- 2 - tousek / EN_ST-80A_04 / 25. 03. 2020

Index

General warning and safety details ........................................................................................................................ 3

1. Notes, general characteristics, Technical data ST 80(V)A und STA 11 ................................................. 4

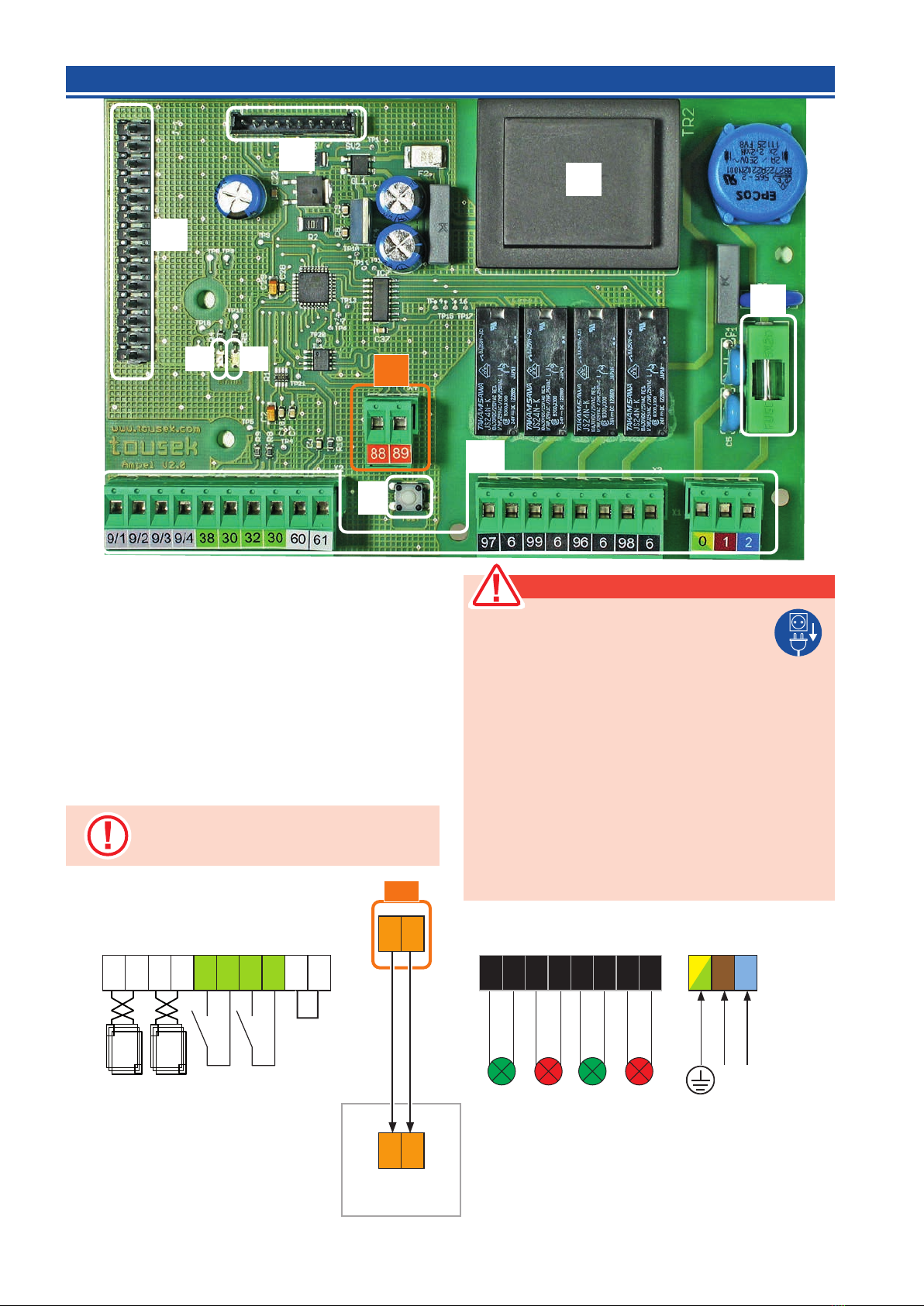

2. TraclightcontrolboardSTA11,function ............................................................................................ 5

2.1 Controlboardoverviewandterminalassignment.................................................................................. 6

2.2 Connectionsandadjustments .................................................................................................................. 7

induction loop input (outside: term. 9/1+9/2, inside: term.9/3+9/4)................................................ 7

impulse button input (outside: term. 38/30, inside: term. 32/30).................................................... 7

Trac light outputs ......................................................................................................................... 7

Connection of trac light control to barrier control unit (term. 88/89)............................................. 7

2.3 Radioreceiver(optional) ........................................................................................................................... 8

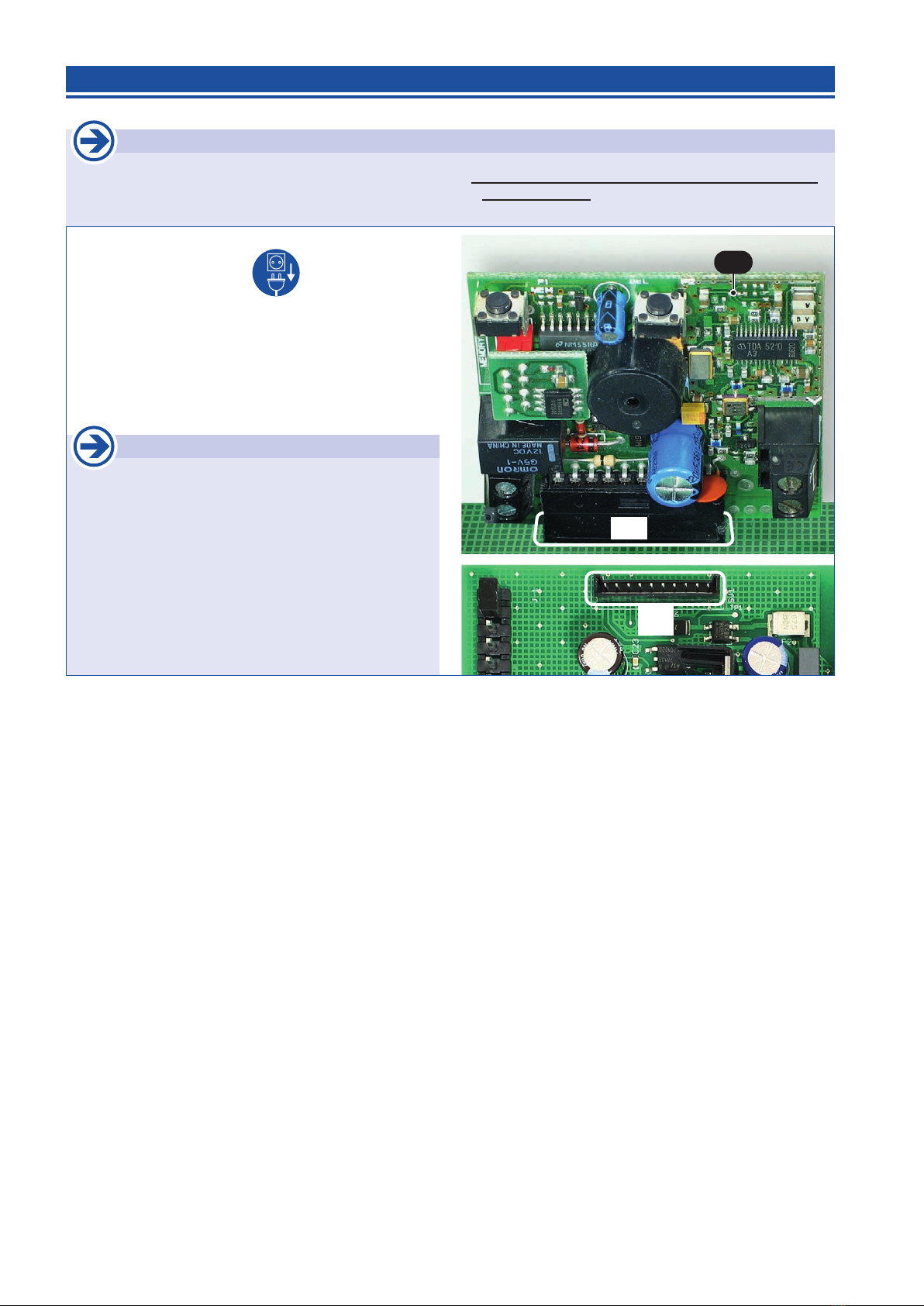

3. BarriercontrolunitST80(V)A,controlboardlayout ........................................................................... 10

3.1 Terminalassignment, connection notes ................................................................................................11

3.2 Adjustments-overview ........................................................................................................................... 12

Programming keys, program menu, basic settings ...................................................................... 12

Menus .......................................................................................................................................... 13

3.3 Connectionsandadjustments ................................................................................................................ 14

Switches/buttons

....................................................................................................................................... 15

Barrierdoorcontactforsafety(terminal30/54) ...................................................................... 15

ISD channel 1 (I-loop 1: terminals 9/1 and 9/2)........................................................................... 15

ISD channel 2 (I-loop 2: terminals 9/3 and 9/4)........................................................................... 15

STOPP-button (terminals 31/37) ................................................................................................. 15

Safety .......................................................................................................................................... 16

G Photocell (contact: terminals 45/46) ............................................................................................. 16

Photocells - connection examples ......................................................................................... 16, 17

G Main closing edge (terminals 50/52)............................................................................................ 18

PHC/ISD-function ......................................................................................................................... 18

PHC/ISD-pause time .................................................................................................................... 18

PHC test ....................................................................................................................................... 18

Motor .......................................................................................................................................... 19

max. force..................................................................................................................................... 19

ARS response time ...................................................................................................................... 19

Speed OPEN................................................................................................................................ 19

Speed CLOSE.............................................................................................................................. 19

Soft runtime .................................................................................................................................. 19

Operatinglogic ......................................................................................................................................... 19

Impulse logic................................................................................................................................. 19

Forced closing (only with ST 80VA) .......................................................................................... 19

Lamps/Lights .......................................................................................................................................... 20

Prewarning OPEN (Signal lamp: terminals 10/11)....................................................................... 20

Green phase................................................................................................................................. 20

Clearance time ............................................................................................................................. 20

Trac light gate CLOSED ............................................................................................................ 20

Trac light logic............................................................................................................................ 20

Boom lamp CLOSE (terminals 70 (-) / 71 (+)) ............................................................................. 20

Peripherals .......................................................................................................................................... 21

Signal contacts ........................................................................................................................... 21

Magnetic clamp (terminals 74 (-) / 75 (+)) ................................................................................... 21

Diagnosis .......................................................................................................................................... 22

Status display ............................................................................................................................... 22

Delete positions............................................................................................................................ 22

Factory setting.............................................................................................................................. 22

Software version........................................................................................................................... 22

Serial number ............................................................................................................................... 22

Protocole ...................................................................................................................................... 22

Status Sensor............................................................................................................................... 22

4. Inductionloopdetector(optional) .......................................................................................................... 23

5. ModuleStatusdisplay(optional) ............................................................................................................ 24

6. Inbetriebnahme.................................................................................................................................... 25,26

7. Erroy analysis .......................................................................................................................................... 26

8. Dimensioneddrawing .............................................................................................................................. 27

This manual is the sole property of the TOUSEK Ges.m.b.H. and may not be made available to competitors. All rights reserved. No part of it may be reproduced without our prior

written permission. We will not accept liability for any claims resulting from misprints or errors. This edition of the manual replaces all earlier publications of the same.