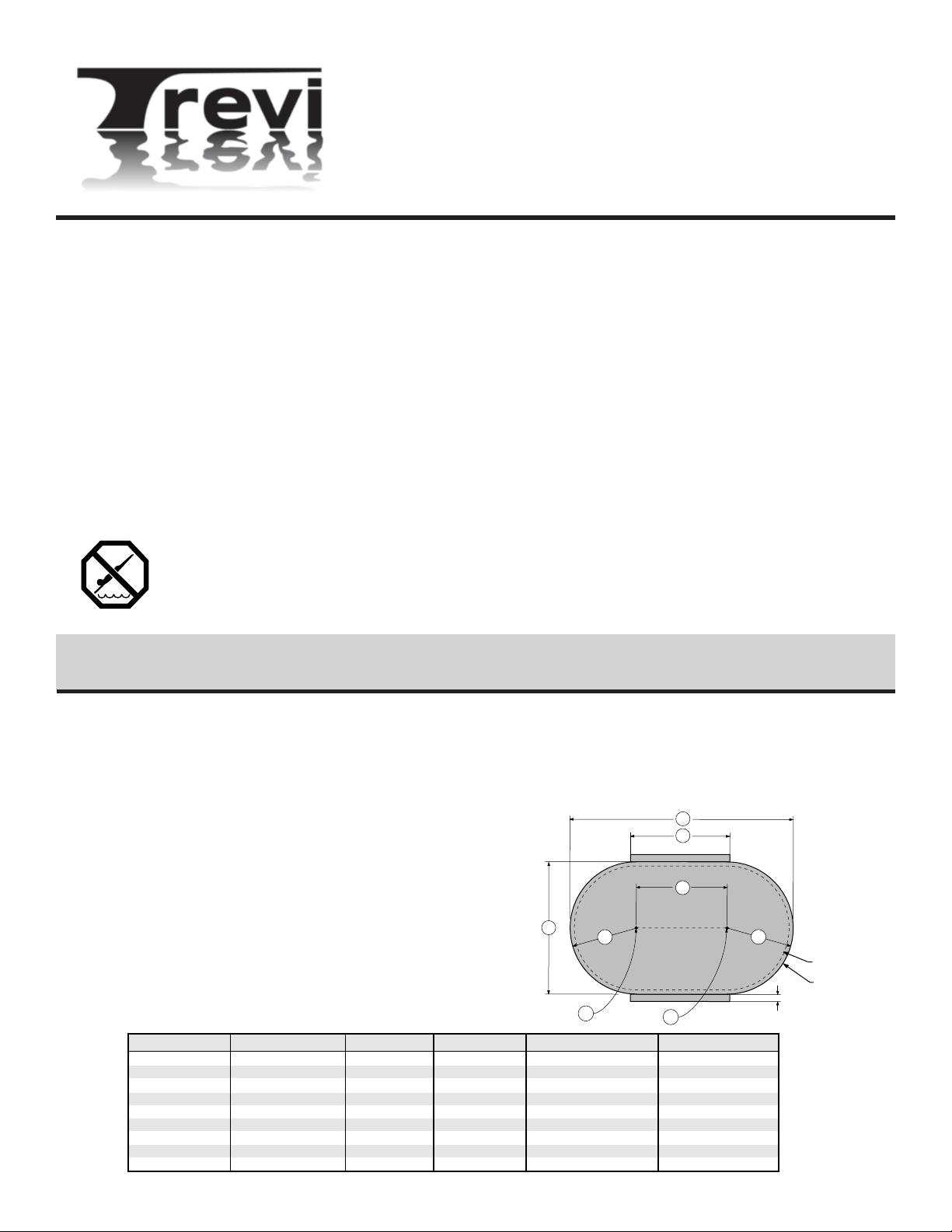

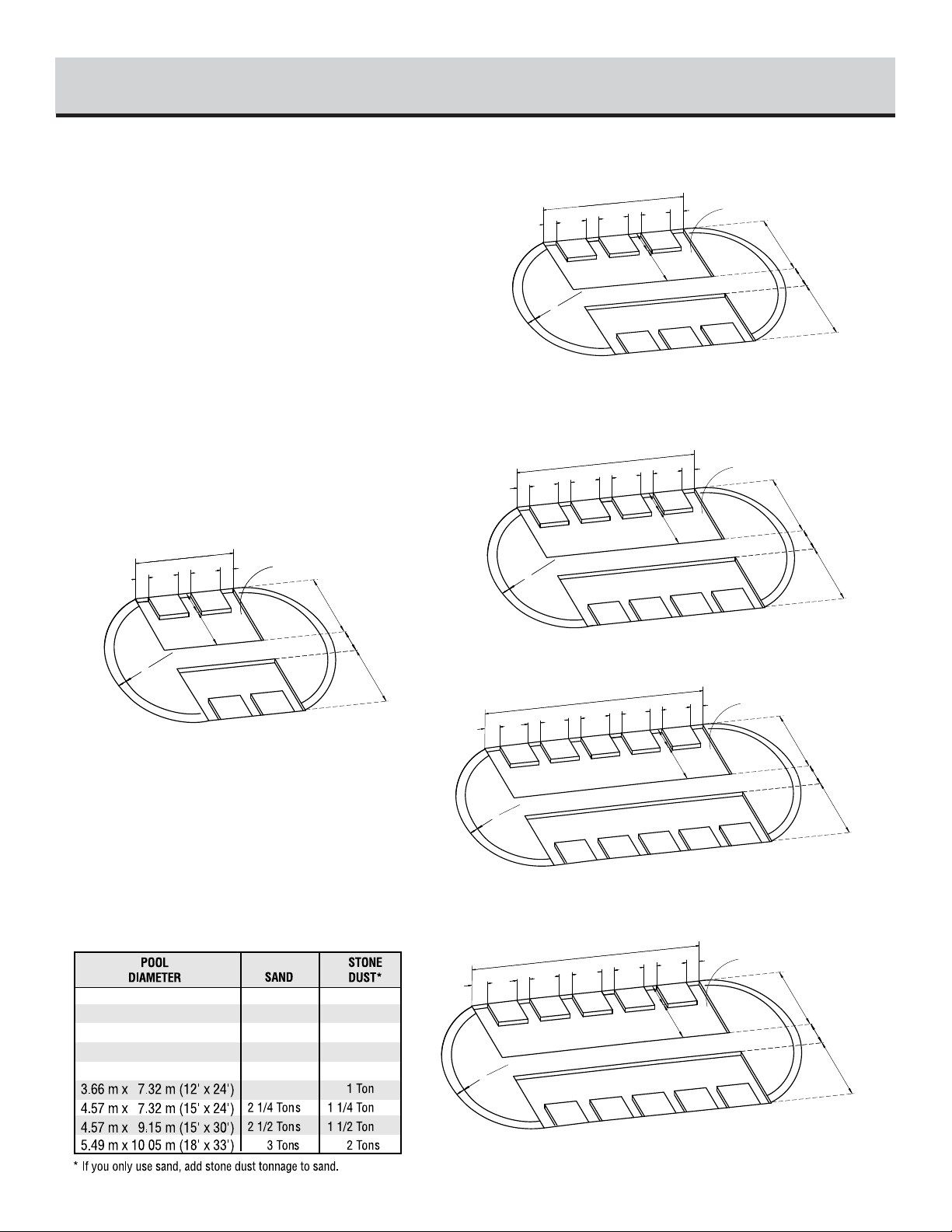

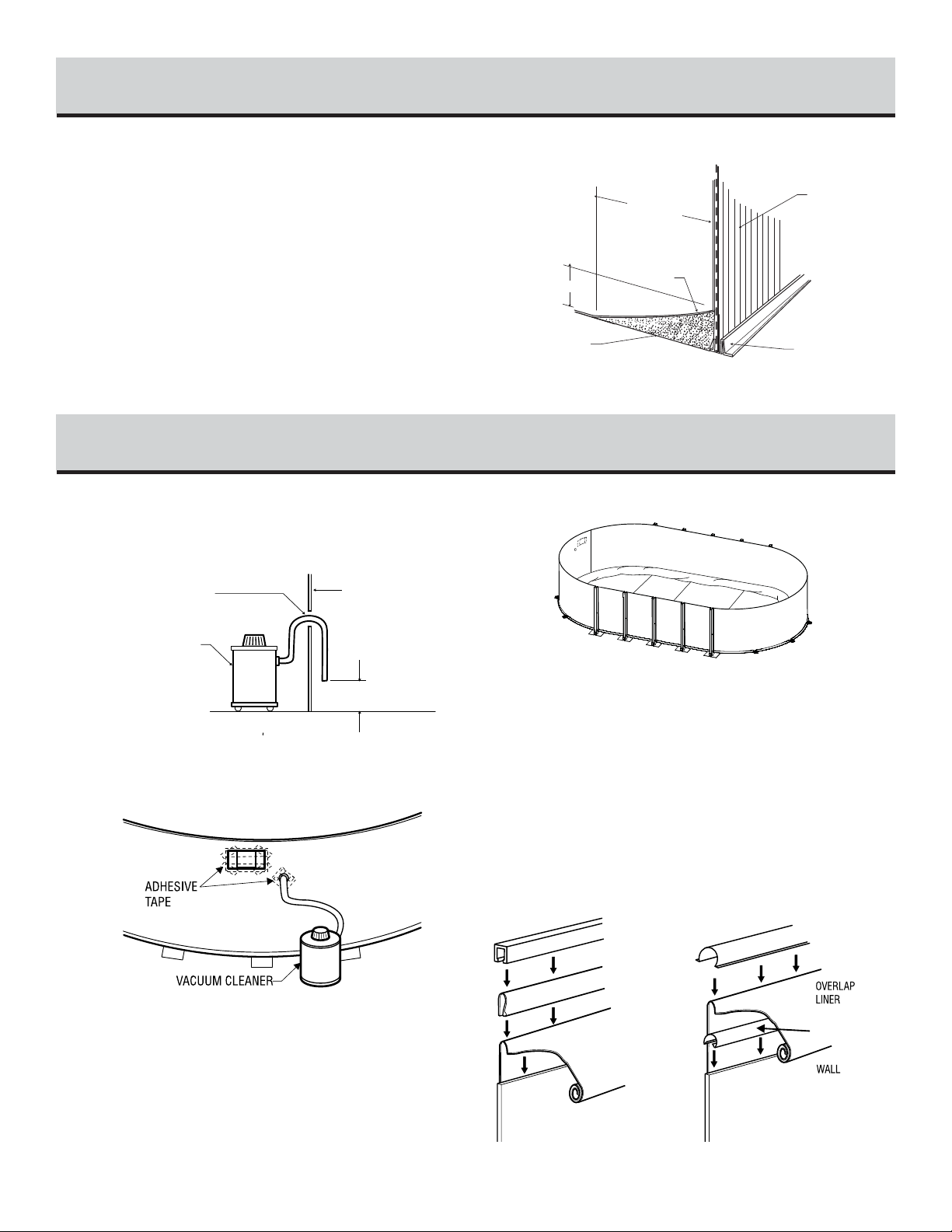

Dig a hole 30 cm (12") wide by approximately 25 cm (10") deep in

the center of the circumference.

From the center hole to the projected location of the pool motor, dig

a 15 cm (6") wide trench. Place the removed soil aside to be used

later to cover the hose.

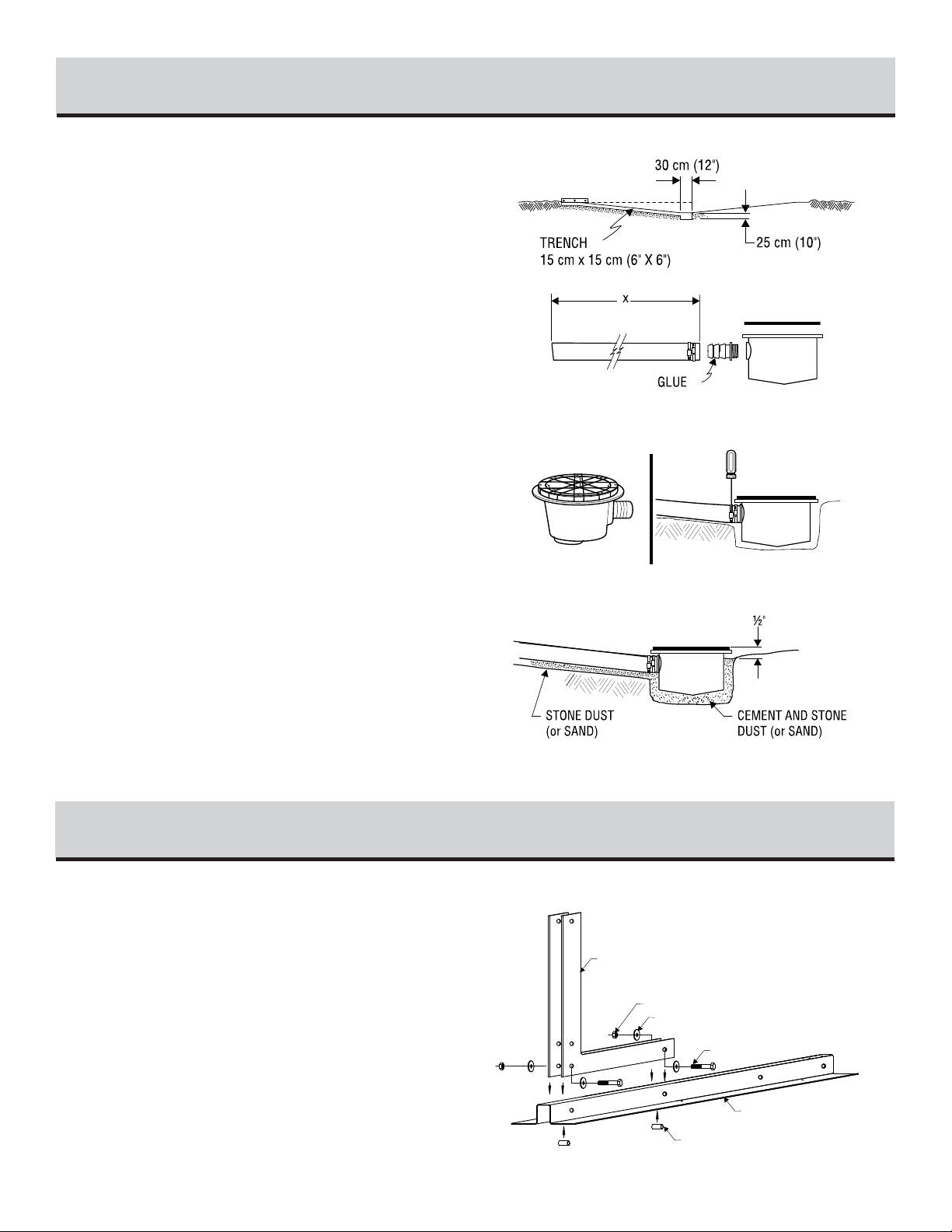

Bottom Drain Assembly

Place teflon tape around the threaded plug. Screw in drain holes

using large pliers. Glue the connector in the appropriate opening.

Take one of the two rubber rings and adjust it to the top of the drain,

aligning the holes carefully. Secure with strips of adhesive tape to

prevent sand from penetrating inside the holes once the drain has

been installed.

Secure one end of the long black or white hose inside the drain

spout. First apply glue on the drain spout and inside the drain end,

then secure with one or two collars.

Cut the hose so that it ends with the stone dust (or sand). Measure

the pool radius from the center of the drain, then add 15 cm (6").

Place the assembled bottom drain in the hole so that it is approxi-

mately 1.3cm (1/2") higher than the surface soil. Bury the hose,

levelling the drain as much as possible. Compact the soil, using

your feet and a tampering tool as well.

Mix three (3) shovels of stone or sand dust with one half shovel of

pure cement, adding a small quantity of water, then pour the cement

around the drain until it reaches 1.3 cm (1/2") from the top.

BOTTOM DRAIN ASSEMBLY (if applicable)

3

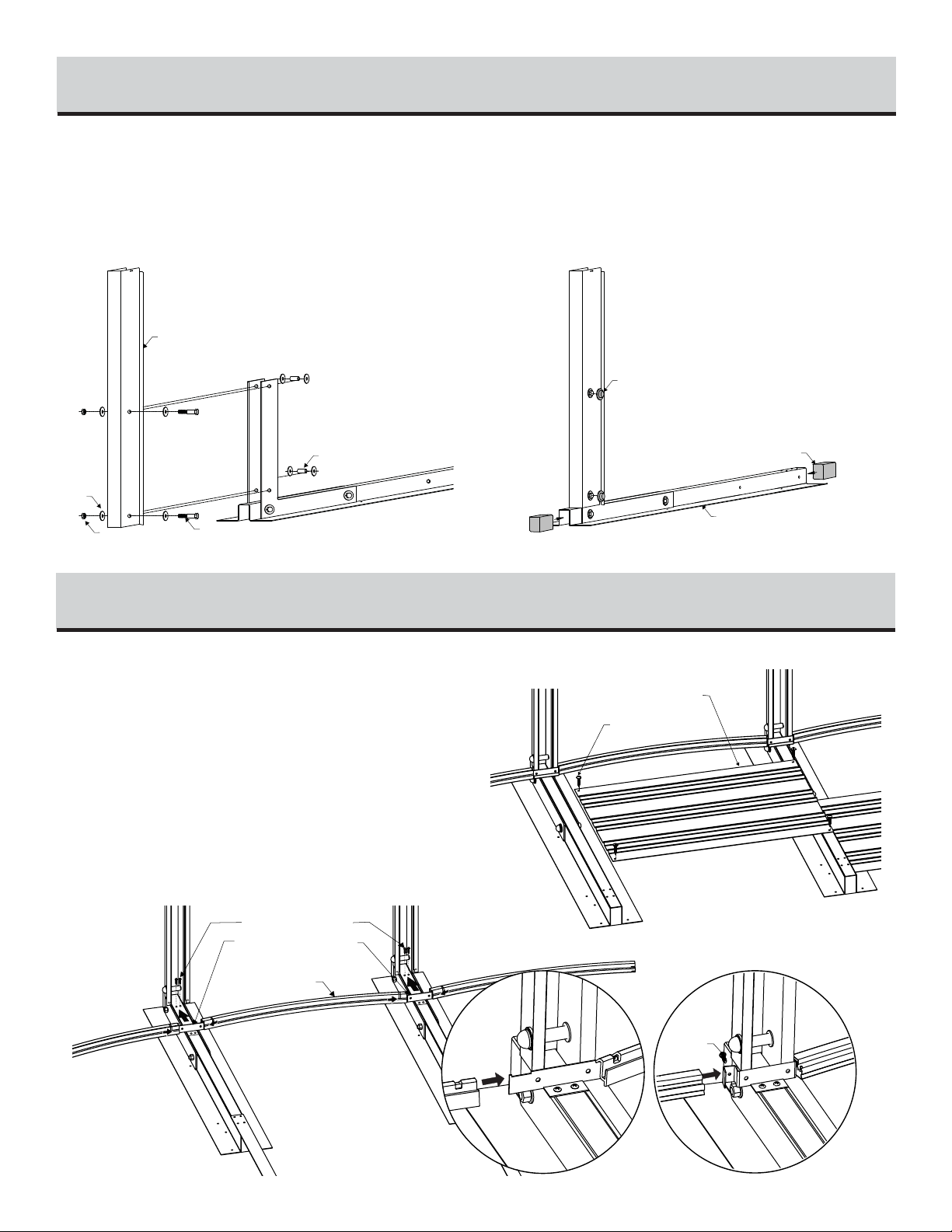

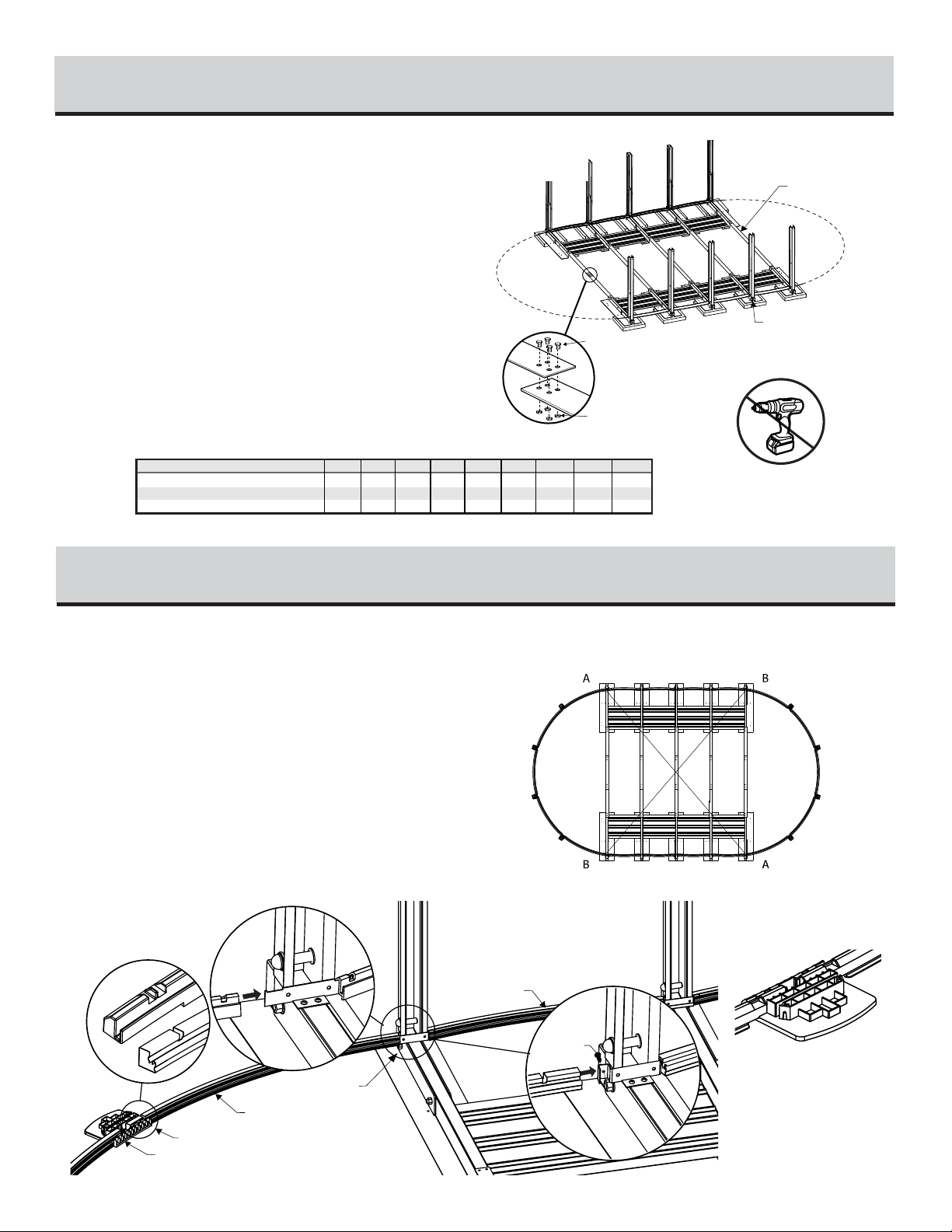

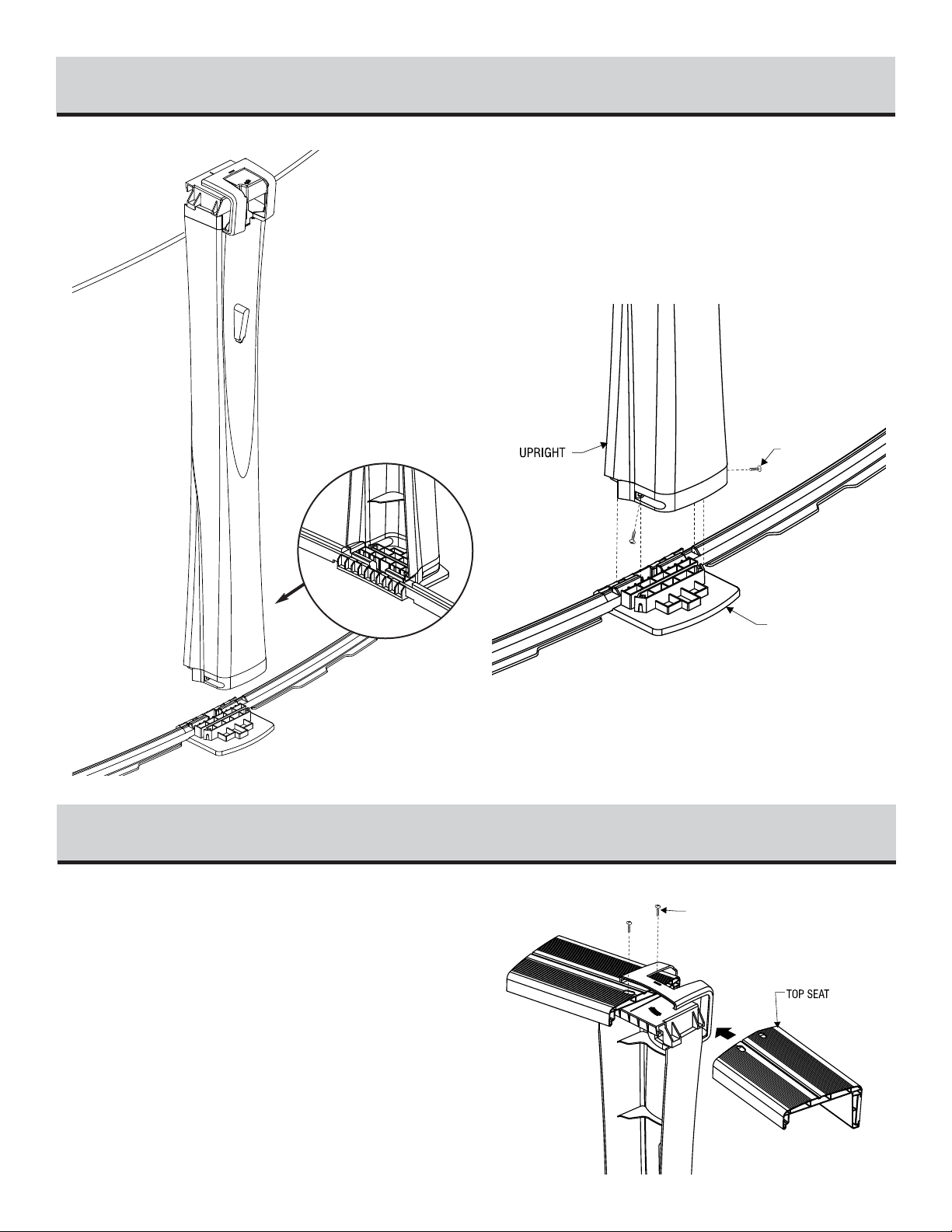

1) Refer to Illustration 4.1. To assemble, join splice brackets (R)

to the foot beam (Q) using the bolt 1/2 "X 3" X #13 (12.7 mm x

76.2 mm) (U), nuts (UU ) and washers (V). Remember to insert a

spacer (T) inside the foot beams aligned to each bolt.

STRAIGHT SECTION BUTTRESS ASSEMBLY

4