Trikke T8 User manual

TECHFAQ’S

BodyPoweredModels

1)“IboughtthisTrikketogetinshapeandhavefunbutcantheTrikkesustainmyweight?”

AllofourTrikkevehiclesarerecommendedtosupportupto250lbsbutwedohavesomecustomers

weighing300lbsthatusewithmoderation,avoidingdownhill,curves,jumpsandarehappywithit.We

recommendyoutryonebeforebuyingittoseehowyoulikeit.

2)ForAirTrikkemodels(T78Air,T8)‐“MyTrikkeisreallyhardtorideincomparisontootherTrikkes,

whyisthis?”

Thereisalistofthingstocheck:

1. Checkthetireairpressurewithagageandpumpituntilitmeetsthe80psiinthereartires.

2. Adjusttheangleofthehandlebaraccordingtotheinstructions.

3. LiftyourTrikkeandchecktherotationofthewheels.Ifthewheelshardlymove:

a. Checkthebrakes.

b. Withahammerhitthecenteroftheaxle(threetimesormoreifneeded).Thisshould

adjusttheseatingofthebearingsandthentrytospinthewheelsagain.

3)BIKEEbalancebike‐“ThehandlebarfrommyBikeedoesn’tstaywhatcanIdotofixit?”

ThemostcommonproblemwithclampsnotlockingthehandlebartotheframeoftheBikeeisbecause

theboltthattightenstheclampwasinsertedinthewrongside.Pleasechecktheboltclosestheclamp

whenyoutightenthebolt,otherwiseinserttheboltintheholeintheoppositeside.

4)Wheelalignmentpushpinorisstuckinsteeringaxle

Removethefrontfork.

UsingtheAllenwrenchthatcamewithyourTrikke,findtheholeintheplasticcaplocatedatthebottom

ofthesteeringaxle.InserttheshortendoftheAllenwrench,removethecapbypryingitoutwiththe

Allenwrench.

Youshouldnowbeabletoreachthepinandpushitbackintoplace.

IfthealignmentpinismissingpleasecontactTrikkeTech(1‐877‐487‐45534553ext200or201)fora

replacementpin.

5)Handlebarheightadjustmentpushpinmissingorstuckinthestempost.

Removethehandlebars.

Openclamponquickreleaselever.

Removetheboltlocatedinthequickreleaselever.

Thereisaplasticbushingthatkeepsthehandlebarstemposttightwhenthequickreleaseclampis

engaged.Thisbushingcanmakethehandlebarstempostremovalalittletoughbecauseofthetightfit.

Aftercompletingsteps1through3,thestempostwillpullout.Justgivethestempostafewtugsand

thebushingwillcomeloose.

Onceyouhavethestempostremovedyoushouldbeabletopushthepinbackintoplaceusingalong

stickordowel.Oncethepinisinplace,reinstallthestem,quick‐releaseandthehandlebars.

IfthealignmentpinismissingpleasecontactTrikkeTech(1‐877‐487‐4553ext200or201)fora

replacementpin

6)Lowerpushpindoesnotfitthroughtheholeonthefork.

Thiscanhappenbecauseofexcesspaintorburrsintheforkalignmenthole.

Tofix,useasmallroundfileandcleantheforkhole.Oncethisisdoneyourforkshouldinstallwithno

issue.

7)T67orT78armsareflaredinorout(wishboned)

ThishappensforabuseorlettingyourTrikkerollbackwards.

Measurethedistanceoftheoutsideofthedecks.Thisdistanceshouldmeasure23inchesaprt,+/‐1

inch.Ifthedistanceisfurtherorcloserthan23inches,youcanpushthearmsinorpullthemapart

dependingonthecorrectionneeded.Youcandothisafewtimesbeforeyoumavemajorproblem

(becauseT67,T78aresteel).RememberridingbackwardsvoidsthewarrantyonTrikkevehicle.

8)Wheeldoesnotspinfreely

Removethewheel.

Placeonefingeragainstthebearingononesideandkeepthisfingerstationary,withyourotherhand

placeafingeronthebearingontheothersideofthewheel.

Turningonefingerandkeepingtheotherstationarytrytomanuallyturnthebearing.Ifyoucan'tfeel

thebearingtryingtoturnwithyourstationaryfingerremovethewheelbearings.

Checkthebearingseatfordebris.Removethedebrisifthereisanypresent.

Checkthemeasurementofthespacerbetweenthebearings,Forthe8.5tiresthisshouldmeasure

26mm.Ifitistooshortortoolongyouwillneedtoreplacetheinnerbearingspacer.

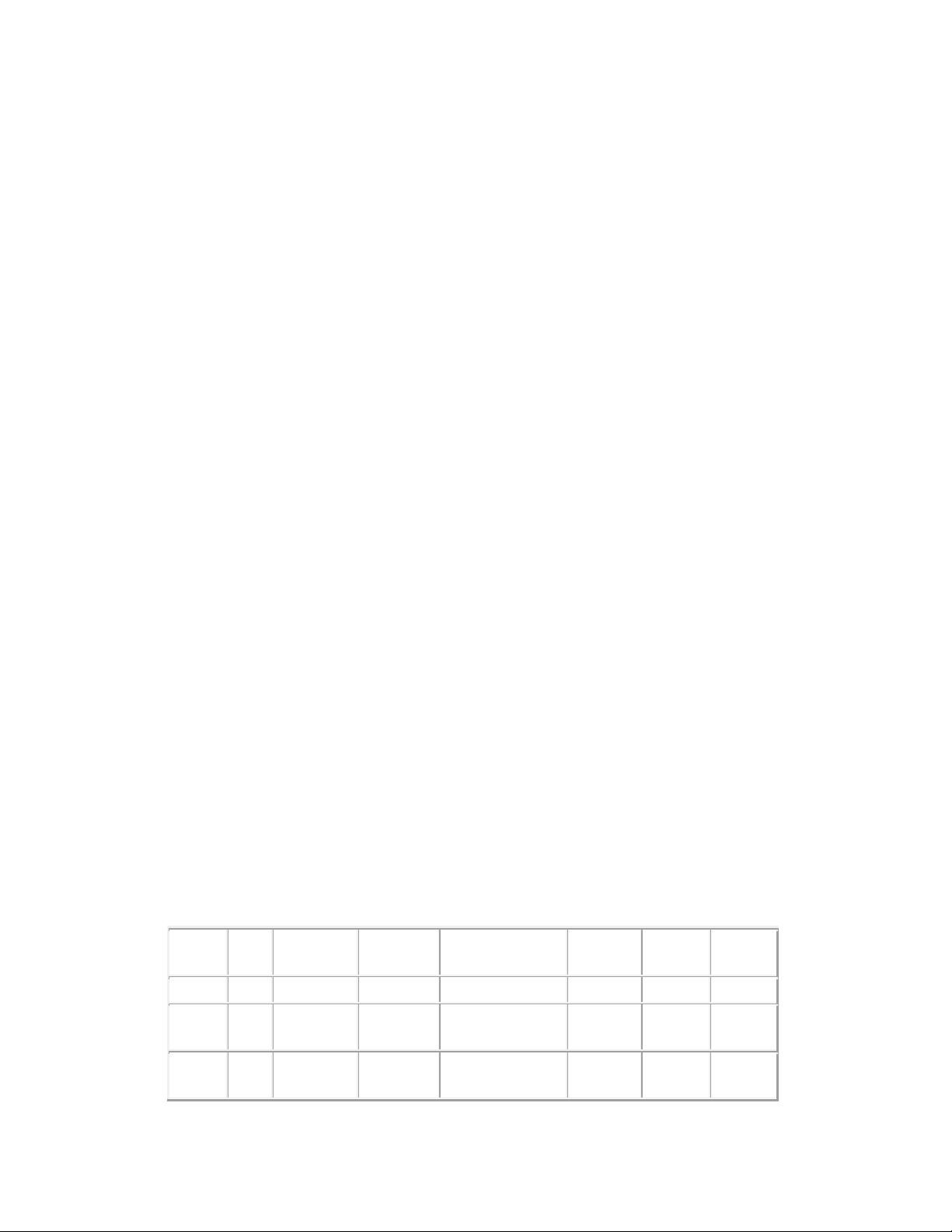

WheelAxlesandSpacers

MODELYEARFRONT

AXLE

REAR

AXLEAXLESPACERBEARING

SPACER WASHERHEX

T78200871.mm71.mm2@13.mm16.2mm none5mm

T8200875.mm75.mm2@12.0mm26.mm2@

2.mm5mm

T8h2008102.79.mm102.79mm 11.9mm/31.5mm 37.5mm 2@

2.mm5mm

T122010100.mm100.mm2@10.5mm52.0mm 2@

2.mm6mm

Ifyouhavedonethisandyourbearingsjustseemtonotspinfreelytheymayneedtobereplaced.

PleasecallTrikkeTechsupporttoresolveyourissue.

9)PolytoAirwheelconversion

ClickheretodownloadPDFinstructions

Removethepolyurethanewheelsusingtwo5mmAllenwrenches.

Usingapairofpliersanda5mmAllenwrenchremovethebrakepadaxelboltandthebrakespring.

Note:Movethebrakelocationoneatatimesoyoucanusethemasreferenceforspringpositionand

orientation.

Therearethreeholesontheframeforthebrakepadaxleboltlocationandthreeholesforthespring.

Foryourbrakestofunctionproperlyyouwillneedtomovethelocationofthebraketothethirdhole

furthestfromthewheelaxle.Positionthespringfirst;makesurethespringisintherightorientation.

Oncethespringismoved,movethebrakepadbyplacingbetweenthewindingsandunderthespring.

Installthebrakeaxlebolt.Makesuretheboltgoesthroughtheframe,springandbrakepad.

Note:Ifthebrakeisinstalledandyoudonothavetensiononthebrakefromthespring,checkthe

orientationofthebrakespring.Ifthespringisupsidedownyouwillnothavetension.

Onceyouhavethebrakepadaxleinplacedonottightenthebrakeaxlenutyet!Firstinstalltheairtires

usingthenewwheelspacersthatwereincludedwithyourtires.

Wheninstallingthetiresmakesurethatthearrowonthesideofthetireisfacingintheforward

direction.(Theairtiresaredirectional).

Oncethetiresareinstalledyouwillneedtoadjustyourbrakes.Loosenthetwoboltsthatholdthecable

tothebrakepadusinga3mmAllenwrench.

PullthecabletowardthefrontoftheTrikkeleavingaslightgap3mmto(1/8").TheDesiredresultisto

setthebrakepadasclosetothewheelaspossiblewithoutthebrakepadrubbingonthetire.

Keepingyourcablesturnedlikethiswilloptimizetheoperatingeffectivenessofyourbrakes.Now

tightentheboltsbacktoholdthetensiononthebrakecables.

Note:Ifyouhavedifficultyremovingtheslackfromthebrakecabletheremaybeakinkorslightbendin

thecable.Checktoinsurethecableisnotbentorhungupsomewhereinthebrakeline.

10)HowtoadjustyourBrakePadsonyourT67,T78,T8Air

Returnthebrakeleveradjustmentknobstotheirseatedposition.

TurnyourTrikkeupsidedownandloosenthetwoboltsthatholdthecabletothebrakepad

PullthecabletowardthefrontoftheTrikkeleavingaslightgap3mmto(1/8").TheDesiredresultisto

setthebrakepadasclosetothewheelaspossiblewithoutthebrakepadrubbingonthetire.

Keepingyourcablesturnedlikethiswilloptimizetheoperatingeffectivenessofyourbrakes.Now

tightentheboltsbacktoholdthetensiononthebrakecables.

Note:Ifyouhavedifficultyremovingtheslackfromthebrakecabletheremaybeakinkorslightbendin

thecable.Checktoinsurethecableisnotbentorhungupsomewhereinthebrakeline.

11)AirwheeltoPolywheelconversion

Note:IfyouareconvertingyourT78airwheels,besuretoorderthecorrect(16mm)wheelspacers.

Removetheairwheelsusingtwo5mmAllenwrenches.

Usingapairofpliersanda5mmAllenwrenchremovethebrakepadaxelboltandthebrakespring.

Note:Movethebrakesoneatatimesoyoucanusethemasreferenceforspringpositionand

orientation.

Therearethreeholesontheframeforthebrakepadaxleboltlocationandthreeholesforthespring.

Foryourbrakestofunctionproperlyyouwillneedtomovethelocationofthebraketothethirdhole

closesttothewheelaxle.Positionthespringfirst;makesurethespringisintherightorientation.

Oncethespringismoved,movethebrakepadbyplacingbetweenthewindingsandunderthespring.

Installthebrakeaxlebolt.Makesuretheboltgoesthroughtheframe,springandbrakepad.

Note:ifthebrakeisinstalledandyoudonothavetensiononthebrakefromthespring,checkthe

orientationofthebrakespring.Ifthespringisupsidedownyouwillnothavetension.

Onceyouhavethebrakepadaxleinplacedonottightenthebrakeaxlenutyet!Firstinstallthepoly

tiresusingthenew16.mmwheelspacers.

Oncethewheelsareinstalledyouwillneedtoadjustyourbrakes.Loosenthetwoboltsthatholdthe

cabletothebrakepadusinga3mmAllenwrench.

PullthecabletowardthefrontoftheTrikkeleavingaslightgap3mmto(1/8").TheDesiredresultisto

setthebrakepadasclosetothewheelaspossiblewithoutthebrakepadrubbingonthewheel.

Keepingyourcablesturnedlikethiswilloptimizetheoperatingeffectivenessofyourbrakes.Now

tightentheboltsbacktoholdthetensiononthebrakecables.

Note:Ifyouhavedifficultyremovingtheslackfromthebrakecabletheremaybeakinkorslightbendin

thecable.Checktoinsurethecableisnotbentorhungupsomewhereinthebrakeline.

12)Brakecablerubbingonwheel:T5,T67,T78,T8Air

Note:IfyouarehavingdifficultywithyourTrikkenotrollingoryounoticethebrakepadisrubbingon

thetireyouwillneedtofallowthebrakepadadjustmentprocedures.

Makesurethebraketensionadjustmentscrewsaretightenedasfarintothebrakeleverastheywillgo.

Loosenthetwobolts(donotremove)thatholdthecabletothebrakepadusinga3mmAllenwrench.

PullthecabletowardthefrontoftheTrikkeleavingaslightgap3mmto(1/8").TheDesiredresultisto

setthebrakepadasclosetothewheelaspossiblewithoutthebrakepadrubbingonthewheel.

Keepingyourcablesturnedlikethiswilloptimizetheoperatingeffectivenessofyourbrakes.Now

tightentheboltsbacktoholdthetensiononthebrakecables.

Note:Ifyouhavedifficultyremovingtheslackfromthebrakecabletheremaybeakinkorslightbendin

thecable.Checktoinsurethecableisnotbentorhungupsomewhereinthebrakeline

Warning:ifyoufailedtoadjustyourbrakesproperlyduringorafterassemblyandyourwheelsare

damagedyourTireswillneedtobereplacebeforeyoucansafelyrideyourTrikkechamberingvehicle.

13)Stripedbrakecaliperbolt:T5,T67,T78,T8Air

Note:Ifatanytimeduringbrakeadjustmentprocedures,youstripthe3.mmboltonthebrakepadyou

willneedtoreplacetheboltforsafeandreliablebraking.PleasecontactTrikkeat1‐877‐487‐4553to

orderanyreplacementparts.

Note:Toremovetheboltyoucanusethefallowingtools.ADremelRotaryTool(suchastheDremel

300seriesvariableSpeedRotaryTool)withacut‐offattachment(suchas4261‐1/4"Fiberglass

ReinforcedCut‐offWheels)whichisheldinplacebyaDremel402Mandrel.ORAmini‐hacksaw,witha

bladenothickerthan0.050"

Warning:remembertousecautionwhenworkingwithtools.Alwayswaresafetygogglesandother

propersafetygearfallowingthecorrectsafetyproceduresforeachspecifictool.

UsetheDremelToolorhacksawtocutaslotacrossthetopofthestrippedbolthead.Cutapproximately

halfwaythroughthebolthead.

Note:Makesuretocenterthesaw/cuttingtooloverthemiddleofthebolttothereisequalamountsof

theboltmaterialoneachsideofthecut.

Note:Makesuretocutverticallyintotheboltheadonly.Avshapewillmakeitverydifficulttoremove

theboltusingaflatheadscrewdriver.

Usingalargeflatheadscrewdriver,cautiouslyremovethedamagedbolt.Takecarenottodamagethe

boltheadfurther.

Oncethebolthasbeenremoved,replaceitwithanewbolt(part#BT‐026)usingahigh‐quality3mm

hexhead(Allen)Wrench.TightenFully,Becautioustonotovertightenandstripthenewbolt.

14)Wheelbearingismakingnoise

RemovetheBearing'sfromtherimandcheckthebearingseat.Ifthereisaccessmaterialintheseatyou

willneedtoremovethematerial.

Greasethebearingseatusingapremiumbearinggrease.

Makesurethebearingspaceristhecorrectlengthandthatthebearingisseatedproperlybyturningthe

innerbearingraceagainstyourfinger.

WheelAxlesandSpacers

MODELYEARFRONT

AXLE

REAR

AXLEAXLESPACERBEARING

SPACERWASHERHEX

T78200871.mm71.mm2@13.mm16.2mmnone5mm

T8200875.mm75.mm2@12.0mm26.mm2@

2.mm5mm

T8h2008102.79.mm102.79mm 11.9mm/31.5mm 37.5mm2@

2.mm5mm

T122010100.mm100.mm2@10.5mm52.0mm2@

2.mm6mm

IfthenoisecontinuestopersistpleasecallTrikkeTechIncTechnicalsupportat

1‐877‐487‐4553forfurtherassistance

15)DifficultyinstallingorremovingthefrontforkonyourTrikkecv.

ToInstalltheFrontforkonyourTrikke,

Makesurethe2FrontforkboltsonyourTrikkearelooseenoughfortheclamptohavesufficientspace

toallowthesteeringaxletofitinsideoftheforkclamp.Ifyoustillhavedifficultyinstallingtheforkyou

canloosenthewheelaxleandthiswillloosentheforkclampafewmoremillimetersallowingsufficient

clearance.

Depressthealignmentpushpinonthelowersteeringaxleandslidetheforkontothesteeringaxleuntil

thelockpinengagesintheforkalignmentpinhole.

Tightenthe2forkboltsandtightenthewheelaxleifitisloose.

Toremovethefrontfork.

Loosenthetwoforkboltsanddepressthealignmentpinonthelowerfrontsteeringaxle.

Nowyoucanremovetheforkassembly.

Note:Ifyouarehavingdifficultyremovingtheforkatthispoint,Loosenthewheelaxlethisshouldgive

youafewmoremillimetersofclearanceintheforkclamptoallowremoval.

16)Steeringaxleishardtoturnorfeelsstiff

Loosentheboltonthehandlebarstemclamp.

Loosenthesteering

LoosentheTopnutonthethreadedheadset.

Slightlyloosenthebottomnutonthethreadedheadset.Note:thisnutpullsthesteeringaxleup

throughthefrontstructure.Ifthenutisovertightenedyoucancompressanddamagethebearings.

Tightenthebottomnutsothesteeringaxleistight.Makesuretoturnthesteeringaxletoinsurethat

thebottomnutisnotovertightened.

Usingtwowrenchestightenthetopnutwhileholdingthebottomnutstationary.Note:thiswilllockthe

twonutstogetherandwillnotallowthebottomnuttoloosen,effectivelyholdingandcompressingthe

bearings.

Tightentheboltonthehandlebarstemclamp.

17)Lowerpushpindoesnotfitthroughtheholeonthefork

Thiscanhappenbecauseofexcesspaintorburrsintheforkalignmenthole.

Tofix,useasmallroundfileandcleantheforkhole.Oncethisisdoneyourforkshouldinstallwithno

issue.

close

Other manuals for T8

1

This manual suits for next models

8

Table of contents

Other Trikke Scooter manuals

Trikke

Trikke T5 JOGO User manual

Trikke

Trikke T67s User manual

Trikke

Trikke T5 JOGO User manual

Trikke

Trikke Colt User manual

Trikke

Trikke DEFENDER User manual

Trikke

Trikke T7 User manual

Trikke

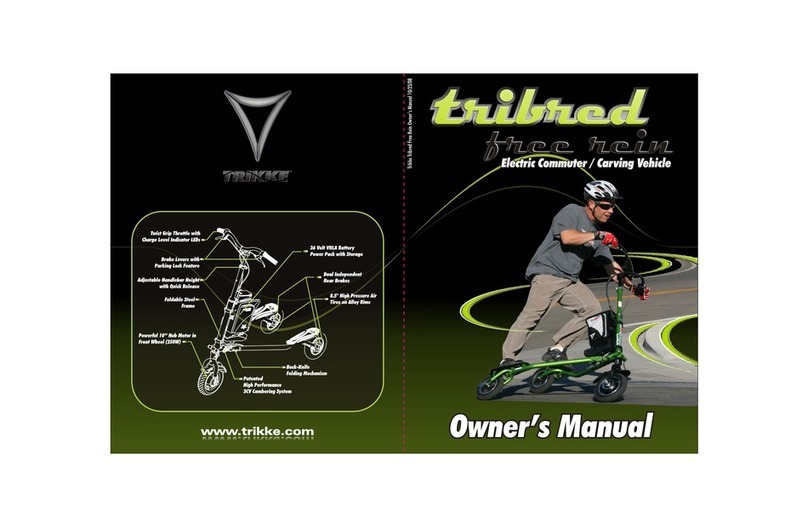

Trikke Tribred tree rein User manual

Trikke

Trikke eV5 User manual

Trikke

Trikke Pon-e 48V User manual

Trikke

Trikke FREEDOM User manual