Tridonic SLE G6 Quick start guide

Ø13,5*

□18,8

Ø13,5*

□18,8

Ø3,3 (2x)

Ø50

Ø19 Ø17,5*

35

Ø3,3 (2x)

Ø50

Ø23 Ø21,5*

35

Ø3,3 (2x)

Ø50

Ø19 Ø17,5*

35

Ø3,3 (2x)

Ø50

Ø23 Ø21,5*

35

Ø3,3 (2x)

Ø50

Ø19 Ø17,5*

35

Ø3,3 (2x)

Ø50

Ø23 Ø21,5*

35

Ø3,3 (2x)

Ø50

Ø19 Ø17,5*

35

Ø3,3 (2x)

Ø50

Ø23 Ø21,5*

35

Ø3,3 (2x)

Ø50

Ø19 Ø17,5*

35

Ø3,3 (2x)

Ø50

Ø23 Ø21,5*

35

Ø8,5*

□13,4

Ø8,5*

□13,4

Ø8,5*

□13,4

LED Module

Module SLE G6

Technical Design-In Guide

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Table of Contents

c2 / 59

...

1. Introduction 3

2. System overview 5

2.1. Complete system solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2. Zhaga . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3. Module variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5. Compatibility between LED module and LED Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6. Standards and directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Mechanical aspects 16

3.1. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Electrical safety 25

4.1. Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

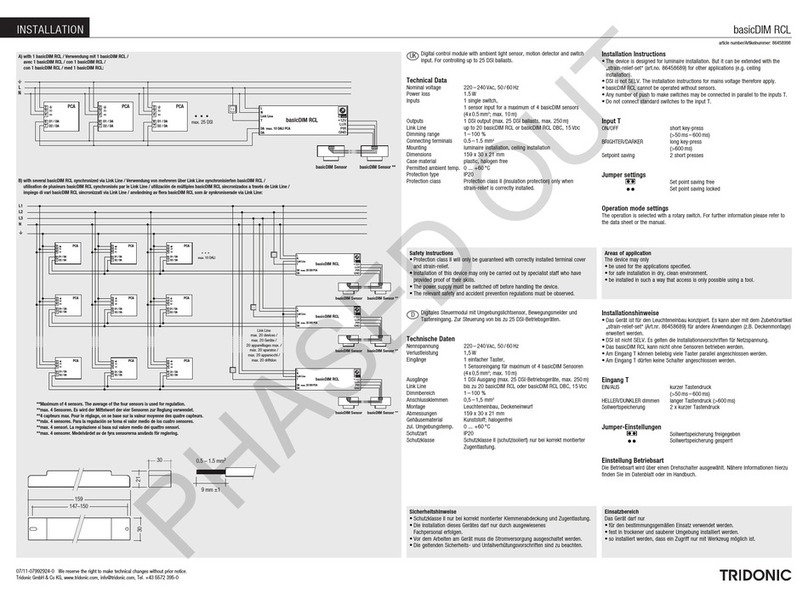

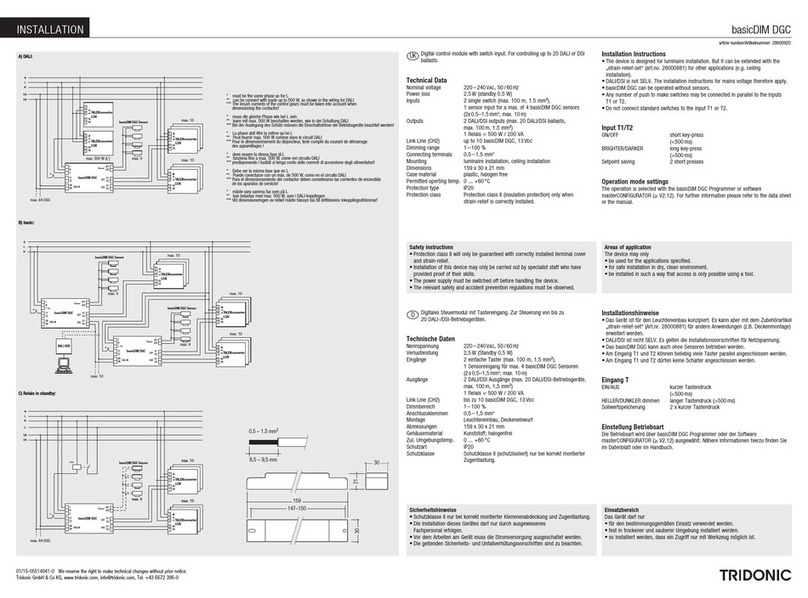

4.2. Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5. Optical aspects 31

5.1. Colour spectrum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2. CRI, Ra and Ri - different colour rendering values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3. SDCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4. Binning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.5. Secondary Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.6. Coordinates and tolerances (to CIE 1931) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.7. Eye safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.8. Reflector design and beam characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6. Thermal aspects 39

6.1. Decrease of luminous flux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2. Passive and active cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3. Fan connection and temperature measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7. Ordering information and sources 48

7.1. Article numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2. Product application matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.3. Partners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Introduction

c3 / 59

This Design-in Guide covers the SLE G6 Spotlight system from Tridonic.

The SLE G6 provides energy efficient lighting solutions with high quality light for retail, catering and other spotlight and downlight

applications.

The system consists of chip-on-board module and mount, chip-on-board module with pre-tinned wires or chip-on-board module

without cable in four versions:

The Design-in guide provides all the information needed to build a luminaire with the SLE G6 Spotlight system and adapt it to the

desired needs.

This includes:

Standard version with different lumen packages and different light colours (2,700 K, 3,000 K, 3,500 K, 4,000 K)_

Three special versions that are optimised for specific applications:_

SLE FOOD:

LED modules specifically for FOOD applications display foods in the very best light – white elements remain white,

colours are more true-to-life and are perceived more intensively. Stronger brown tones for example make baked goods

appear more crispy, and the red of meats is emphasised to greater effect.

_

SLE ART:

This new LED module offers the high quality of light that is needed for displaying high value exhibits. Unique Tridonic

full spectrum technology provides excellent colour rendering. The average value for all the products in the SLE ART

series is CRI 98, a truly impressive figure. And you can also rely on outstanding colour consistency (MacAdam 2) for

your applications.

_

SLE FASHION:

The modern FASHION LED light is ideal for the sparkling display of fashion. The technology conceals several years of

intensive research targeted specifically for lighting in the retail sector. SLE FASHION generates brilliant colours with

pleasant warm tones and high saturation, and completely without UV light, as well as intensive and friendly white

tones thanks to the specific blue light component, for the display of goods in perfect, colour-true light.

_

Dimensioning of the heat sink and reflector_

Selection of compatible LED Drivers_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Introduction

c4 / 59

...

Designing the luminaire with respect to thermal and mechanical needs_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c5 / 59

2.1. Complete system solution

The use of LEDs in general lighting has many advantages: LEDs are versatile in their application, highly energy efficient and virtually

maintenance-free. With the Engine SLE G6 you get a complete system solution for spot and downlights, consisting of perfectly

matched components: LED module and LED Driver.

2.2. Zhaga

Zhaga is a consortium, initiated in 2010, which takes care of the needs of LED lighting and its standardisation. It is active worldwide

and has more than 200 member companies (as of 2012).

The aim of the Zhaga consortium is to ensure interchangeability and compatibility of LED luminaires between different manufacturers.

To this end, Zhaga defines standards for the interfaces of the various lighting fixtures and holders. This includes the physical

dimensions of the lamp base, as well as the photometric, electrical and thermal behaviour of LED luminaires. These standardizing

measures help to make products comparable, a step that both the manufacturing industry and the consumers benefit from.

The Zhaga logo verifies compatibility with Zhaga standards. Only certified devices are allowed to bear this logo.

The SLE G6 modules meet the mechanical requirements of the Zhaga guidelines from book number 3. Products that meet the Zhaga

standards in physical, electrical and thermal points are listed on the website of Zhaga: www.zhagastandard.org

INOTICE

All information in this guide has been created with great care. Errors, additions and omissions excepted. For any resulting damage

Tridonic accepts no liability. The latest version of this guide can be found at or at your sales partner.led.tridonic.com

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c6 / 59

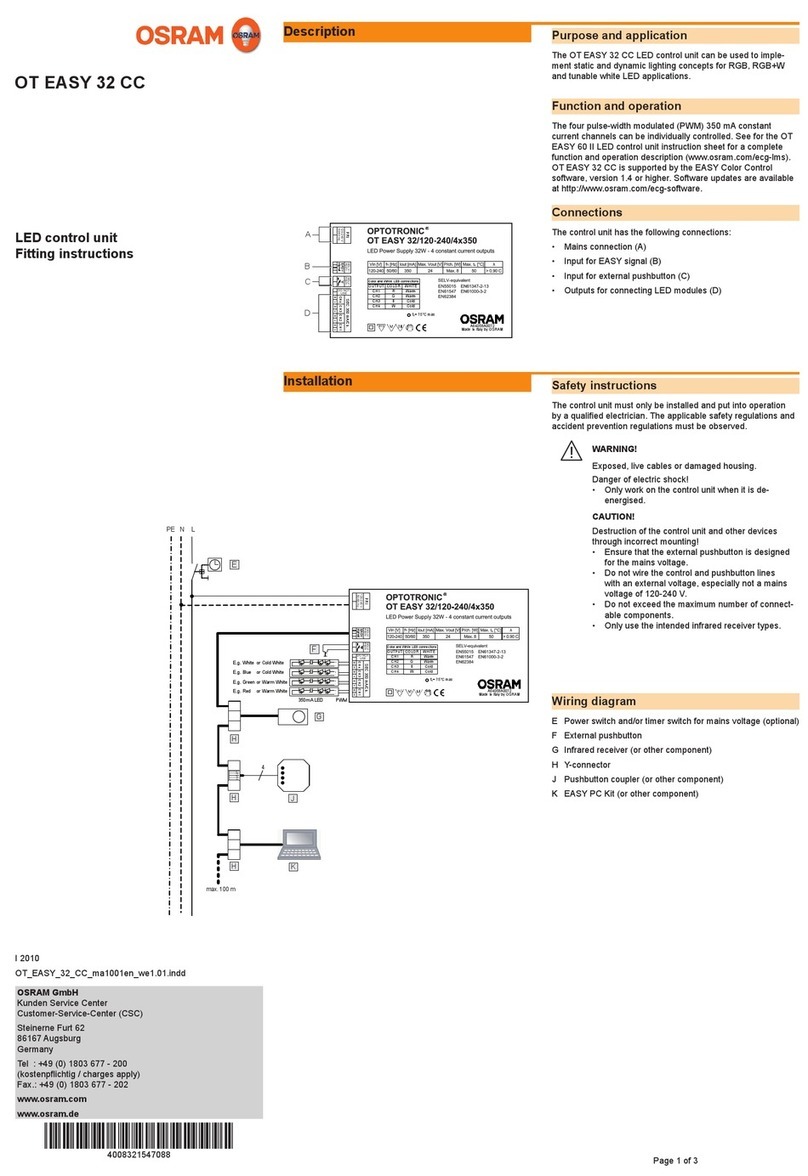

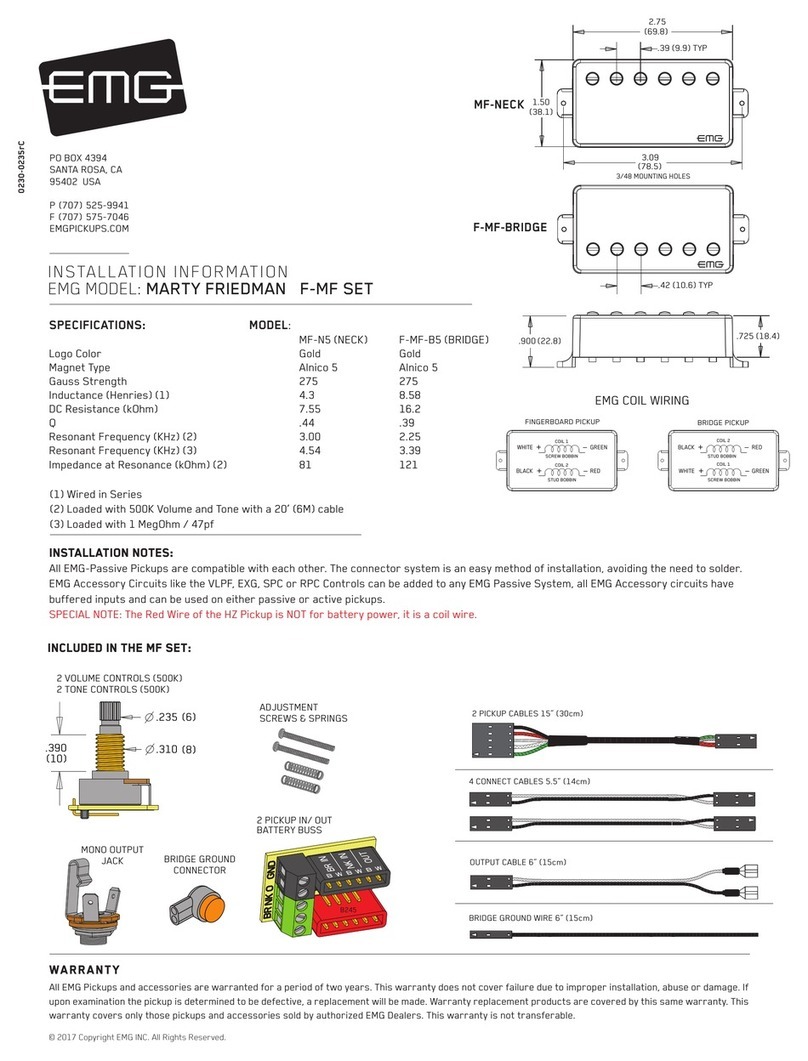

2.3. Module variants

Module name Housing Thermal interface material Connection cable

with affix "H",

e.g. SLE G6 19mm 5000lm 830 H ADV

with affix "H" and "T",

e.g. SLE G6 19mm 5000lm 830 H ADV T

with affix "C",

e.g. SLE G6 19mm 5000lm 830 C ADV

with affix "R",

e.g. SLE G6 19mm 5000lm 830 R ADV

...

INOTICE

The SLE G6 series comprises different variants of modules:

with housing_

with housing and thermal interface material_

without housing, with or without connection cable_

Modules without housing or connection cable have a certain affix in their name:

Modules without housing have the affix "H" in their name_

Modules with housing and have the affix "H" and "T" in their namethermal interface material_

Modules with have the affix "C" in their nameconnection cable_

Modules without connection cable have the affix "R" in their name_

Modules without housing or connection cable have a certain affix in their name:

Modules without housing have the affix "PURE" in their name_

Modules without connection cable have the affix "W/O-C" in their name_

Abbreviations:

H ... housing; T ... thermal interface material; C ... cable; R ... raw_

The following variants are available:

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c7 / 59

The system Engine STARK SLE GEN4 is available in different variants:

SLE G6 ADV

Main qualities Simplicity itself:

Available variants Available in 4 variants:

Light Emitting Surface ( LES) 10 mm, 15 mm, 17 mm, 19 mm, 23 mm

Colour temperature 2,700 K, 3,000 K, 3,500 K, 4,000 K

Luminous flux (1) up to 9,960 lm

Colour rendering / colour tolerance CRI 80, CRI 90

MacAdam 3 SDCM

System efficiency (1) up to 154 lm/W

Module efficiency up to 180 lm/W

Energy efficiency class up to A++

Life time (2) > 60,000 h

Warranty 5 years

(1) Values at t =65°C, all values apply to tp rated

p

relating to L70/B50

(2)

2.3.1. Type code for modules

The following type code is used to identify the modules:

Static White with CRI > 80 and CRI > 90_

long life-time_

high lm/W output_

with housing, without thermal interface material_

with housing, with thermal interface material_

without housing, without thermal interface material_

without housing, with thermal interface material_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c8 / 59

Type code for modules for SLE G6 19mm 5000lm 830 H ADV T for example

Reference SLE G6 19mm 5000lm 830 H ADV T

Meaning Form: Spotlight

Engine

Size Type: Luminous flux at nominal

current

CRI 80

3000K

with

housing

ADV with thermal interface

material (TIM)

2.4. Accessories

2.4.1. LED Drivers

LED Drivers are available in different variants:

PRE EXC

Dimming Amplitude

Dimming range 100 to 1 % 100 to >= 15 %

DALI V2-DT6

DSI

switchDIM

corridorFUNCTION V2

ready2mains

DC operation supporting EN 50172

DC level fixed

DC level adjustable

Current adjustment Adjustable

Via resistor or plug

INOTICE

The exact minimum value depends on the used device and the

load.

For certain devices, the minimum value may be higher_

When operating with lower load, the minimum value is

generally higher

_

More information can be found in the data sheet of the device.

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c9 / 59

Via DALI V2-DT6

ready2mains

current resolution 1 mA 1 mA

current tolerances ± 3-10 % see data sheet

Functions &

Performances

CLO function

Intelligent temperature

guard

Standby losses <0.2 W

Rated supply voltage 220-240 V 220-240 V

2.4.2. Possible combinations

Possible combinations of LED Drivers and LED modules can be found in the LED system matrix:

www.tridonic.com/com/en/lamp-matrix.asp

Some typical combinations are listed here:

SLE G6 10mm: Operating current: 350mA

SLE G6 15mm: Operating current: 500mA

SLE G6 17mm: Operating current: 900mA

SLE G6 19mm: Operating current: 1050mA

Dimmable: LCA 25W 350-1050mA one4all C PRE (28000665)_

Dimmable/Fixed Output: LC 17W 250-700mA flexC SC EXC (28000705)_

Fixed Output: LC 15W 350mA fixC SC ADV (87500448)_

Fixed Output: LC 15W 350mA fixC C SNC (87500565)_

Dimmable: LCA 25W 350-1050mA one4all C PRE (28000665)_

Dimmable/Fixed Output: LC 25W 350-1050mA flexC SC EXC (28000706)_

Fixed Output: LC 20W 500mA fixC SC ADV (87500449)_

Fixed Output: LC 20W 500mA fixC C SNC (87500566)_

Dimmable: LCA 45W 500-1400mA one4all SC PRE (28000676)_

Fixed Output: LC 40W 900mA fixC SC ADV (87500344)_

Fixed Output: LC 40W 900mA fixC C SNC (87500560)_

Dimmable: LCAI 55W 900-1750mA ECO C (28000128)_

Fixed Output: LC 47W 1050mA fixC SC ADV (87500451)_

Fixed Output: LC 45W 1050mA fixC C SNC (87500564)_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c10 / 59

SLE G6 23mm: Operating current: 1400mA

Type codes for LED Drivers

The following type code is used to identify LED Drivers:

Type code for LED Drivers LCA 45W 500-1400mA one4all SR PRE

Reference LCAI 45W 500-1400mA one4all SR / C / SC PRE

Meaning Dimmable LED

Driver

Power Output current

range

Interface Housing form:

SR: Strain Relief, C: Compact, SC: Stretch

Compact

Type

The exact type designation of the LED Driver can be found on the label of the LED Driver.

...

Dimmable: LCAI 55W 900-1750mA ECO C (28000128)_

Fixed Output: LC 60W 1400mA fixC C SNC (87500570)_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c11 / 59

2.5. Compatibility between LED module and LED Driver

There are two stages involved in the check for compatibility between the LED module and the LED Driver.

2.5.1. Comparison of data sheet values with a 5-point guideline

Different values for the two devices need to be considered when comparing the data sheets. The following table shows which values

are involved and which requirements they must meet.

Comparison

of…

Value in

LED module

Value in LED

Driver Detailed procedure

(1) Current Imax = Output

current

continue...

Max. DC

forward

current

>= Output

current +

tolerances

...

½CAUTION!

LED modules SLE G6 are basic isolated against ground up to 75 V (for LES10, LES15 and LES17: 50 V) and can be mounted directly

on earthed metal parts of the luminaire.

If the max. output voltage of the LED Driver (also against earth) is above 75 V (for LES10, LES15 and LES17: 50 V), an additional

isolation between LED module and heat sink is required (for example by isolated thermal pads) or by a suitable luminaire

construction.

At voltages > 60 V an additional protection against direct touch (test finger) to the light emitting side of the module has to be

guaranteed. This is typically achieved by means of a non removable light distributor over the module.

The requirements for operating together can be checked by comparing the data sheets_

Subsequent practical tests can ensure that there are no unexpected problems during actual operation_

Determine forward current of LED module_

Check whether LED Driver can be operated with the same output

current

_

Check whether max. DC forward current of LED module is greater than

or equal to output current of LED Driver (including tolerances)

_

½CAUTION!

The max. DC forward current can be temperature dependent!

Refer to the derating curve of the LED module data sheet.

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c12 / 59

Comparison

of…

Value in LED

module

Value in LED

Driver Detailed procedure

(2) Voltage Min. forward

voltage

> Min. output

voltage

Max. forward

voltage

< Max. output

voltage

Min. forward

voltage

@ min. dim

level

> Min. output

voltage

(3) LF current

ripple

Max.

permissible

LF current

ripple

>= Output LF

current ripple

(<120 Hz)

(4) Max. peak

current

Max.

permissible

peak current

> Max. output

current peak

(5) Power

(pertinent for

multi channel

LED Driver)

Min. power

consumption

> Min. output

power

Max. power

consumption

< Max. output

power

Check whether voltage range of LED module is completely within

the voltage range of LED Driver

_

½CAUTION!

!The forward voltage is temperature dependent

Refer to the Vf/t diagram in the data sheet.

p

INOTICE

To ensure full dimming performance the forward voltage of the LED

module at min. dim level must be greater than or equal to the min.

output voltage of the driver.

Determine the forward voltage of the LED module at lowest dim

level

_

In case there is no data available for the LED module at lowest dim

level: take the min. forward voltage minus 20 % as an

approximation

_

Check whether the forward voltage of the LED module is greater

than or equal to the min. output voltage of the driver

_

Check whether max. permissible LF current ripple of LED module is

greater than or equal to output LF current ripple of LED Driver

_

Check whether max. permissible peak current of LED module is

greater than max. output current peak of LED Driver

_

Check whether power range of LED module is completely within

output power range of LED Driver

_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c13 / 59

2.5.2. Practical tests

The following aspects must be checked:

Technical aspects

Visual aspects

When conducting the tests the following conditions must be considered:

Conditions

½CAUTION!

Following the comparison of the data sheet values a practical test is required. Only a practical test can ensure that the system

LED Drivercomponents (luminaire, , LED module, wiring) are coordinated and working properly.

Transient behaviour_

Colour shift_

Connection during operation_

Parasitic capacitance_

Flickering_

Stroboscopic effect (video applications)_

Dimming behaviour_

Colour change/stability_

Luminous flux_

All tolerances_

Entire temperature range_

Different output voltage ranges (incl. no load)_

Entire dimming range_

Short circuit_

IHINWEIS

If the values are slightly over or under the specified threshold values or if there are any other concerns or questions please contact

Technical Support:

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c14 / 59

2.6. Standards and directives

2.6.1. Standards and directives for modules

The following standards and directives were taken into consideration in designing and manufacturing the modules:

CE

Name Description

2006/95/EG Low-voltage directive: Directive relating to electrical equipment for use within certain voltage limits

2004/108/EG EMC directive: Directive relating to electromagnetic compatibility

RoHS

Name Description

2002/95/EC RoHS directive: Directive on the restriction of the use of certain hazardous substances in electrical and electronic

(1)

equipment

(1) RoHS: Restriction of (the use of certain) hazardous substances

Safety

Name Description

DIN IEC 62031:2008 Safety requirements for LED modules

EN 60598-1:2008 und A11:2009 General requirements and tests for luminaires

EN 60598-2-2:1996 und A1:1997 Luminaires - Part 2. Special requirements;

Main section 2: Recessed luminaires

EN 62471:2008 Photo-biological safety of lamps and lamp systems

Safety and performance

Name Description

EN 61347-1:2009 General and safety requirements

EN 61347-2-13:2007 Special requirements for dc and ac powered electronic operating equipment for LED modules

EN 62384:2007 IEC 62384 A1:2009 Operational requirements

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

System Overview

c15 / 59

Energy labelling

Name Description

EU Regulation No: 874/2012 "Energy labelling of electrical lamps and luminaires"

2.6.2. Standards and directives for LED Drivers

The following standards and directives were taken into consideration in designing and manufacturing the LED Drivers:

EMI

Name Description

EN 55015 2008 Limit values measurement methods for radio interference properties of electrical lighting equipment

and similar electrical devices

EN 61000-3-2:2005 A1: 2008

und A2:2009

Limit values for harmonic currents (equipment input current < 16 A per conductor)

EN 61000-3-3:2005 Limit values for voltage fluctuations and flicker in low-voltage systems for equipment with an input

current < 16 A per conductor that are not

subject to any special connection conditions

EN 61547:2001 EMC requirements

(1)

(1) EMC: Electromagnetic compatibility

Safety

Name Description

EN 50172 2005 Safety lighting systems

DALI

Name Description

IEC 62386-101:2009 General requirements, system

IEC 62386-102:2009 General requirements, controller

IEC 62386-207:2009 Special requirements, controller; LED modules

...

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Mechanical Aspects

c16 / 59

3.1. Installation

The guideline for installation can be taken from the ESD documentThe SLE G6 modules were tested with severity level 4. .

Image Description

Integrated terminal for a time-saving assembly

Back of the module for thermal connection to the heat sink

INOTICE

EOS/ESD safety guidelines

The device/module contains components that are sensitive to electrostatic discharge and may only be installed in the factory and

on site if appropriate EOS/ESD protection measures have been taken. No special measures need be taken for devices/modules with

enclosed casings (contact with the pc board not possible), just normal installation practice.

Please note the requirements set out in the document EOS/ESD guidelines (Guideline_EOS_ESD.pdf) at:

http://www.tridonic.com/com/de/download/technical/Richtlinie_EOS_ESD_de.pdf_

http://www.tridonic.com/com/en/technical-docs.asp_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Mechanical Aspects

c17 / 59

Version without housing for individual integration in the light

3.1.1. Notes on installation

Depending on the installation situation for the LED Driver and the modules, the following requirements must be met:

Protection measures against damage

Mechanical stress

LED modules contain electronic components that are sensitive to mechanical stress. Such stress should be kept to an absolute

minimum. In particular the following mechanical stresses should be avoided as these may cause irreversible damage:

½CAUTION!

LED module and the associated housings are crimped together by sleeves.

Trying to separate LED module and housing will destroy the LED module!

All warranty and guarantee claims are void if LED module and housing are separated or if the LED module is altered, modified or

disassembled in any form.

Sufficient distance to active conducting materials_

Sufficient strain relief when the LED Driver cover is closed_

Sufficient cooling of the modules (the max. temperature at the tc point must not be exceeded)_

Unrestricted exit of light from the modules_

The module's push-in terminals allow easy wiring. They can be released via the trigger_

Pressure_

Drilling_

Milling_

Breaking_

Sawing_

and similar mechanical processing._

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Mechanical Aspects

c18 / 59

Compressive stresses

The components of the LED modules (circuit boards, glob-top, lenses, electronic components etc.) are sensitive to compressive

stresses. The components must not be exposed to compressive stresses.

Chemical compatibility

LED modules can be damaged by other materials, if these materials have certain chemical properties. The cause for these damages

are different gaseous compounds, which penetrate into the encapsulant of the LED and thereby attack the encapsulant, the colour

conversion phosphor or the LED chips and can affect the electrical contacts or the substrate.

Application areas for chemical substances

The following are known areas in which chemical substances are used:

The following materials must be checked for their safety:

Putting together a "safe list" is not possible due to the complexity of the topic. The following table lists possible contaminants for LED

modules, the classes of compounds and examples of possible sources.

The list shows the most commonly used materials but does not claim to be complete.

If glass or Plexiglas shields are used make sure that pressure is not exerted on the glob-top._

Only touch the LED modules at the edges

correct (left) and incorrect (right)

_

use of protective coating in applications with high relative humidity (outdoor applications),_

encapsulation of LED modules,_

cementing of LED modules,_

sealing of luminaires._

All components and auxiliaries used in the assembly of the luminaire:_

Solvents of adhesives and coatings_

Other so-called VOC ("volatile organic compounds")_

All other additional substances present in the atmosphere:_

Outgassing of adhesives, sealants and coatings_

Cleaning agents and processing aids (e.g. cutting oils and drilling coolants)_

INOTICE

Contact your LED manufacturer for questions about the materials used and possible interactions and risks.

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Mechanical Aspects

c19 / 59

Class of compounds Chemical names Occurs in

Acids

Organic acids

Alkalis

Organic solvents

VOC

(volatile organic compounds)

Mineral oils

Vegetable oils and synthet. oils

Harder, vulcanizer

hydrochloric acid_

sulfuric acid_

nitric acid_

phosphoric acid_

cleaner_

cutting oils_

acetic acid_ RTV silicones_

cutting oils_

degreaser_

adhesives_

ammonia_

amines_

sodium hydroxide_

detergents_

cleaner_

ethers (e.g. glycol )_

ketones (e.g. Methylethylketon )_

aldehydes (e.g. formaldehyde)_

aromatic hydrocarbons (e.g. xylene and toluene)_

cleaner_

benzine_

petroleum_

paints and varnishes_

acetate_

acrylates_

aldehydes_

serve_

super glue_

all-purpose glue_

screw locking varnish_

coatings_

paints and varnishes_

hydrocarbons_ machine oil_

lubricants_

siloxanes_

fatty acids_

silicone oils_

linseed oil_

fats_

sulfur compounds_ seals_

sealants_

colours_

Technical Design-in Guide SLE G6 | 12-2018 | 2.1 | en

Mechanical Aspects

c20 / 59

Protection measures for the glob top material

The following guidelines must be observed to avoid damage to the glob-top:

Example of damaged encapsulant material, recognizable by the change of the chromaticity coordinates:

Image Description

powerLED P211, original

powerLED P211, damaged by dissolver waste gas

Protection measures in regards to sealing

The points above also apply to chemicals used for sealing luminaire casings. If however the LED module is not installed in the

luminaire until after the sealing compound has been completely cured (see relevant material information) the above points can be

ignored.

If the LED modules have already been installed in the luminaire, possible damage to the encapsulant can be reduced to a minimum by

ensuring adequate spacing (>10 cm) and ventilation (open casing and air circulation, extraction / fan) during the curing process.

Protection measures in regards to cementing

To avoid damaging the LED modules you must not use any tools or exert any pressure on the electronic components or the

encapsulant.

Cleaning the LED module

Make sure that the chemicals used in LED applications are not solvent-based, condensation crosslinked or acetate crosslinked

(acetic acid). These give rise to reagents (e.g. solvent vapors, acetic acid) that may damage LED modules or the encapsulant.

This applies to chemicals that are used not in the immediate vicinity of the modules (e.g. seals) and also to chemicals that

come into direct contact with the modules (e.g. insulating coatings, adhesives).

_

To ascertain the chemicals used and the type of cross linking a technical data sheet containing a list of substances must be

requested from the manufacturer.

_

If glass or Plexiglas shields are used make sure that pressure is not exerted on the encapsulant._

Only touch the LED modules at the edges_

½CAUTION!

It is not permitted to clean LED modules during operation. It is necessary to disconnect the power supply. This means for example

removing the spotlight from the supply rail only after that it is allowed to clean the module.

Table of contents

Other Tridonic Control Unit manuals

Popular Control Unit manuals by other brands

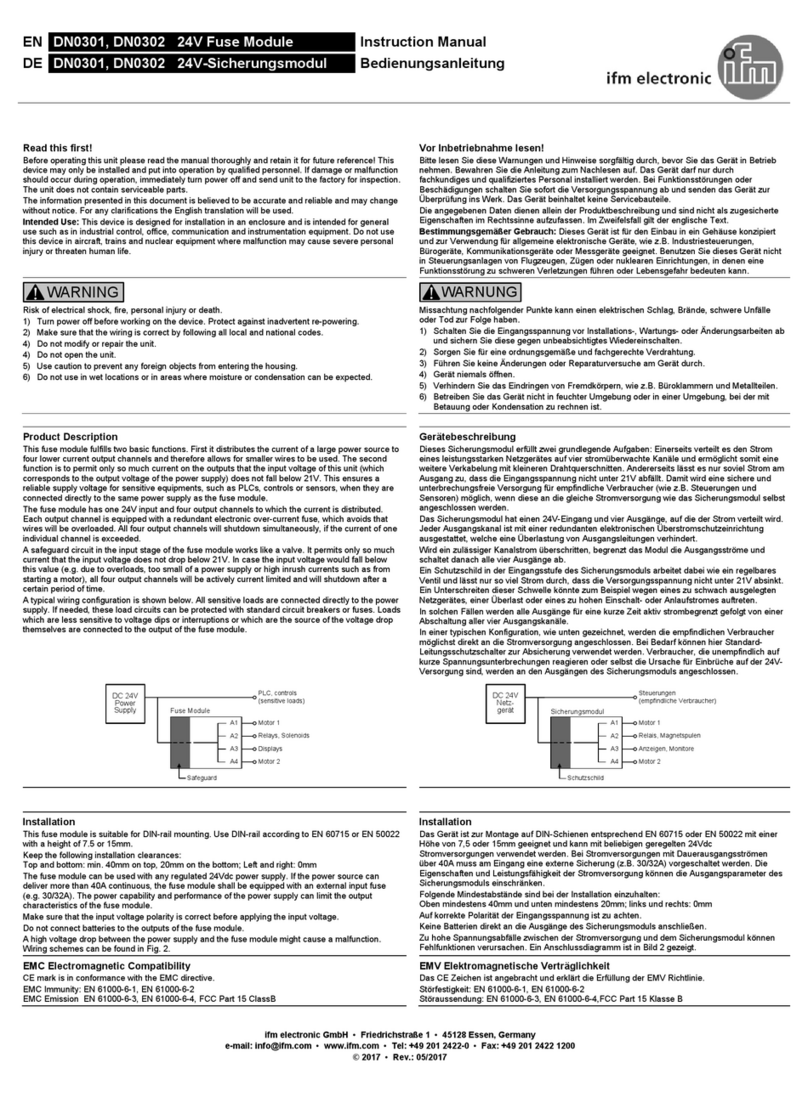

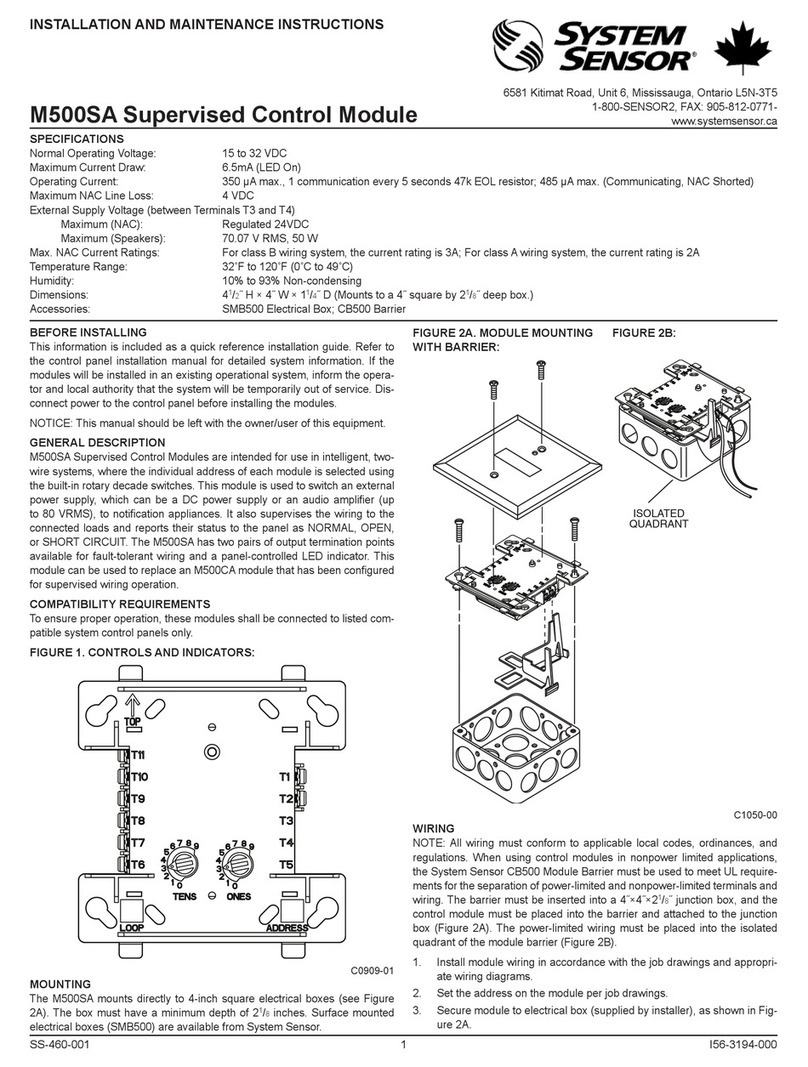

System Sensor

System Sensor M500SA Installation and maintenance instructions

Imi Heimeier

Imi Heimeier 4343-01.300 Installation and operating instructions

Conti+

Conti+ lino W45 Installation & user manual

Elkron

Elkron IT700-WIFI quick start guide

Murphy

Murphy Selectronic TTD Series Installation and operation manual

Dualsky

Dualsky VR Pro Duo instruction manual