetheneedfortheextensionorrotationblocks.

Thisinformationwillhelptodeterminethedepthrange

oftheaerator.

1.Securetheconnectinglinkendofthehydraulictop

linktothetractorwiththepinssuppliedwiththe

tractor(Figure5).Positionthehydraulictoplinkso

therodendistowardtheaerator.Thecylinderports

shouldbepositionedtowardthetractor'sauxiliary

powerhydraulics.

Note:Ifthehydrauliccylindermustbepositioned

withtheportsfacingupward,usetherotationalblock

insteadofthestandardmountingblocktoreposition

thecylinder(Figure5).A90degreehydraulictting

maybeusedinsteadoftherotationalblock(ttings

arenotsupplied).

Installtherotationalblockasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

10

(Figure5).Removetheconnectinglinkfromthe

cylinder.

B.Installtherotationalblocktothecylinderwith

thepinspreviouslyremoved(Figure5).

Figure5

1.Aeratorhitchpin7.Tractorlinkpin

2.Hydraulictoplink8.Clevis&lynchpin

3.Rotationalblock9.2–1/2foothydraulichose

4.Connectinglink10.3–1/2foothydraulichose

5.3inchextensionblock11.Hosequickcouplings

6.5inchextensionblock12.Tractorhydraulicports

2.Connectthe3–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttotheaerator

Figure5.ApplyTeontapeorpipethreadsealantto

thehosethreadstopreventanyleaks.

3.Connectthe2–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttothetractor

(Figure5).ApplyTeontapeorpipethreadsealant

tothehosethreadstopreventanyleaks.

4.Installquickcouplingstothehydraulichoses

(1/2–14NPTFhoseendthreadsize).ApplyTeon

tapeorpipethreadsealanttothehosethreadsto

preventanyleaks.

5.Connectthetwohydraulichosequickcouplingsto

theportsprovidedonthetractor.

6.Startthetractorengineandoperatethetractorspool

valvetochecktheextendandretractmotionofthe

hydraulictoplink.

Note:Reversethehoseconnections,atthetractor,

iftheydonoagreewiththetractorcontroloperation.

7.Securetherodendofhydraulictoplinktothemost

forwardholepossibleintheaeratorbracketwithlink

pinandlynchpin(Figure6,Figure7orFigure8).

Important:Whensecuringtherodendof

thehydrauliclink,makesuretousethemost

forwardmountingholesinthemountingbracket

sothereisenoughclearanceforthebarrelofthe

cylinderwhenretracted.

Figure6

SR54andSR70mountingshown

1.Rodendofcylinder3.Linkpin

2.Lynchpin4.Aeratorbracket(forward

holes)

Figure7

SR48andSR72mountingshown

1.Lynchpin3.Linkpin

2.Aeratorbracket4.Rodendofcylinder

11

Figure8

SR75mountingshown

1.Linkpin3.Rodendofcylinder

2.Aeratorbracket4.Lynchpin

Ifthehydrauliccylinderdoesnotreachtheaerator

mountingbracket,useanextensionblockinsteadof

thestandardmountingblocktoconnectthecylinder

tothetractor(Figure5).

Note:Ifanextensionblockisinstalledandthe

cylinderneedstoberetractedtobeinstalled,the

aeratortineheadswillgetclosertotheground.

Installtheextensionblocksasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglinkfromthe

cylinder.

B.Installtherequiredlengthextensionblockto

thecylinderwiththepinspreviouslyremoved

(Figure5).

4

Connectingthe

TractorUpperLink

(ModelsSR54–SandSR70–S)

Partsneededforthisprocedure:

1Springloadedtoplink

3Linkpin

3Lynchpin

Procedure

1.Mountthespringloadedtoplinktotheaerator

bracketwithtwolinkpinsandlynchpins(Figure9)

2.Loosenthelocknutonthetractorupperlink.Adjust

theupperlinklengthuntilitalignswiththeclevison

thespringloadedtoplinkoftheaerator(Figure9).

Figure9

1.Springloadedtoplink4.Lynchpin

2.Upperlink5.Locknut

3.Linkpin

3.Connectthetractorupperlinktotheclevisonthe

springloadedtoplinkandsecurewithalinkpinand

lynchpin(Figure9).

4.Greasethethreadedsteelupperlinktubes.

5.Measurethelengthofthespringinthetoplink.

6.Rotatetheupperlinkuntilthespringiscompressed

byabout1/2inch(Figure9).

7.Tightenthelocknuttosecuretheupperlinkinto

position.

12

5

VerifyingtheHydraulicTop

LinkSetUp

NoPartsRequired

Procedure

•Extendingthehydrauliccylinderwillincreasethe

tinedepth.

•Fullyextendthehydrauliccylindertodetermine

thelocationofthetineheadsandtoverifyifthey

contacttheground.

CAUTION

Ifthetineheadscontacttheground,turf

damagemayoccur.

Note:Onundulatingturf,theoperatorcanadjust

thecylindertomaintaintinedepth(crestingahill)

butitwillbenecessarytohavethetineheadsset

about2inchesbelowground.

•Ifthetineheadscontacttheground,adjustthe

locationofthecylinderendstomovethetopofthe

aeratorclosertothetractor.

•Ifthetineheadsdonotcontacttheground,

extensionbrackets(includedwithaerator)canbe

installedtothetoplinktomovethetineheadscloser

totheground.

Important:WhenconnectingthePTO,besure

thattheaeratorisnotbeingliftedhigherthanis

necessary.Liftingthemachinetoohighwillcause

thePTOshaftknucklestobreak(Figure10).Never

leavethePTOturningwhentheaeratorislifted.

ThePTOcanbeoperateduptoanangleof25º,but

canneverexceeda35ºanglewhentheaeratoris

atitshighestpositionorsevereshaftdamagemay

occur.

Figure10

1.Breakagewilloccurhere

6

CheckingthePTOAngle

NoPartsRequired

Procedure

Important:Makesurethetinesareremovedbefore

performingthisoperation.

Withtheaeratorpositionedonthegroundandlowered

tothedeepestlocation,checktheanglebetweenthe

PTOandtheaerator.

Lifttheaeratorandfullyretractthehydraulictoplink

cylinder.Usinganangleindictor,checktheangle

betweenthePTOandtheaerator.Ifthisangleisgreater

than35degrees,makeadjustmentstothetractorso

thattheaeratorcannotbeliftedpast35degrees.This

canbeaccomplishedbyusingthetractorliftstop(if

soequipped)ormovingthelowerlinkstoahigher

mountinghole(ifsoequipped).

13

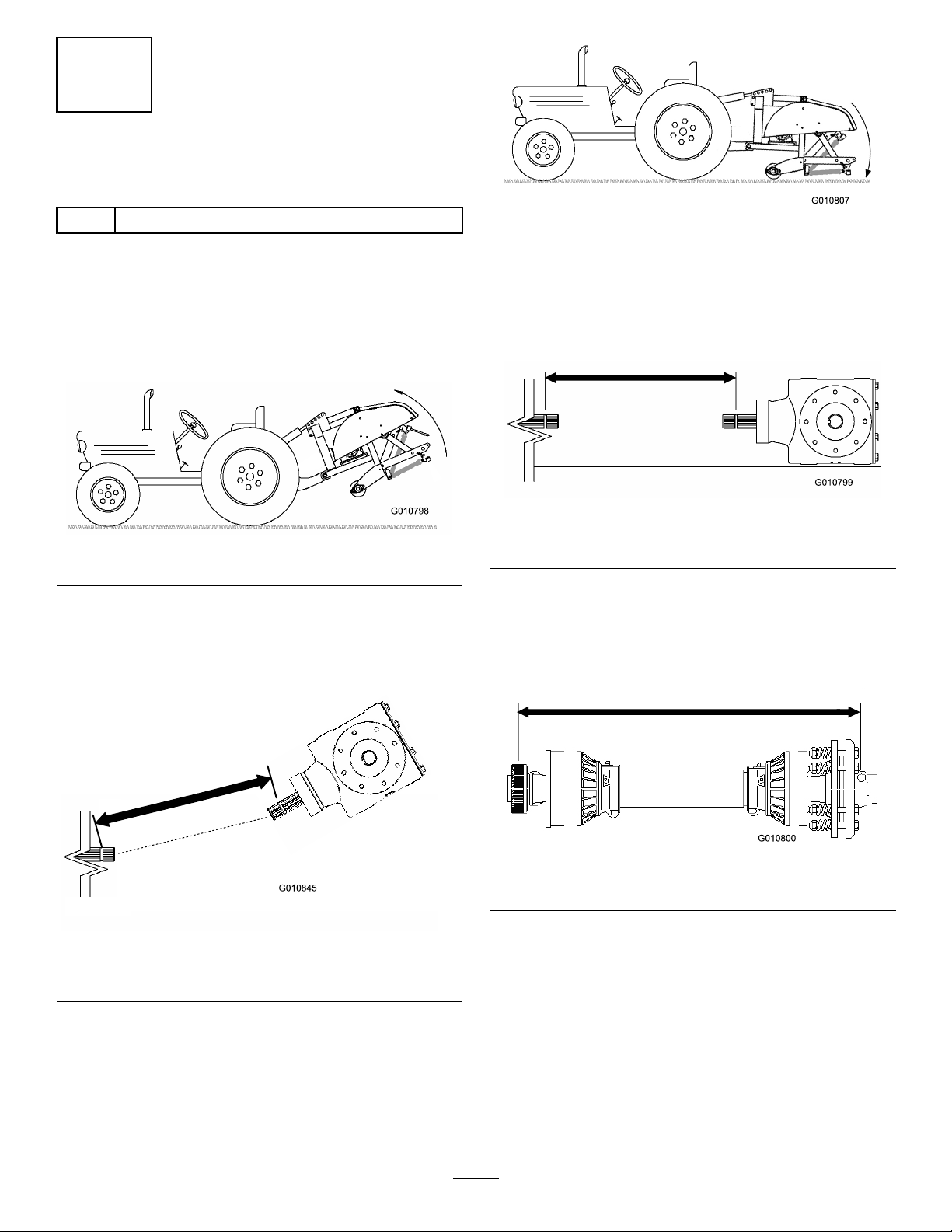

7

FittingthePTOshaft

Partsneededforthisprocedure:

1PTOshaft

Procedure

1.Movethetractorandaeratortoalevelsurface.

2.Raisetheaeratorcompletelyandfullyretractthe

hydraulictoplinkcylinderorupperlink(Figure11).

Figure11

3.Measurethedistancefromthelockinggrooveonthe

endofthetractorPTOshafttothelockinggroove

ontheaeratorgearboxPTOshaft(Figure12).

Recordthisdistance.Example:26.5inches(67cm).

Figure12

1.Measurehere2.Lockinggroove

4.Lowertheaeratortothegroundandfullyextendthe

hydraulictoplinkcylinderorupperlink(Figure13).

Figure13

5.Measurethedistancefromthelockinggrooveonthe

endofthetractorPTOshafttothelockinggroove

ontheaeratorgearboxPTOshaft(Figure14).

Recordthisdistance.Example:27.5inches(70cm).

Figure14

1.Measurehere2.Lockinggroove

6.OnthePTOshaft,measurethedistancefromthe

centeroflockingpinballononeendtothecenterof

thelockingpinontheotherend(Figure15).Record

thisdistance.Example:32inches(81cm).

Figure15

1.Measurehere

7.Usingthesmallerofthetwomeasurementsin

Figure14andFigure12,subtractthatdistancefrom

thedistanceinFigure15.Example32(81cm)inches

minus26.5inches(67cm)equals5.5inches(14cm).

8.Theexamplemeasurementsshowthattheshaftis

5.5inchestoolong.Addanextra1/2inch(1.2cm)

tobesurethatthePTOshaftwillnotbottomout

whentheaeratorisliftedtoitshighestposition.

Example:5.50inches(14cm)plus1/2inch(1.2cm)

equals6.00inches(15cm).

14

9.SlidethePTOshafttubestogetheruntiltheyare

fullycollapsed.Verifythattheinsidetubedoesnot

protrudeintothecrossandbearingsectionofthe

outertube(Figure16).Ifthishappens,morewill

havetobecutofftheinsidetube,tocorrectthe

problem.Proceedtonextstep.

10.Measurethedistancetheinsidetubeprotrudesinto

thecrossandbearingsectionoftheoutertube

(Figure16).Addthisdistancetothedimension

attainedinstep8.

Figure16

1.Cutoff2.Insidetube

11.SeparatethetwohalvesofthePTOshaft(Figure17,

illustration1).

12.Measurethedistancefromtheendofeachtubeto

itssafetyshield(Figure17,illustration1).Record

thedistances.

13.Usingthedimensionsdeterminedinstep8,locate,

markandcutofftheshieldandtubefromeachPTO

half(Figure17,illustrations2&3).

Note:Morewillhavetobecutofftheinsidetubeif

itwasprotrudingintothecrossandbearingsection

oftheoutertube.

14.Usingthedimensionsdeterminedinstep11,locate,

markandcutoffjustthesafetyshieldstoexposethe

tubesFigure17,illustrations4&5.

15.Carefullydeburrtheendsofthetubeswithaleand

removeallthelingsfromthetubes.

16.Greasetheinsidetube.

Note:Telescopingtubesmustalwaysoverlapby

1/2oftheirlengthinnormaloperationandatleast

1/3oftheirlengthinallworkingconditions.During

transport,whenthedrivelineisnotrotating,the

telescopingtubesmusthaveasuitableoverlapto

maintainthetubesalignmentandallowthemtoslide

freely.

Figure17

1.Measurehere

8

InstallingthePTOShield

Partsneededforthisprocedure:

1PTOShield

Procedure

1.Removethe4bolts,lockwashersandatwashers

securedtotherearoftheaeratorgearbox(Figure18).

15

Figure18

1.PTOshield4.Bolt

2.Flatwasher5.Accesspanel

3.Lockwasher

2.MountthePTOshieldtotheaeratorgearboxwith

thefastenerspreviouslyremoved(Figure18).When

mountingthePTOshield,makesuretheaccess

panel(Figure18)ispositionedtothetoporside

dependingontheaeratorframeconguration.

9

ConnectingthePTOShaft

Partsneededforthisprocedure:

1Pin(suppliedwithPTOshaft)

1Nut(suppliedwithPTOshaft)

Procedure

Note:Theaccesspanel(Figure18)canbeopened

toeasetheremovalandinstallationofthePTOshaft

mountingfasteners.

1.RemovethepinandnutfromthePTOshaft

(Figure19).

2.ConnecttheclutchendofthePTOshafttothe

aeratorgearboxinputshaftwithpinandnut

previouslyremoved(Figure19).Thepincanonly

beinsertedoneway.

Figure19

1.Gearboxinputshaft3.Pin

2.PTOshaftcoupler4.Nut

Note:MakesuretocloseandlatchthePTOshield

accesspanelifopened.

Note:Makesurethepinisfullyinsertedintothe

yokeofthePTO.

3.ConnectthePTOshafttothetractorPTOshaft

(Figure20).

Figure20

1.Tractoroutputshaft3.PTOshaft

2.PTOshaftcoupler

4.SlidethePTOshaftforwardasfarasthetractor

allows.

5.PullbackonthelockingcollartosecurethePTO

shaftinplace.SlidethePTOshaftbackandforthto

makesureitisproperlylocked.

6.ConnecttheshieldsafetychainstothePTOshield

andthetractorbracket(Figure21).Makesurethe

chainsremainslackwhentheaeratorisraisedor

lowered.

16

Figure21

1.Safetychains

Note:Toavoidexcesslift,connecttheliftarmsof

thetractorintothetopholesoftheliftbracket,if

soequipped(Figure22).Themaximumangleon

thePTOshaftis35º.

Figure22

1.Topholes

Important:WhenconnectingthePTO,be

surethattheaeratorisnotbeingliftedhigher

thanisnecessary.Liftingthemachinetoohigh

willcausethePTOshaftknucklestobreak

(Figure23).NeverleavethePTOturningwhen

theaeratorislifted.ThePTOcanbeoperated

uptoanangleof25º,butcanneverexceeda35º

anglewhentheaeratorisatitshighestposition.

7.VerifythatthePTOshielddoesnotinterferewith

theclutch.

Figure23

1.Breakagewilloccurhere

10

AdjustingtheSwayLinks

NoPartsRequired

Procedure

Theaeratorisdesignedtobecenteredwiththetractor

PTOshaftcenterline.Adjusttheswaylinksasrequired.

ThePTOshaftshouldbeasstraightaspossibletothe

tractorPTOshaft.

Adjusttheswaylinksonthelowerliftarmstominimize

side-to-sideswaytoamaximumof1inch(25mm)on

eachside(Figure24).

Figure24

1.Swaylink

17

Adjustthelowerlinksinboarduntiltheycontactthe

aeratormountingplates.Thiswillreducethestress

onthepins.Ifthetractorhasswaychainsinsteadof

swaylinks,itisrecommendedthatwashersbeinstalled

betweenthelowerlinkarmandlynchpintoreducethe

overhungloadontheliftpins.

Note:RefertothetractorOperator'sManualfor

additionalinstallationandadjustmentprocedures.

11

LevelingtheAerator

Side-to-Side

Partsneededforthisprocedure:

1Level(notsupplied)

Procedure

1.Parkthetractorandaeratoronalevel,rmsurface.

2.Placealevelontopoftheaeratorframetocheckfor

levelside-to-side(Figure25).

Figure25

1.Level

3.Turntheadjustablelinkbody(ifprovided)toraise

orlowerthelinkarmuntiltheaeratorisleveled

side-to-side.

Note:RefertotractorOperator'sManualfor

additionaladjustmentprocedures.

12

InstallingtheTines

Partsneededforthisprocedure:

A/RTines

Procedure

Awideselectionoftinesareavailablefortheaerator.

Choosethetinetype,sizeandspacingsrequiredforthe

job.RefertothePartsCatalogforthelistofaccessories.

1.Makecertaintheaeratorisfullysupportedonthe

standsorsupportblocks.

2.Turnoffthetractorengineandremovethekey.

3.Loosentheclampingboltsandremovethepreviously

usedtines(Figure26).

Figure26

1.Tine2.Clampingbolt

4.Slidethenewtinesintotheholessizedtotthetines

selected.Neverusesmalldiametertinesinthelarge

diameterholes-thetinesshouldtcloselyinthe

hole.Besuretoslidethetineupintotheheaduntil

itbottomsout.

Note:Hollowcoringtinesshouldbepositioned

withtheejectionslottotherearwhilethesolidtines

shouldhavethetinetipanglefacingthemachine

(Figure26).

5.Tightentheclampingboltsrmlytosecurethetines.

6.Setthetineangleforthenewtines.Referto

AdjustingtheTineAngleintheOperationsection.

7.Beforeaeratingformalturfforthersttimeafter

installingtines,testtheaeratoronalessimportant

areasothatyoucantryalternativetractorgearsand

netunetheadjustmenttoachievetheholespacing

andturfappearancedesired.

18

13

SettingtheTineDepth

(ModelsSR54–SandSR70–S)

NoPartsRequired

Procedure

Thetinedepthcanbechangedbyraisingorloweringthe

rearroller.Therollerheightisadjustedbymovingthe

rolleradjustingboltstothedesiredposition.

Note:TheaeratorisshippedinPositionA.

Figure27

•PositionA-Maximumdepth

•PositionB-Depthisdecreased1–1/2inchesfrom

PositionA

•PositionC-Depthisdecreased3inchesfrom

PositionA

14

InstallingtheRearGuard

Partsneededforthisprocedure:

1Rearguard

4Screw,3/8x3–1/4inch

12Flatwasher,.438x1.00inch

4Locknut

2Endcap

Procedure

1.Inserttheendcapsintotheendsoftherearguard

tubes(Figure28).

Figure28

1.Rearguard3.Uppermountinghole

2.Endcap4.Lowermountinghole

2.Aligntheholesintherearguardmountingtubes

withtheholesintheaeratorsideplates(Figure28).

Note:OnSR54–SandSR70–Smodels,mountthe

endsofthetubestothelowersideplatemounting

holesiftheaeratortinedepthissetinPositionA

(Figure29).Usetheuppermountingholesfordepth

settingPositionsBorC.

19

Figure29

3.Securetheguardmountingtubestothesideplates

with(4)screws,atwashersandnuts(Figure28).

Note:Usetheremainingwashers,asrequired,toll

anygapbetweenthetubesandtheaeratorsideplates.

15

InstallingtheLatchLock

Partsneededforthisprocedure:

2Lockplate

2Tapbolt

2Retainingring

Procedure

1.Positionthelatchplateoverthehoodlatchwhile

aligningthemountingholewiththeholeintheside

plate(Figure30).

Figure30

1.Retainingring3.Latchplate

2.Mountinghole4.Tapbolt

2.Securethelatchplatetothesideplatewithatapbolt

andaretainingring(Figure30).

3.Repeattheprocedureontheotherhoodlatch.

16

RemovingtheStorageStands

(ModelsSR54andSR70)

NoPartsRequired

Procedure

1.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

2.Removethebolts,lockwashersandnutssecuringthe

storagestandstoeachendoftheaerator(Figure31).

20

This manual suits for next models

13

Table of contents

Other Toro Tiller manuals