Before you begin installing this top please read through the instructions to get a general knowledge of how the soft tops are installed.

Installers Tip: It is recommended to install the top when the fabric has been resting in temperatures above 75° F. Colder

temperatures will shrink the soft components. It is recommended to lay the top components out in the sun or in a warm garage.

Allowing the top components to warm will greatly ease the installation process.

Step One: Remove your Old Top Fabric

1. Allow the vehicle to warm in the sun prior to removal of top. This will ease removal. Put on Safety Glasses.

2. Park the vehicle on a level surface and apply the e-brake. Un-latch the windshield header

3. Unzip and remove the rear window and the two side quarter windows.

4. Next remove the top from each rear corner by pulling down to release the fabric from the corner track retainers.

5. Un-screw the fabric from the rear bow and release the hook and loop flap from the center bow of the jeep.

6. Remove the fabric from the front header by folding the top completely down over the hood of the vehicle. Un-screw all header

screws (19 or 27 screws depending on model year) and two corner screws. SAVE THESE SCREWS! Lift up the metal top plate and

pull out the fabric from the header. See pictures below.

7. for 2010-2012 models you will need to peel back the corner foam and unscrew the cable attachment on both ends of the header

using a T-15 Torx. For 07-09 models, you will need to peel back the foam and remove the two corner screws that hold a plastic

mounting flange located in the same vicinity. See pictures below:

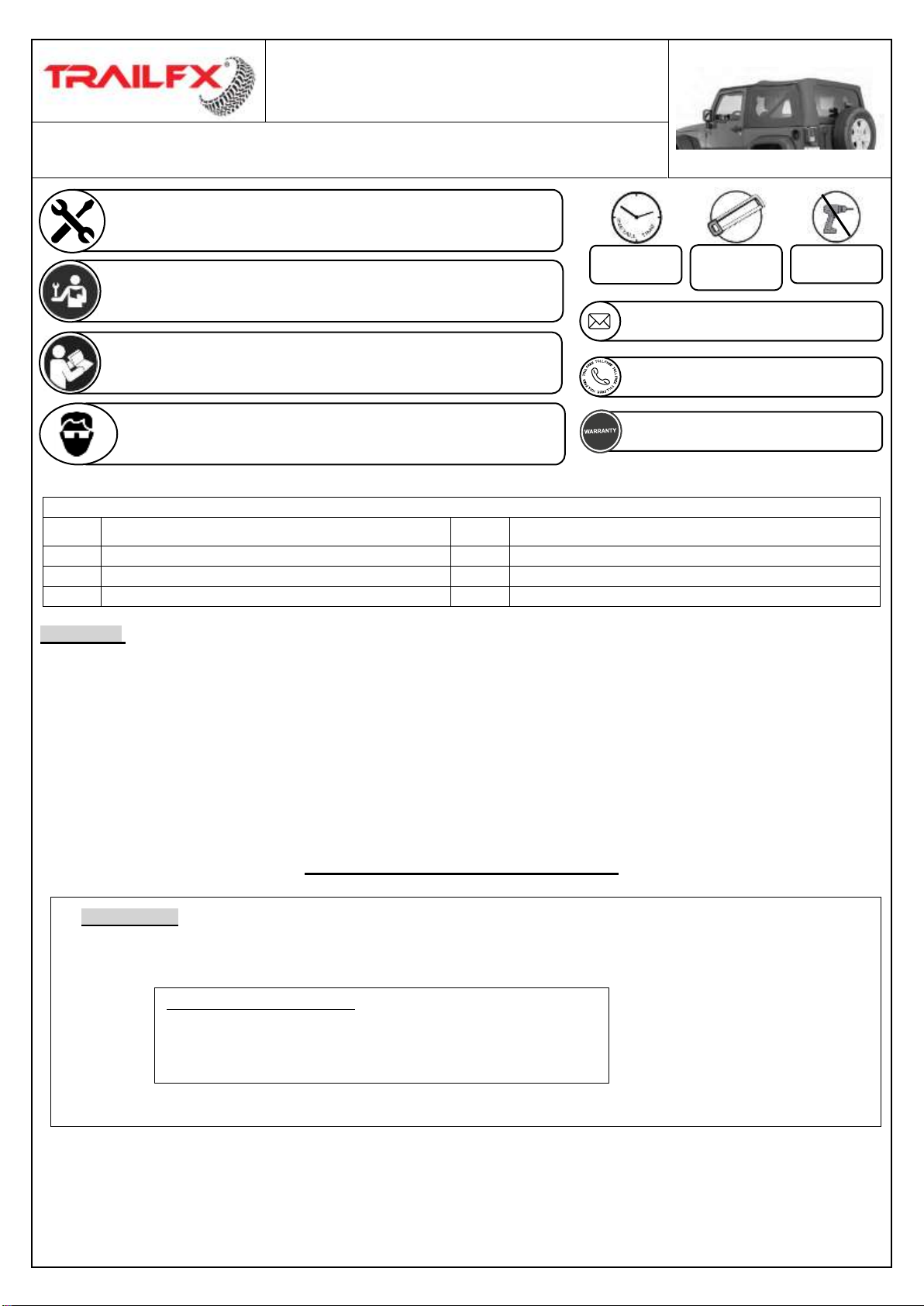

Remove Windows Un-screw fabric from rear bow Remove header screws Remove corner Screws

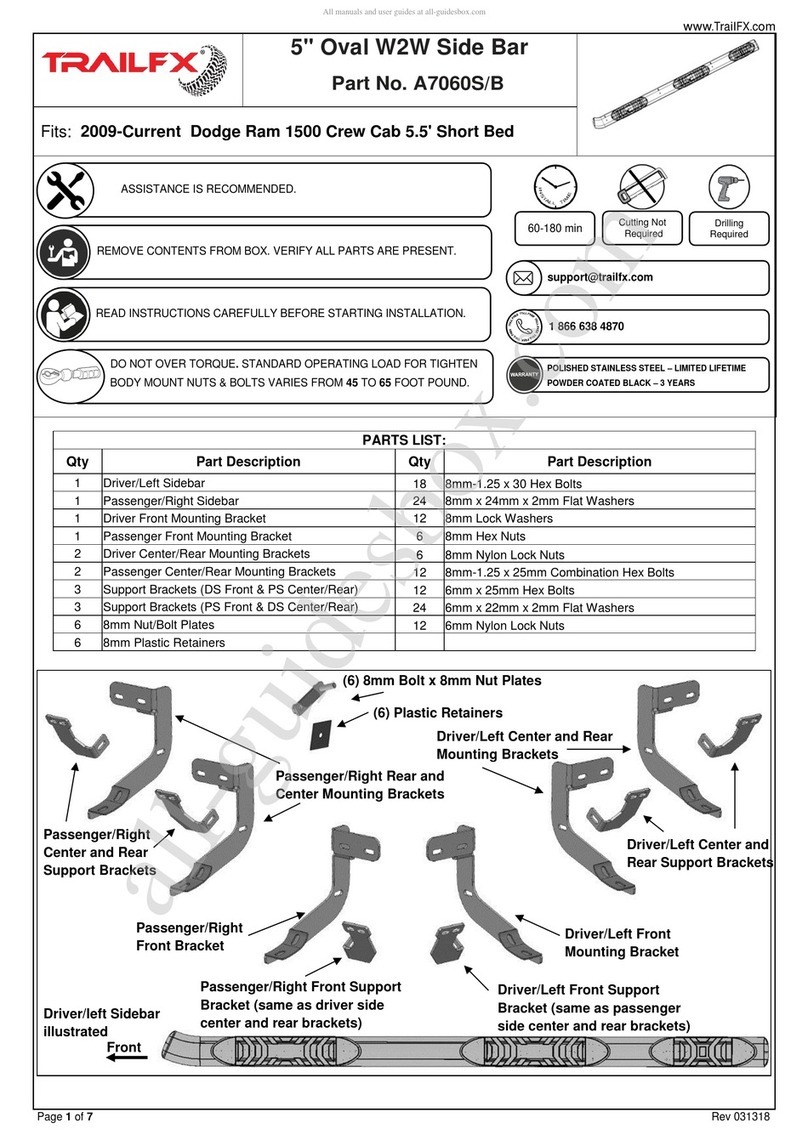

Peel back foam to expose two screws which need to be removed. Save the screws

Leave hardware on the vehicle with your front header resting on the windshield.

Step Two: Install New Fabric to your Soft Top Hardware

Important Installation Note: The following header installation will be easier to accomplish with the help of another person. This step

will most likely be the most difficult step in the install and you should take your time. The easiest way to install this header is standing

on the front seats facing forward. We suggest placing a towel or cover on the seats to protect them from dirt and debris from your

shoes. Once the soft top header fabric is installed in the factory header, the remaining installation should be very straight forward.

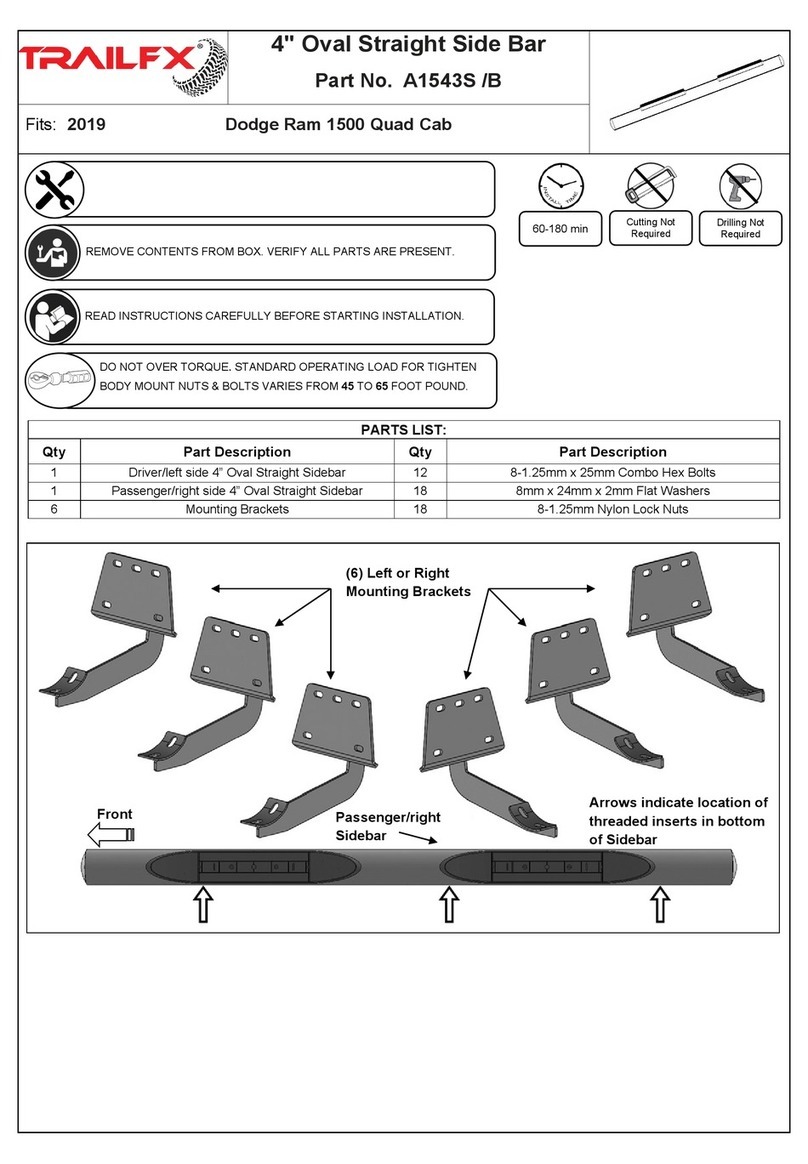

Fig 1 Fig 2

1. Install New Top Fabric to your Windshield Header. With the old top completely removed and the top header plate un-

screwed from the lower header, raise the bow assembly and lock the header to the windshield (See Fig 1). As seen in Fig 2,

drape the soft top fabric backing side up over the hood and the windshield and locate the front extrusion sewn into the front

header of the Top. Locate the masking tape and have it ready for the next step.