3200A SERIES OPERATION MANUAL

TRANSMILLE LTD. Page 5

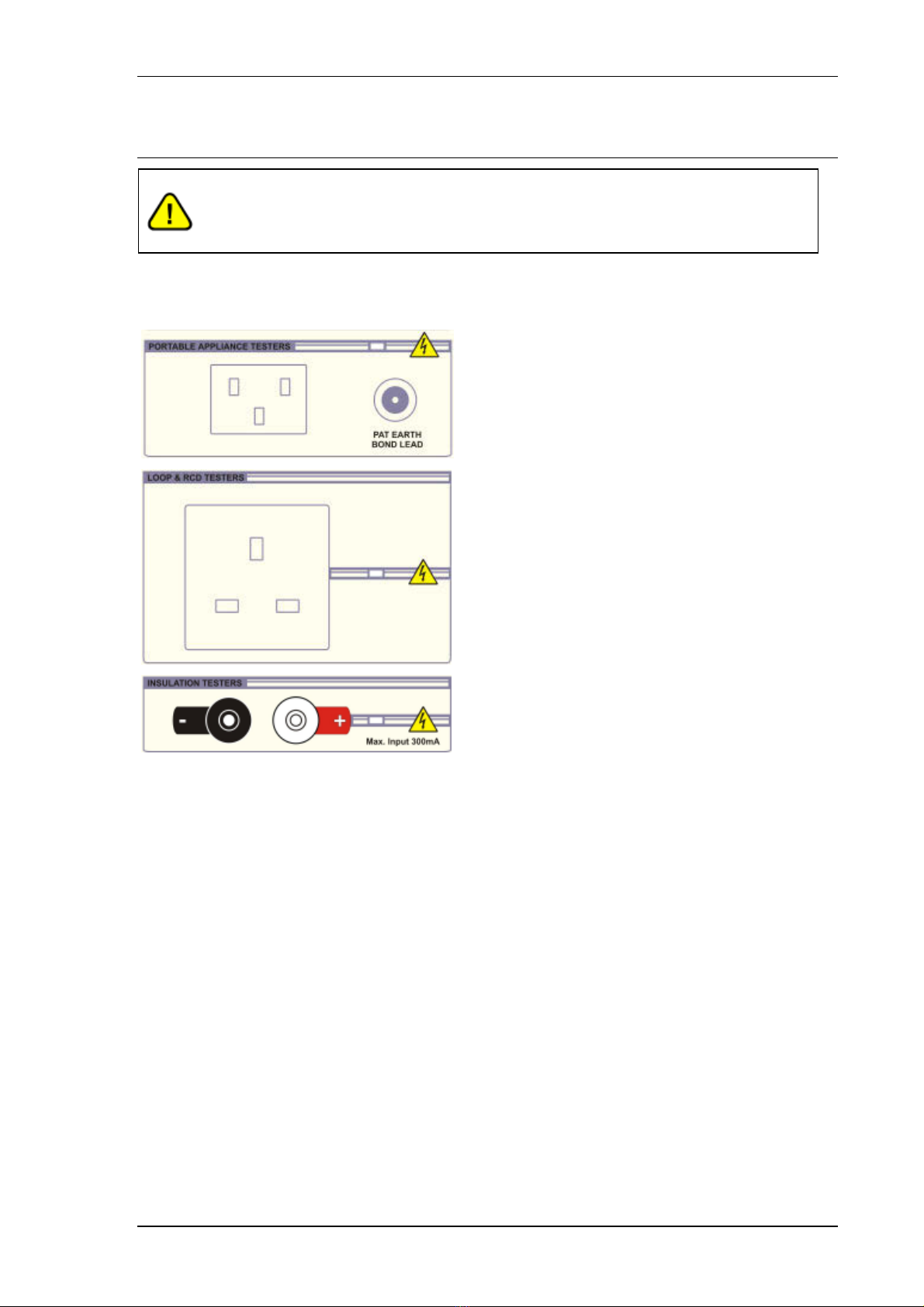

Calibrating Portable Appliance Testers (PATs) ..............................................................36

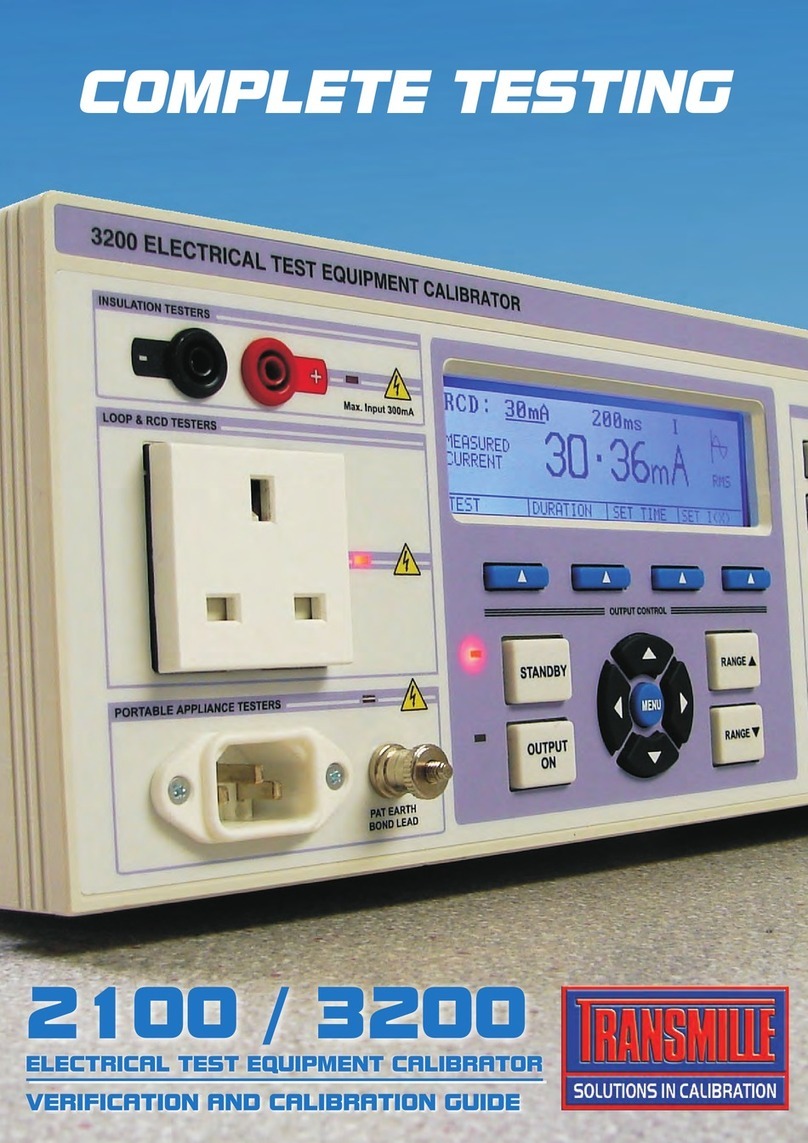

1. PAT: Earth Bond Resistance ..................................................................................36

2. PAT: Earth Bond Current ........................................................................................38

3. PAT: Insulation Testing ...........................................................................................40

4. PAT : Load Testing..................................................................................................41

5. PAT : Flash Testing [OPTION]................................................................................43

6. PAT: Leakage..........................................................................................................45

Introduction to LOOP Testers...........................................................................................46

Calibrating LOOP Testers using the 3200A.....................................................................52

PSCC (Prospective Short Circuit Current) Testing.........................................................55

Introduction to Breakdown / Hipot Testers .....................................................................56

Calibrating BREAKDOWN / HIPOT Testers using the 3200A & 2102 adapter [OPTION] ...........57

Remote Programming ............................................................................................................60

USB Interface......................................................................................................................60

Programming Commands .................................................................................................60

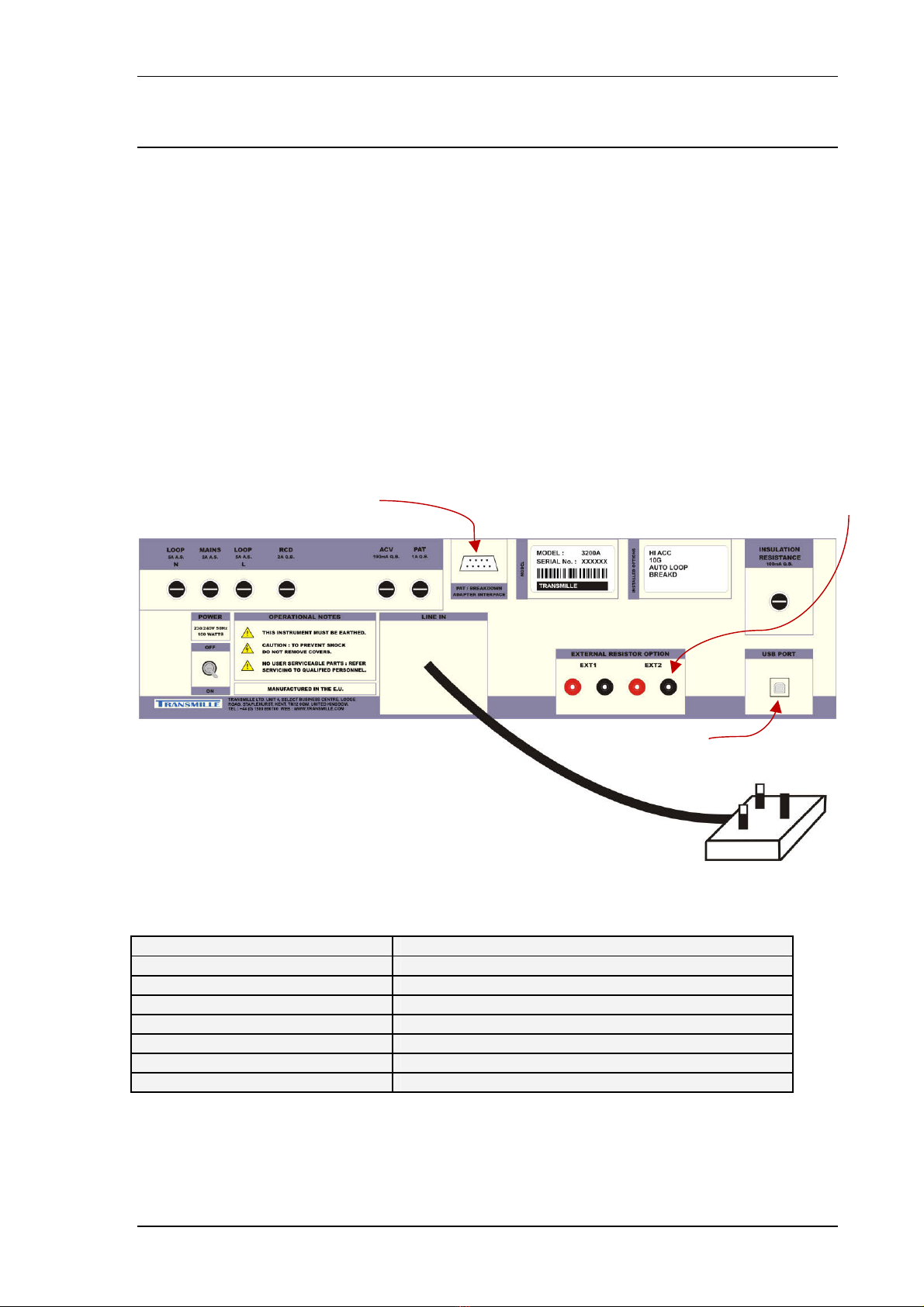

Technical Description ............................................................................................................69

General ................................................................................................................................69

Construction .......................................................................................................................69

Internal Fuses. ....................................................................................................................70

Opening The Case..............................................................................................................70

Access to Internal Fuses...................................................................................................70

PCB Removal (Not required to gain access to internal fuses)......................................71

Processor Board ................................................................................................................71

Calibration and Maintenance.................................................................................................72

General ................................................................................................................................72

Electrical Safety Tests .......................................................................................................72

Cleaning the external case................................................................................................72

Calibration Overview .........................................................................................................72

Guarantee and service ...........................................................................................................74

Appendix A..............................................................................................................................76

Installing the USB Interface Driver (Windows XP)..........................................................76

Installing the USB Interface Driver (Windows Vista / 7)................................................77

Checking the COM Port setting for the USB Interface ..................................................78