Toro 23515 User manual

FormNo.3365-260RevB

21-inchWalk-BehindAerator

ModelNo.23515—SerialNo.312000001andUp

ModelNo.33515—SerialNo.312000001andUp

g017576

Registeratwww.Toro.com.

OriginalInstructions(EN)*3365-260*B

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thisaerator,whichiscontrolledbyawalkingoperator,

isintendedtobeusedbytrainedoperatorsinresidential

andcommercialapplications.Itisprimarilydesignedfor

aeratingsmalltomid-sizedareasofwell-maintainedlawnson

residentialgrounds,parks,sportselds,andoncommercial

grounds.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

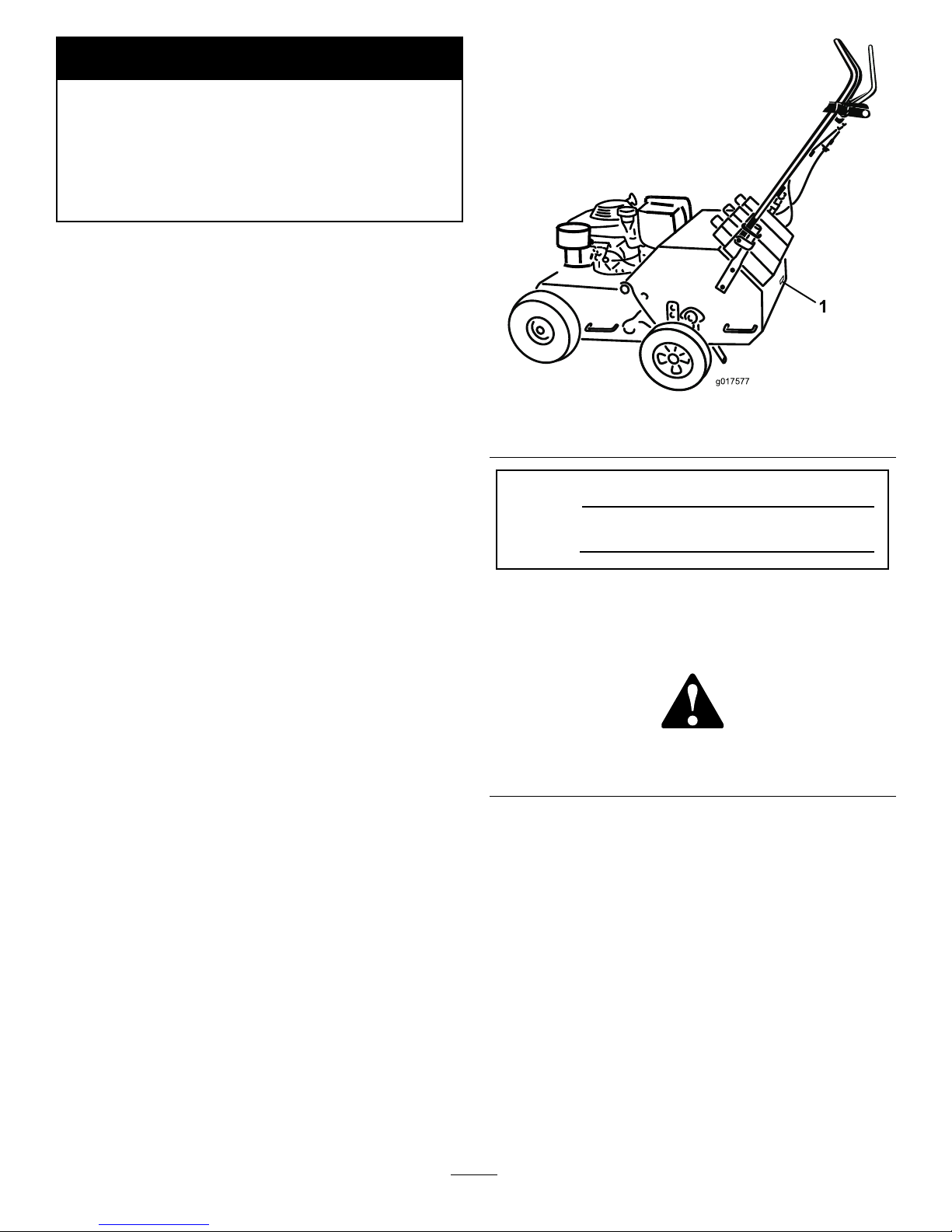

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

g017577

1

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................7

UnfoldingtheHandle..............................................7

CheckingtheOilLevel.............................................7

ProductOverview..........................................................7

Controls................................................................7

Specications.........................................................8

Attachments/Accessories.........................................8

Operation.....................................................................8

CheckingtheEngineOilLevel..................................8

FillingtheFuelTankwithGasoline............................9

StartingtheEngine..................................................9

StoppingtheEngine...............................................10

DrivingtheMachine...............................................10

Aerating................................................................11

AddingWeight.......................................................11

AdjustingtheCoringDepth.....................................11

SecuringtheMachineforTransport..........................12

OperatingTips......................................................12

Maintenance.................................................................13

RecommendedMaintenanceSchedule(s)......................13

PremaintenanceProcedures........................................13

AccessingtheTines................................................13

TippingtheMachine...............................................14

Lubrication...............................................................15

GreasingtheCenterTines.......................................15

LubricatingtheDriveChains....................................15

EngineMaintenance..................................................16

ServicingtheAirCleaner.........................................16

ChangingtheEngineOil.........................................16

ChangingtheOilFilter............................................17

ServicingtheSparkPlug..........................................17

FuelSystemMaintenance...........................................18

ReplacingtheFuelFilter..........................................18

DriveSystemMaintenance.........................................19

CheckingtheTirePressure......................................19

CheckingtheTensionofAeratorDrive

Chains...............................................................19

BeltMaintenance......................................................20

CheckingtheHydrostaticDriveBelt.........................20

ControlsSystemMaintenance.....................................20

AdjustingtheMachineGroundSpeed.......................20

TineMaintenance......................................................21

Checking/ReplacingTines.......................................21

Storage........................................................................22

Troubleshooting...........................................................23

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

means

Caution

,

W ar ning

,or

Danger

—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheANSI

B71.4—2004andB71.8—2004standard.

Training

•ReadtheOperator’sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglishitis

theowner’sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsafetyglassesand

hearingprotection.Longhair,looseclothing,orjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

becontactedbytheaerator.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordraintheaeratorindoors.

•Checkthatthecontrols,safetyswitches,andshieldsare

attachedandfunctioningproperly.Donotoperateunless

theyarefunctioningproperly.

3

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingengine.

•Neveroperatewithouttheshields,covers,orotherguards

securelyinplace.Besureallinterlocksarefunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Raisethetines,stopthemachine,andstoptheengine

beforeleavingtheoperator’spositionforanyreason.

•Stoptheequipmentandinspectthetinesafterstrikingan

objectorifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperation.

•Keephandsandfeetawayfromthetinearea.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdown,andusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.

•Donotoperatetheaeratorundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Useextremecarewhenloadingorunloadingtheaerator

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeintheareaof

operation.Planyouraerationpathtoavoidcontactwith

anyobstaclebyyouorthemachine.

SlopeOperation

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheoperatingarea.Tallgrasscanhideobstacles.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.Raisethetines,stopthemachine,stopthe

engine,anddisconnectthesparkplugwire.

•Cleangrassanddebrisfromthetines,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransportingontrailers.

Donotstorefuelnearamesordrainindoors.

•Parktheaeratoronlevel,hardground.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupportthemachine

whenworkingunderit..

•Removethesparkplugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•UseonlyToro-approvedattachments.Thewarranty

maybevoidedifthemachineisusedwithunapproved

attachments.

4

SlopeIndicator

G01 1841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

121-6150

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

119-0217

1.Warning—stoptheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

121-2008

1.Tostarttheengine,readtheOperator’s

Manual—(1)Parkthemachineona

levelsurface(2)Filltheenginewithoil

(3)Movethecontrolbarstoaneutral

position(4)Starttheengine.

2.Tractiondrive—movethetraction

controlleverforwardtomovethe

machineforward;movethetraction

controlleverbackwardtomovethe

machinebackward.

3.Rasing/Loweringthetines—pushthe

controlleverdowntolowerthetines;

pullthecontrolleveruptoraisethe

tines.

121-2009

1.Warning—readthe

Operator’sManual.

3.Thrownobject

hazard—stopthemachine

andpickupdebrisbefore

operating.

5.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

7.Warning—stoptheengine

andremovethesparkplug

wirebeforeperforming

anymaintenanceonthe

machine.

2.Warning—donotoperate

thismachineunlessyou

aretrained.

4.Warning—keephands

awayfrommovingparts,

keepallguardsandshields

inplace.

6.Warning—stoptheengine

beforeleavingthemachine.

6

Setup

UnfoldingtheHandle

1.Raisethehandletotheoperatingposition.

g017578

Figure4

2.Slidetheovallockingringsdowneachsideofthe

upperhandleoverthelowerhandle,lockingthehandle

sectionstogether.

CheckingtheOilLevel

Beforeoperating,checktheengineoilleveltoensurethatit

hasenoughoil.RefertoCheckingtheEngineOilLevelin

CheckingtheEngineOilLevel(page8),foroilspecications

andinstructions.

ProductOverview

7

8

9

10

11

12

13

14

15

g017579

1

2

3

4

5

6

Figure5

1.Fuelshut-offvalve9.Tractioncontrollever

2.Aircleaner10.Throttlelever

3.Sparkplugwire11.Tinecontrollever

4.Engine12.Ovalhandlelockingring

5.Recoilstarter13.Coringdepth,wheelstop

6.Fueltank14.Tie-down/liftloops

7.Rearweights15.Tines

8.Handle

Controls

RecoilStarter

Pulltherecoilstarterhandletostartengine(Figure5).

FuelShut-offValve

Closethefuelshut-offvalvewhentransportingorstoring

themachine(Figure5).

ThrottleLever

Beforestartingacoldengine,movethethrottleleverforward

totheChokeposition.Aftertheenginestarts,pullthethrottle

leverbacktotheFastposition.

Note:Awarmenginerequireslittleornochoking.

TractionControlLever

Thetractioncontrollevercontrolstheforward,

reverse,andneutralactionsofthemachine.Referto

DrivingtheMachine(page10)formoreinformation.

7

TineControlLever

Thetinecontrolleverliftstherearwheels,causingtherear

ofthemachinetobesupportedontheaeratingtines.Push

thetinecontrolleverdowntoliftthewheelsanddropthe

tines.Pullituptolowerthewheelsandraisethetinesout

oftheground.

g013076

1

2

Figure6

1.Tinecontrollever—raised

position

2.Tinecontrol

lever—loweredposition

Specications

Length(operating)61inches(155cm)

Length(withhandlestored)48.5inches(123cm)

Width31inches(79cm)

Height(operating)45.25inches(115cm)

Height(withhandlestored)32.5inches(82.5cm)

Weight(asshippedwith1

weight)

310lb(140.6kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesare

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theenginecrankcasecanhold20ounces(0.55liters)of

oil.Useonlyhigh-qualitySAE10W-30weightdetergentoil

thathastheAmericanPetroleumInstitute(API)service

classicationSH,SJ,Slorhigher.

Note:Whenthecrankcaseisempty,pourabout3/4ofthe

crankcasecapacityofoilinthecrankcase,thenfollowthe

procedureinthissection.

1.Movethemachinetoalevelsurface.

2.Cleanaroundthedipstick(Figure7).

g017580

Figure7

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

rotatethecapclockwisetosecureit,thenremoveit.

6.Readtheoillevelonthedipstick.

7.Iftheoillevelreadingisbelowthelowerlimitmarkon

thedipstick,removethedipstickandslowlypouronly

enoughoilintothellerholetoraisetheoillevelto

theupperlimitmarkonthedipstick.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagewillresult.

Draintheexcessoiluntiltheoillevelreachesthe

upperlimitmarkonthedipstick.

8.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

8

FillingtheFuelTankwith

Gasoline

Fueltankcapacity:1USGallon(3.8l)

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,and

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2in.(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

thegasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainerand

keepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

gasoline.

DANGER

Whenfueling,undercertaincircumstances,astatic

chargecandevelop,ignitingthegasoline.Areor

explosionfromgasolinecanburnyouandothers

anddamageproperty.

•Alwaysplacegasolinecontainersontheground

andawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegasoline-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheround.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,notfromagasolinedispensernozzle.

•Ifyoumustuseagasolinedispensernozzle,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•DoNotaddoiltogasoline.

Important:Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizerswithan

alcoholbasesuchasethanol,methanol,orisopropanol.

1.Cleanaroundthefueltankcap(Figure8).

g017581

1

Figure8

1.Fueltankcap

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedgasolinetowithin1/4

to1/2inch(6to13mm)fromthetopofthetank.Do

notllintothellerneck.

Important:Donotllthetankmorethan1/4

inch(6mm)fromthetopofthetankbecausethe

gasolinemusthaveroomtoexpand.

4.Installthefueltankcapandwipeupanyspilled

gasoline.

StartingtheEngine

1.Connectthewiretothesparkplug.

2.Openthefuelvalvebyturnitin-linewiththefuelhose

(Figure9).

9

12

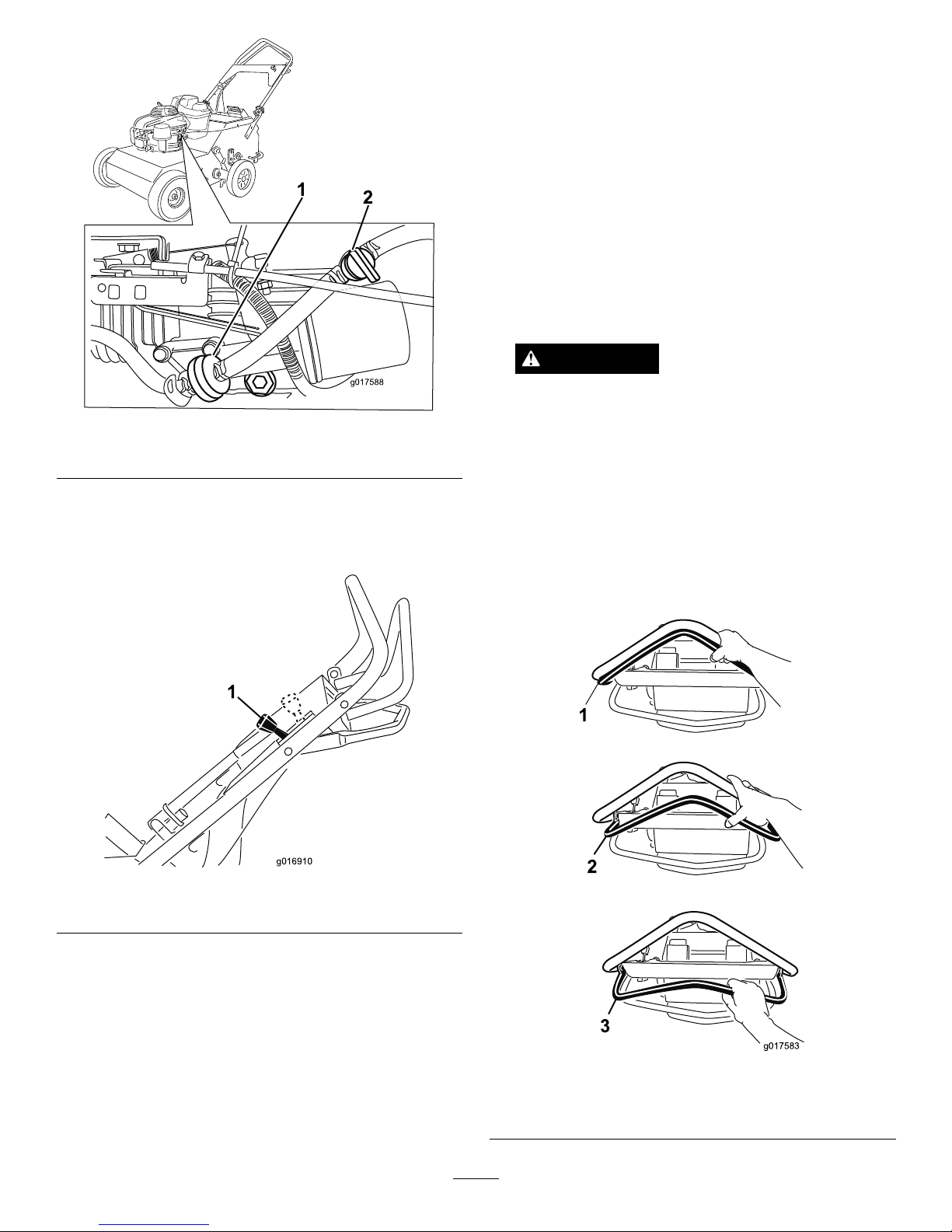

g017588

Figure9

1.Fuellter2.Fuelvalve—offposition

3.Movethethrottlecontrolallthewayforwardtothe

Chokeposition(Figure9).

Note:Donotusethechokewhentheengineiswarm.

g016910

1

Figure10

1.Throttlecontrol

4.Pullthestarterhandlelightlyuntilyoufeelresistance,

thenpullitsharply.Allowtheropetoreturntothe

handleslowly.

5.Whentheenginestarts,movethethrottlecontrolto

theFastposition.

Note:Thethrottlesettinggovernsthemaximumdrive

speedoftheaerator.

StoppingtheEngine

1.Releasethetractioncontrolleverandallowittoreturn

toneutral.

2.Movethethrottleleverallthewayrearwardtostop

theengine.

DrivingtheMachine

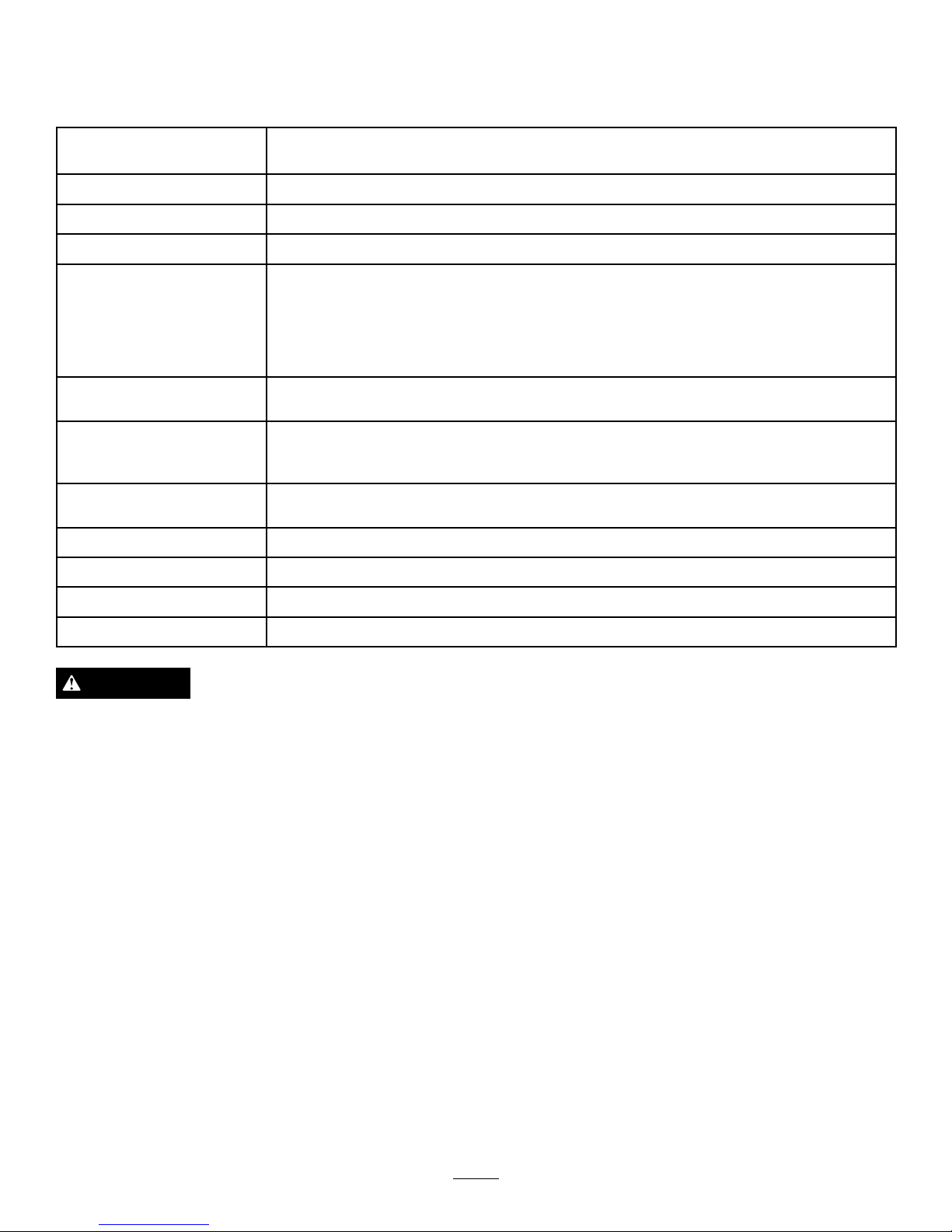

•Tomoveforward,pressthecontrolleverforward

(Figure11).Thefurtherforwardyoupushit,thefaster

themachinewilltravel.

•Tomoveinreverse,pullthecontrolleverrearward

(Figure11).Thefurtherforwardyoupullit,thefaster

themachinewilltravel.

WARNING

Theaeratortinesaresharpandcanpuncture

yourfeetorotherbodyparts.

Useextremecarewhenmovinginreverseso

thatyoudonotallowyourfeettogoclosetothe

tines.Watchforandavoidobstaclesyoucould

tripover.

•Toturnthemachine,moveslowlyandpressdownonthe

handles;turnthemachineinthedesireddirectionthen

resumenormaloperation.

•Tostop,releasethecontrollever(Figure11).

g017583

Figure11

1.Forward3.Reverse

2.Neutral(Stop)

10

Note:Ifyourmachineismovingtooslowlyandnotproperly

aerating,seeAdjustingtheMachineGroundSpeed(page20)

Aerating

1.Drivethemachinetothedesiredlocationandstopit.

2.Pushthetinecontrolleverdownandforwardtoraise

therearwheelsandengagethetines.

g013076

1

2

Figure12

1.Tinecontrollever—disengaged

2.Tinecontrollever—engaged

3.Drivethemachinetoaeratethedesiredarea.

Note:Themachinewithaerateinbothforwardand

reverse.

4.Whennished,stopthemachineandpullthetine

controlleverrearwardanduptolowertherearwheels

andliftsthetinesoutoftheground.

Important:Donotdrivethemachineacross

pavementorotherhardsurfaceswithoutrst

raisingthetines.Crossinghardsurfaceswiththe

tinesloweredwilldamagethetines.

AddingWeight

Toensurethatthetinespenetratefullyintothesoil,youcan

addweighttothebackofthemachine.Themachinehas

threeweightpocketsthatholdtheweights(Figure13).When

placingweight,ensurethatyouhaveabalancedload;ifusing

onlyoneweight,placeitinthecenterpocketandifusingtwo,

placetheminthesidepockets.

g017584

Figure13

1.Weight

AdjustingtheCoringDepth

Acoringdepthof2-1/2inches(6.35cm)isrecommended,

butyoucanchangethedepthasfollows:

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthesparkplugwire.

2.Loosenthenutssecuringthewheelstopontheright

sideofthemachine(Figure14).

Figure14

1.Nuts2.Wheelstop

3.Raisethewheelstoptoincreasethecoringdepthand

lowerittoreducethedepthasrequired.

4.Tightenthenutssecurelytolockthewheelstopin

place.

5.Repeatsteps2through4forthewheelstopontheleft

sideofthemachine.Setthewheelstopstothesame

heightoneachside.

11

SecuringtheMachinefor

Transport

Whentransportingthemachineonatrailer,alwaysusethe

followingprocedure:

Important:Donotoperateordrivethemachineon

roadways.

1.Drivethemachineontothattrailer,stopthemachine,

stoptheengine,turnoffthefuelvalve,anddisconnect

thesparkplugwire.

Important:Ifyoudonotturnoffthefuelvalve,

theenginemayoodduringtransport.

2.Securethemachinetothetrailerwithchainsorstraps

usingthetie-down/liftloops(Figure5).

OperatingTips

•Forbestperformanceandmaximumtinepenetration,

watertheturfthoroughlythedaybeforeaerating.

•Cleantheareaofdebrisbeforeusingthemachine.

•Markandavoidshallowobstaclessuchassprinklerheads

andinvisiblefencewires.

12

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst8hours•Changetheengineoil.

Aftertherst10hours•Checkthetensionofthedrivechains.

Aftertherst25hours•Checkthetensionofthehydrostaticdrivebelt.

Beforeeachuseordaily

•Checktheengineoillevel.

•Lubricatethepivotarms.

•Checkthetirepressure.

•Checktheconditionofthecoringtinesandreplaceanythataredamagedor

excessivelyworn.

•Checkforloosefasteners.

Every25hours•Lubricateandcheckthedrivechains.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

Every50hours

•Changetheengineoil.

•Checkthetensionofthedrivechains.

•Checkthetensionofthehydrostaticdrivebelt.

Every100hours•Changetheoillter.

•Inspect,clean,andadjustthesparkplug;replaceitifnecessary.

Every200hours•Replacethesparkplug.

Every250hours•Replacethefuellter.

Every300hours•Replacethepaperairlter(morefrequentlyindustyconditions).

Yearlyorbeforestorage•T ouchupchippedpaint

CAUTION

Ifyouleavethesparkpugwireconnected,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Beforeperforminganymaintenance,parktheunitonalevelsurface,stoptheengine,anddisconnectthe

sparkplugwire.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Premaintenance

Procedures

AccessingtheTines

Themachinehasarearaccesspanelthatyoucanremoveas

illustratedintoaccessandmaintainthetines.

13

g017585

1

Figure15

WARNING

Ifyouoperatethemachinewiththerearaccess

panelremoved,someonecouldbeseverelyinjured

bycontactwiththemovingtinesorbyyingdebris.

Alwayssecurelyinstalltherearaccesspanelbefore

operatingthemachine.

TippingtheMachine

Ifyouneedtoworkontheundersideofthemachine,youcan

tipitbackuntilitisrestingontherearguard(Figure16).Do

nottipthemachineforwardoryouwillfoultheaircleaner

withgasoline.Securethemachinewithajackstandbefore

workingunderit.

g017586

1

Figure16

1.Jackstand

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

machineandcauseaseriousinjury.

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

14

Lubrication

GreasingtheCenterTines

ServiceInterval:Beforeeachuseordaily

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthesparkplugwire.

2.Removetherearaccesspanel;referto

AccessingtheTines(page13)

3.Manuallyrotatethe2centertineassembliesuntilyou

canseethegreasettings(Figure17).

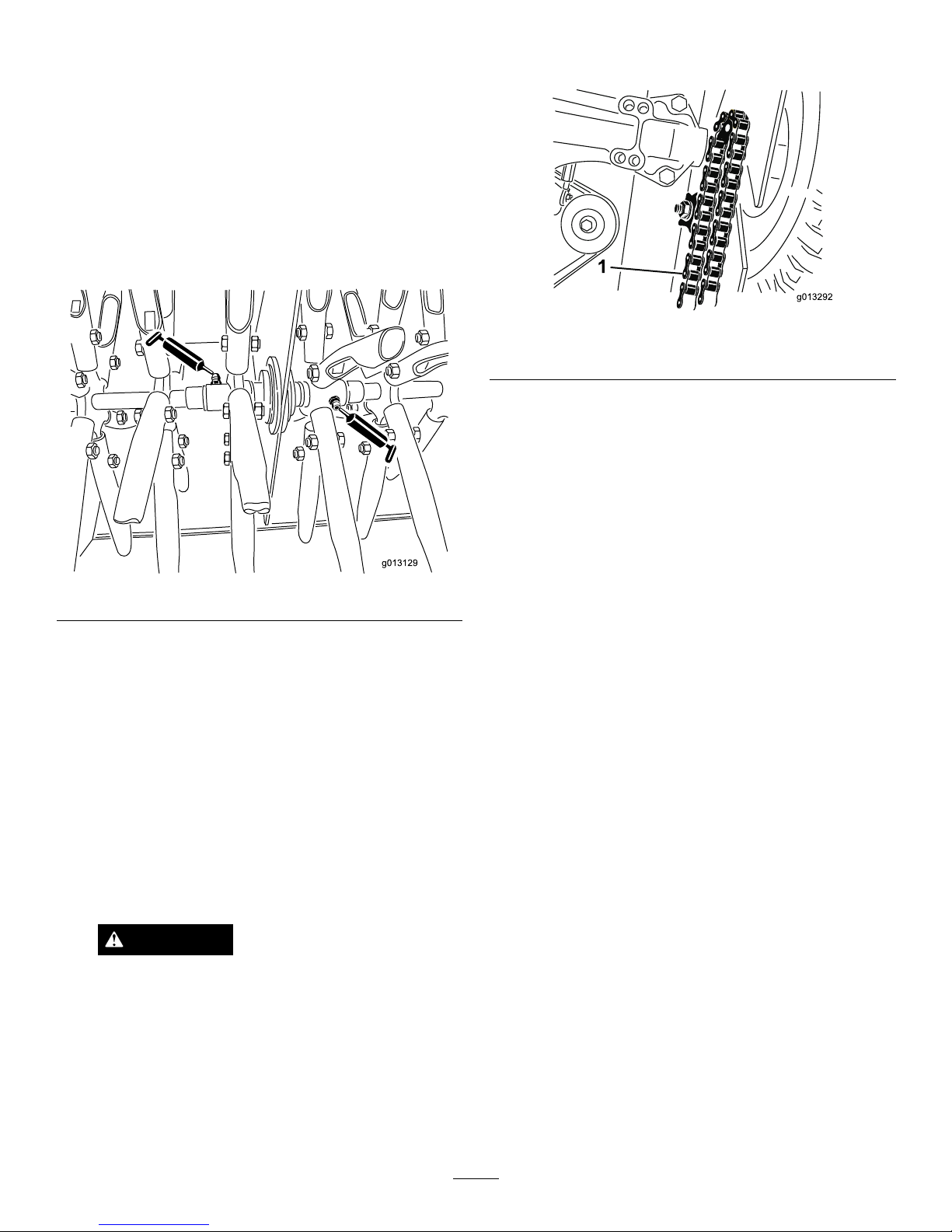

Figure17

4.Wipethegreasettingswithacleanrag.

5.Installagreasegunontothettingandgentlyapply2

or3pumpsof#2multi-purposelithiumbasegrease.

Important:Excessivegreasepressuremay

damagetheseals.

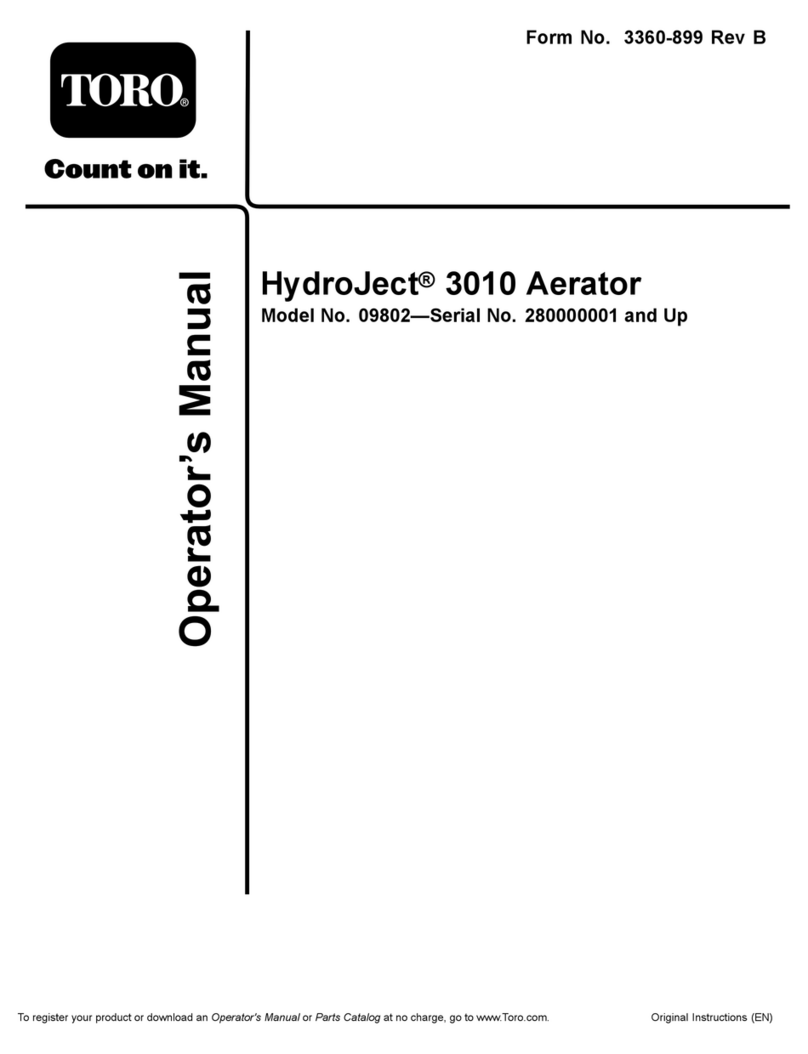

LubricatingtheDriveChains

ServiceInterval:Every25hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthesparkplugwire.

2.Raisethefrontofthemachinetogainaccesstothe

chains(Figure18)andblockitinplace.

CAUTION

Ifyoudonotsecurelyblocktheupthefront

ofthemachine,themachinecouldfallonyou

duringservice,injuringyou.

Ensurethatyouplaceajack-standorblock

underthefrontofthemachinetoholditup

securely.

Important:Donotraisetherearofthemachine.

Raisingtherearofthemachinewillcausethe

enginetooodandtheaircleanertobefouled

withgasoline.

g013292

1

Figure18

1.Chain(leftsideshown)

3.Applyageneralpurposeoil(10W30)ontothelower

chainspanwhilerotatingthefrontwheeltoexpose

un-oiledchainlinksuntilthewholechainisoiled.

4.Repeatstep3fortheotherchain.

5.Wipeupanyoilthatspilledandlowerthemachineto

thegroundwhennished.

15

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every25hours—Cleanthefoam

pre-cleaner(morefrequentlyindusty

conditions).

Every300hours—Replacethepaperairlter(more

frequentlyindustyconditions).

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagemayoccur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethecoverandcleanitthoroughly(Figure19).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

g017587

1

2

3

Figure19

1.Cover3.Paperairlter

2.Foampre-cleaner

4.Removethefoampre-cleanerandwashitwithamild

detergentandwater,thenblotitdry(Figure19).

5.Removeandinspectthepaperairlter(Figure19);

discarditifitisexcessivelydirty.

Important:Donottrytocleanapaperlter.

6.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

7.Installthefoampre-cleanerontothepaperairlter.

Note:Useanewpaperairlterifyoudiscardedthe

oldone.

8.Installtheairlterassemblyandcover.

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every50hours

OilCapacity

Withoillter29ounces(0.85L)

Withoutoillter22ounces(0.65L)£

1.Runtheenginetowarmtheengineoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

WARNING

Oilmaybehotafterenginehasbeenrun,and

contactwithhotoilcancauseseverepersonal

injury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug.

4.Placeadrainpanonthegroundtotherightofthe

machine.

5.Removethedipstick(Figure20).

G016924

Figure20

6.Removethedrainplug(Figure21)andtipthemachine

sotheoilowstothepan.

16

g017582

12

Figure21

1.Oildrainplug2.Oillter

7.Tipthemachineuprightagain,cleantheoilfromthe

framewitharapandreplacethedrainplug.

8.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

9.Slowlypouroilintotheoillltube,periodically

checkingthelevelwiththedipstick,untilthedipstick

indicatesthattheengineisfull.Donotoverll.(Max.

ll:20oz.(0.55l),type:SAE30Wdetergentoilwith

anAPIserviceclassicationofSH,SJ,SL,orhigher.)

Note:Ifyouoverlltheengine,poursomeoilout

ofit.

10.Installthedipsticksecurely.

11.Recycletheusedoilaccordingtolocalcodes.

ChangingtheOilFilter

ServiceInterval:Every100hours

1.Draintheengineoil;referto

ChangingtheEngineOil(page16).

2.Placearagundertheoillter(Figure21)tocatchany

oilthatmayleakoutasyouremovethelter.

3.Removetheoillter.

4.Useyourngertocoatthegasketonthenewlter

withoil(Figure22).

Figure22

5.Installthenewlterandhandtightenit2/3turnonly.

6.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

7.Slowlypouroilintotheoillltube,periodically

checkingthelevelwiththedipstick,untilthedipstick

indicatesthattheengineisfull.Donotoverll.(Max.

ll:20oz.(0.55l),type:SAE30Wdetergentoilwith

anAPIserviceclassicationofSH,SJ,SL,orhigher.)

Note:Ifyouoverlltheengine,poursomeoilout

ofit.

8.Installthedipsticksecurely.

9.Connectthewiretothesparkplug.

10.Runtheengineforabout3minutes.

11.Stoptheengine,waitforallmovingpartstostop,and

checkforoilleakagearoundthelter.

12.Checkandaddoiltocompensatefortheoilintheoil

lter.Donotoverll.

13.Recycletheusedoillteraccordingtolocalcodes.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Inspect,clean,and

adjustthesparkplug;replaceitif

necessary.

Every200hours—Replacethesparkplug.

UseanNGKBPR6ESsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.030inch(0.76mm)

(Figure23).

17

Figure23

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Carefullyinstallthesparkplugbyhand(toavoidcross

threading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnifitis

new;otherwise,tightenitanadditional1/8to1/4turn.

Important:Aloosesparkplugcanbecomevery

hotandcandamagetheengine;overtighteninga

sparkplugmaydamagethethreadsinthecylinder

head.

8.Connectthewiretothesparkplug.

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every250hours

1.Stoptheengineandwaitforittocooldown.

Important:Draingasolinefromacoldengine

only.

2.Disconnectthewirefromthesparkplug.

3.Closethefuelvalve.

4.Clampoffthefuellineoneithersideofthefuellter

(Figure24)topreventfuelfromleakingoutwhenyou

removethelter.

12

g017588

Figure24

1.Fuellter2.Fuelvalve

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure24).

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampscloseto

thelter(Figure24).

8.Removetheclampsfromthefuellines.

9.Openthefuelshutoffvalve.

18

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthetiresasspecied.Checkthe

tireswhentheyarecoldtogetthemostaccuratereading.

Pressure:46psi(317kPa)

1

G003793

Figure25

1.Valvestem

CheckingtheTensionof

AeratorDriveChains

ServiceInterval:Aftertherst10hours

Every50hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthesparkplugwire.

2.Raisethefrontofthemachinetogainaccesstothe

chainsandblockitinplace.

CAUTION

Ifyoudonotsecurelyblocktheupthefront

ofthemachine,themachinecouldfallonyou

duringservice,injuringyou.

Ensurethatyouplaceajackstandorblock

underthefrontofthemachinetoholditup

securely.

Important:Donotraisetherearofthemachine.

Raisingtherearofthemachinewillcasuethe

enginetooodandtheaircleanertobefouled

withgasoline.

3.Pulldownoneachchainneartheopeningintheframe

with10pounds(4.5kg)offorce(Figure26).Ifa

chaincontactsthebottomoftheopeningintheframe,

tightenitasfollows:

g013126

1

2

Figure26

1.Flexinthechain2.Bottomoftheframe

opening

A.Loosenthenutsecuringtheidlersprocketofthe

chainyouaretensioning(Figure27).

Figure27

1.Idlersprocket

B.Pulldownontheidlersprocketuntiltheslackis

takenoutofthechainandthereismorethan1/4

inch(6mm)ofspacebetweenthechainandthe

bottomoftheopeningintheframewhenyou

apply10pounds(4.5kg)offorcetothechain.

C.Tightentheidlersprocketnutandtorqueitto30

ft-lb(40.6N-m).

19

BeltMaintenance

CheckingtheHydrostatic

DriveBelt

ServiceInterval:Aftertherst25hours

Every50hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthesparkplugwire.

2.Raisethefrontofthemachinetogainaccesstothe

pumpdrivebeltandblockitinplace.

CAUTION

Ifyoudonotsecurelyblocktheupthefront

ofthemachine,themachinecouldfallonyou

duringservice,injuringyou.

Ensurethatyouplaceajackstandorblock

underthefrontofthemachinetoholditup

securely.

Important:Donotraisetherearofthemachine.

Raisingtherearofthemachinewillcasuethe

enginetooodandtheaircleanertobefouled

withgasoline.

3.Pushonaspanofthedrivebeltwith10pounds(4.5

kg)offorce(Figure28).Ifthebeltexesmorethan

1/2inch(1.3cm),tightenitasfollows:

G013125

123

Figure28

1.Pumpdrivebelt3.Idlerpulleynut

2.Idlerpulley

A.Loosenthenutsecuringtheidlerpulley

(Figure28).

B.Pushtheidlerpulleytothelefttotightenthebelt.

C.Tightentheidlerpulleynutandtorqueitto30

ft-lb(40.6N-m).

ControlsSystem

Maintenance

AdjustingtheMachineGround

Speed

1.Loosenthe2boltssecuringthecableattachment

bracketandslideitasfaraspossibletotheleftthen

tightenthe2bolts(Figure29).

12

G020483

Figure29

1.Bolts2.Cableattachmentbracket

2.Adjustthetractiondrivecableattheloweranchorby

movingthenuttotheendofthethreadandtightening

thejamnut(Figure30).

12

G020484

Figure30

1.Nut2.Jamnut

3.Adjustthetractiondrivecableatthehandleasfollows:

•Loosenandremovethelinkageadjustmentfrom

thebracket(Figure31).

•Movethelowernuttotheendofthethread

(Figure31).

20

Other manuals for 23515

4

This manual suits for next models

1

Table of contents

Other Toro Tiller manuals

Toro

Toro 29517 User manual

Toro

Toro 9701 User manual

Toro

Toro 33513 User manual

Toro

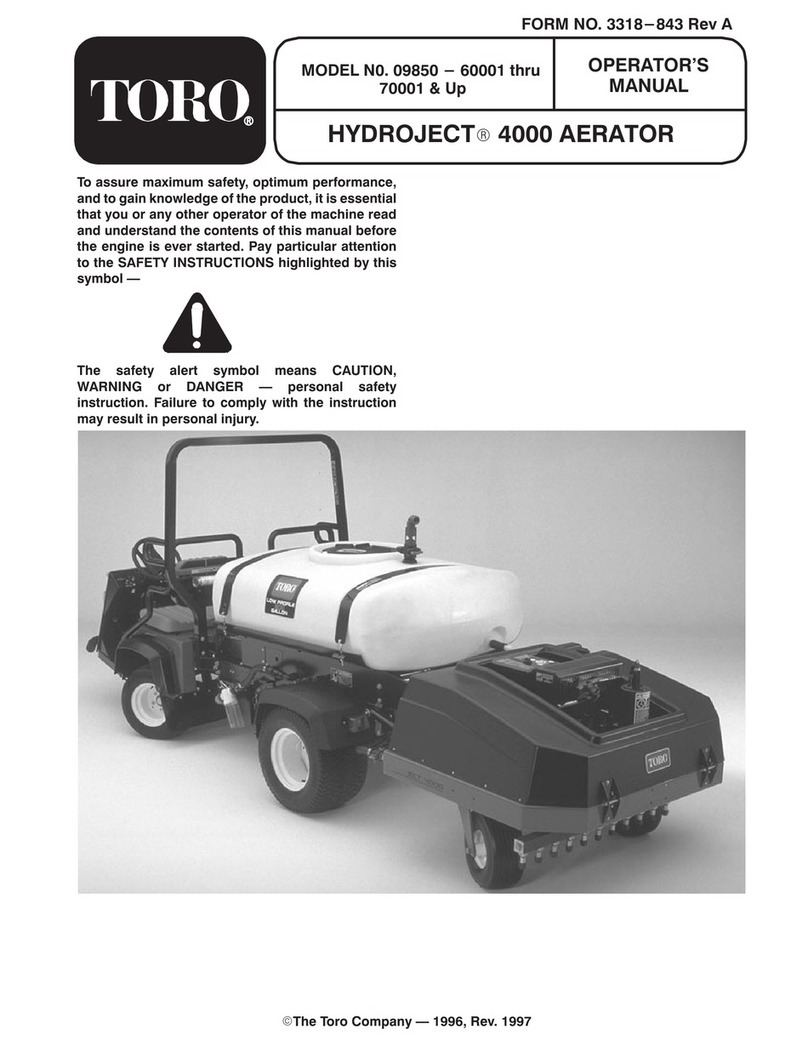

Toro Hydroject 3000 User manual

Toro

Toro 23518 User manual

Toro

Toro Power Shovel 39909 User manual

Toro

Toro 23515 User manual

Toro

Toro 09802 HydroJect 3010 User manual

Toro

Toro Dingo 22445 User manual

Toro

Toro 09802 HydroJect 3010 User manual